Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Reduce coke inactivation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

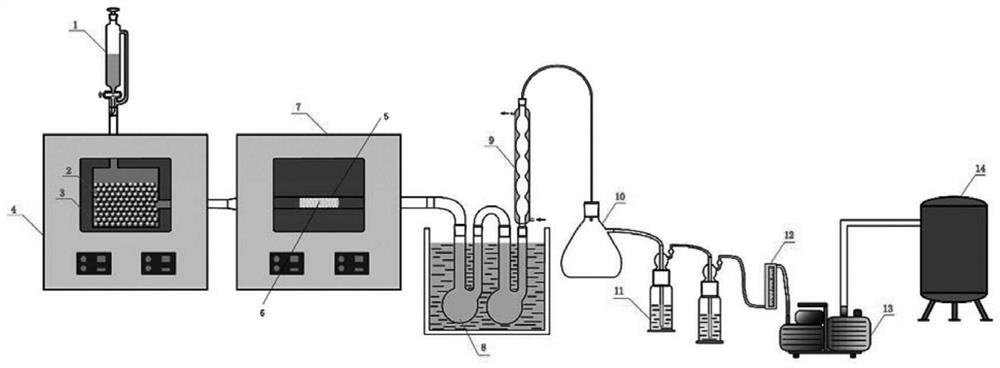

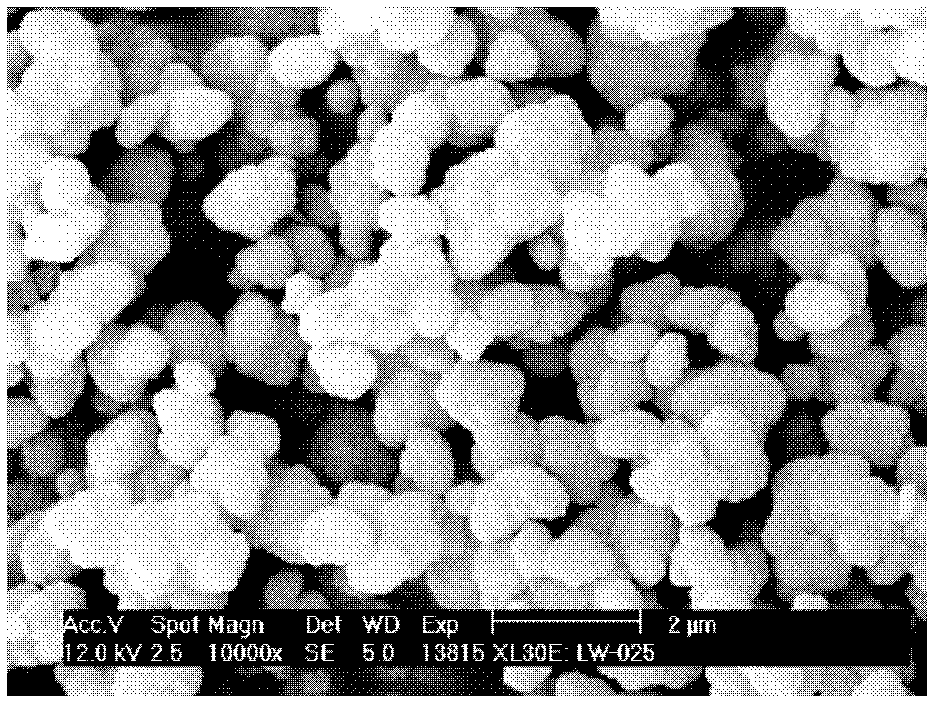

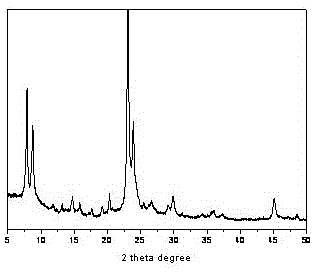

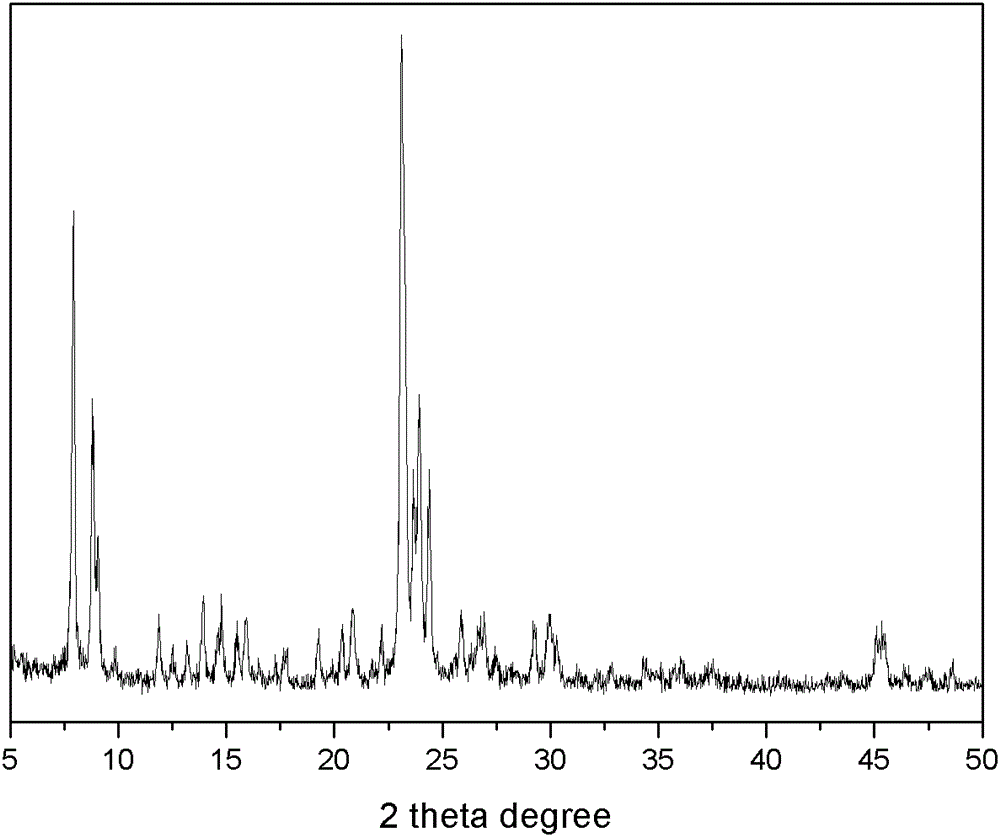

Phosphorus-containing MFI structure molecular sieve and preparation method thereof

ActiveCN107973317APromote generationFacilitated DiffusionMolecular sieve catalystsPentasil aluminosilicate zeoliteMolecular sieveActive component

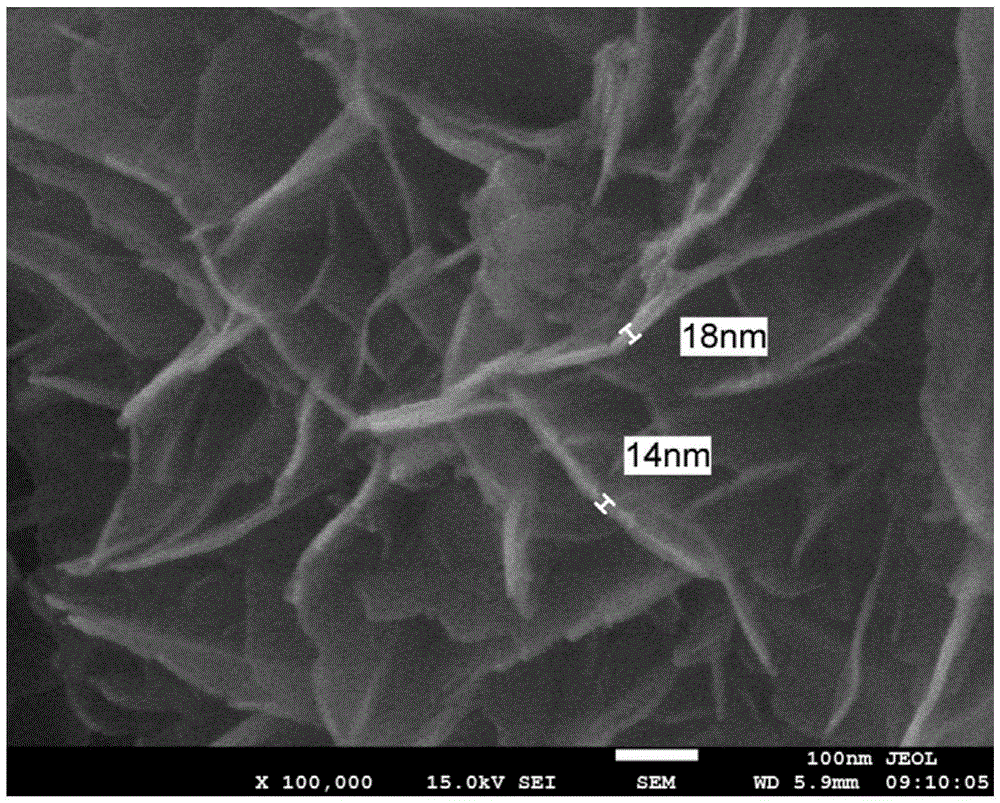

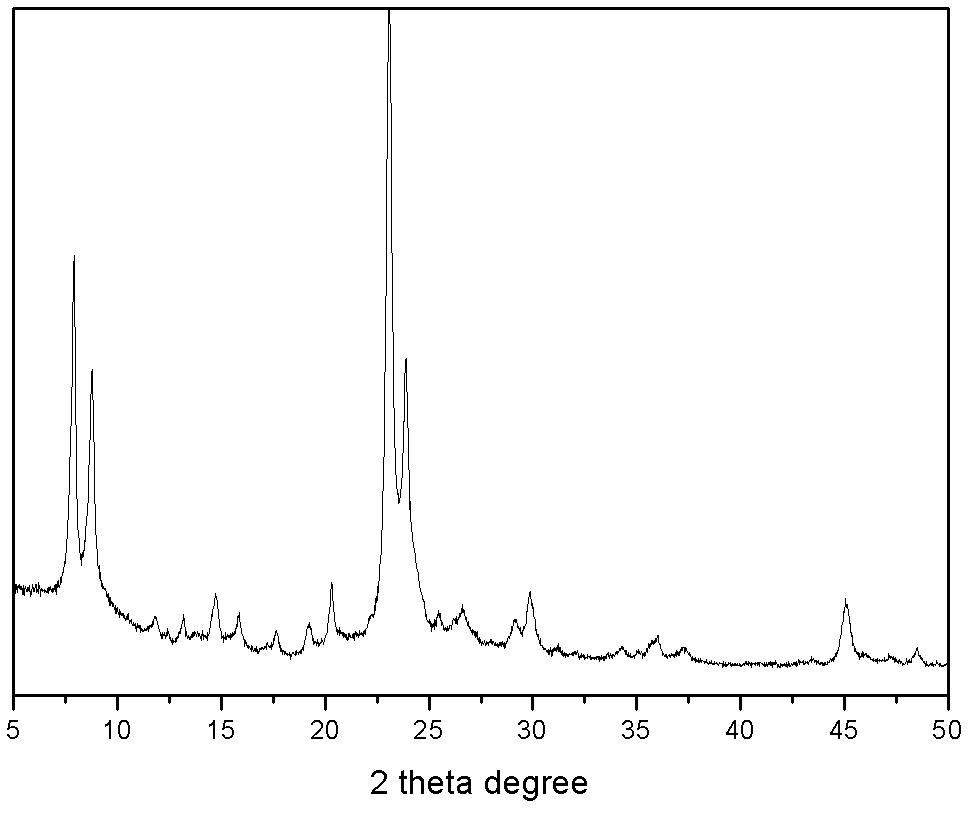

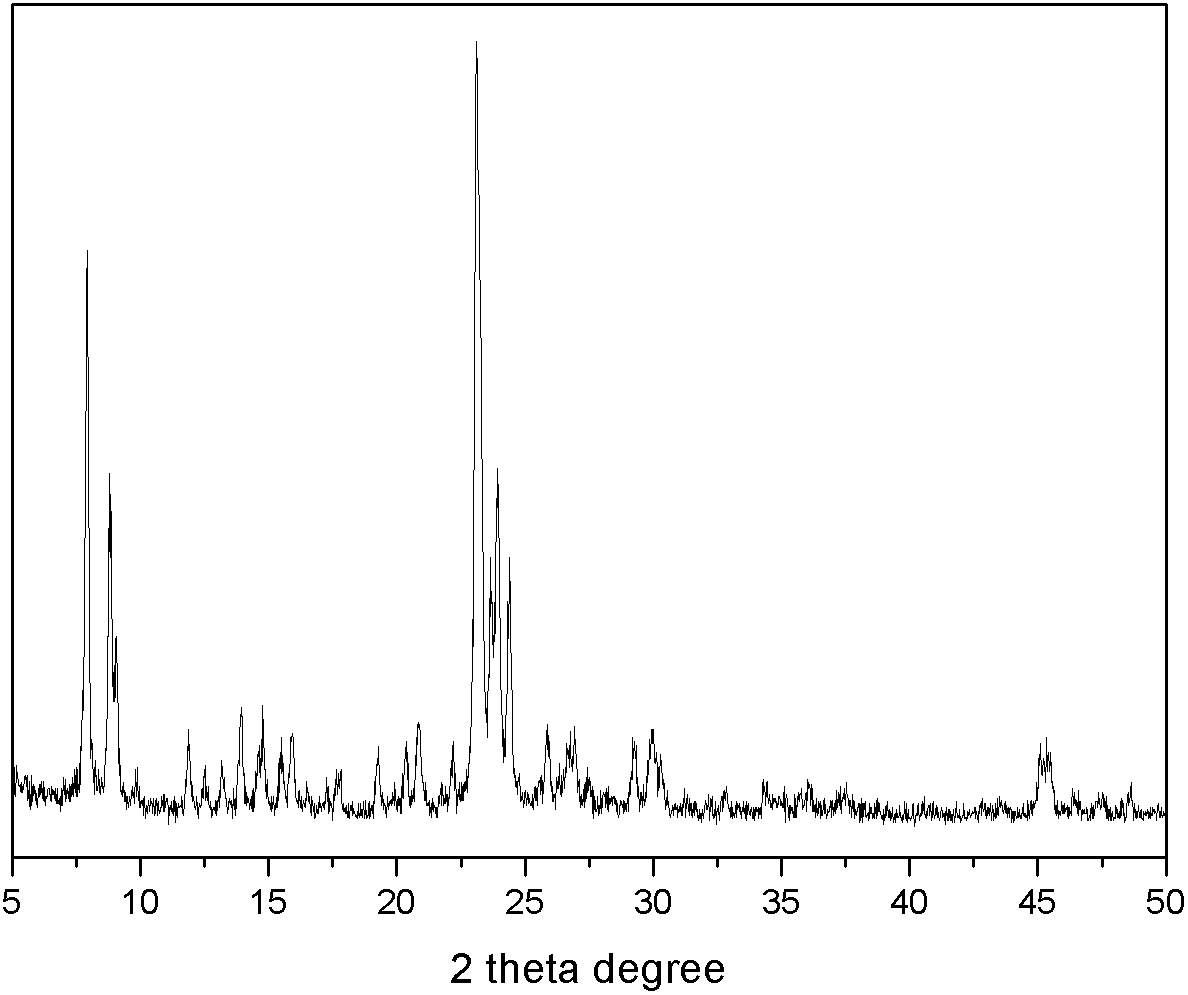

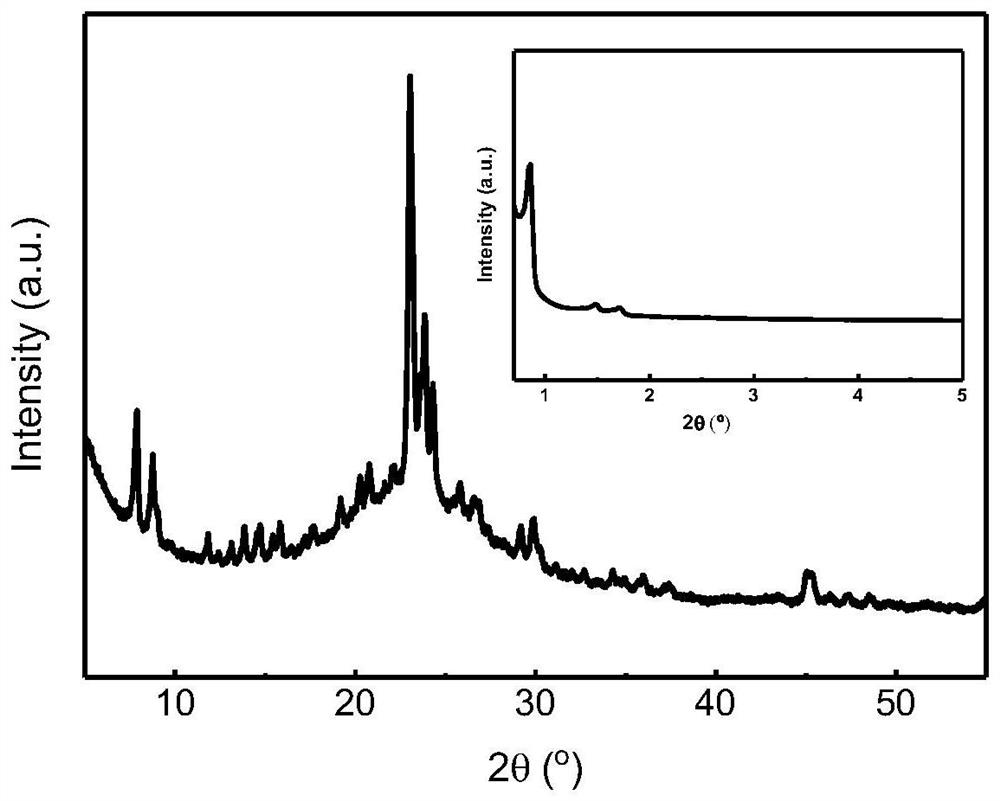

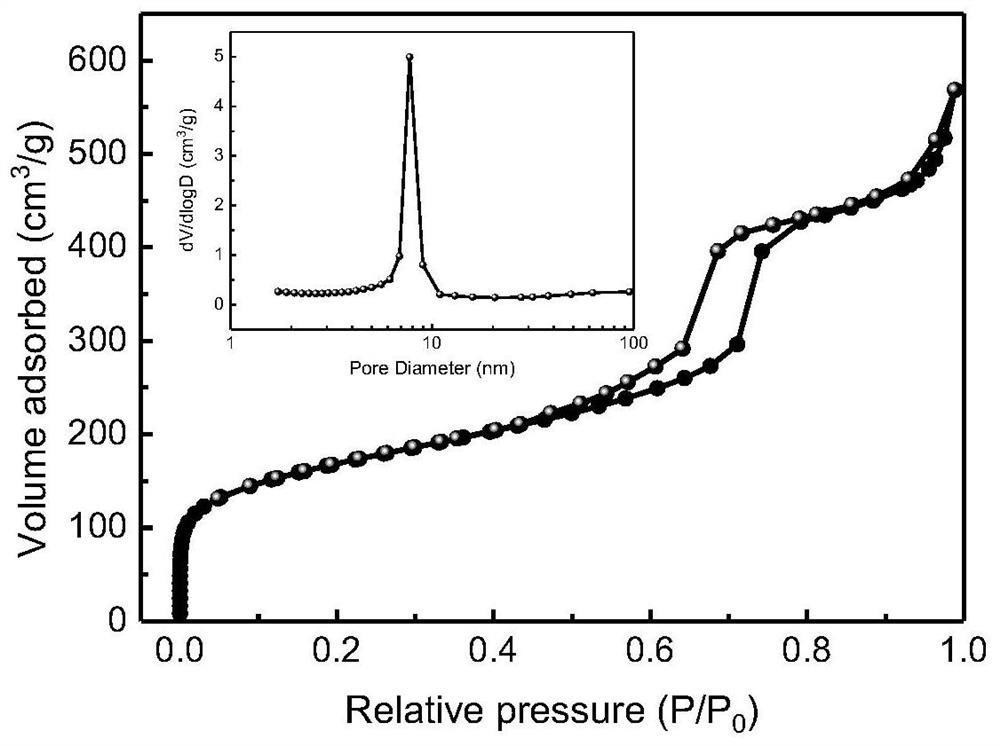

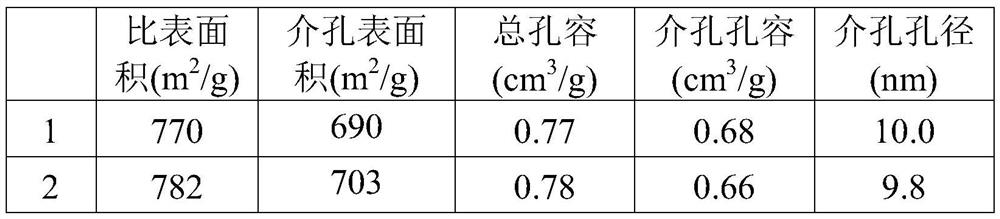

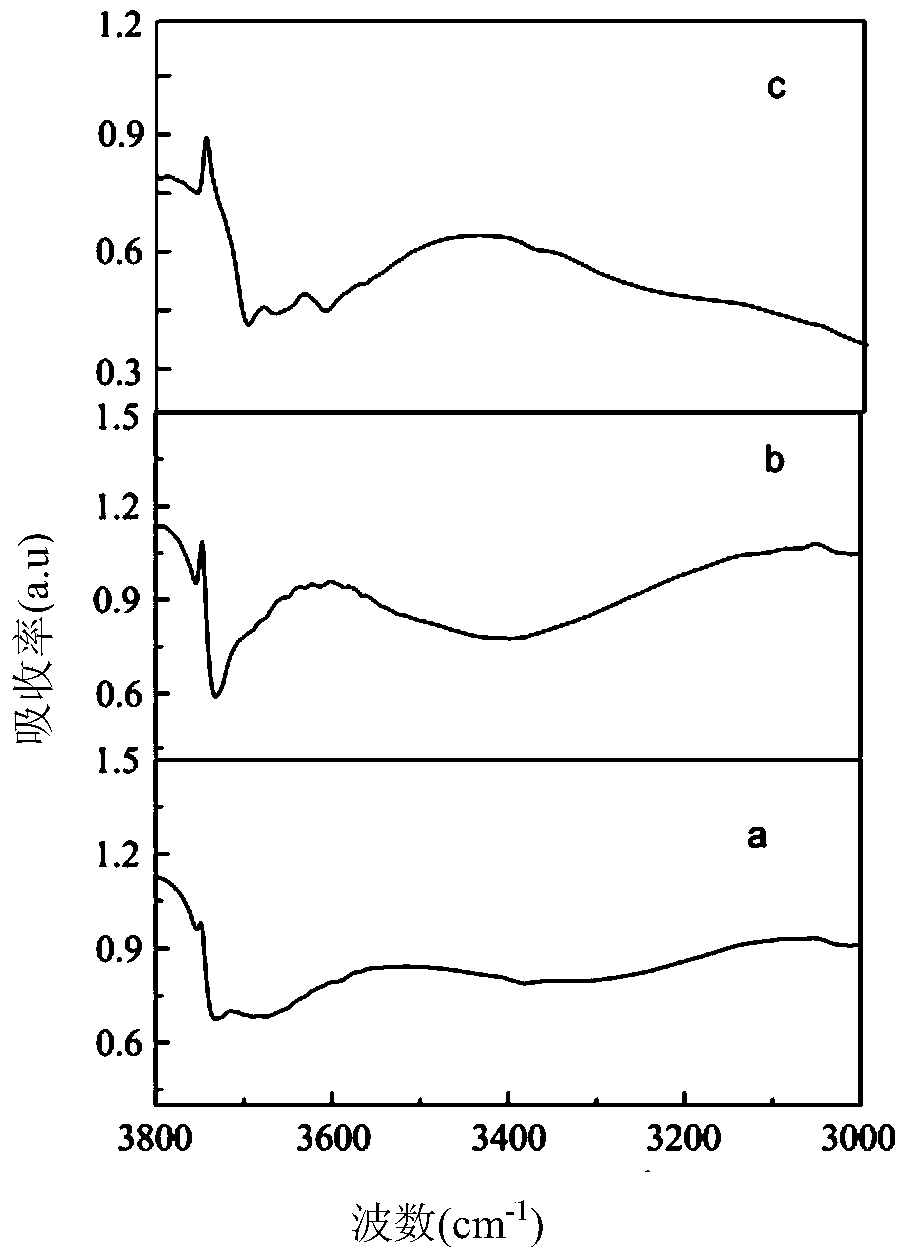

The invention discloses a phosphorus-containing MFI structure molecular sieve and a preparation method thereof, wherein the n(SiO2) / n(Al2O3) of the molecular sieve is more than 18 and is less than 70,the phosphorus content (calculated as P2O5) of the molecular sieve is 1-15 wt% by using the dry base weight of the molecular sieve as the reference, the volume of the mesopores of the molecular sieveaccounts for 40-70% of the total pore volume, the volume of the mesopores with the pore size of 2-20 nm accounts for more than 85% of the total mesopore volume, the amount of the strong acid of the molecular sieve accounts for 45-75% of the total acid amount, and a ratio of the acid B to the acid L is 8-30. According to the present invention, with the catalyst or the auxiliary agent prepared by using the phosphorus-containing MFI structure molecular sieve as the active component, the propylene yield and the propylene selectivity can be effectively increased in the catalytic cracking or catalytic cracking reaction of petroleum hydrocarbons while the yield of BTX can be increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of polymethoxymethylal

ActiveCN103121927AHigh activityIncrease profitOrganic chemistryMolecular sieve catalystsMolecular sieveActive component

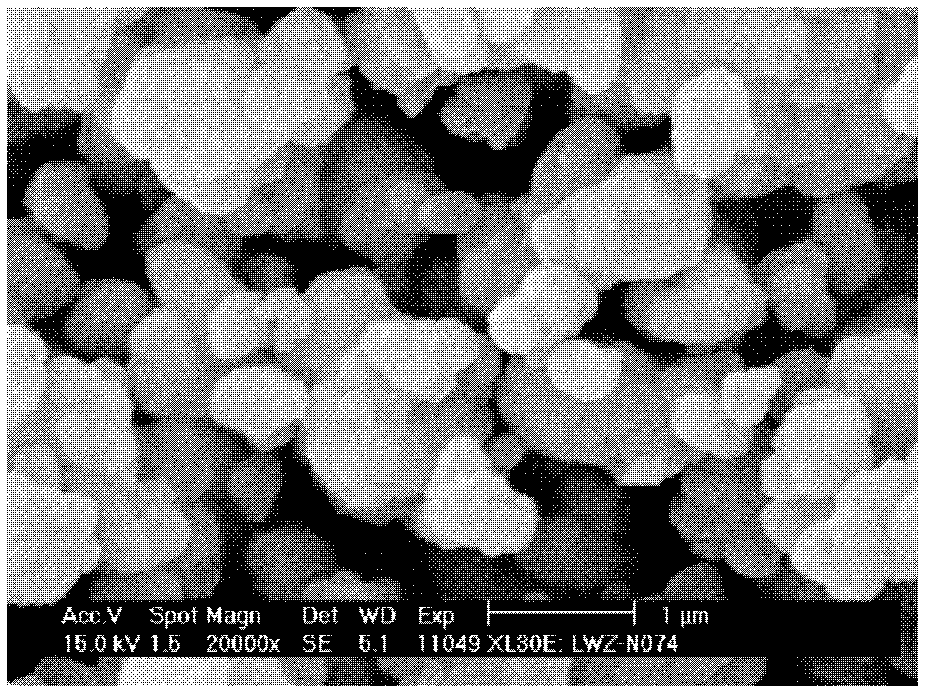

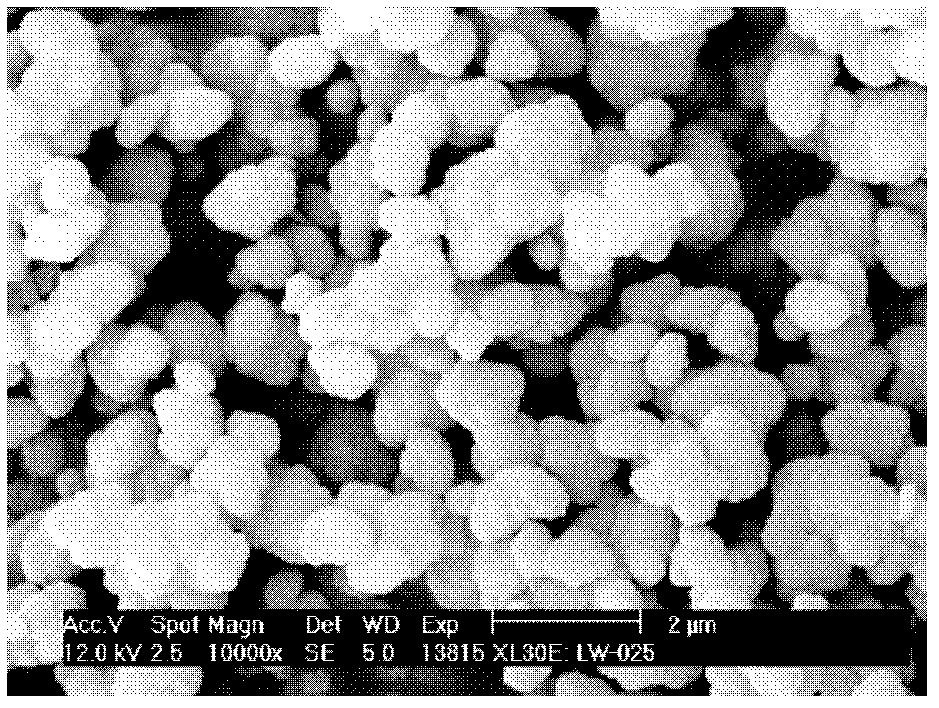

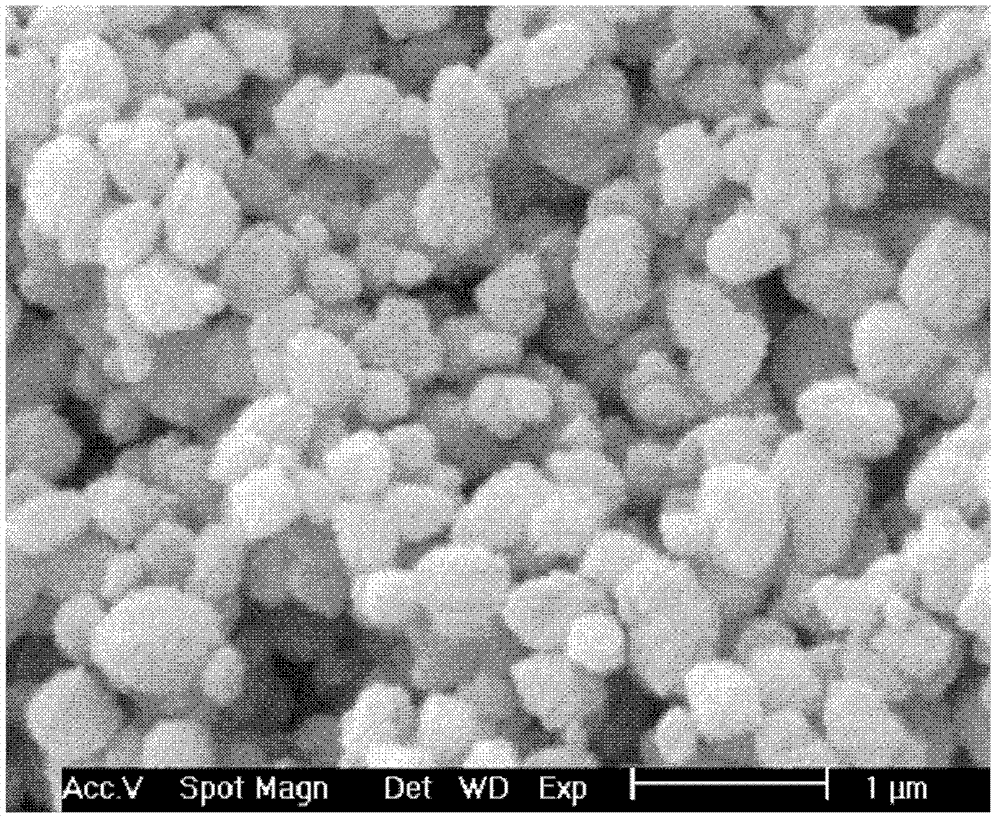

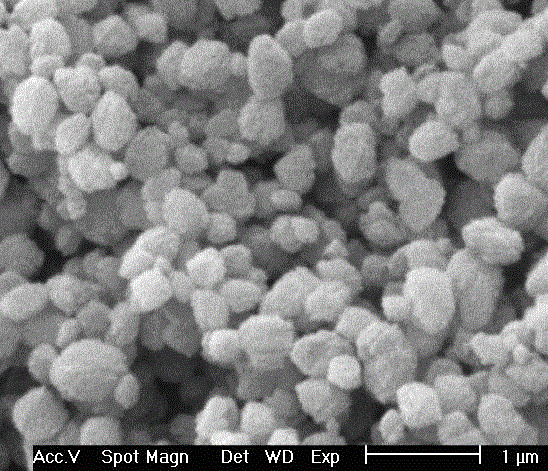

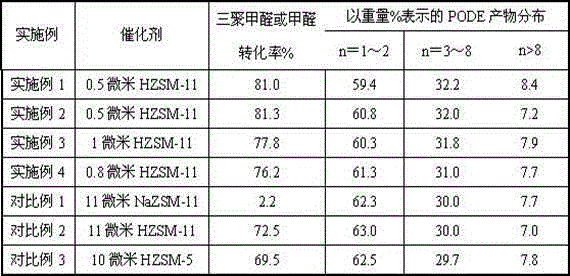

The invention relates to a preparation method of polymethoxymethylal, mainly solving the problem that in the prior art, the catalyst has corrosivity. The method comprises the following step: by taking methanol or dimethyl ether and formaldehyde or trioxymethylene as raw materials, contacting the reaction raw materials with a catalyst to generate the polymethoxymethylal under the conditions that the molar ratio of the methanol or the dimethyl ether to the formaldehyde or the trioxymethylene is 1: (0.1-10), the reaction temperature is 50 to 200 DEGC and the reaction pressure of 0.1-10 MPa, wherein a molecular sieve ZSM-5 with the size of less than or equal to 5 microns is adopted as the active component of the used catalyst. through using the technical scheme, the problem is solved well. The method provided by the invention can be applied to industrial production of the poly methoxy methylal.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of SBA-16/MOR composite molecular sieve, catalyst and application in double branched chain isomerization

ActiveCN112642474ALow costReduce pollutionMolecular sieve catalystsHydrocarbon oils refiningMolecular sievePtru catalyst

The invention relates to the field of petroleum processing, discloses a preparation method of a novel SBA-16 / MOR composite molecular sieve material and application in double branched chain isomerization for the first time, and in particular relates to a low-cost green preparation method of an SBA-16 / MOR composite molecular sieve material with suitable acidity and a three-dimensional stepped pore channel structure and a double-branched-chain isomerization catalyst prepared by loading non-noble metal on the SBA-16 / MOR composite molecular sieve material. The catalyst is applied to a catalytic cracking (FCC) gasoline hydroisomerization reaction. According to the catalyst, natural minerals are used as raw materials for green synthesis of an MOR molecular sieve nanocrystalline precursor solution without a template agent, and then an SBA-16 / MOR composite molecular sieve carrier is prepared through in-situ assembly by adopting a prehydrolysis method under low acidity, so that the production cost is greatly reduced, the equipment damage is relieved, and the pollutant emission is reduced. Therefore, the method provided by the invention has good economic and environmental benefits, and provides technical support for upgrading the quality of oil products in China.

Owner:PETROCHINA CO LTD +1

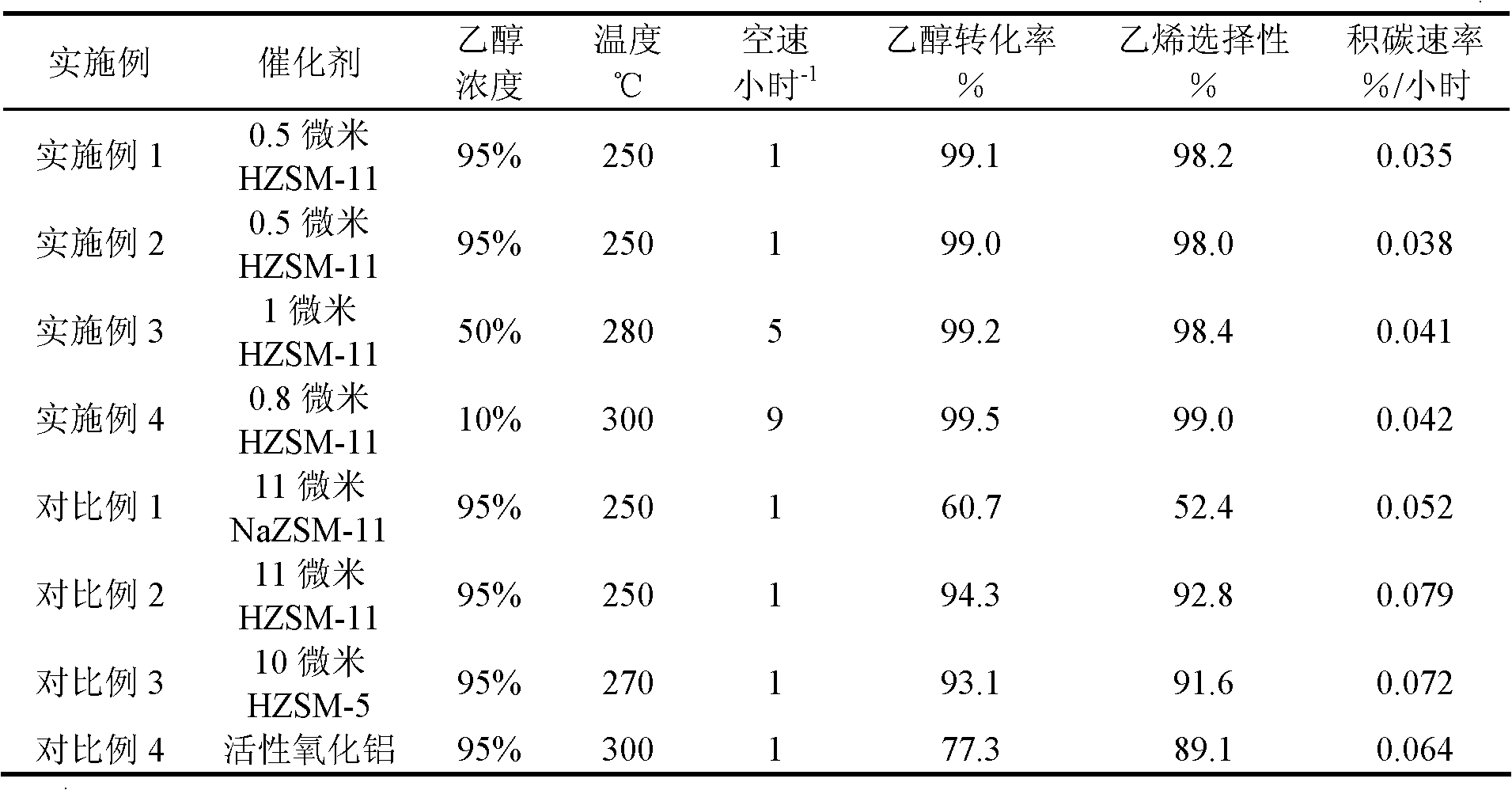

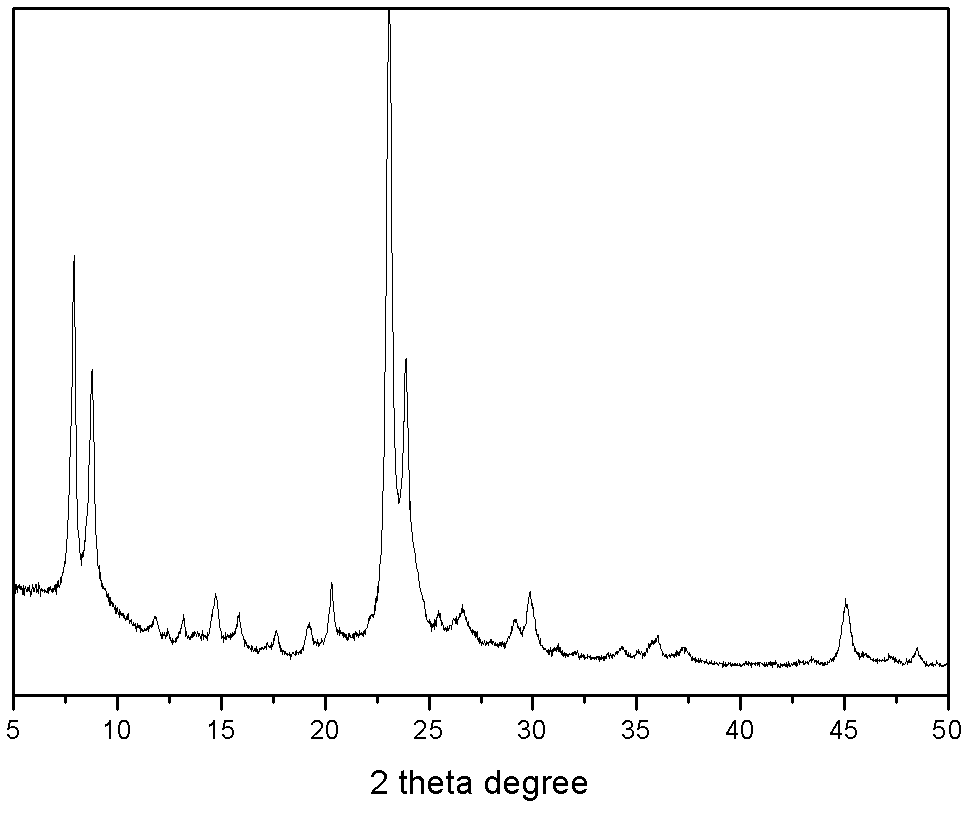

Method for preparing ethylene through ethanol catalytic dehydration

InactiveCN103030489AIncrease profitIncreased focus capacityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsReaction temperatureSpace velocity

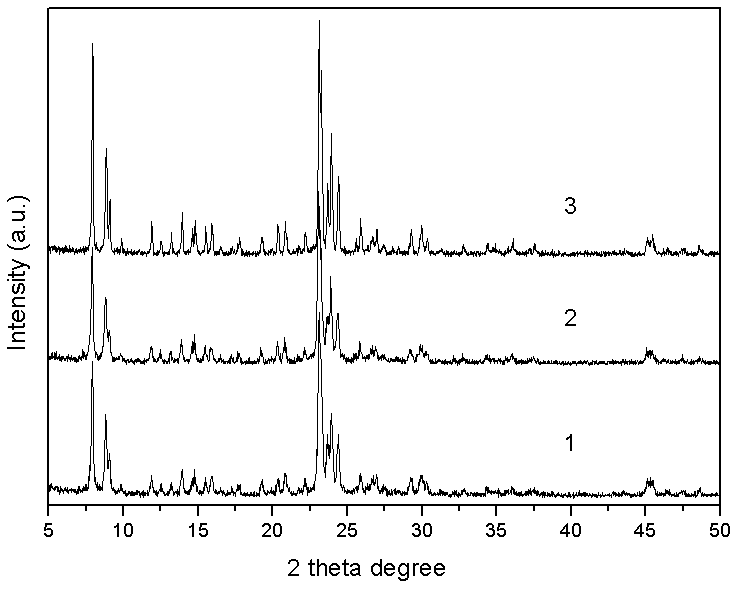

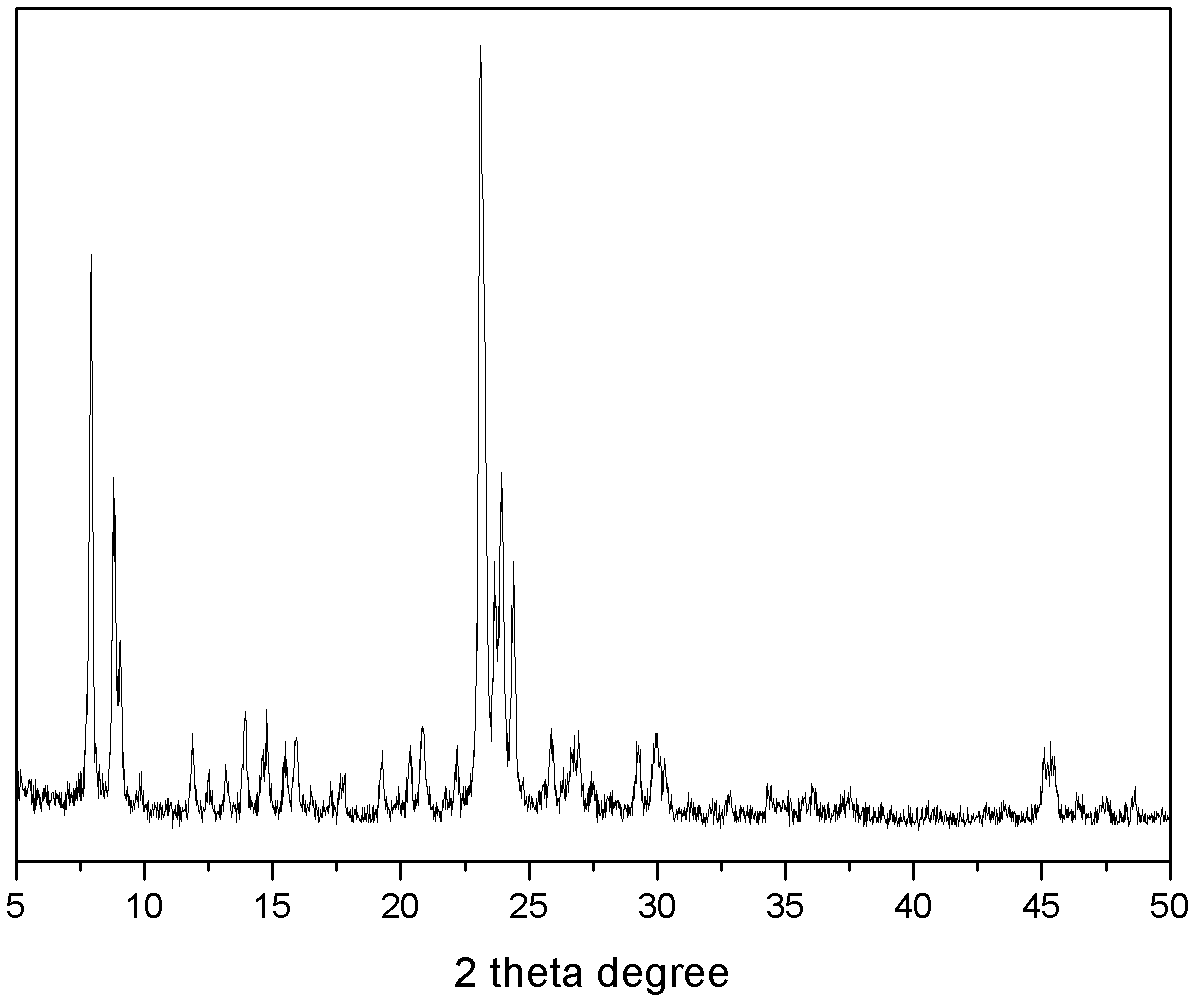

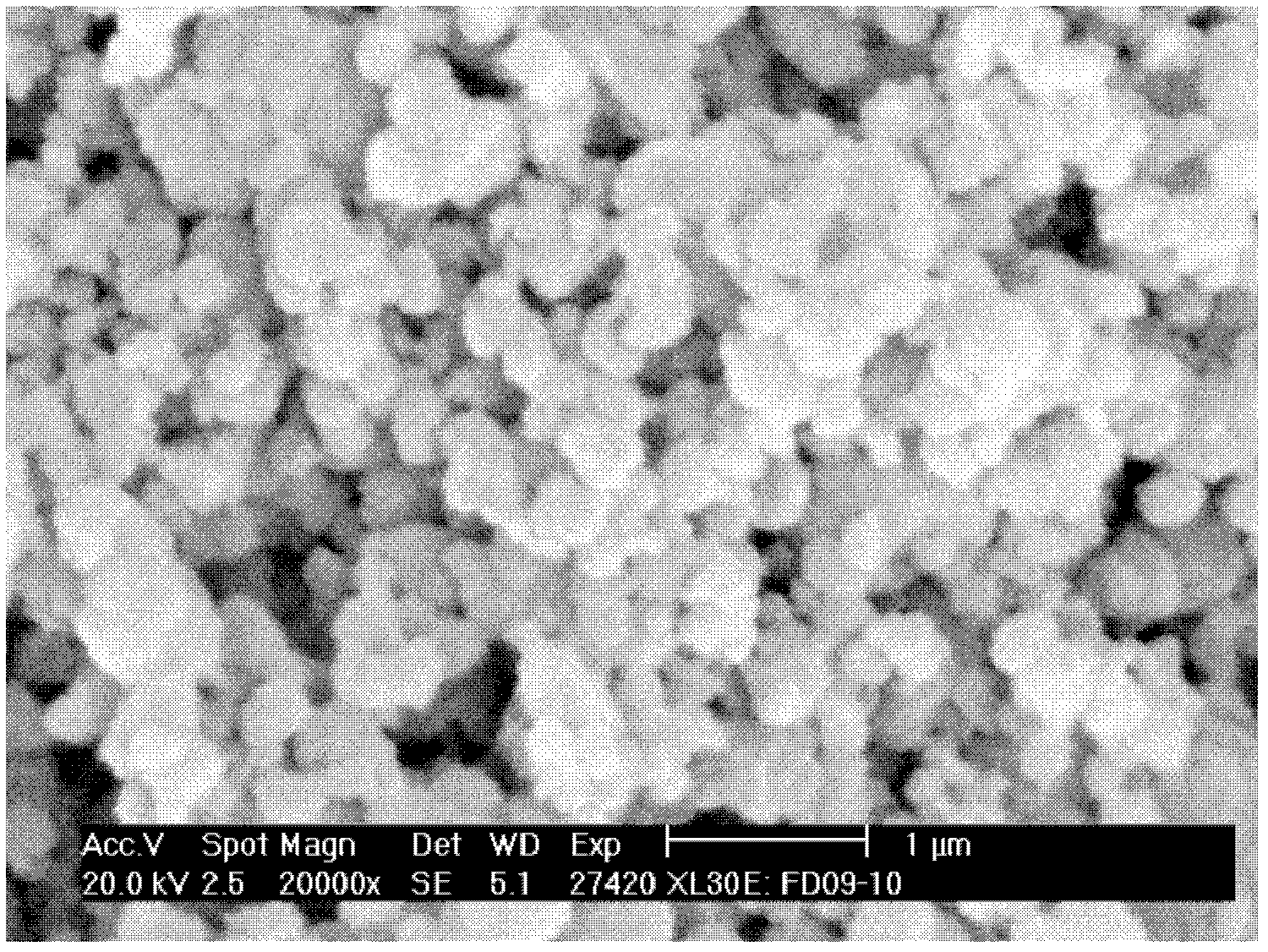

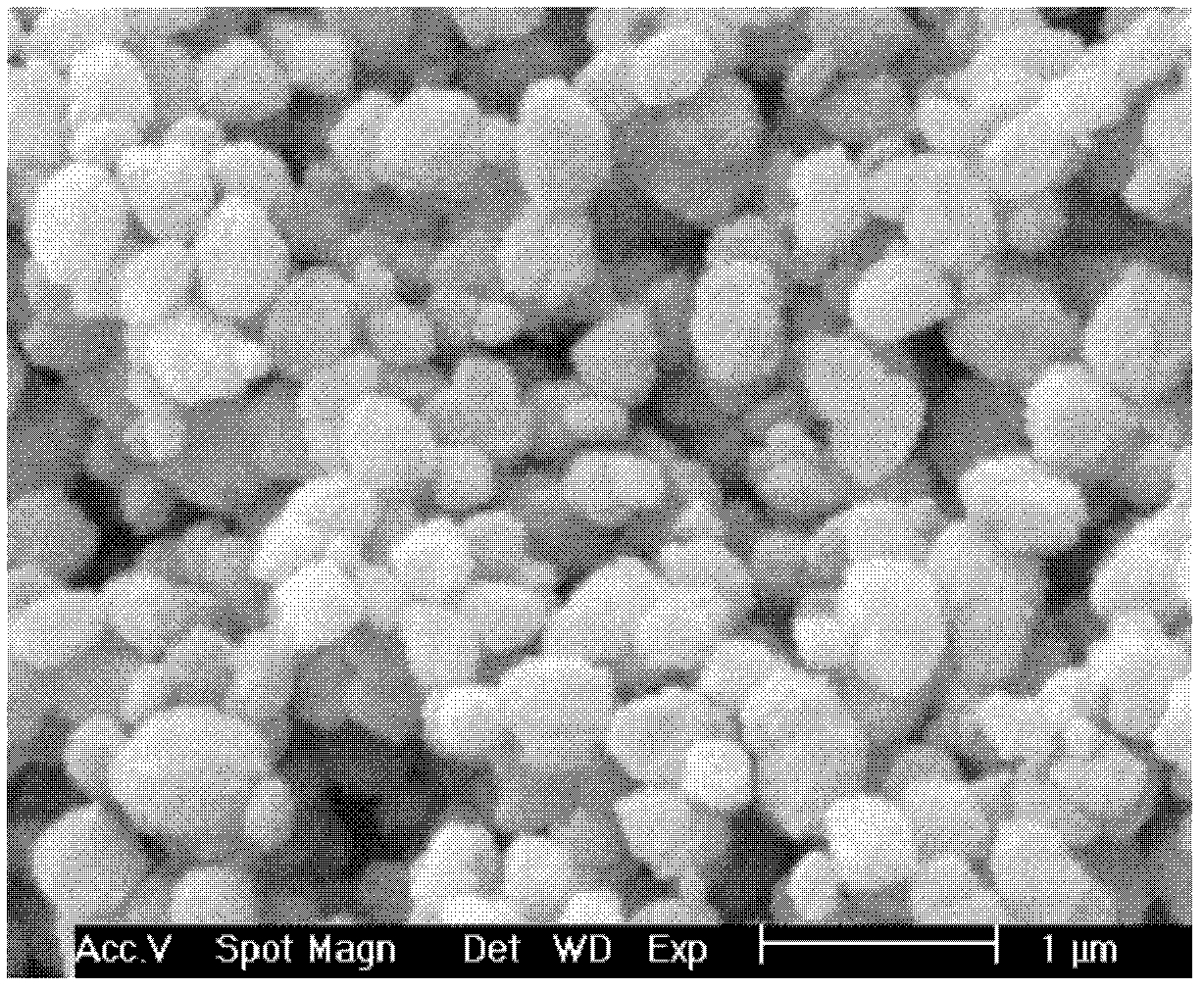

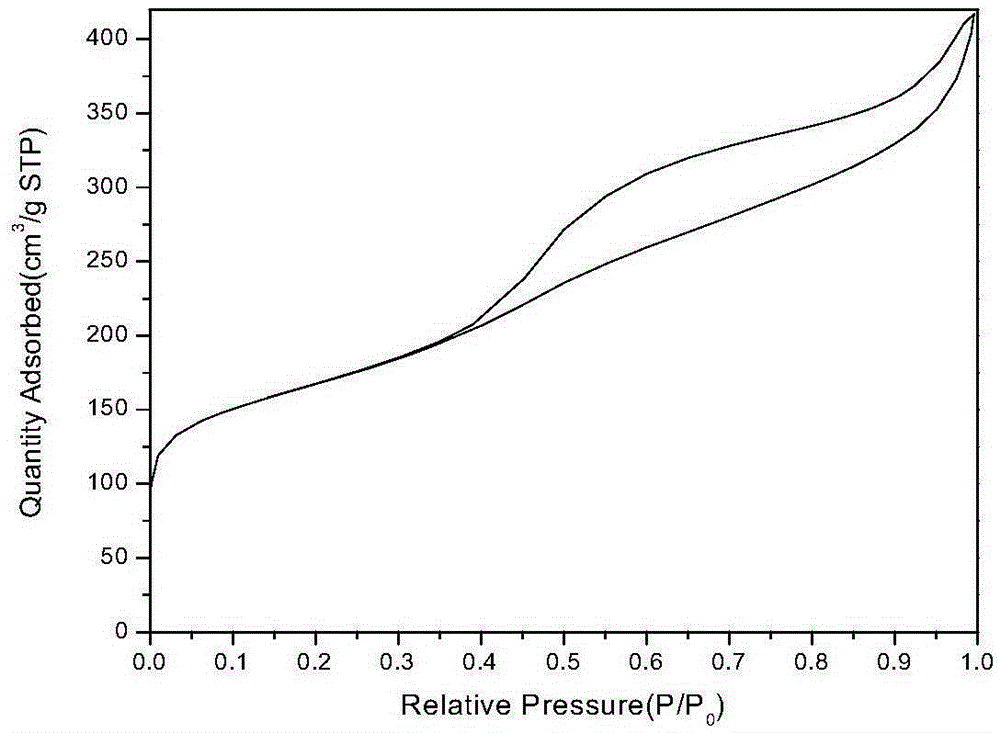

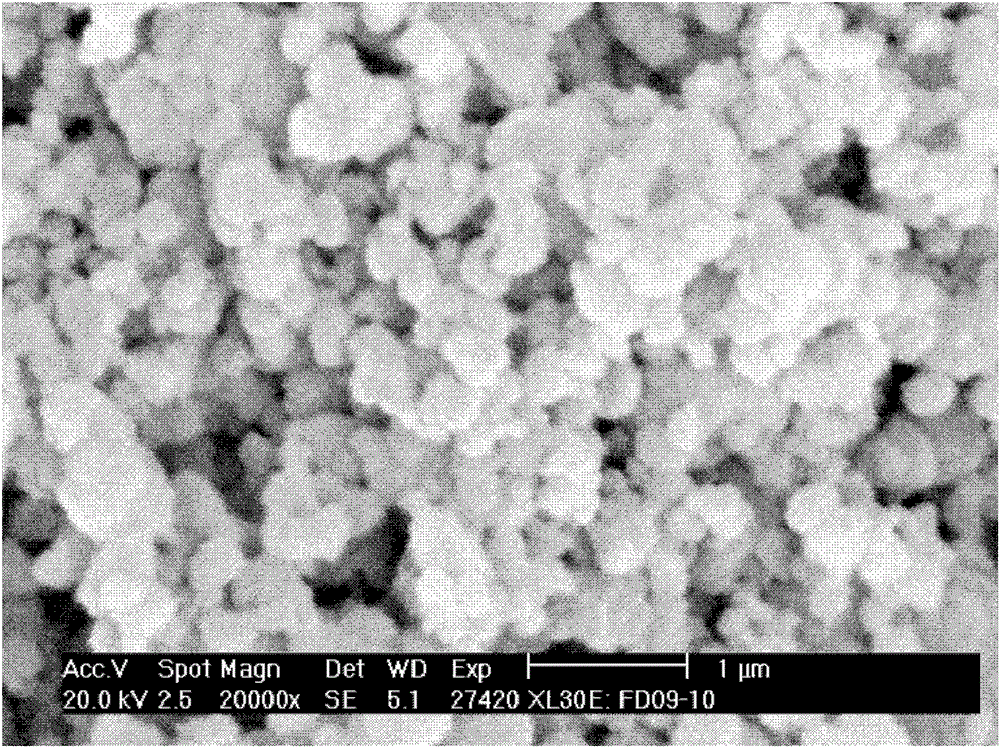

The invention relates to a method for preparing ethylene through ethanol catalytic dehydration and mainly solves the problem of poor reaction stability in the prior part. According the method, ethanol with the weight percentage concentration being 5 to 100 percent is used as raw materials, reaction raw materials and catalysts are in contact to generate ethylene under the conditions that the reaction temperature is 200 to 400 DEG C, and the volume space velocity relative to the ethanol is 0.1 to 15 h<-1>, wherein the used catalysts are MSM-5 zeolite, the MSM-5 zeolite has the crystal grain diameter being smaller than or equal to 5 microns and simultaneously has mesoporouses and micropores, and the mesoporous volume / micropore volume value of the MSM-5 zeolite is 1.5 to 10. Through the technical scheme, the problems are perfectly solved, and the preparation method can be used in the industrial production of ethylene preparation through ethanol dehydration.

Owner:CHINA PETROLEUM & CHEM CORP +1

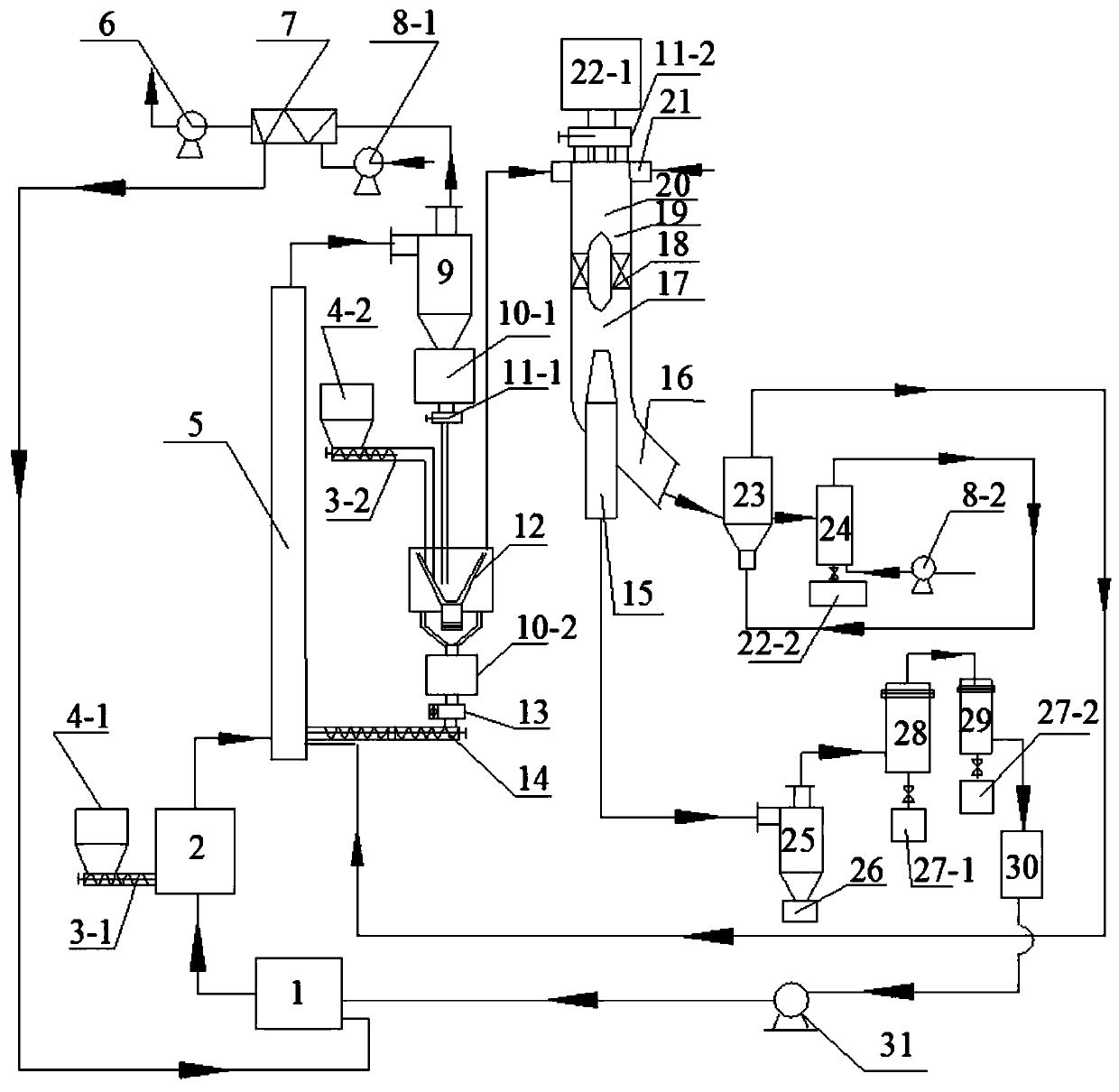

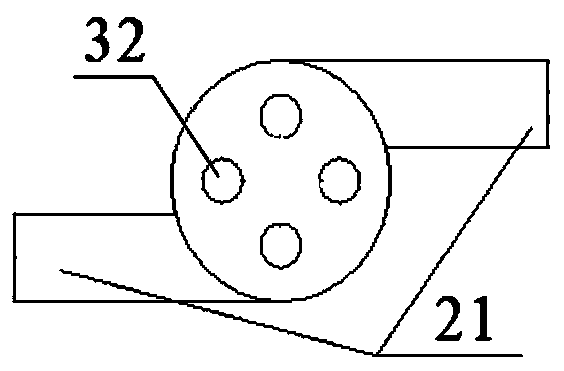

Ex-situ catalytic pyrolysis liquefaction system for biomass

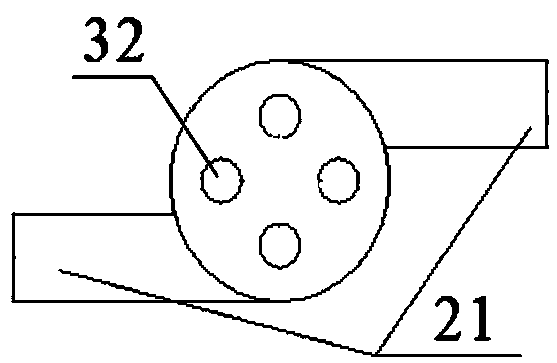

ActiveCN108728143AEasy to operate and controlReduce coke inactivationBiofuelsLiquid hydrocarbon mixture productionCycloneCatalytic pyrolysis

The invention relates to the technical field of conversion and utilization of biomass energy, in particular to an ex-situ catalytic pyrolysis liquefaction system for biomass. The ex-situ catalytic pyrolysis liquefaction system comprises a gasifier, a riser heater, a rotating cone reactor, a flow-guide cyclone reactor, a catalyst regeneration system, a gas-solid separator and a condensation system,wherein the bottom of the gasifier is connected with a first biomass feeder, and the upper part of the gasifier is connected with the lower part of the riser heater; a quartz sand feeder is connectedwith the lower part of the riser heater; the upper part of the riser heater is connected with an inlet of a quartz sand separator; the lower part of the quartz sand separator is connected with a heated sand box which is connected with an inlet of the rotating cone reactor; an outlet of the rotating cone reactor is connected with a gas inlet of the flow-guide cyclone reactor through a gas pipe; the flow-guide cyclone reactor is connected with a catalyst box at the upper part through catalyst inlets. An ex-situ catalytic pyrolysis process is performed on biomass with the system, operation is convenient and controllable, and working condition parameters in a pyrolysis process and a catalytic cracking process can be adjusted and controlled respectively.

Owner:SHANDONG UNIV OF TECH

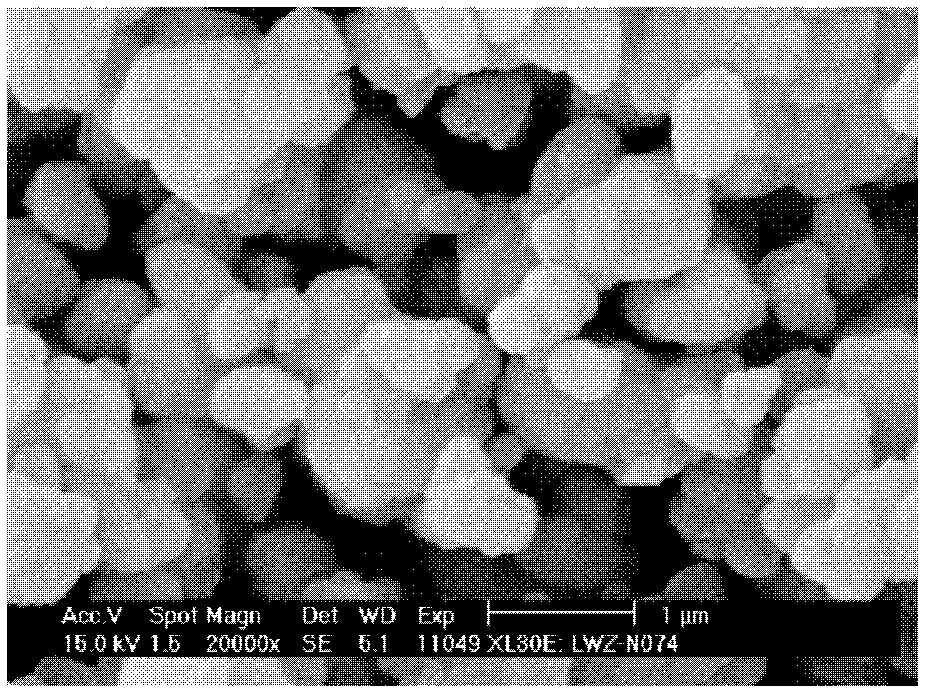

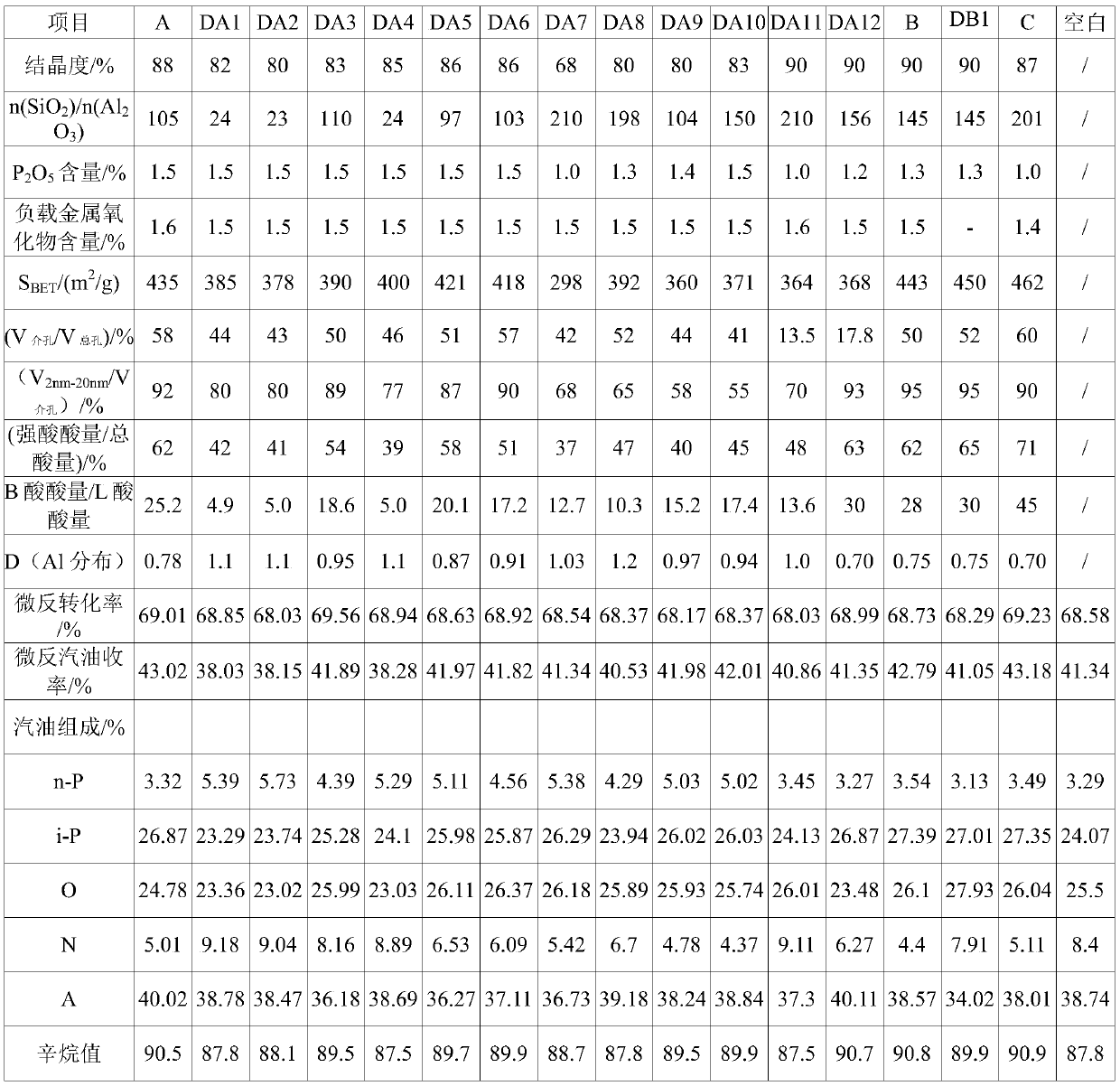

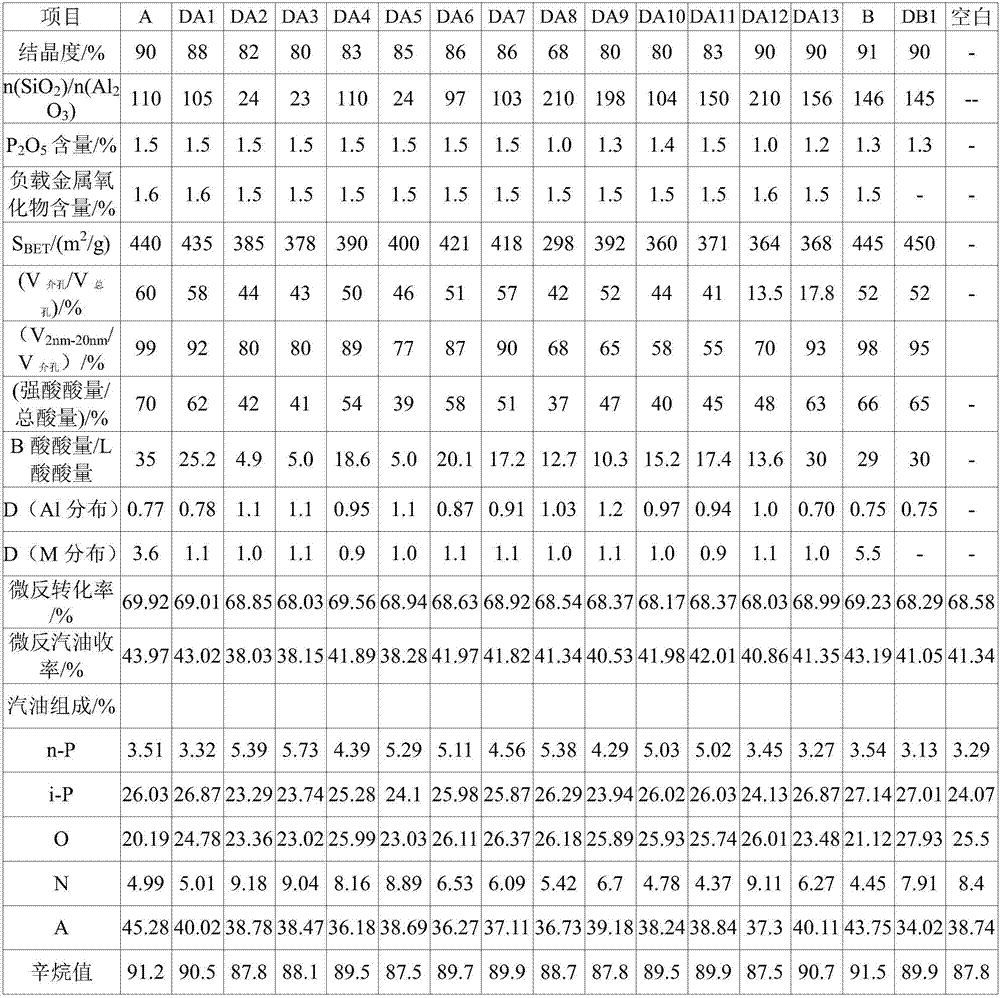

Phosphorus-containing and supported-metal-containing MFI molecular sieve and preparation method thereof

ActiveCN107970978AHigh ratio of silicon to aluminumLow total acidCatalytic crackingMolecular sieve catalystsMolecular sieveActive component

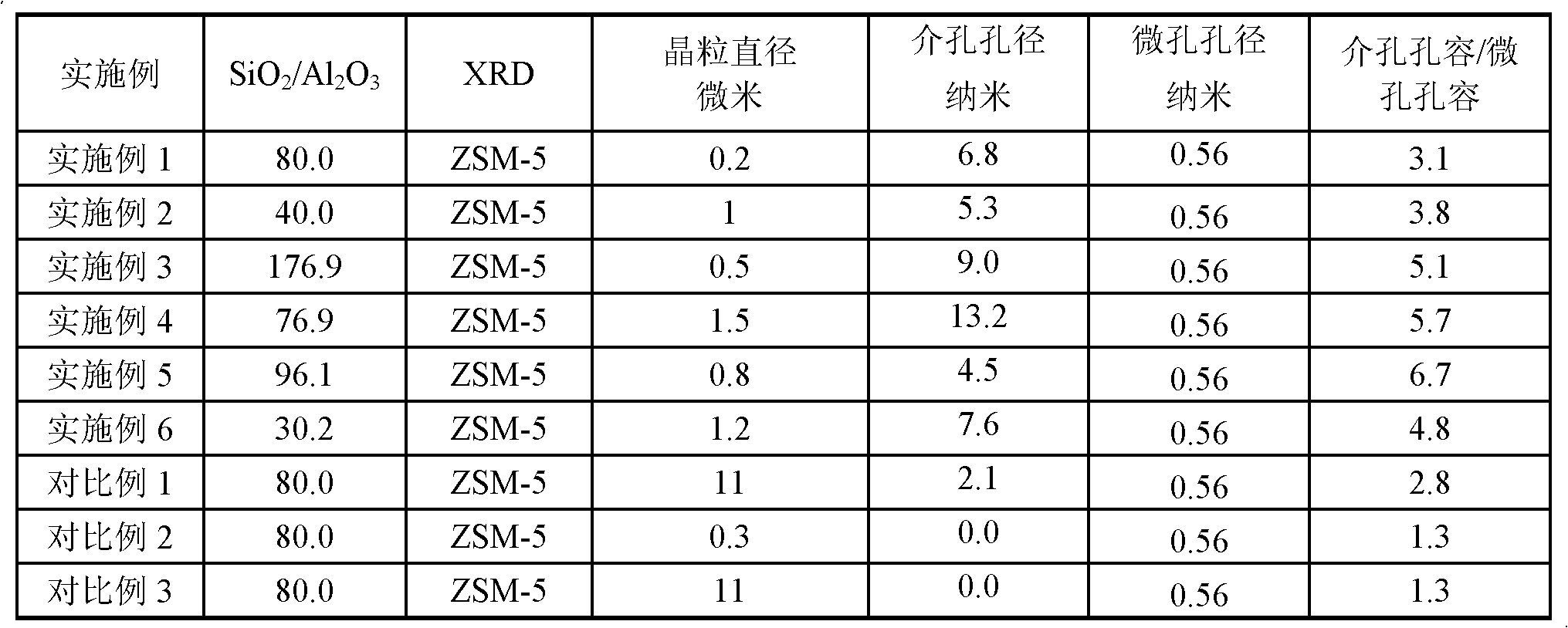

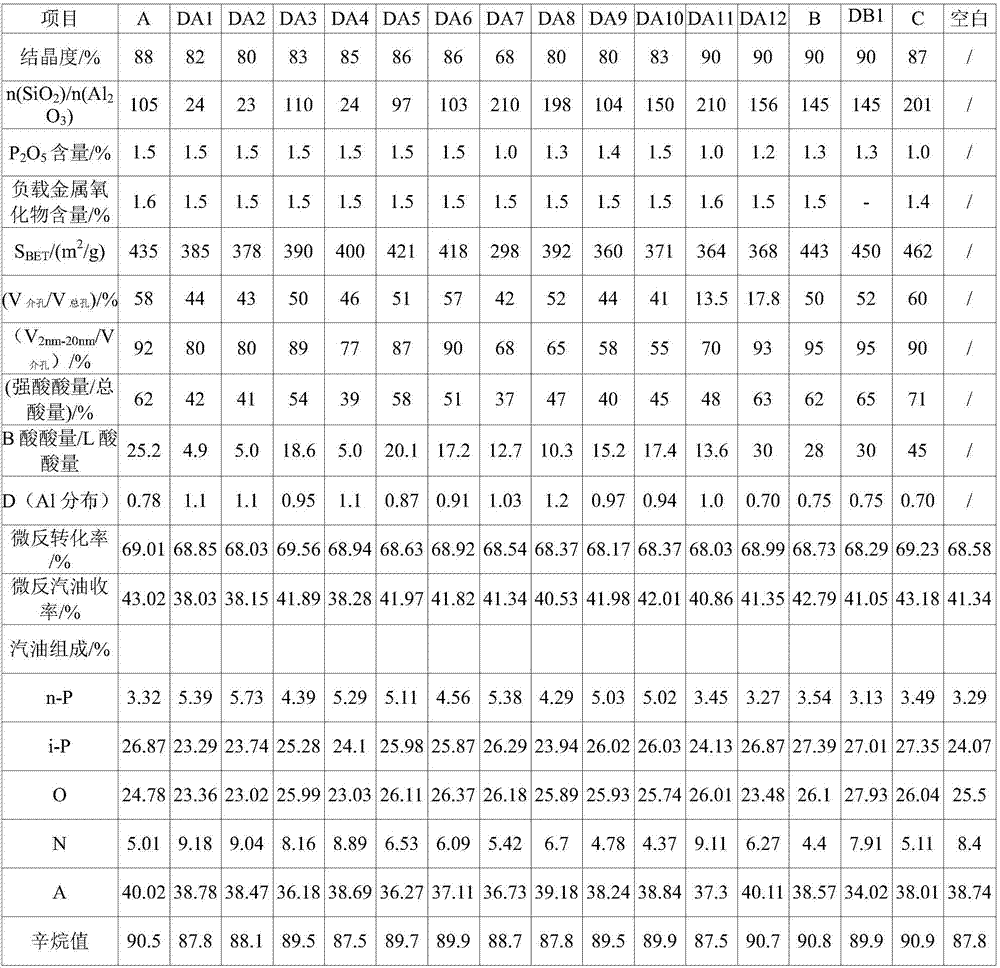

The invention discloses a phosphorus-containing and supported-metal-containing MFI molecular sieve and a preparation method thereof, wherein the n(SiO2) / n(Al2O3) of the molecular sieve is greater than100, the phosphorus content of the molecular sieve is 0.1-5 wt%, the supported metal content of the molecular sieve is 0.1-5 wt%, the Al distribution parameter D (Al) of the molecular sieve is more than or equal to 0.6 and is less than or equal to 0.85, the volume of the mesopores of the molecular sieve accounts for 40-80% of the total pore volume, the volume of the mesopores with the pore size of 2-20 nm accounts for more than 90% of the total mesopore volume, the amount of the strong acid of the molecular sieve accounts for 60-80% of the total acid amount, and a ratio of the acid B to the acid L is 15-80. According to the present invention, with the catalyst or the auxiliary agent prepared by using the phosphorus-containing and supported-metal-containing MFI structure molecular sieve asthe active component, the yield of gasoline in the catalytic cracking reaction of petroleum hydrocarbons can be maintained while the octane number of gasoline can be effectively increased, or the octane value of gasoline can be maintained while the yield of gasoline is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

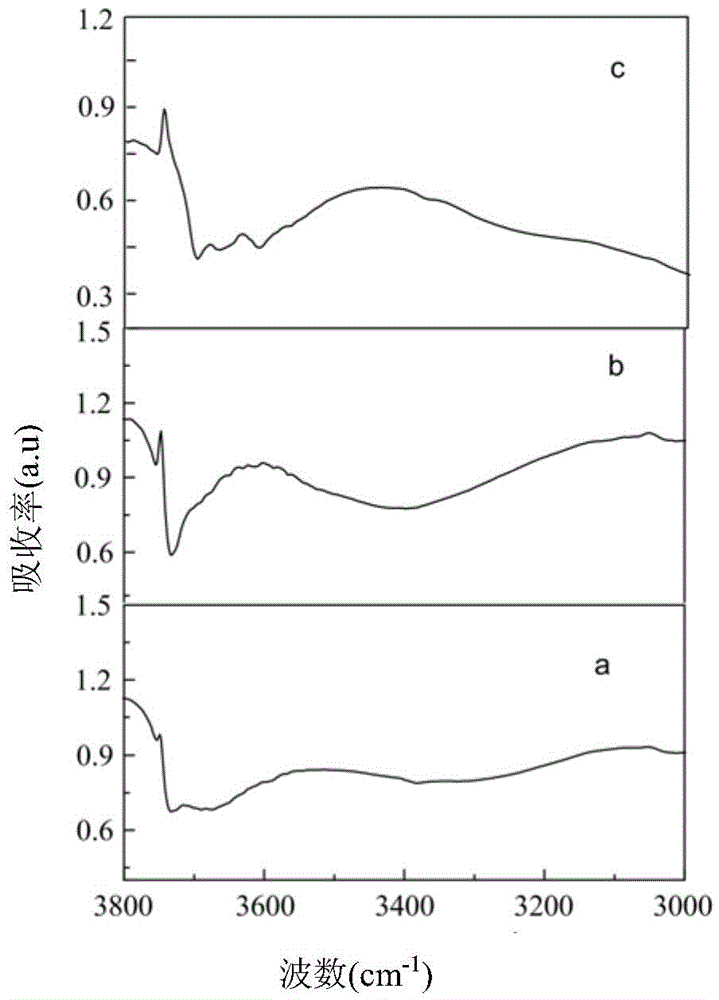

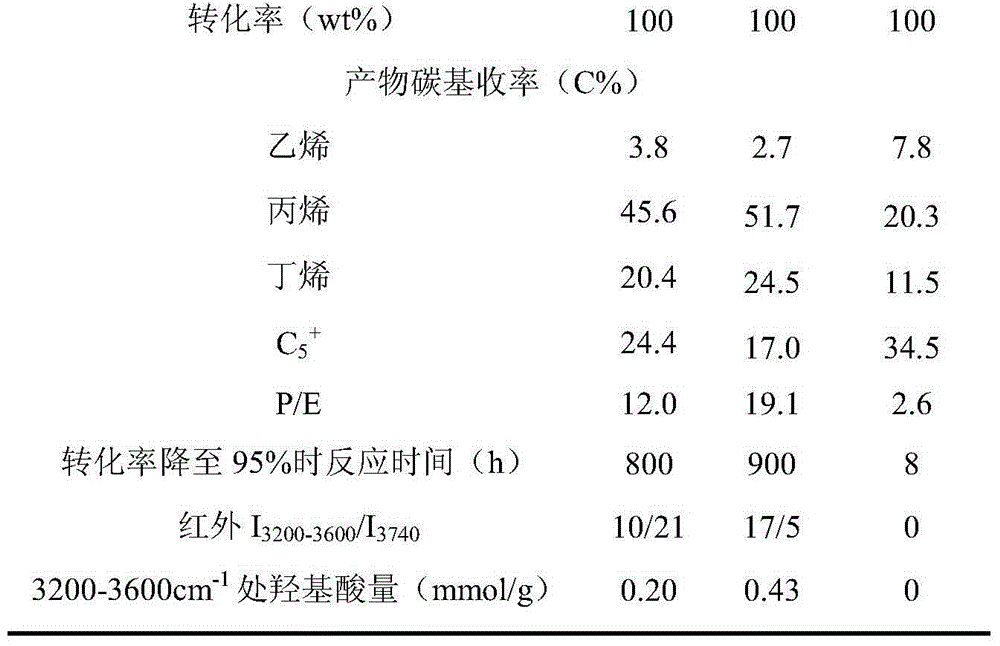

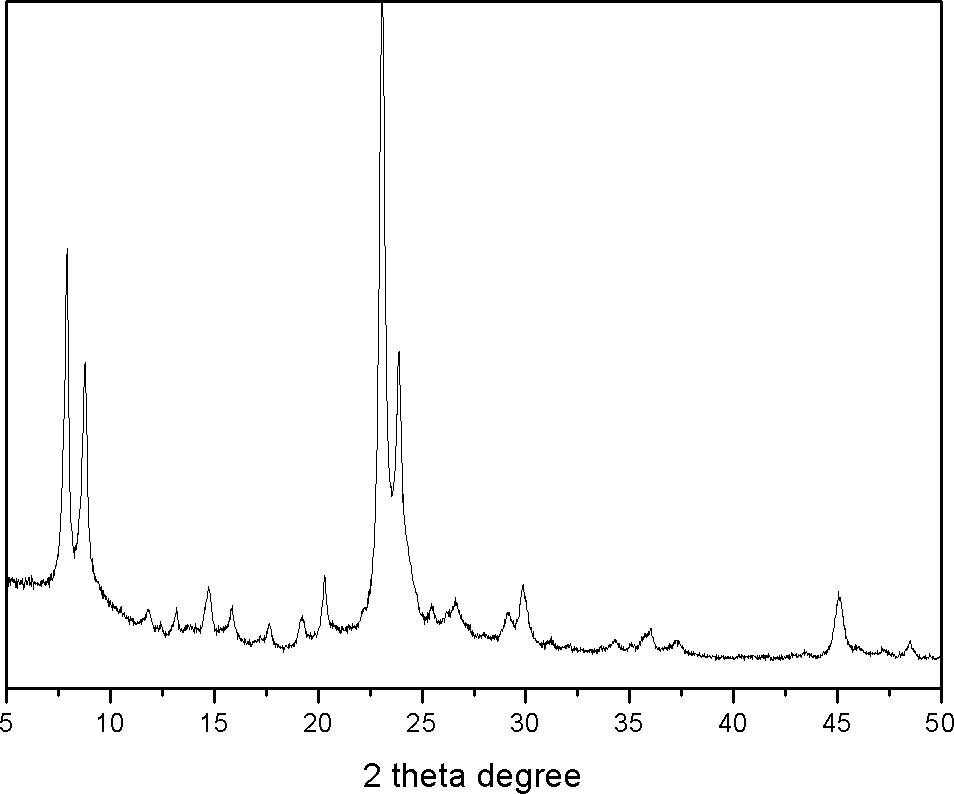

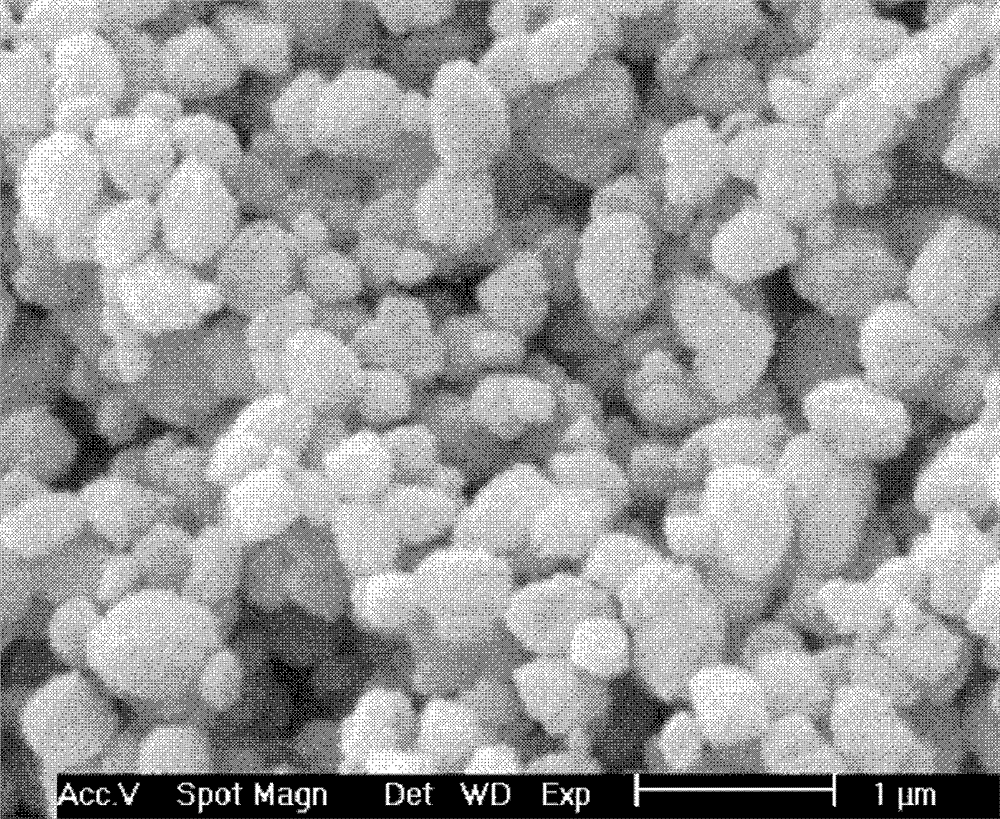

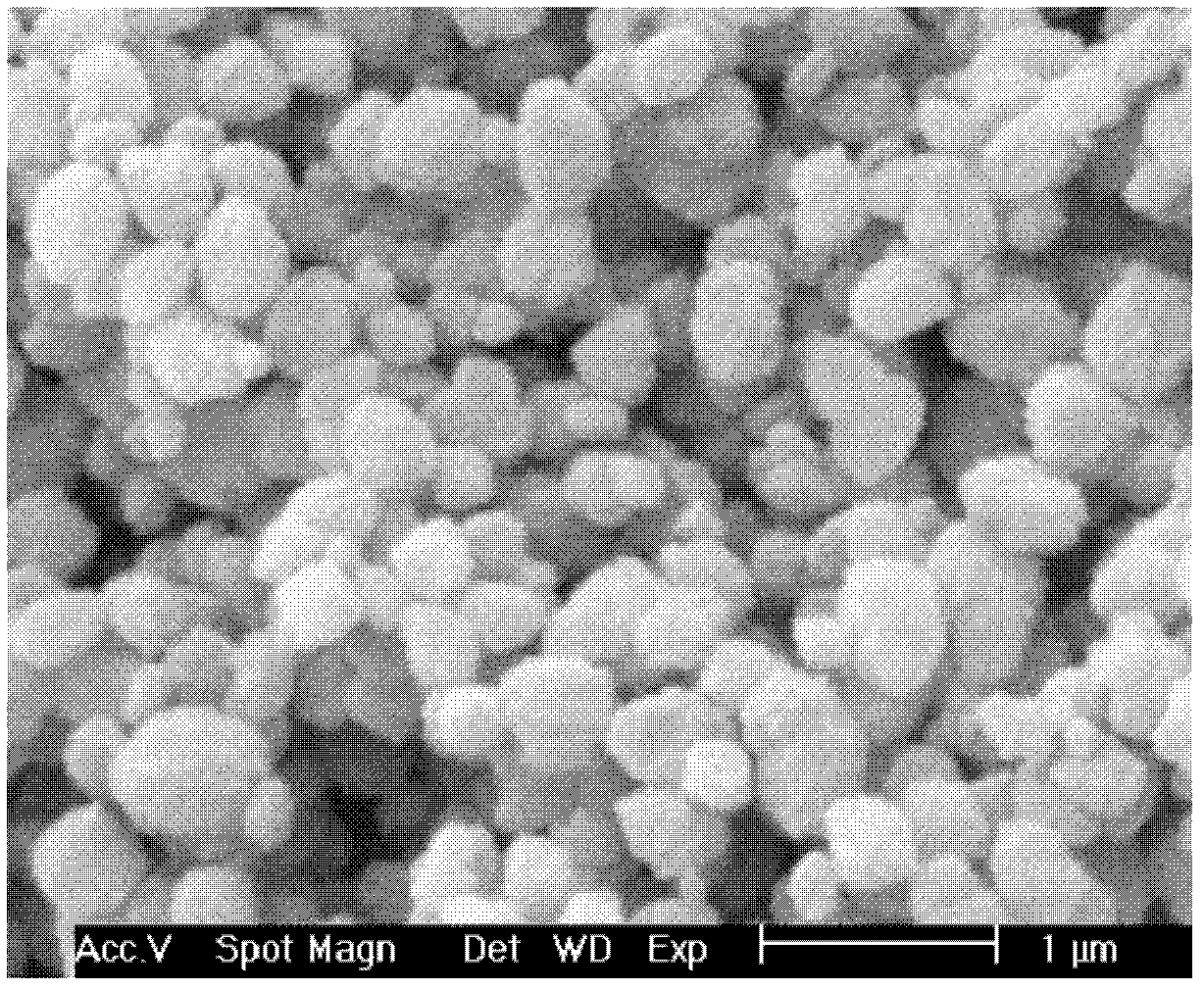

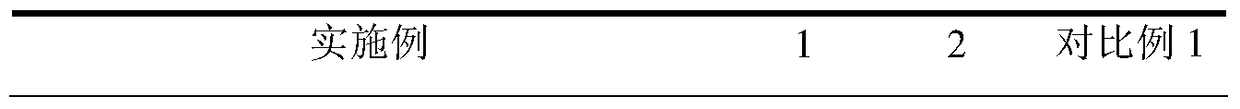

Propylene all-silicon molecular sieve based catalyst prepared through methanol conversion and preparation method thereof

InactiveCN106140268AHigh activityPropylene selectivity is highMolecular sieve catalystsHydrocarbon from oxygen organic compoundsExtrusion mouldingIon

A preparation method of a propylene catalyst prepared through methanol conversion comprises the following steps that 1, an all-silicon molecular sieve is treated in alkali liquor, the concentration of the alkali liquor ranges from 0.005 mol / L to 0.5 mol / L, the mass ratio of the molecular sieve to the solution is 1:1 to 1:50, and preferably, the concentration of the alkali liquor ranges from 0.01 mol / L to 0.2 mol / L, and the mass ratio of the molecular sieve to the solution is 1:5 to 1:30; 2, the all-silicon molecular sieve after alkali treatment in the step 1 is directly dried, or filtering and drying are carried out after ion exchange; 3, the all-silicon molecular sieve in the step 2 is dried and calcined and then pressed into particles, and the propylene catalyst prepared through methanol conversion is obtained; or the all-silicon molecular sieve after calcination in the step 2 is mixed and kneaded with an adhesive, then extrusion moulding, drying and calcination are carried out, and the propylene catalyst prepared through methanol conversion is obtained. The prepared catalyst is high in methanol conversion activity, good in propylene selectivity and high in stability.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

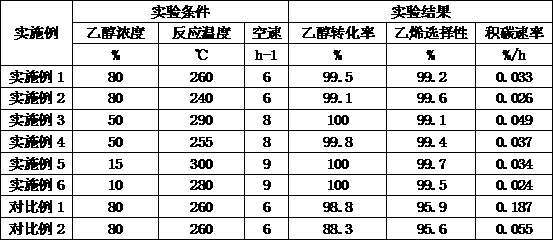

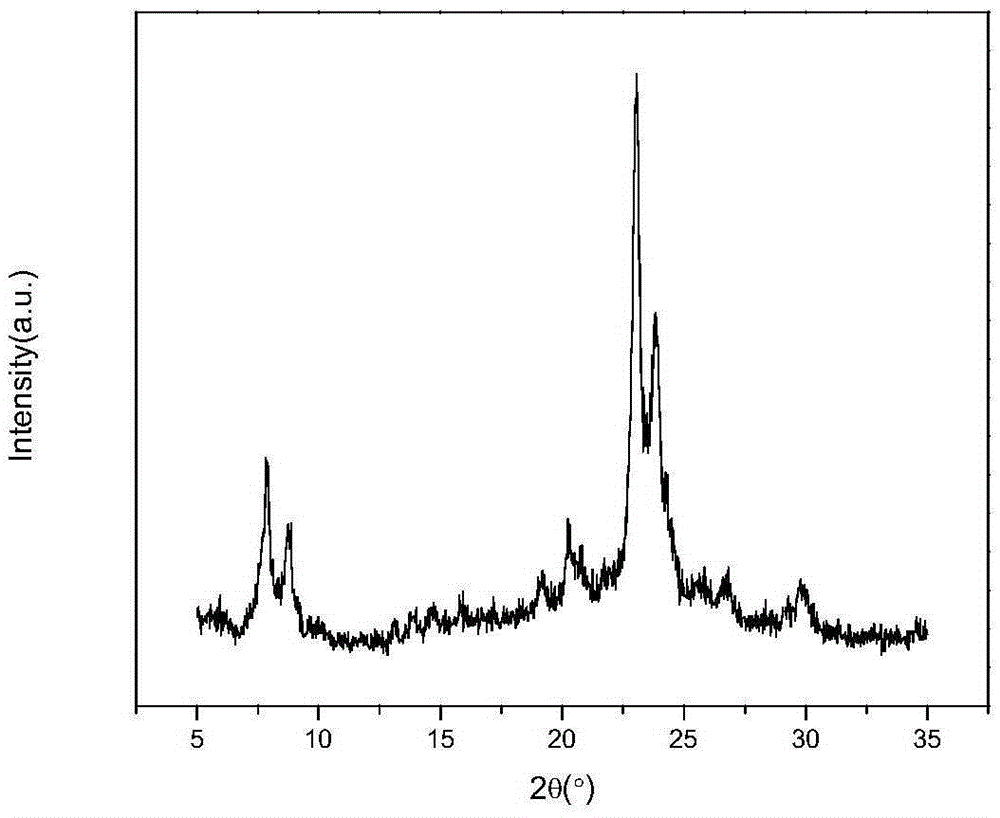

Method for preparing ethylene by dehydrating ethanol

ActiveCN103121903BIncrease profitIncreased focus capacityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsReaction temperatureEthylene

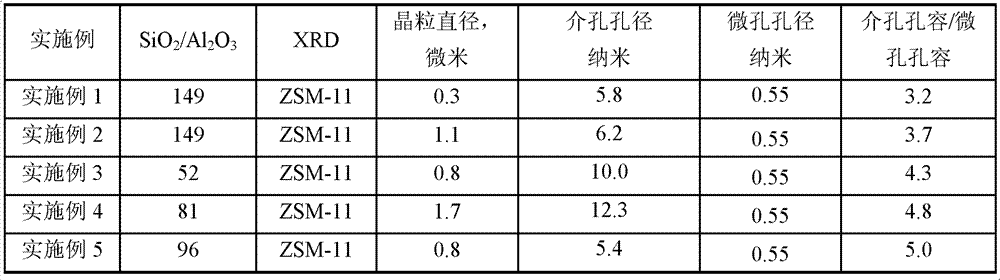

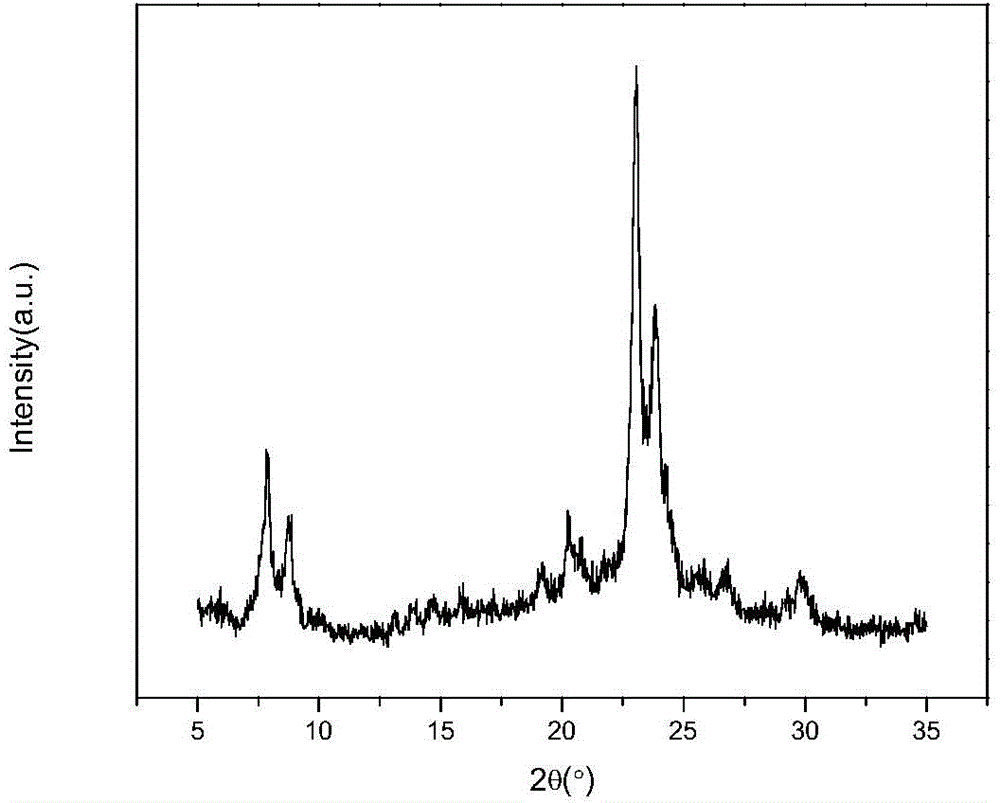

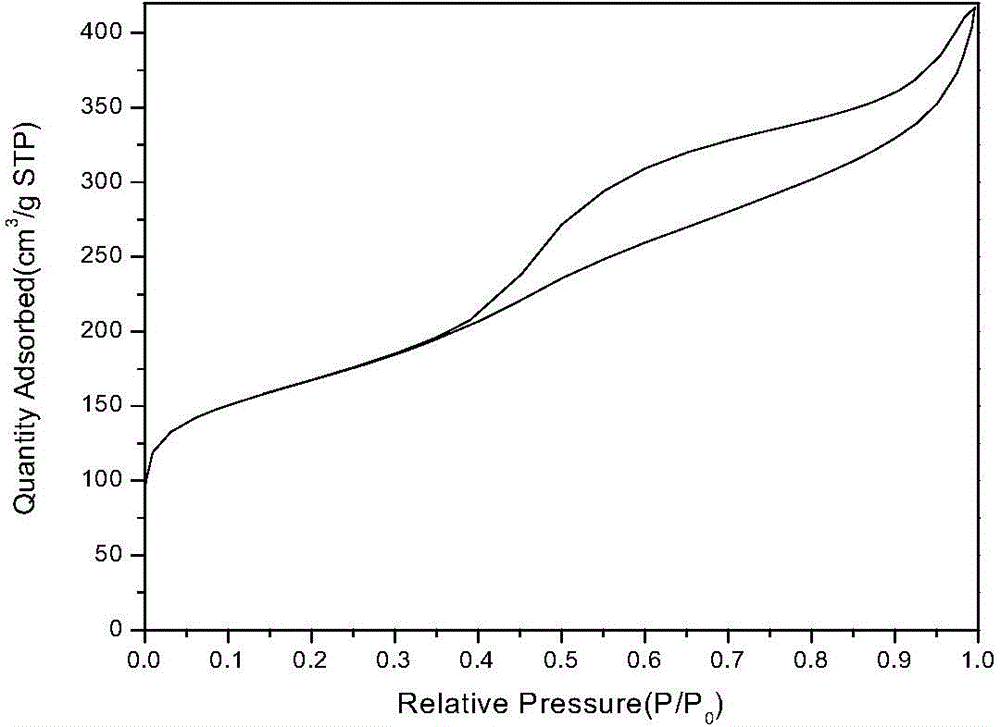

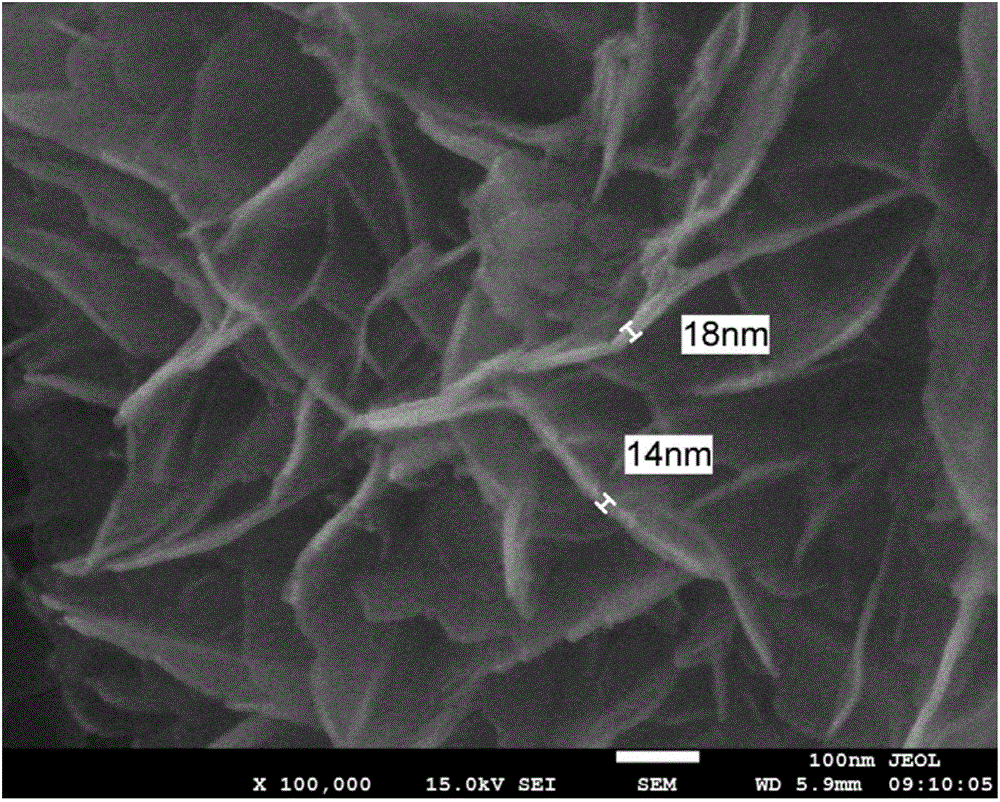

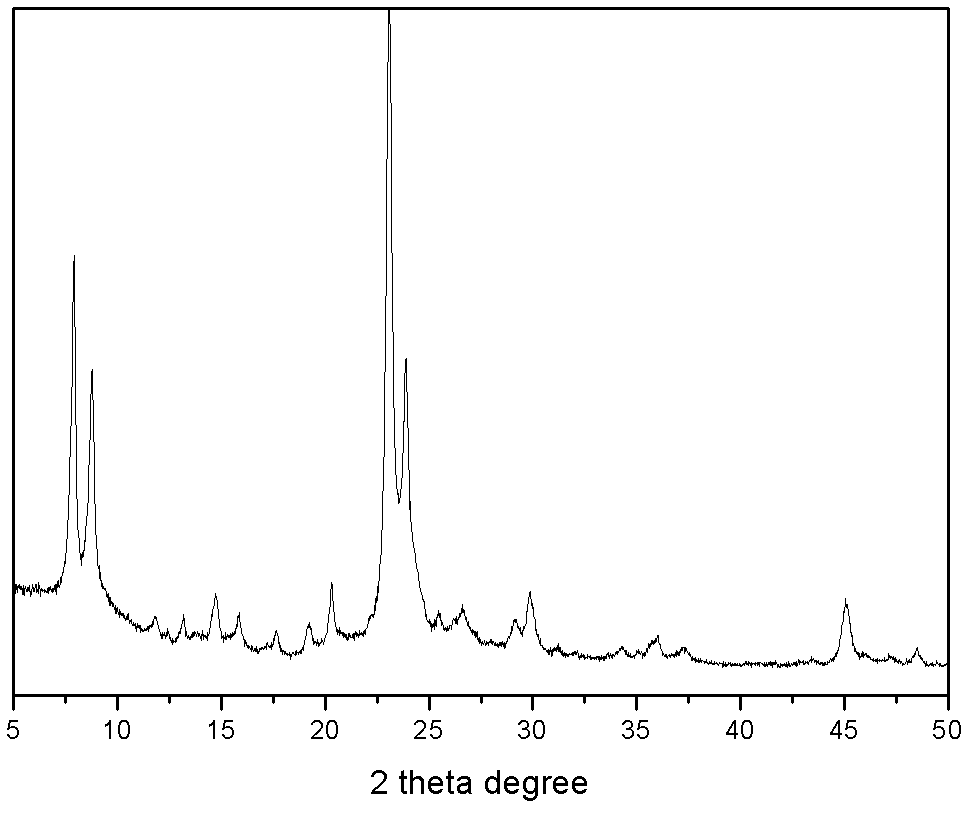

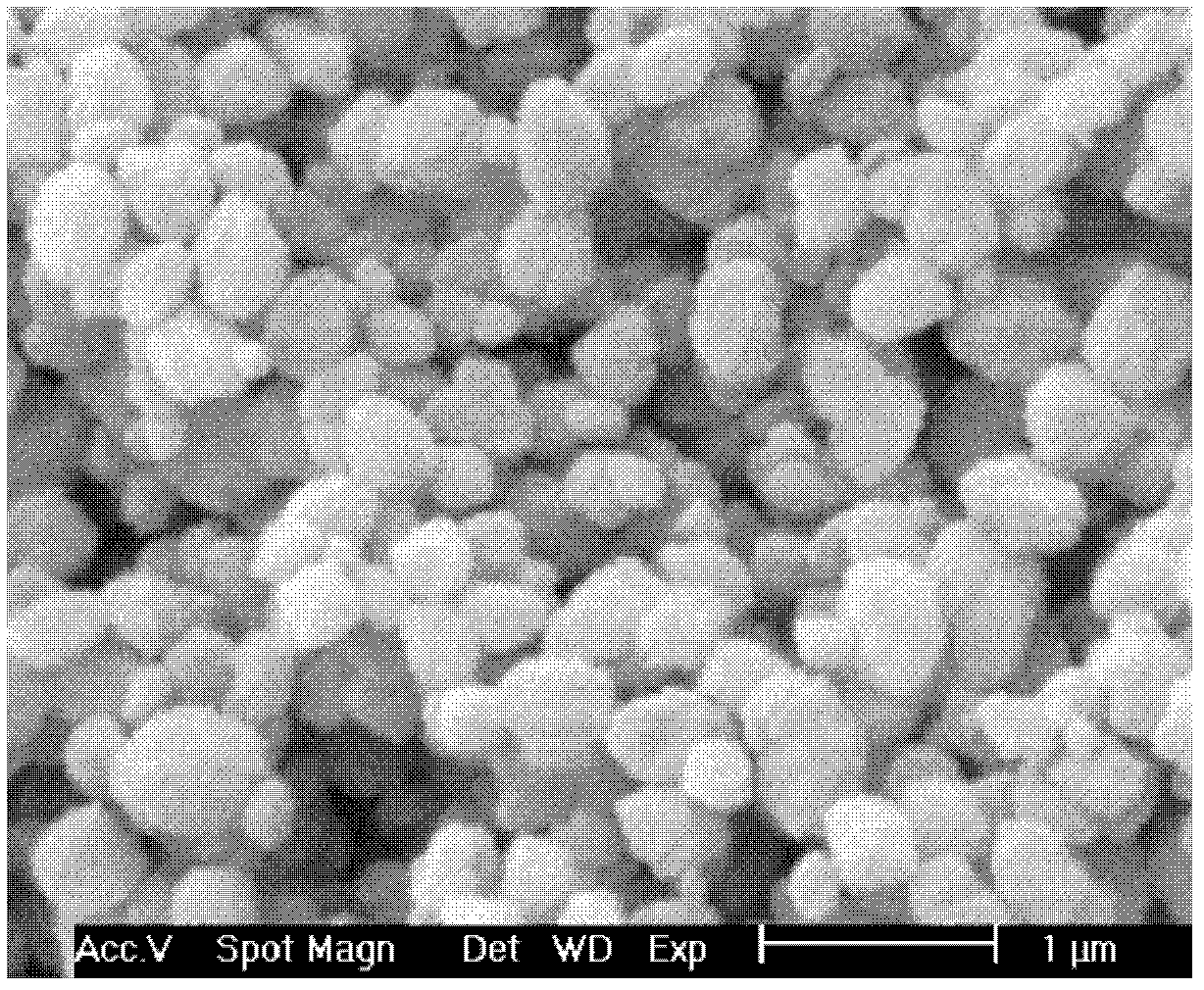

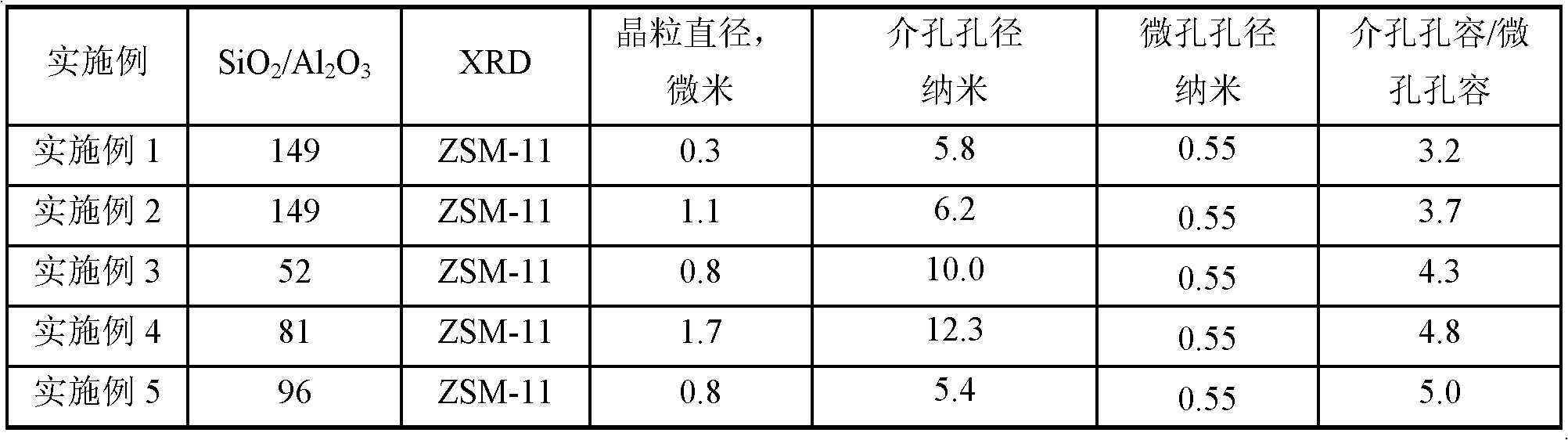

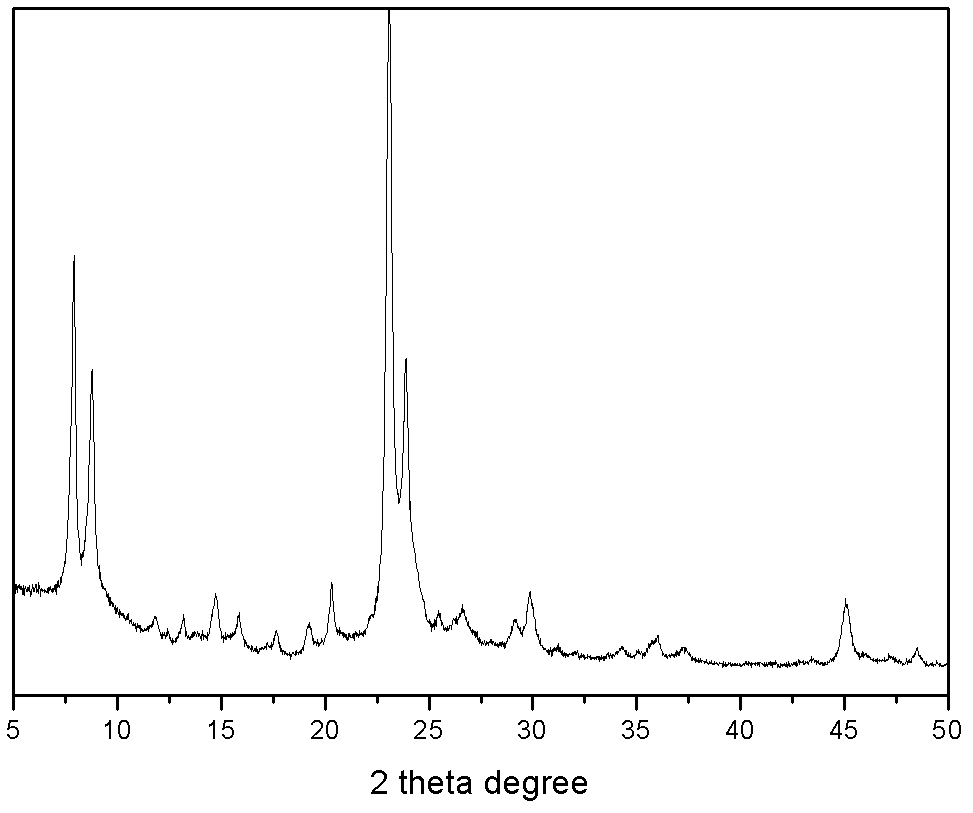

The invention relates to a method for preparing ethylene by dehydrating ethanol and mainly aims to solve the problem of poor reaction stability in the prior art. The method comprises the step of making a raw material to contact and react with a catalyst to generate ethylene under the conditions that the temperature is 200-400 DEG C and the space velocity relative to the volume of the ethylene is 0.1-15h<-1>, wherein the raw material is the ethanol with the concentration of 5-100% by mass, and the catalyst is a ZSM-11 zeolite with mesopores and micropores, wherein the ratio of the volume of the mesopores to the volume of the micropores of the ZSM-11 zeolite is 1.5-10, and the diameter of the crystalline grain of the catalyst is not more than 5 microns. The technical scheme well solves the problem of poor reaction stability in the prior art and can be used for the industrial production of the ethylene by dehydrating the ethanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method and application of thin-layer nano flaky total-silicon molecular sieve for preparing caprolactam

The invention relates to a preparation method of a thin-layer nano flaky total-silicon molecular sieve for preparing caprolactam. The preparation method comprises the following steps: uniformly stirring a silicon source and an alkali source to obtain a mixture I; dissolving a template agent in a mixed solution of deionized water and ethanol to obtain a mixture II, and gradually dropwise adding the mixture I into the mixture II to be stirred to obtain a mixture III, and stirring the mixture III in a water bath to obtain initial gel; dynamically crystallizing the initial gel in a closed reaction kettle, and washing and drying the initial gel to obtain the thin-layer nano flaky total-silicon molecular sieve. The preparation method has the advantages of low cost, small energy consumption, high conversion rate, no pollution and capability of realizing industrial production.

Owner:TAIYUAN UNIV OF TECH +1

Method for preparing ethylene by dehydrating ethanol

ActiveCN103121903AIncrease profitIncreased focus capacityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsReaction temperatureSpace velocity

The invention relates to a method for preparing ethylene by dehydrating ethanol and mainly aims to solve the problem of poor reaction stability in the prior art. The method comprises the step of making a raw material to contact and react with a catalyst to generate ethylene under the conditions that the temperature is 200-400 DEG C and the space velocity relative to the volume of the ethylene is 0.1-15h<-1>, wherein the raw material is the ethanol with the concentration of 5-100% by mass, and the catalyst is a ZSM-11 zeolite with mesopores and micropores, wherein the ratio of the volume of the mesopores to the volume of the micropores of the ZSM-11 zeolite is 1.5-10, and the diameter of the crystalline grain of the catalyst is not more than 5 microns. The technical scheme well solves the problem of poor reaction stability in the prior art and can be used for the industrial production of the ethylene by dehydrating the ethanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing ethylene through ethanol dehydration

InactiveCN103030490AIncrease the external specific surface areaLarger surface areaMolecular sieve catalystsCatalyst activation/preparationMolecular sieveAcid washing

The invention relates to a method for preparing ethylene through ethanol dehydration and mainly solves the problem of poor reaction stability in the prior part. According the method, ethanol with the weight percentage concentration being 5 to 100 percent is used as raw materials, reaction raw materials and catalysts are in contact to generate ethylene under the conditions that the reaction temperature is 200 to 400 DEG C, and the volume space velocity relative to the ethanol is 0.1 to 15 h<-1>, wherein the used catalysts comprise the following ingredients through be metered in parts by weight: a, 40 to 95 parts of ZSM-11 molecular sieves, wherein the silicon aluminum mol ratio (SiO2 / Al2O3) is 200-300, and the crystal grain diameter is smaller than or equal to 5 microns; and b, 5 to 60 parts of bonding agents; and the ZSM-11 molecular sieves are at least subjected to acid washing for once. Through the technical scheme, the problem is perfectly solved, and the method can be used in the industrial production of ethylene preparation through ethanol dehydration.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing ethylene through ethanol dehydration

ActiveCN108101727ASuitable for acidityHigh catalytic activityMolecular sieve catalystsMolecular sieve catalystMolecular sievePolymer science

The invention relates to a method for preparing ethylene through ethanol dehydration. According to the method, H-NaZSM-5 and SAPO-34 molecular sieves with different channels and acidities are compounded through a synthesis method, problems of each of the H-NaZSM-5 and SAPO-34 molecular sieves are overcome, and meanwhile the grain diameter of a composite catalyst is controlled to be not greater than 10 micrometers. The composite catalyst has a unique double-channel structure, high specific surface area and suitable acidity, is beneficial to the improvement of stability, ensures that both the ethanol conversion rate and the ethylene selectivity reach 99 percent or more when catalyzing ethanol dehydration to prepare ethylene, and the ethanol conversion rate and the ethylene selectivity stillkeep 96 percent after 100h of continuous reaction.

Owner:李宝尔

A kind of preparation method and application of thin-layer nano-sheet all-silicon molecular sieve for preparing caprolactam

Owner:TAIYUAN UNIV OF TECH +1

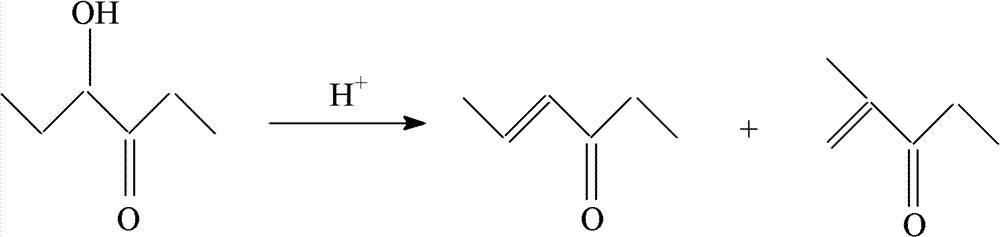

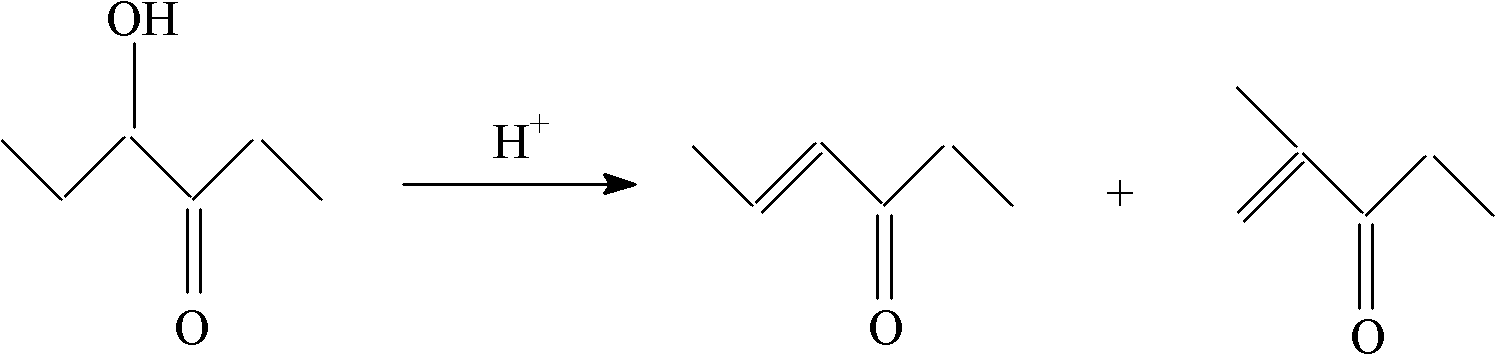

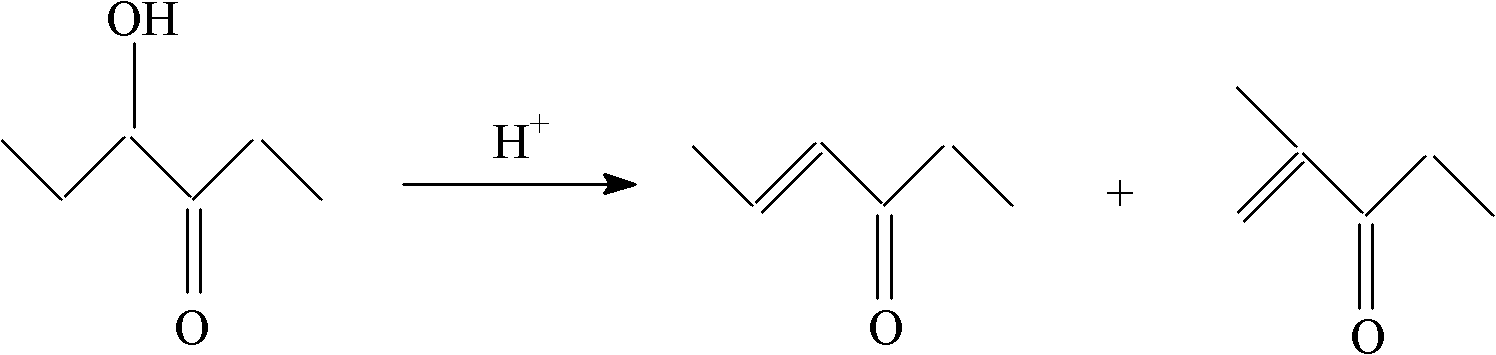

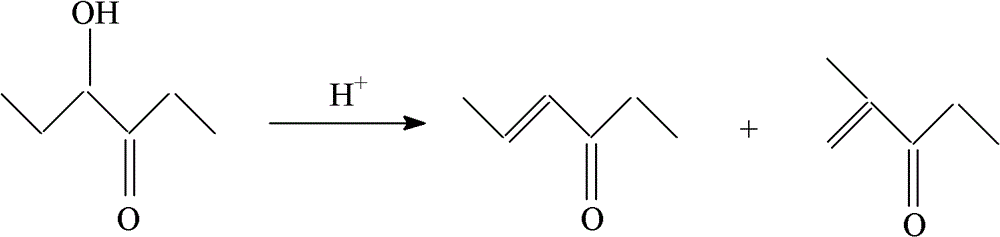

Catalytic dehydrating preparation method of 4-hexen-3-ketone by 4- hydroxy-3-hexanone

ActiveCN103121932BIncrease profitIncreased focus capacityMolecular sieve catalystsOrganic compound preparationReaction temperatureKetone

The invention relates to a catalytic dehydrating preparation method of 4-hexen-3-ketone by 4- hydroxy-3-hexanone and solves problems of low catalytic activity, high reaction temperature and low airspeed in the prior art. The 4- hydroxy-3-hexanone is adopted as a raw material, on conditions that reaction temperature ranges from 200 DEG C to 400 DEG C and the airspeed of 4- hydroxy-3-hexanone liquid quality is 0.5-15 hour -1, the raw material is contacted with a catalyst to form the 4-hexen-3-ketone. The grain diameter of the catalyst is < / = 5 micron, the catalyst is provided with zeolite ZSM-11 with mesopores and micropores, and the values of pore volumes of the mesopores and micropores of the zeolite ZSM-11 are 1.5-10. According to the technical scheme, the catalytic dehydrating preparation method solves the problems effectively and can be used in industrial production of 4-hexen-3-ketone by 4- hydroxy-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

4-hydroxyl-3-hexanone catalytic dehydration method

ActiveCN103121933AIncrease profitIncreased focus capacityMolecular sieve catalystsOrganic compound preparationLow activityReaction temperature

The invention relates to a 4-hydroxyl-3-hexanone catalytic dehydration method and mainly aims to solve the problems of a catalyst in the prior art, such as low activity, high reaction temperature and low space velocity. According to the technical scheme, 4-hydroxyl-3-hexanone serving as a raw material comes into contact with a catalyst to generate 4-hexylene-3-hexanone under the conditions that the reaction temperature ranges from 200 DEG C to 400 DEG C and the liquid mass space velocity relative to the 4-hydroxyl-3-hexanone is equal to 0.5-15h<-1>, wherein the used catalyst has the crystal grain diameter being at most 5mm, and has ZSM-5 zeolite with mesopores and micropores, and the ratio of the volume of the mesopores to the volume of the micropores in the ZSM-5 zeolite is equal to 1.5-10. The problems in the prior art can be well solved by adoption of the technical scheme. The 4-hydroxyl-3-hexanone catalytic dehydration method can be used for industrial production of 4-hexylene-3-hexanone prepared by using the 4-hydroxyl-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of molecular sieve containing phosphorus MFI structure and preparation method thereof

ActiveCN107973317BPromote generationFacilitated DiffusionMolecular sieve catalystsPentasil aluminosilicate zeoliteMolecular sieveActive component

Owner:CHINA PETROLEUM & CHEM CORP +1

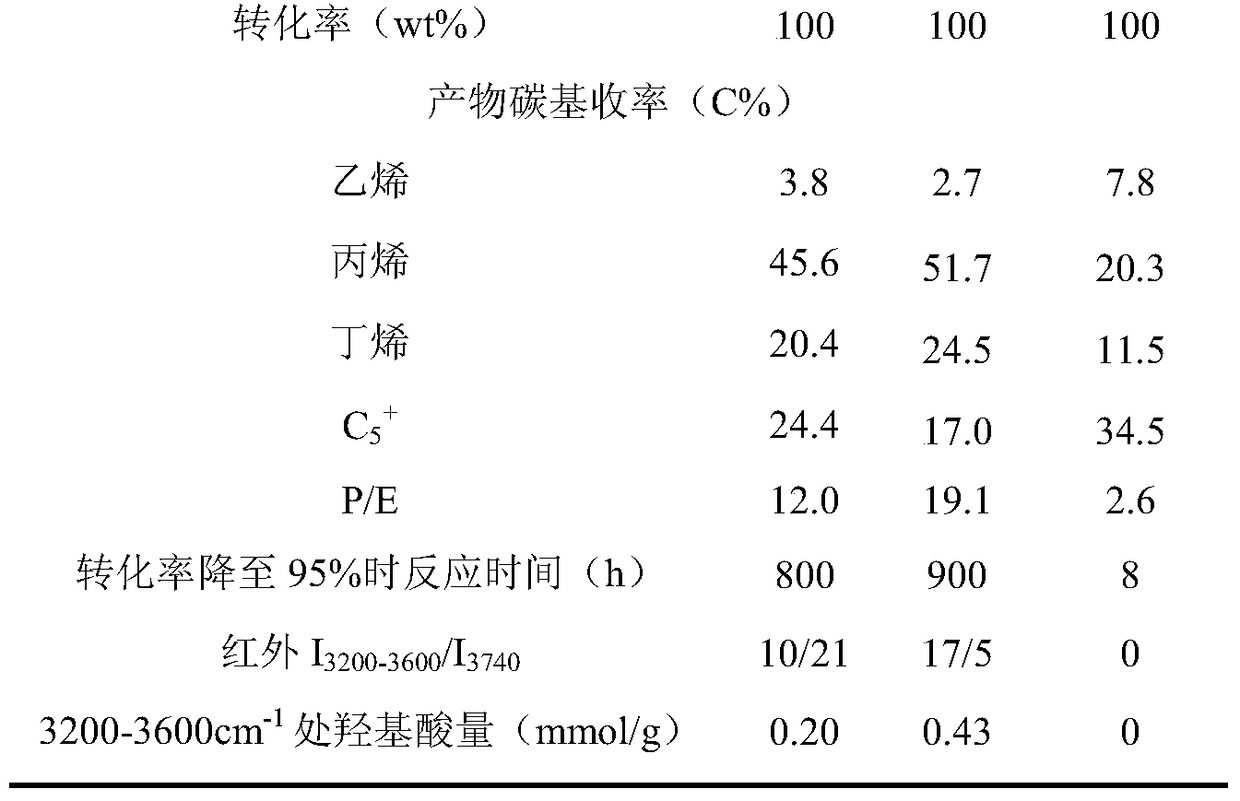

Biomass ex situ catalytic pyrolysis liquefaction system

ActiveCN108728143BEasy to operate and controlReduce coke inactivationBiofuelsLiquid hydrocarbon mixture productionCatalytic pyrolysisPtru catalyst

The invention relates to the technical field of conversion and utilization of biomass energy, in particular to an ex-situ catalytic pyrolysis liquefaction system for biomass. The ex-situ catalytic pyrolysis liquefaction system comprises a gasifier, a riser heater, a rotating cone reactor, a flow-guide cyclone reactor, a catalyst regeneration system, a gas-solid separator and a condensation system,wherein the bottom of the gasifier is connected with a first biomass feeder, and the upper part of the gasifier is connected with the lower part of the riser heater; a quartz sand feeder is connectedwith the lower part of the riser heater; the upper part of the riser heater is connected with an inlet of a quartz sand separator; the lower part of the quartz sand separator is connected with a heated sand box which is connected with an inlet of the rotating cone reactor; an outlet of the rotating cone reactor is connected with a gas inlet of the flow-guide cyclone reactor through a gas pipe; the flow-guide cyclone reactor is connected with a catalyst box at the upper part through catalyst inlets. An ex-situ catalytic pyrolysis process is performed on biomass with the system, operation is convenient and controllable, and working condition parameters in a pyrolysis process and a catalytic cracking process can be adjusted and controlled respectively.

Owner:SHANDONG UNIV OF TECH

A kind of MFI structure molecular sieve containing phosphorus and loaded metal and preparation method thereof

ActiveCN107973303BEnhanced structuring performanceReduce olefin contentMolecular sieve catalystsPentasil aluminosilicate zeoliteMolecular sieveActive component

The invention discloses a phosphorus-containing and supported-metal-containing MFI structure molecular sieve and a preparation method thereof, wherein the n(SiO2) / n(Al2O3) of the molecular sieve is greater than 100, the phosphorus content of the molecular sieve is 0.1-5 wt%, the supported metal content of the molecular sieve is 0.5-5 wt%, the Al distribution parameter D (Al) of the molecular sieveis more than or equal to 0.6 and is less than or equal to 0.85, the volume of the mesopores of the molecular sieve accounts for 40-80% of the total pore volume, the volume of the mesopores with the pore size of 2-20 nm accounts for more than 90% of the total mesopore volume, the amount of the strong acid of the molecular sieve accounts for 60-80% of the total acid amount, and a ratio of the acidB to the acid L is 15-80. According to the present invention, with the catalyst or the auxiliary agent prepared by using the phosphorus-containing and supported-metal-containing MFI structure molecular sieve as the active component, the yield and the octane number of gasoline can be improved in the catalytic cracking reaction of petroleum hydrocarbons while the olefin content in gasoline can be effectively reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of 4-hexene-3-ketone by virtue of dehydration of 4-hydroxy-3-hexanone

ActiveCN103058838BIncrease profitIncreased focus capacityMolecular sieve catalystsOrganic compound preparationMolecular sieveReaction temperature

The invention relates to a preparation method of 4-hexene-3-ketone by virtue of dehydration of 4-hydroxy-3-hexanone, and the method is mainly used for solving the problems in the prior art that the catalyst activity is low, the reaction temperature is high and the space velocity is low. The technical scheme adopted by the invention is as follows: according to the preparation method, 4-hydroxy-3-hexanone which is used as a raw material, is contacted with a catalyst so as to generate 4-hexene-3-ketone under the condition that the reaction temperature is 200-400 DEG C, and the space velocity relative to the liquid weight of 4-hexene-3-ketone is 0.5-15h<-1>, wherein the catalyst comprises the following components in parts by weight: a), 40-95 parts of ZSM-11 molecular sieve with the silicon aluminum mole ratio (SiO2 / Al2O3) of 20-300 and the crystal particle diameter of equal to or less than 5 microns and b), 5-6 parts of binding agent, and the ZSM-11 molecular sieve is at least subjected to once acid pickling, so that the problems in the prior art are better solved, and the method can be used in the industrial production of 4-hexene-3-ketone prepared by utilizing 4-hydroxy-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of SBA-15/ZSM-5 composite molecular sieve, catalyst and application in double branched chain isomerization

PendingCN112642473ALow costReduce pollutionMolecular sieve catalystsHydrocarbon oils refiningPtru catalystIsomerization

The invention relates to the field of petroleum processing, discloses a preparation method of an SBA-15 / ZSM-5 composite molecular sieve material and application in double branched chain isomerization, and in particular relates to a low-cost green preparation method of an SBA-15 / ZSM-5 composite molecular sieve material with proper acidity and a stepped pore channel structure and a sulfur-tolerant double-branched-chain isomerization catalyst prepared by loading non-noble metals on the SBA-15 / ZSM-5 composite molecular sieve material. The catalyst is applied to a catalytic cracking (FCC) gasoline hydroisomerization reaction. According to the invention, a ZSM-5 molecular sieve nanocrystalline precursor solution is greenly synthesized by taking natural minerals as raw materials without a template agent, and then the SBA-15 / ZSM-5 composite molecular sieve carrier is prepared through in-situ assembly by adopting a low-acidity prehydrolysis method, so that the production cost is greatly reduced, the equipment corrosion is relieved, and the pollutant emission is reduced. Therefore, the method provided by the invention has good economic and environmental benefits, and provides technical support for promoting the industrialization process.

Owner:PETROCHINA CO LTD +1

Methanol conversion to propylene all-silicon molecular sieve catalyst and preparation method thereof

InactiveCN106140268BThere is no dealuminationHigh activityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveAdhesive

The preparation method of the catalyst for the conversion of methanol to propylene comprises the following steps: (1) treating the all-silicon molecular sieve in lye, the concentration of the lye is 0.005-0.5mol / L, and the mass ratio of the molecular sieve to the solution is 1:1- 1:50; preferably, the concentration of the lye is 0.01-0.2mol / L, and the mass ratio of the molecular sieve to the solution is 1:5-1:30; (2) The all-silicon molecular sieve after the alkali treatment in step (1) is directly dried or after ion exchange, then filter and dry; (3) the all-silicon molecular sieve in step (2) is compressed into particles after being dried and roasted to obtain a catalyst for methanol conversion to propylene; or the all-silicon molecular sieve after step (2) is roasted and The binder is mixed and kneaded, extruded, dried and calcined to obtain a catalyst for methanol conversion to propylene. The prepared catalyst has high methanol conversion activity, good propylene selectivity and high stability.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Two-stage microwave tandem catalytic pyrolysis device for waste oil

PendingCN112387227AAchieving coke inactivationAchieving yieldFatty acid chemical modificationEnergy based chemical/physical/physico-chemical processesCatalytic pyrolysisCatalytic reforming

The invention relates to a two-stage microwave tandem catalytic pyrolysis device for waste oil. The device comprises a feeder, a microwave absorbent bed layer, a double-port quartz reaction bottle, afirst-stage microwave pyrolysis device, a quartz catalytic tube, a catalyst bed layer, a second-stage microwave catalytic device, a bio-oil collection device, a condensation system, a suck-back prevention device, a gas washing device, a gas flow monitoring device, a sucking pump and a gas collection device. After the microwave absorbent bed layer reaches the target pyrolysis temperature, materialsare added into a double-port quartz reaction bottle through a feeder for rapid pyrolysis, generated pyrolysis steam is subjected to catalytic reforming through a catalyst bed layer, and then enters acondensation system to be condensed into bio-oil, the non-condensable gas enters the suck-back preventing device, and the gas washing device, the gas flow monitoring device and the sucking pump in sequence and is finally collected by the gas collecting device. According to the method, rapid pyrolysis of the waste oil is realized, the bio-oil yield is increased, the catalytic effect can be improved, coking deactivation of the catalyst is slowed down, and the service life of the catalyst is prolonged.

Owner:NANCHANG UNIV

Preparation method of polymethoxymethylal

ActiveCN103121927BHigh activityIncrease profitOrganic chemistryMolecular sieve catalystsActive componentReaction temperature

The invention relates to a preparation method of polymethoxymethylal, mainly solving the problem that in the prior art, the catalyst has corrosivity. The method comprises the following step: by taking methanol or dimethyl ether and formaldehyde or trioxymethylene as raw materials, contacting the reaction raw materials with a catalyst to generate the polymethoxymethylal under the conditions that the molar ratio of the methanol or the dimethyl ether to the formaldehyde or the trioxymethylene is 1: (0.1-10), the reaction temperature is 50 to 200 DEGC and the reaction pressure of 0.1-10 MPa, wherein a molecular sieve ZSM-5 with the size of less than or equal to 5 microns is adopted as the active component of the used catalyst. through using the technical scheme, the problem is solved well. The method provided by the invention can be applied to industrial production of the poly methoxy methylal.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of MFI structure molecular sieve containing phosphorus and loaded metal and preparation method thereof

ActiveCN107970978BHigh ratio of silicon to aluminumLow total acidCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a phosphorus-containing and supported-metal-containing MFI molecular sieve and a preparation method thereof, wherein the n(SiO2) / n(Al2O3) of the molecular sieve is greater than100, the phosphorus content of the molecular sieve is 0.1-5 wt%, the supported metal content of the molecular sieve is 0.1-5 wt%, the Al distribution parameter D (Al) of the molecular sieve is more than or equal to 0.6 and is less than or equal to 0.85, the volume of the mesopores of the molecular sieve accounts for 40-80% of the total pore volume, the volume of the mesopores with the pore size of 2-20 nm accounts for more than 90% of the total mesopore volume, the amount of the strong acid of the molecular sieve accounts for 60-80% of the total acid amount, and a ratio of the acid B to the acid L is 15-80. According to the present invention, with the catalyst or the auxiliary agent prepared by using the phosphorus-containing and supported-metal-containing MFI structure molecular sieve asthe active component, the yield of gasoline in the catalytic cracking reaction of petroleum hydrocarbons can be maintained while the octane number of gasoline can be effectively increased, or the octane value of gasoline can be maintained while the yield of gasoline is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of phosphorus-containing MFI structure molecular sieve and preparation method thereof

ActiveCN107973308BPromote generationFacilitated DiffusionCatalytic crackingMolecular sieve catalystsMolecular sieveActive component

The present disclosure provides a phosphorus-containing MFI-structure molecular sieve and a preparation method thereof, wherein the n(SiO2) / n(Al2O3) of the molecular sieve is more than 100, the phosphorus content (calculated as P2O5) of the molecular sieve is 0.1-5 wt% by using the dry base weight of the molecular sieve as the reference, the Al distribution parameter D of the molecular sieve is more than or equal to 0.6 and is less than or equal to 0.85, the volume of the mesopores of the molecular sieve accounts for 40-80% of the total pore volume, the volume of the mesopores with the pore size of 2-20 nm accounts for more than 90% of the total mesopore volume, the amount of the strong acid of the molecular sieve accounts for 60-80% of the total acid amount, and a ratio of the acid B to the acid L is 15-80. According to the present invention, with the catalyst or the auxiliary agent prepared by using the phosphorus-containing MFI-structure molecular sieve as the active component, theyield of gasoline in the catalytic cracking reaction of petroleum hydrocarbons can be maintained while the octane number of gasoline can be effectively increased, or the octane value of gasoline can be maintained while the yield of gasoline is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of MFI structure molecular sieve containing phosphorus and loaded metal and preparation method thereof

ActiveCN107973318BPromote generationFacilitated DiffusionMolecular sieve catalystsPentasil aluminosilicate zeoliteMolecular sieveActive component

The invention discloses a phosphorus-containing and supported-metal-containing MFI structure molecular sieve and a preparation method thereof, wherein the n(SiO2) / n(Al2O3) of the molecular sieve is greater than 18 and less than 70, the phosphorus content (calculated as P2O5) of the molecular sieve is 1-15 wt% by using the dry base weight of the molecular sieve as the reference, the supported metalcontent (calculated as the oxide of the supported metal) of the molecular sieve is 0.1-5 wt% by using the dry base weight of the molecular sieve as the reference, the volume of the mesopores of the molecular sieve accounts for 40-70% of the total pore volume, the volume of the mesopores with the pore size of 2-20 nm accounts for more than 85% of the total mesopore volume, the amount of the strongacid of the molecular sieve accounts for 45-75% of the total acid amount, and a ratio of the acid B to the acid L is 8-30. According to the present invention, with the catalyst or the auxiliary agentprepared by using the phosphorus-containing and supported-metal-containing MFI structure molecular sieve as the active component, the propylene yield and the propylene selectivity can be effectivelyincreased in the catalytic cracking or the catalytic cracking reaction of petroleum hydrocarbons while the yield of BTX can be increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

The preparation method of polyoxymethylene dimethyl ether

ActiveCN103539644BIncrease profitIncreased focus capacityOrganic chemistryMolecular sieve catalystsMolecular sieveAdhesive

The invention relates to a preparation method of polyoxy methylene dimethyl ether, which mainly solves the problem of corrosiveness of the catalyst in the prior art. The method comprises the following step: contacting raw materials methanol or dimethyl ether and formaldehyde or trioxymethylene in a mol ratio of 1:(0.1-10) with a catalyst to react at the reaction temperature of 50-200 DEG C under the reaction pressure of 0.1-10 MPa to generate the polyoxy methylene dimethyl ether. The catalyst comprises the following components in parts by weight: a) 40-95 parts of ZSM-11 molecular sieve of which the silicon / aluminum (SiO2 / Al2O3) mol ratio is 20-300 and the crystal grain diameter is at most 5 micrometers, and b) 5-60 parts of adhesive. The ZSM-11 molecular sieve is subjected to acid washing at least once. The technical scheme provided by the invention well solves the problem, and can be used for industrial production of the polyoxy methylene dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of method of ethanol dehydration preparation ethylene

ActiveCN108101727BIncrease profitImprove stabilityMolecular sieve catalystsMolecular sieve catalystMolecular sievePtru catalyst

The invention relates to a method for preparing ethylene through ethanol dehydration. According to the method, H-NaZSM-5 and SAPO-34 molecular sieves with different channels and acidities are compounded through a synthesis method, problems of each of the H-NaZSM-5 and SAPO-34 molecular sieves are overcome, and meanwhile the grain diameter of a composite catalyst is controlled to be not greater than 10 micrometers. The composite catalyst has a unique double-channel structure, high specific surface area and suitable acidity, is beneficial to the improvement of stability, ensures that both the ethanol conversion rate and the ethylene selectivity reach 99 percent or more when catalyzing ethanol dehydration to prepare ethylene, and the ethanol conversion rate and the ethylene selectivity stillkeep 96 percent after 100h of continuous reaction.

Owner:李宝尔

Phosphorus-containing and supported-metal-containing MFI structure molecular sieve and preparation method thereof

ActiveCN107973303AEnhanced structuring performanceReduce olefin contentMolecular sieve catalystsPentasil aluminosilicate zeoliteMolecular sieveActive component

The invention discloses a phosphorus-containing and supported-metal-containing MFI structure molecular sieve and a preparation method thereof, wherein the n(SiO2) / n(Al2O3) of the molecular sieve is greater than 100, the phosphorus content of the molecular sieve is 0.1-5 wt%, the supported metal content of the molecular sieve is 0.5-5 wt%, the Al distribution parameter D (Al) of the molecular sieveis more than or equal to 0.6 and is less than or equal to 0.85, the volume of the mesopores of the molecular sieve accounts for 40-80% of the total pore volume, the volume of the mesopores with the pore size of 2-20 nm accounts for more than 90% of the total mesopore volume, the amount of the strong acid of the molecular sieve accounts for 60-80% of the total acid amount, and a ratio of the acidB to the acid L is 15-80. According to the present invention, with the catalyst or the auxiliary agent prepared by using the phosphorus-containing and supported-metal-containing MFI structure molecular sieve as the active component, the yield and the octane number of gasoline can be improved in the catalytic cracking reaction of petroleum hydrocarbons while the olefin content in gasoline can be effectively reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic dehydration method of 4-hydroxy-3-hexanone

ActiveCN103121933BIncrease profitIncreased focus capacityMolecular sieve catalystsOrganic compound preparationLow activityReaction temperature

The invention relates to a 4-hydroxyl-3-hexanone catalytic dehydration method and mainly aims to solve the problems of a catalyst in the prior art, such as low activity, high reaction temperature and low space velocity. According to the technical scheme, 4-hydroxyl-3-hexanone serving as a raw material comes into contact with a catalyst to generate 4-hexylene-3-hexanone under the conditions that the reaction temperature ranges from 200 DEG C to 400 DEG C and the liquid mass space velocity relative to the 4-hydroxyl-3-hexanone is equal to 0.5-15h<-1>, wherein the used catalyst has the crystal grain diameter being at most 5mm, and has ZSM-5 zeolite with mesopores and micropores, and the ratio of the volume of the mesopores to the volume of the micropores in the ZSM-5 zeolite is equal to 1.5-10. The problems in the prior art can be well solved by adoption of the technical scheme. The 4-hydroxyl-3-hexanone catalytic dehydration method can be used for industrial production of 4-hexylene-3-hexanone prepared by using the 4-hydroxyl-3-hexanone.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com