Method for preparing ethylene through ethanol dehydration

A technology for ethanol dehydration and ethylene, applied in chemical instruments and methods, hydrocarbon production from oxygen-containing organic compounds, including molecular sieve catalysts, etc., can solve problems such as poor stability and short catalyst service life, and achieve improved catalytic activity and stability. The effect of uniformity, acid distribution and moderate acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

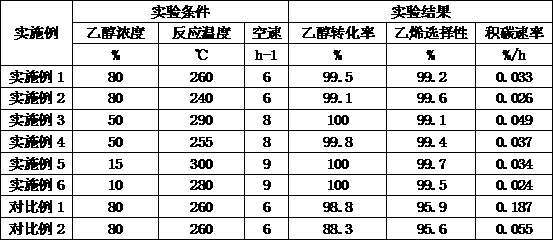

Examples

Embodiment 1

[0023] Fully mix commercially available H-NaZSM-5 molecular sieves with deionized water to prepare slurry I; mix sodium metaaluminate, phosphoric acid, 40% silica sol, and distilled water according to n(Al):n(P):n(Si) : n(H 2 O) the molar ratio is 1:1:0.1:40 mixing, stirring for 20 minutes, to obtain gel II; slurry I is added in gel II, stirring for 30 minutes, according to the molar ratio n (template agent): n (P) is 2:1 Add the template agent isopropylamine, continue to stir until a uniform gel is formed, put the gel into the reaction kettle, and crystallize at 170°C for 1 day. The crystallized product was quenched, filtered, and washed with water until the pH value was 8, dried at 120°C for 12 hours, and roasted in a muffle furnace at 550°C to remove the template agent to obtain Synthetic Catalyst A, which was characterized by SEM with an average grain size of 5 microns .

[0024] The performance evaluation of the catalyst was carried out on a fixed-bed reaction device at...

Embodiment 2

[0026] Fully mix commercially available H-NaZSM-5 molecular sieves with deionized water to obtain slurry I; divide pseudo-boehmite, phosphoric acid, water glass, and distilled water into n(Al): n (P): n(Si): n(H 2 O) the molar ratio is 1:1:0.1:40 mixing, stirring for 20 minutes, to obtain gel II; slurry I is added in gel II, stirring for 30 minutes, according to the molar ratio n (template agent): n (P) is 2:1 Add the template agent isopropylamine, continue to stir until a uniform gel is formed, put the gel into the reaction kettle, and crystallize at 170°C for 1 day. The crystallized product was quenched, filtered, and washed with water until the pH value was 8, dried at 120°C for 12 hours, and roasted in a muffle furnace at 550°C to remove the template agent to obtain Synthetic Catalyst B, which was characterized by SEM with an average grain size of 8 microns .

[0027]The performance evaluation of the catalyst was carried out on a fixed-bed reaction device at normal press...

Embodiment 3

[0029] Fully mix commercially available H-NaZSM-5 molecular sieves with deionized water to prepare slurry I; mix sodium metaaluminate, phosphoric acid, 40% silica sol, and distilled water according to n(Al):n(P):n(Si) : n(H 2 O) the molar ratio is 1:1:0.1:40 mixing, stirring for 20 minutes, to obtain gel II; slurry I is added in gel II, stirring for 30 minutes, according to the molar ratio n (template agent): n (P) is 2:1 Add the template agent triethylamine, continue to stir until a uniform gel is formed, put the gel into the reaction kettle, and crystallize at 170°C for 1 day. The crystallized product was quenched, filtered, and washed with water until the pH value was 8, dried at 120°C for 12 hours, and roasted in a muffle furnace at 550°C to remove the template agent to obtain Synthetic Catalyst C, which was characterized by SEM with an average grain size of 7 microns .

[0030] The performance evaluation of the catalyst was carried out on a fixed-bed reaction device at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com