Two-stage microwave tandem catalytic pyrolysis device for waste oil

A technology for catalytic pyrolysis and waste oil, applied in the production of fatty acids, chemical instruments and methods, chemical/physical processes, etc. The problem of irreversible loss of catalysts can avoid irreversible deactivation of carbon deposits, improve the yield of bio-oil, and improve the catalytic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

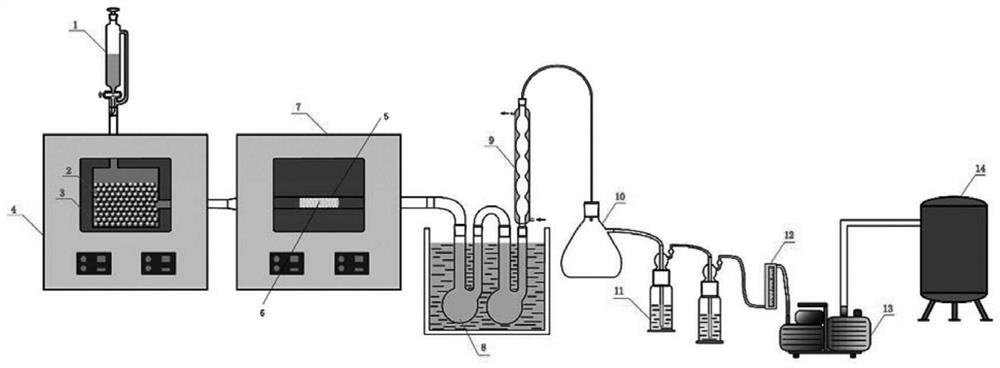

[0026] The present invention will be further illustrated by the following examples in conjunction with the accompanying drawings.

[0027] Such as figure 1 As shown, the present embodiment comprises a feeder (1), a microwave absorbent bed (2), a double-mouthed quartz reaction flask (3), a first-stage microwave pyrolysis device (4), a quartz catalytic tube (5), Catalyst bed (6), second-stage microwave catalytic device (7), bio-oil collection device (8), condensation system (9), anti-suckback device (10), scrubber device (11), gas flow monitoring device (12), suction pump (13), gas collection device (14).

[0028] The first-stage microwave pyrolysis device (4) is provided with a microwave absorbent bed (2) and a double-mouthed quartz reaction bottle (3), and the upward branch pipe port of the double-mouthed quartz reaction bottle (3) is connected to the feeder (1 ), the right branch pipe port is connected to the left end of the quartz catalytic tube (5) in the second-stage mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com