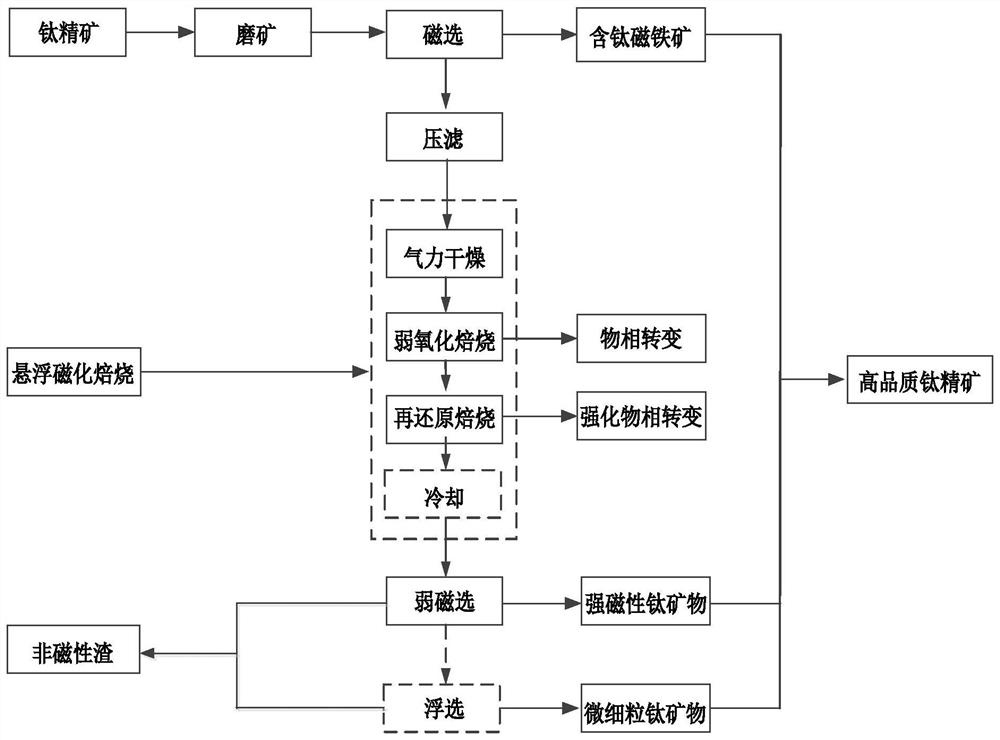

A method for impurity removal and purification of titanium concentrate by suspension roasting

A technology of suspension roasting and suspension roasting furnace, which is applied in the field of metallurgy, can solve the problems of failing to meet the requirements of high-quality titanium concentrate, and achieve the effects of operating productivity and operating efficiency, simple process flow, and large equipment processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Grind titanium concentrate until the particle size is ≤ 0.074mm, accounting for 80% of the total mass, and make titanium concentrate powder; titanium concentrate contains TiO by mass percentage 2 48.54%, Fe 26.23%, MgO 4.31%, Al 2 o 3 1.67%, CaO 0.93%, SiO 2 4.62%;

[0038] The titanium concentrate powder is subjected to a stage of magnetic separation, the magnetic field strength of the stage of magnetic separation is 1000Oe, and a stage of magnetic separation concentrate and a stage of magnetic separation tailings are obtained;

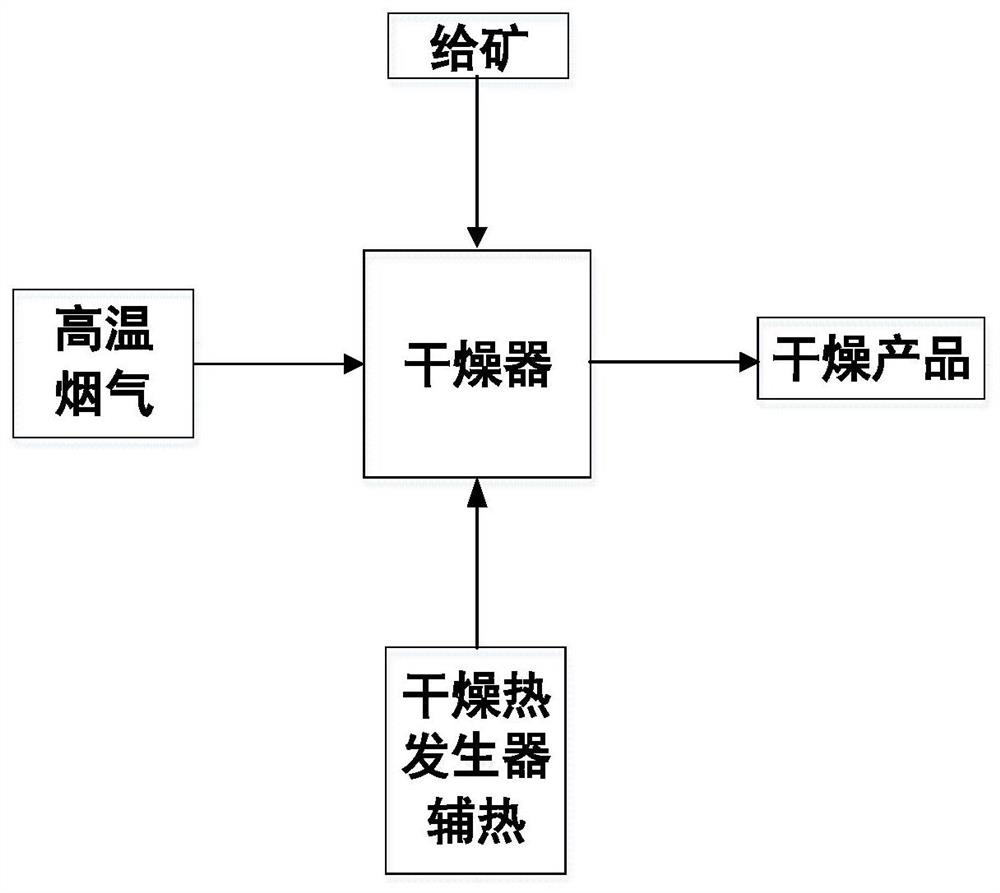

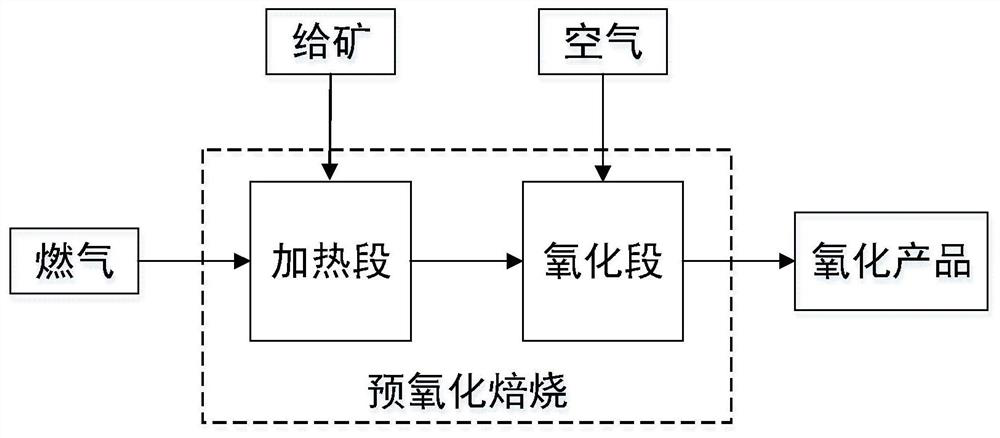

[0039] A section of magnetic separation tailings is dewatered by pressure filtration to make a press filter residue with a mass percentage of water ≤ 10%, and then the press filter residue is transported to a dry suspension roaster, and at the same time, a high temperature of 100-150°C is introduced into the dry suspension roaster Flue gas, under the action of high-temperature flue gas, the filter press residue is in a suspended state and...

Embodiment 2

[0043] Method is with embodiment 1, and difference is:

[0044] (1) Titanium concentrate contains TiO by mass percentage 2 41.21%, Fe 25.32%, MgO 4.66%, Al 2 o 3 2.52%, CaO 1.54%, SiO 2 5.54%; the part where the titanium concentrate is ground to a particle size of ≤0.074mm accounts for 75% of the total mass;

[0045] (2) The magnetic field strength of a section of magnetic separation is 1500Oe;

[0046] (3) The residence time of the filter press residue in the suspension roaster is 25min;

[0047] (4) Heating to 700°C for weak oxidation reaction for 30 minutes;

[0048] (5), the magnetic field intensity of the second stage magnetic separation is 1500Oe; the purified titanium concentrate product contains TiO by mass percentage 2 53.24%, TFe 27.53%, MgO 2.21%, Al 2 o 3 1.02%, CaO 0.94%, SiO 2 2.32%; Titanium recovery rate 85.73%.

Embodiment 3

[0050] Method is with embodiment 1, and difference is:

[0051] (1) Titanium concentrate contains TiO by mass percentage 2 46.72%, Fe 38.57%; the portion of titanium concentrate ground to a particle size ≤ 0.038mm accounts for 90% of the total mass;

[0052] (2) The magnetic field strength of a section of magnetic separation is 2000Oe;

[0053] (3) The residence time of the filter press residue in the suspension roaster is 25min;

[0054] (4) Heating to 800°C for weak oxidation reaction for 20 minutes;

[0055] (5), the magnetic field intensity of the second stage magnetic separation is 2000Oe; the purified titanium concentrate product contains TiO by mass percentage 2 53.24%, TFe 27.53%, MgO 2.21%, Al 2 o 3 1.02%, CaO 0.94%, SiO 2 2.32%; Titanium recovery rate 85.73%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com