Method for producing hydrogen by catalyzing methane cracking with activated carbon as catalyst

A technology of activated carbon and catalyst, which is applied in the field of hydrogen production from methane cracking, which can solve the problems of high initial catalytic activity, influence on popularization and use, and low catalytic efficiency, and achieve the effects of improving conversion efficiency, low production cost, and prolonging deactivation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take an appropriate amount of 8-16 mesh coconut shell activated carbon catalyst, in N 2 Calcined at 900°C for 3 hours in the atmosphere to remove the ash and volatile matter contained in the activated carbon, and then activated in N 2 Natural cooling down to room temperature under the atmosphere, set aside.

[0022] Take 2g of activated coconut shell activated carbon, fill it evenly in a quartz tube with an inner diameter of 20mm, fix it with quartz wool on both sides, and then place it in a gas-solid-phase catalytic fixed-bed reactor at normal pressure. Leak, feed nitrogen, the space velocity is 20ml / min g, the heating rate is 30°C / min, when the temperature is raised to the cracking temperature of 900±5°C, the nitrogen is turned off, and the methane gas is switched to methane catalytic cracking to produce hydrogen. Introduce hydrogen sulfide gas with a concentration of 200ppm; adjust the mass flow meter so that the methane flow rate is constant at 40ml / min, that is, t...

Embodiment 2

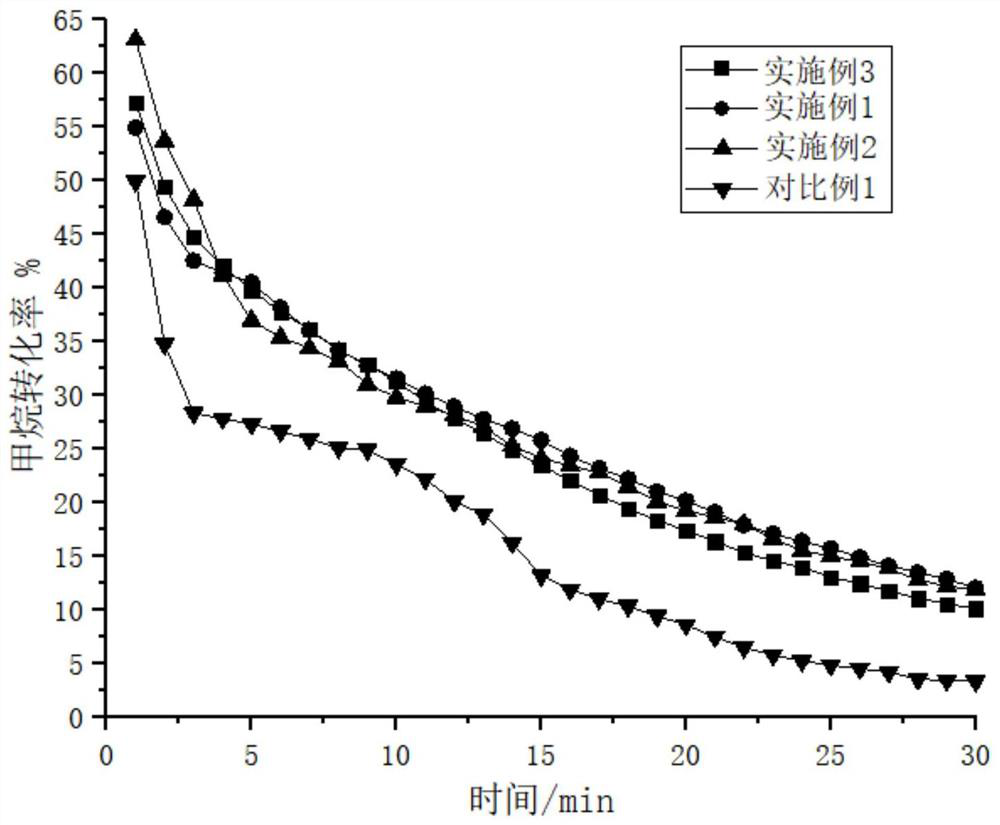

[0026] The methane catalytic cracking process is basically the same as in Example 1, except that the concentration of hydrogen sulfide gas introduced is 100ppm. The change curve of methane conversion rate of methane catalytic cracking hydrogen production with time is as follows figure 1 shown.

Embodiment 3

[0028] The methane catalytic cracking process is basically the same as in Example 1, except that the concentration of hydrogen sulfide gas introduced is 300ppm. The change curve of methane conversion rate of methane catalytic cracking hydrogen production with time is as follows figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com