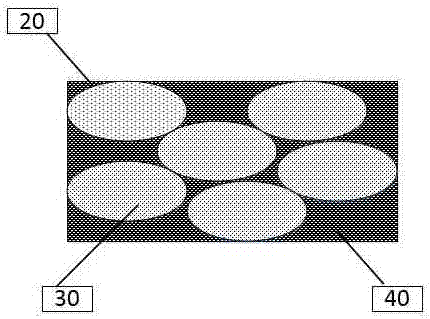

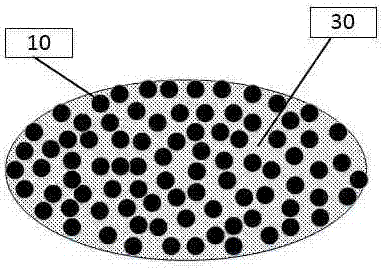

Preparation method of compact C/C composite material

A composite material and densification technology, applied in the field of C/C composite material and dense C/C composite material preparation, can solve the problems of high viscosity of resin solution, inability to densify fiber bundles, and inability to fill fiber filament voids, etc., and achieve low porosity , long service life, high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Prepare a 3D woven carbon fiber preform with a carbon fiber volume fraction of 37%;

[0017] (2) Put the preform into a vacuum chemical vapor deposition furnace, the pressure in the furnace is 1000Pa, the temperature is raised to 1000°C, methane and hydrogen are introduced, and the pyrolytic carbon produced by the decomposition of methane is infiltrated into the preform by chemical vapor infiltration , the deposition time is 120h, and the densification of carbon fiber filaments in the preform is realized, so that the preform becomes a C / C composite material skeleton, and the porosity of the C / C composite material skeleton is 20%;

[0018] (3) The thermosetting resin solution was impregnated into the C / C composite skeleton obtained in step (2) by using the precursor impregnation cracking method, and the glassy carbon matrix was obtained by high-temperature cracking in a vacuum furnace. The cracking temperature was 900°C. The thermosetting resin solution concentration...

Embodiment 2

[0021] (1) Prepare a 2.5D woven carbon fiber preform with a carbon fiber volume fraction of 45%;

[0022] (2) Put the preform into a vacuum chemical vapor deposition furnace with a pressure of 10 4 Pa, the temperature is raised to 1200°C, methane and hydrogen are introduced, and the pyrolytic carbon produced by the decomposition of methane is infiltrated into the preform by chemical vapor infiltration. Become a C / C composite material skeleton, and the porosity of the C / C composite material skeleton is 35%;

[0023] (3) The thermosetting resin solution was impregnated into the C / C composite skeleton obtained in step (2) by using the precursor impregnation cracking method, and the glassy carbon matrix was obtained by high-temperature cracking in a vacuum furnace. The cracking temperature was 1200°C. The thermosetting resin solution concentration described above is 50%, and the thermosetting resin is furan resin.

[0024] (4) Repeat the cycle step (3), and stop when the weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com