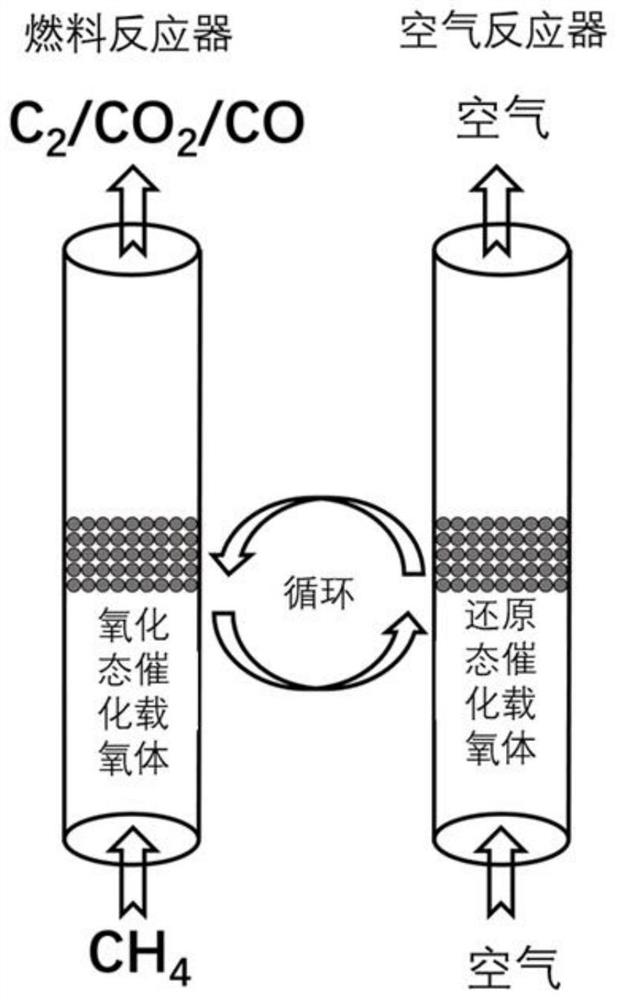

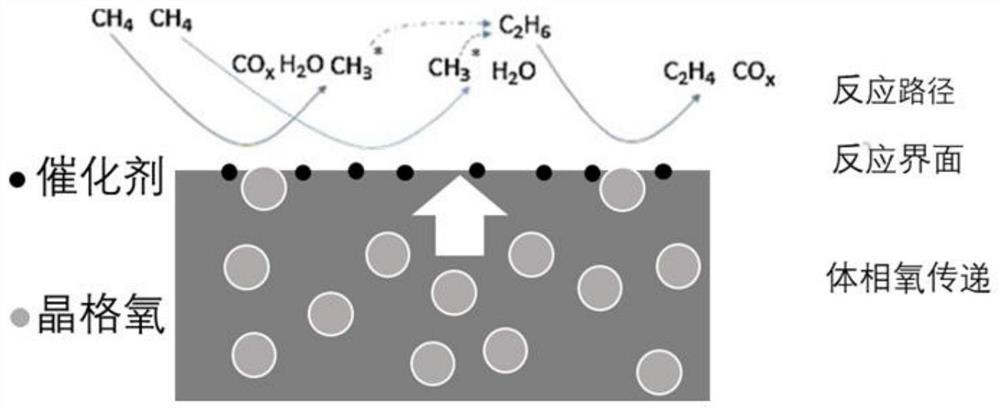

A methane oxidative coupling method based on chemical chain lattice oxygen transfer technology

A technology of oxidative coupling and lattice oxygen, which is applied in chemical instruments and methods, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of high operating costs, low selectivity and yield of olefins, and complex structures. Achieve high reactivity and selectivity, reduce excessive oxidation, and avoid direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

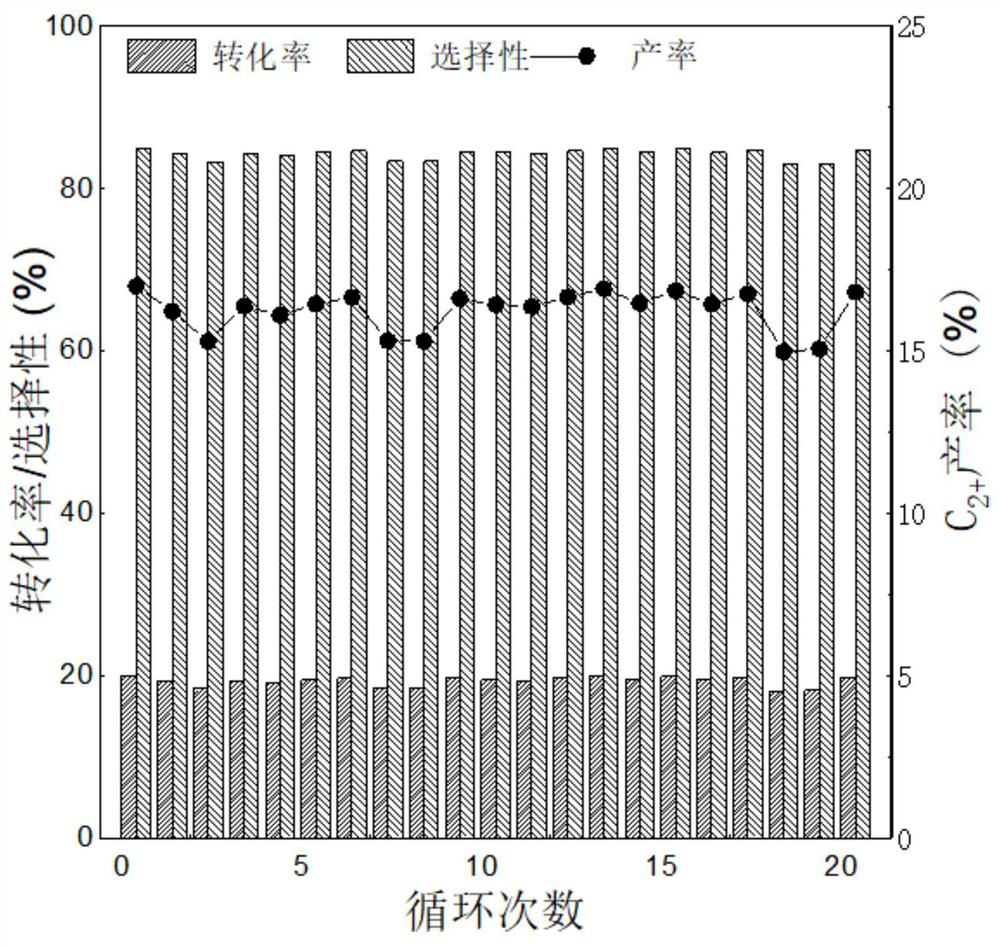

Examples

Embodiment 1

[0030] raw material:

[0031] Mn(NO 3 ) 2 .4H 2 O: 0.58g, Na 2 WO 4 .2H 2 O: 3.09g, SiO 2 : 7g, urea: 250g.

[0032] Among them, Mn(NO 3 ) 2 .4H 2 O to MnO 2 mass meter, Na 2 WO 4 .2H 2 O to Na 2 WO 4 Mass meter, SiO 2 The mass ratio of the three is 2:28:70;

[0033] Chemical Chaining Methane Oxidative Coupling Method

[0034](1) Dissolve manganese nitrate and sodium tungstate in 1L of water, stir to form a transparent solution, add silicon dioxide and urea to the transparent solution, the pH value is 9.5, raise the temperature to 95°C, stir for 3 hours, wash the obtained solution, After two to three times of suction filtration, put it into a 75°C drying oven to dry for 12 hours. The dried sample is put into a muffle furnace with a heating rate of 5°C / min and a final temperature of 750°C for 4 hours to obtain Na 2 WO 4 / MnO 2 / SiO 2 Catalytic oxygen-donating material.

[0035] (2) Put 2g of catalytic oxygen-supplying material in the fixed bed, raise the ...

Embodiment 2

[0037] raw material:

[0038] Mn(NO 3 ) 2 .4H 2 O: 2.31g, Na 2 WO 4 .2H 2 O: 2.21g, SiO 2 : 7.2g, urea: 250g.

[0039] Among them, Mn(NO 3 ) 2 .4H 2 O to MnO 2 mass meter, Na 2 WO 4 .2H 2 O to Na 2 WO 4 Mass meter, SiO 2 The mass ratio of the three is 8:20:72;

[0040] Chemical Chaining Methane Oxidative Coupling Method

[0041] (1) Dissolve manganese nitrate and sodium tungstate in 1L of water, stir to form a transparent solution, add silicon dioxide and urea to the transparent solution, the pH value is 9.5, raise the temperature to 95°C, stir for 3 hours, wash the obtained solution, After two to three times of suction filtration, put it into a 75°C drying oven to dry for 12 hours. The dried sample is put into a muffle furnace with a heating rate of 5°C / min and a final temperature of 750°C for 4 hours to obtain Na 2 WO 4 / MnO 2 / SiO 2 Catalytic oxygen-donating material.

[0042] (2) Put 2g of catalytic oxygen-supplying material in the fixed bed, raise t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com