Horizontal efficient plug flow bubbling reactor

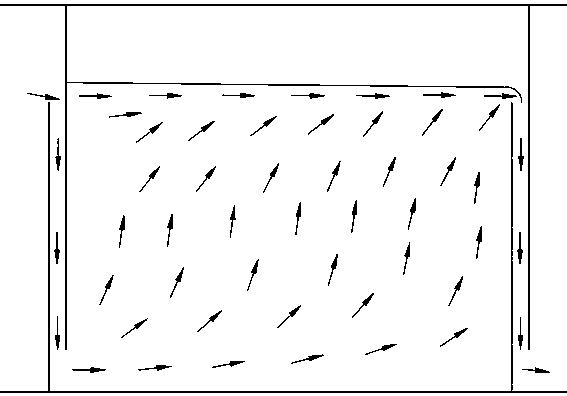

A bubbling reactor and plug flow technology, applied to the reaction of liquid and gas under foam/aerosol/bubble, the chemical method, chemical instrument and method to make liquid and gas medium react, and can solve the problem of liquid Solve problems such as different phase residence time, low gas holdup, and increased hydrogen peroxide decomposition rate of organic matter, so as to achieve uniform and stable bubble distribution, prevent circulation back-mixing, and reduce over-oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

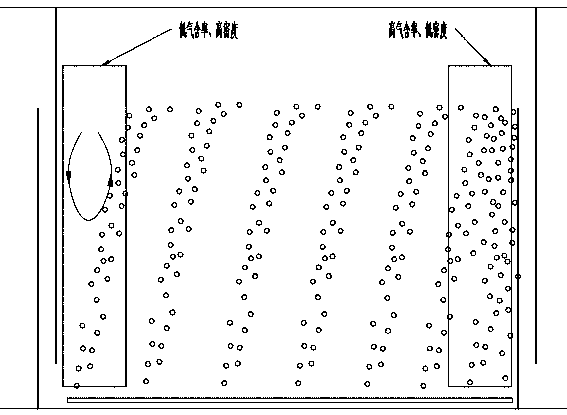

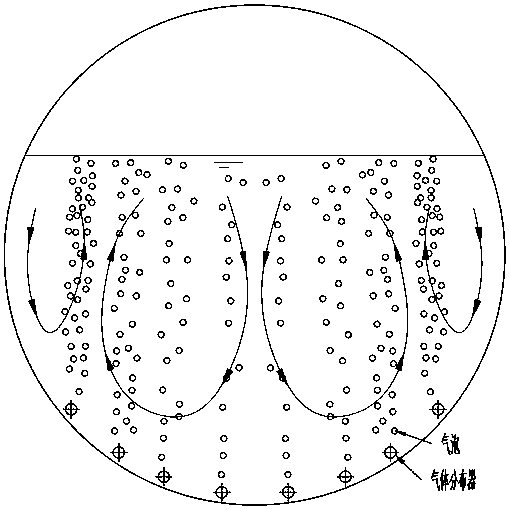

[0040] Such as Figure 4As shown: the reactor involved in this embodiment is a horizontal bubbling reactor in form, which is suitable for the oxidation reaction of organic matter and oxygen-containing gas, and its cross section has a circular structure; inside the reactor body 1 there are three set of baffles, each set of baffles includes an outlet baffle 8 and an inlet baffle 9, and three sets of baffles separate the reactor body to form four connected reaction units; the two ends of the reactor body 1 are respectively provided with feed Port 4 and discharge port 10; the first reaction unit communicates with feed port 4, and the end of the last reaction unit is provided with an outlet partition, which is connected to discharge port 10 after the material flows out of the exit partition;

[0041] Such as Figure 4 with Figure 5 As shown, the lower end of the outlet partition 8 in each set of partitions is fixedly connected to the bottom of the reactor body 1; the inlet parti...

Embodiment 2

[0049] According to the structure shown in Example 1, the present embodiment has manufactured a test reactor, and the structural dimensions of the reactor are shown in Table 1:

[0050] project

size

diameter D

300 mm

Single length (cylinder) H

1370 mm

number of reaction units

4

Reaction unit length

275 mm

bubble zone height

150mm

Gas distributor height

60mm

[0051] Table 1: Main size table of embodiment 2 reactor

[0052] Such as Figure 7 Shown: The reactor is used in the test of ethylbenzene oxidation to produce ethylbenzene hydroperoxide, and the reaction system is constructed. The ethylbenzene feed flow rate is 35kg / h, the air feed flow rate is 2.06m3 / h, and the nitrogen feed flow rate is 1.26m3 / h. After the reaction, analyze the oxidizing solution, and calculate the conversion rate of ethylbenzene and the selectivity of ethylbenzene hydroperoxide.

[0053] Such as Figure 5 , Figure 7...

Embodiment 3

[0059] Such as Figure 8 shown. On the basis of Embodiment 1, the liquid phase inlet deflector 2 is placed above the main distributor 3 - 1 , and connected with the corresponding liquid phase outlet deflector 5 to form a bubble deflector 15 .

[0060] In the reactor of this embodiment, in terms of diversion effect, the liquid phase inlet deflector 2 and the liquid phase outlet deflector 5 are combined into one bubble deflector 15, which can separate the large bubble reactor into parallel The small bubbling area completely eliminates the amplification effect of the bubbling area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com