Preparation method of high-performance nickel-plated carbon fibers

A nickel-plated carbon fiber, high-performance technology, applied in the direction of carbon fiber, fiber treatment, liquid chemical plating, etc., can solve the problems of less polar groups on the surface, low surface energy, affecting the mechanical properties of composite materials, etc., and achieve good stability , good combination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

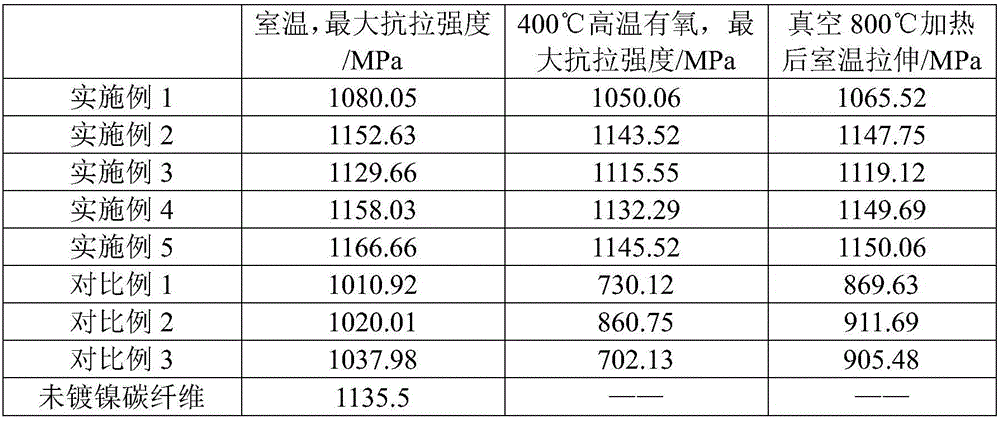

Examples

Embodiment 1

[0031] A preparation method of high-performance surface nickel-plated carbon fiber, comprising the following steps:

[0032] (1) Burn the carbon fiber at a high temperature of 350°C for 10 minutes, then place it in a 10% sodium hydroxide solution, ultrasonicate it for 20 minutes at a power of 100W, then take it out and wash it with deionized water until it is neutral, and dry it at 80-90°C. stand-by;

[0033] (2) Soak the carbon fiber obtained in step (1) in concentrated nitric acid, seal it, and treat it in a water bath at 80°C at a speed of 800 rpm for 10 minutes, take it out, wash it with deionized water until it is neutral, and then dry it to obtain crude melted carbon fiber;

[0034] (3) Mix and stir palladium chloride, ammonium chloride and deionized water evenly, then add sodium thiocyanate to the solution, 300W power ultrasonic 10min, and make the activation solution; wherein, the concentration of each component is: palladium chloride 0.1g / L, ammonium chloride 0.1g / L...

Embodiment 2

[0040] A preparation method of high-performance surface nickel-plated carbon fiber, comprising the following steps:

[0041] (1) Burn the carbon fiber at a high temperature of 550°C for 30 minutes, then place it in a 10% sodium hydroxide solution, ultrasonicate it for 50 minutes at a power of 400W, then take it out and wash it with deionized water until it is neutral, and dry it at 80-90°C. stand-by;

[0042] (2) Soak the carbon fiber obtained in step (1) in concentrated nitric acid, seal it, and treat it in a water bath at 100°C at a speed of 1500 rpm for 40 minutes, take it out, wash it with deionized water until it is neutral, and then dry it to obtain crude melted carbon fiber;

[0043] (3) Mix and stir palladium chloride, ammonium chloride and deionized water evenly, then add sodium thiocyanate to the solution, 300W power ultrasonic 30min, and make the activation solution; wherein, the concentration of each component is: palladium chloride 0.5g / L, ammonium chloride 0.3g...

Embodiment 3

[0049] A preparation method of high-performance surface nickel-plated carbon fiber, comprising the following steps:

[0050] (1) Burn the carbon fiber at a high temperature of 400°C for 15 minutes, then place it in a 10% sodium hydroxide solution, ultrasonicate it for 30 minutes at a power of 200W, then take it out and wash it with deionized water until it is neutral, and dry it at 80-90°C. stand-by;

[0051] (2) Soak the carbon fiber obtained in step (1) in concentrated nitric acid, seal it, and treat it in a water bath at 85°C at a speed of 900 rpm for 20 minutes, take it out, wash it with deionized water until it is neutral, and then dry it to obtain crude melted carbon fiber;

[0052] (3) Mix and stir palladium chloride, ammonium chloride and deionized water evenly, then add sodium thiocyanate to the solution, 300W power ultrasonic 15min, and make the activation solution; wherein, the concentration of each component is: palladium chloride 0.2g / L, ammonium chloride 0.15g / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com