Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

144 results about "Fibrous Glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fibrous glass is a synthetic fiber made from tiny particles of glass. It can harm the eyes, skin, and the lungs. Workers may be harmed from exposure to fibrous glass. The level of exposure depends upon the dose, duration, and work being done. Fibrous glass is used in many industries.

Polyamide moulding composition and use thereof

ActiveUS20140066560A1Good mechanical propertyHigh rigidityAnti-corrosive paintsChemistryHigh intensity

Owner:EMS PATENT AG

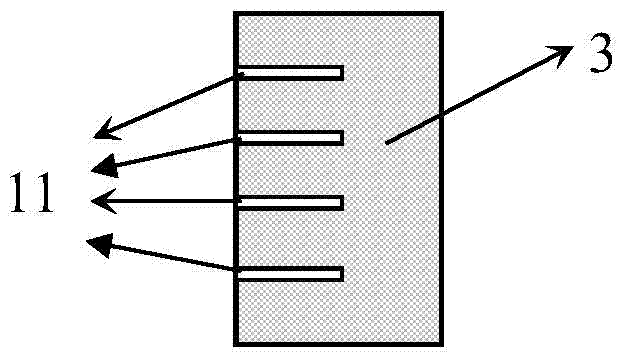

Low boron containing microfiberglass filtration media

InactiveUS6933252B2Enhanced filtration performance characteristicSmall toleranceFibre treatmentSynthetic resin layered productsAir filtrationFiber

The present invention provides nonwoven glass composites formed from an essentially boron free glass wool and an essentially boron free chopped glass fiber, used as a reinforcing material. The nonwoven glass composites are suitable for air filtration apparatus and can be used in the semiconductor industry where the elimination of boron from clean rooms is of importance.

Owner:HOLLINGSWORTH VOSE

Reinforced PCT compositions

ActiveUS20080153954A1Good dimensional stabilityImprove mechanical propertiesLayered productsSpecial tyresFiberFibrous Glass

The invention relates to polymer compositions comprising PCT (poly((cyclohexylene-dimethylene) terephthalate)) polymer and a fibrous glass filler having a non-circular cross-sectional aspect ratio of greater than at or about 4.

Owner:TICONA LLC

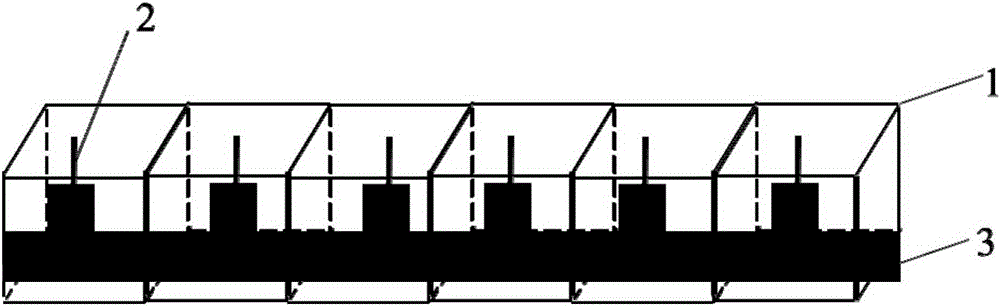

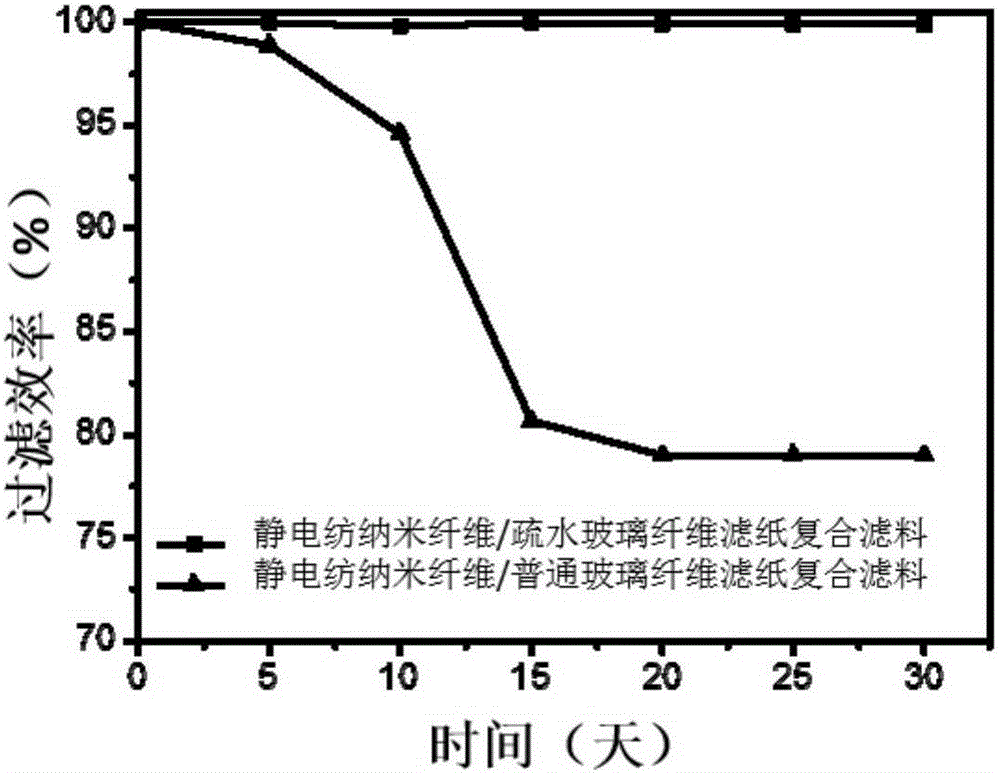

Static spinning method and nano fiber/glass fiber composite filter material prepared by same

ActiveCN105233568AImprove uniformityElectric field interference weakenedFilament/thread formingFiltration separationGlass fiberFiber

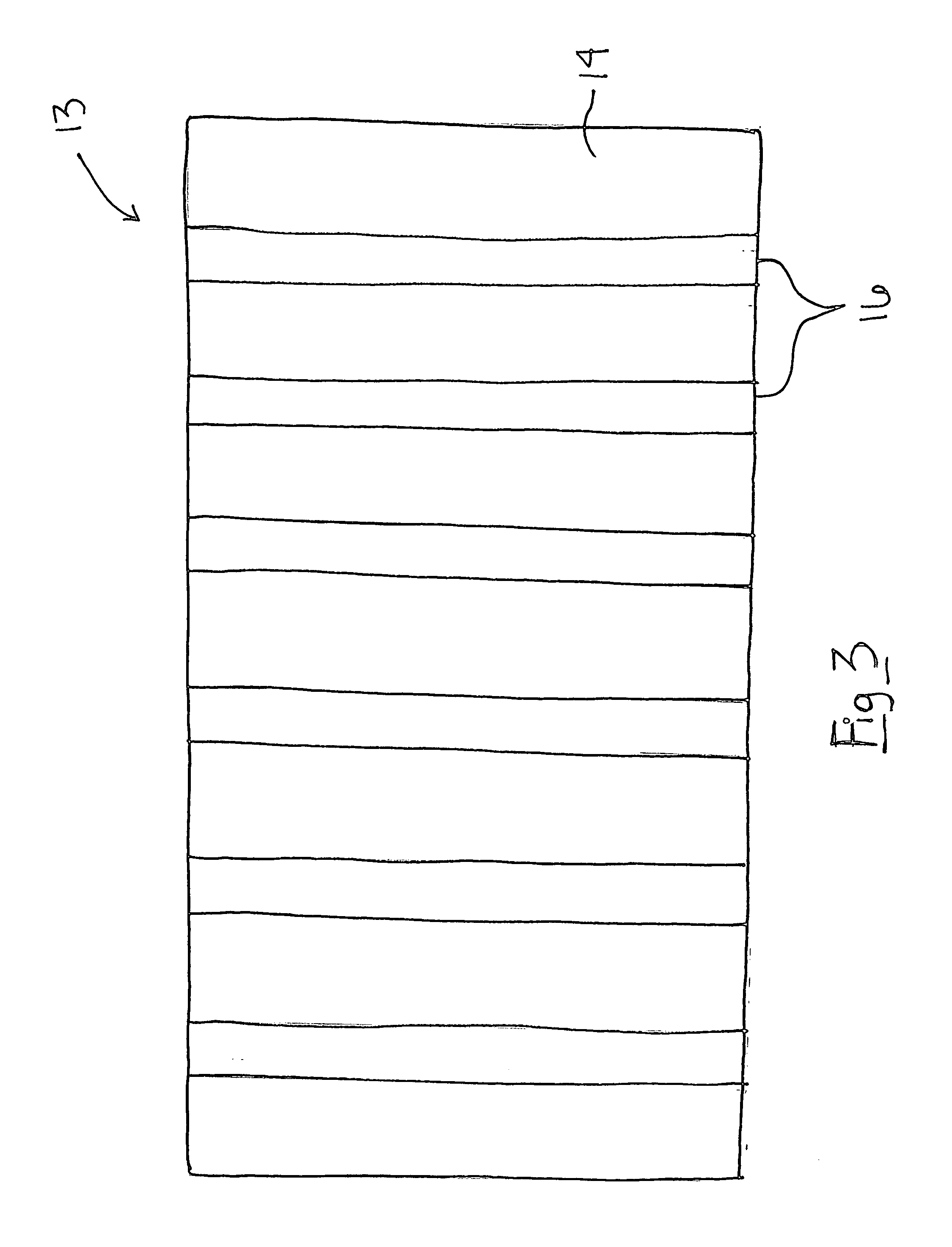

The invention relates to a static spinning method and a nano fiber / glass fiber composite filter material prepared by the same. According to the static spinning method, multiple needles are used to carry out static spinning, and the needles are insulated to each other. The nano fiber / glass fiber composite filter material is prepared by laminating and combining different filter materials together from bottom to top, wherein the filter efficiency of filter materials increases from bottom to top; the side, which is provided with static spun fibers, of each filter material layer is upward, the surface of the top layer is covered by glass fiber filter paper to ensure that the top layer and bottom layer of the filter material are both made of glass fiber filter paper. For two neighbored filter material layers, the filter efficiency of the upper layer on particles with a size of 0.02 to 10 [mu]m is 1.03 to 1.3 times higher than that of the lower layer. The composite filter material comprises two to six filter material layers, and has an sandwich structure, wherein in the sandwich structure, glass fiber filter paper and nano fiber with an electret effect are arranged alternately. The nano fiber / glass fiber composite filter material has a filter efficiency of 99.999% or more on particles with a size of 0.02 to 10 [mu]m, and the pressure resistance is maintained at 10 to 30 Pa.

Owner:上海迅江科技有限公司

Multidensity liner/insulator having reinforcing ribs

InactiveUS20050191921A1Improve performanceImproved compressive and flexural propertyAdhesive processesLamination ancillary operationsFiberFibrous Glass

A liner / insulator including a base layer of fibrous material and a plurality of ribs of fibrous insulation material thermally bonded to said base layer. The fibrous material is constructed of either (a) thermoplastic polymer staple fibers and thermoplastic bicomponent fibers, (b) glass staple fibers and thermoplastic bicomponent fibers and (c) a combination of (a) and (b).

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

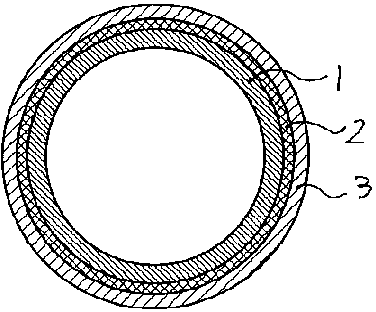

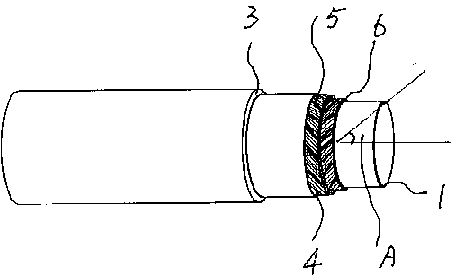

Coiled plastic composite pipe reinforced with fibre

ActiveCN103062528ASmall bending radiusEasy to transportFibre treatmentFlexible pipesPolyesterGlass fiber

The invention belongs to the technical field of a plastic composite pipe, and discloses a coiled plastic composite pipe reinforced with fibre. The technical scheme includes that an inner tube layer is made of polymer materials, the outer wall of the inner tube layer is wound or braided a wear-resistant fibrous layer constituted by polyester industrial fibers, aramid fibers and glass fibers, the outer surface of the fibrous layer is coated with a modified polymer corrosion protection layer, and the inner tube layer, the fibrous layer and the protective layer composite into one integral structure. The coiled plastic composite pipe reinforced with fibre has the advantages of small bending radius, high pressure resistance and high temperature resistance.

Owner:河北宇通特种胶管有限公司

Hybrid fiber composite material door/window section and preparation process thereof

The invention relates to a hybrid fiber composite material door / window section. The hybrid fiber composite material door / window section comprises the following components in percentage by weight: 10-30 percent of basalt fiber, 30-50 percent of glass fiber, 0-10 percent of glass fiber mat, 20-40 percent of resin and 0-10 percent of an additive. The resin is one of unsaturated polyester resin, epoxyresin and polyurethane resin. The additive is calcium carbonate. A preparation process of the door / window section comprises the following steps: enabling 10-30 percent of basalt fiber, 30-50 percent of glass fiber and 0-10 percent of glass fiber mat to pass through yarn rows of a fiber guiding device creel; enabling the fiber to enter a resin tank containing 20-40 percent of resin and 0-10 percent of the additive for impregnating; enabling the fiber to enter a window body section preforming pultrusion die, wherein the basalt fiber, the glass fiber and the glass fiber mat are uniformly arrayed in the window body section preforming pultrusion die to form a required section structure; heating and curing the fiber in a heat setting die to form the required window body section.

Owner:安徽梦谷纤维材料科技有限公司

Plastic pipe enhanced by continuous fiber winding

The invention relates to a plastic tube which uses long fiber (glass fiber, carbon fiber, and metallic fiber) to strengthen the thermal plastic (polythene, polypropylene, and rigid polyvinyl chloride) to coil and shape a plastic tube whose diameter is 4m, while the pressure can reach 1.2MPa, and the thickness is lower than general tubes, with high strength (stress strength can reach 20-30MPa), lower cost and light weight. The invention can be used to pressure transmit the tap water. The method for coating long fiber with adhesive is similar to the one for extruding wire, that coating the adhesive on the fiber to be coiled on the plastic tube with bottom layer, or online extruding coating to be coiled on one heated cylinder stainless steel core, to attain said continuous long fiber strengthen thermal plastic.

Owner:BEIJING UNIV OF CHEM TECH

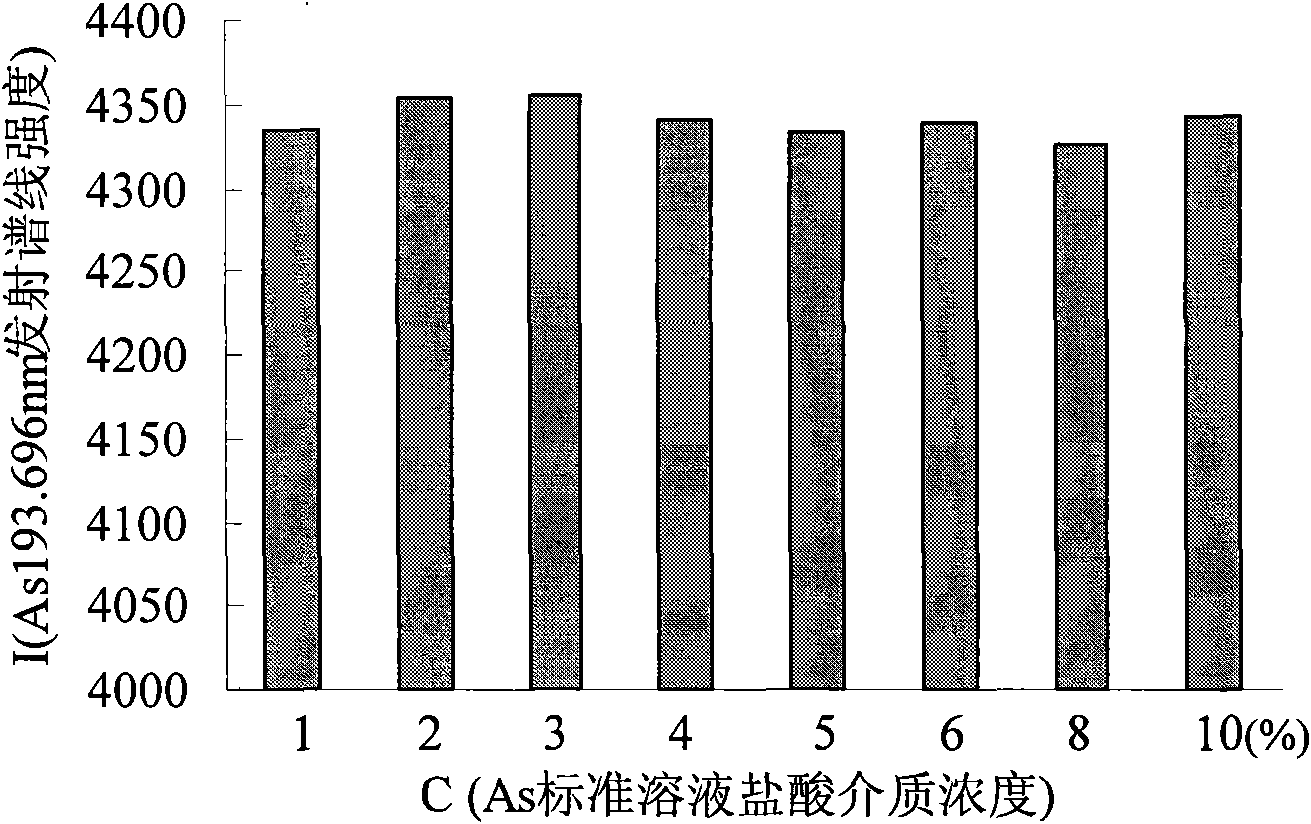

Method for analyzing total arsenic in glass

ActiveCN101776607AAvoid volatile lossSimplify the analysis processAnalysis by thermal excitationManganesePotassium

The invention relates to a method for analyzing total arsenic in glass, comprising the following steps of: preparing sample digestion liquid by using nitric acid-hydrogen peroxide as the pre-oxidant and using hydrofluoric acid-perchloric acid as dissolver processing sample; and measuring the content of arsenic in the digestion liquid by an inductive coupling plasma atomic emission spectrum method. The analyzing method can effectively avoid volatilization loss of low-valent arsenic in the acid solution process; besides, devices such as a hydride generator and the like are not needed by directly measuring the arsenic content in the sample digestion solution; the dissolver is general and easy to obtain, and the digestion step is simple and controllable. Compared with the dissolving sample method of arsenic in the national standard GB / T 1549-2008 of the fibre glass chemical analyzing method, the method has the advantages that a great amount of impurity elements such as manganese, potassium, sulphur, and the like can not be introduced, thereby the method can be used for decomposing and measuring most chemical components including arsenic, manganese, potassium, sulphur, and the like in the glass ample in one step; and precipitation reaction is not performed between the dissolver and the chemical components in the sample so that the method can be used for measuring arsenic in high-lead glass sample.

Owner:中国科学院上海硅酸盐研究所苏州研究院

Anticracking agent for outer wall beat insulating anticracking water proofing coating material and its preparation method

InactiveCN1590473AGuaranteed waterproof performanceGuaranteed insulation effectCoatingsGlass fiberEmulsion

An anticracking agent for the insulating and anticracking water-proof paint used for external wall is prepared from water, elastic acrylic emulsion, OP-10, ethanediol, defoaming agent, anticorrosion agent, methyl cellulose, glass microbeads, glass fibres, and wood fibre.

Owner:TIANHONG CHEM PAINT DECORATION TANGGU DISTRICT TIANJIN CITY

Urea-resin foaming thermal-insulating composite powder, the synthetic board therewith and method

A urea resin formaldehyde thermal-insulating composite powder and its production are disclosed. The composite powder consists of urea formaldehyde plastic 60-90 proportion, cellulosine or straw powder 5-20 proportion, fibrous glass 0.5-6 proportion, asbestos 1-8 proportion, gypsum 1-8 proportion, silicate 0.1-1.5 proportion and glycerin 0.5-3 proportion. It has excellent strength, fire-retardant and insulating performances. It can be used to substitute plastics, ceramics, cast iron and glass fiber reinforced plastics to produce pipes, flanged disk, valve and pump.

Owner:刘兴国

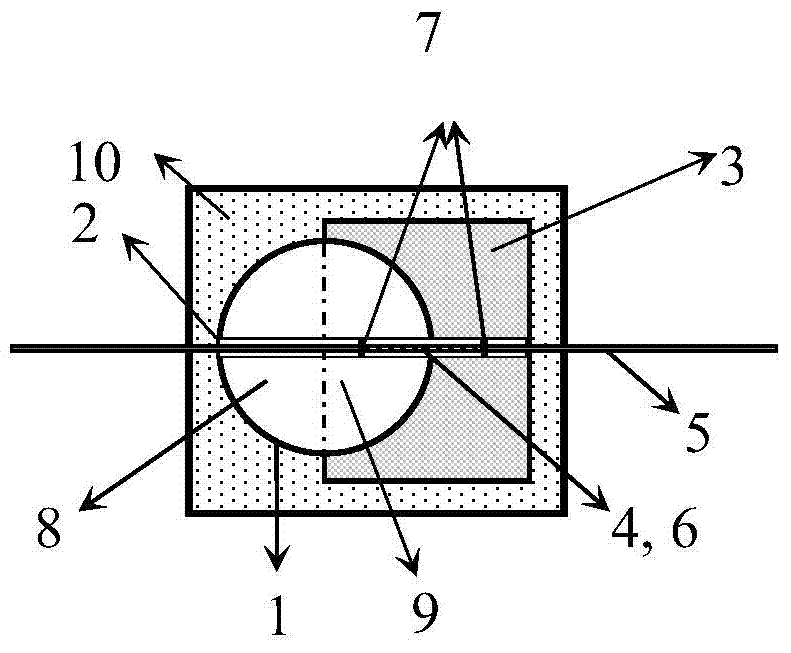

Optical fiber sensor combination for monitoring corrosion of reinforced concrete

ActiveCN103616325AImprove survival rateCounteract the reaction forceWeather/light/corrosion resistanceGratingReinforced concrete

The invention discloses an optical fiber sensor combination for monitoring the corrosion of reinforced concrete. The optical fiber sensor combination comprises an optical fiber sensor and a compensation sensor, wherein the optical fiber sensor and the compensation sensor comprise reinforcing steel bar elements, reinforced fiber glass reinforced plastic support bases, optical fiber Bragg gratings and connecting optical fibers, protective sleeves, silicon sheets, reinforcing steel bar coating regions, reinforcing steel bar un-coating regions, and mortar housings, wherein the reinforcing steel bar elements of the optical fiber sensors are reinforcing steel bars to be tested, and the reinforcing steel bars of the compensation sensor are 316L stainless steel bars. According to the optical fiber sensor combination, a reaction force of mortar is counteracted to a certain extent, the local corrosion of the reinforcing steel bars is favorably monitored, and the sensitivity of monitoring is improved. The compensation sensor is made by adopting a manner of replacing common reinforcing steel bars by 316L stainless steel, and is simple in principle and convenient to operate. The optical fiber sensor combination is simple in structure, convenient to manufacture, low in cost, good in sensitivity, high in accuracy, strong in anti-electromagnetic interference, high in reliability, good in durability, and high in stability, and is suitable for monitoring the long-term durability of reinforcing steel concrete structures such as saline and alkaline land, seawater and deicing salt under multiple environments.

Owner:TIANJIN PORT ENG INST LTD OF CCCC FIRST HARBOR ENG +2

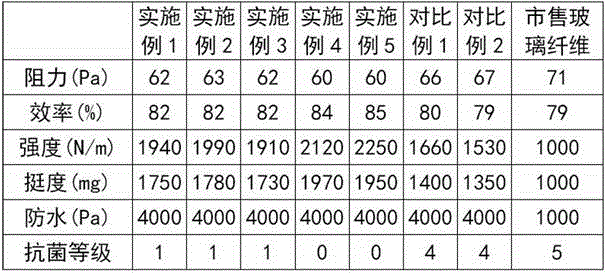

Antibacterial glass fiber air filter paper and preparation method thereof

ActiveCN106245423AIncrease the areaImprove bindingGlass making apparatusPaper coatingChemistryPre treatment

The invention discloses antibacterial glass fiber air filter paper and a preparation method thereof, wherein the preparation method comprises the following steps: (1) preparation of glass fibers; (2) pretreatment of the glass fibers; (3) preparation of silver-supported glass fibers; (4) coating of porous graphene; (5) preparation of the silver / titanium dioxide supported glass fibers; and (6) preparation of the glass fiber filter paper. Through the method, graphene, silver and titanium dioxide can be more effectively and evenly dispersed and coated on the glass fibers, and the interaction area and interface binding force of the glass fibers are further increased, so that the mechanical properties of the glass fiber filter paper are more excellent, and the material strength and stiffness are greatly improved; and the composite material has excellent antibacterial properties due to antibacterial properties of silver and titanium dioxide.

Owner:陕西容纳材料科技有限公司

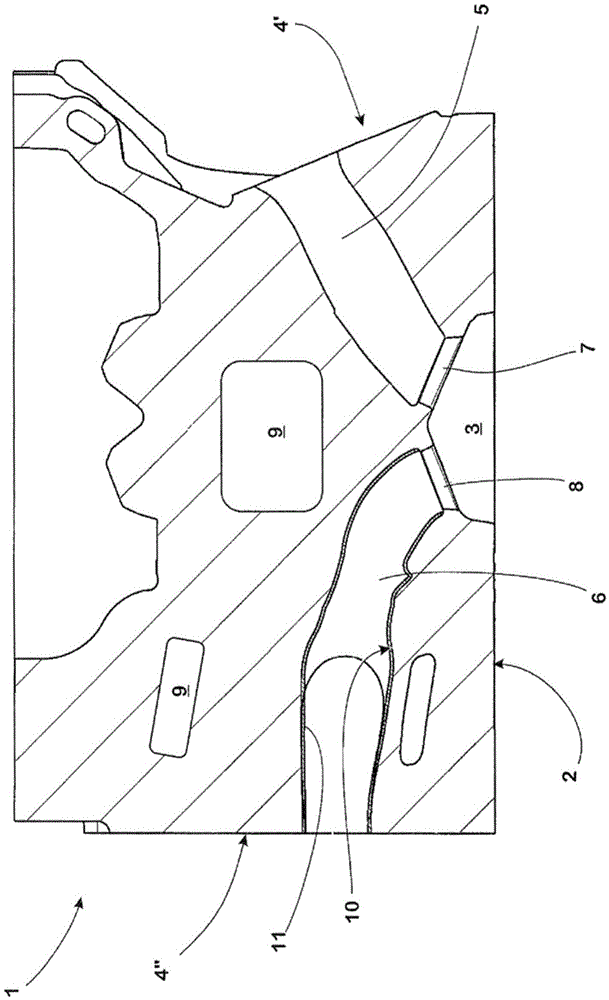

Enamel powder, metal component having a surface portion provided with an enamel coating and method for producing such a metal component

According to the invention, an enamel powder for producing a coating that is able to withstand high mechanical and thermal stresses and is simultaneously easily workable is provided as a mixture containing 100 parts of a glass powder, optionally 10-22 parts of coarse glass grains that are larger than the glass powder particles, 0.1-7.5 parts of ceramic fibres, glass fibres or carbon fibres, and as alternatives to one another or in combination with one another, 10-21 parts of a powdered oxide compound of a light metal or 1-5 parts of a powdered heavy metal. A metal component provided with a coating produced from an enamel powder according to the invention reliably withstands application of a hot gas flow. Therefore the coating according to the invention is particularly suitable for coating internal combustion engine components exposed to a flow of exhaust gas. The invention also specifies a method with which such metal components can be provided with an enamel coating.

Owner:NEMAK S A B DE

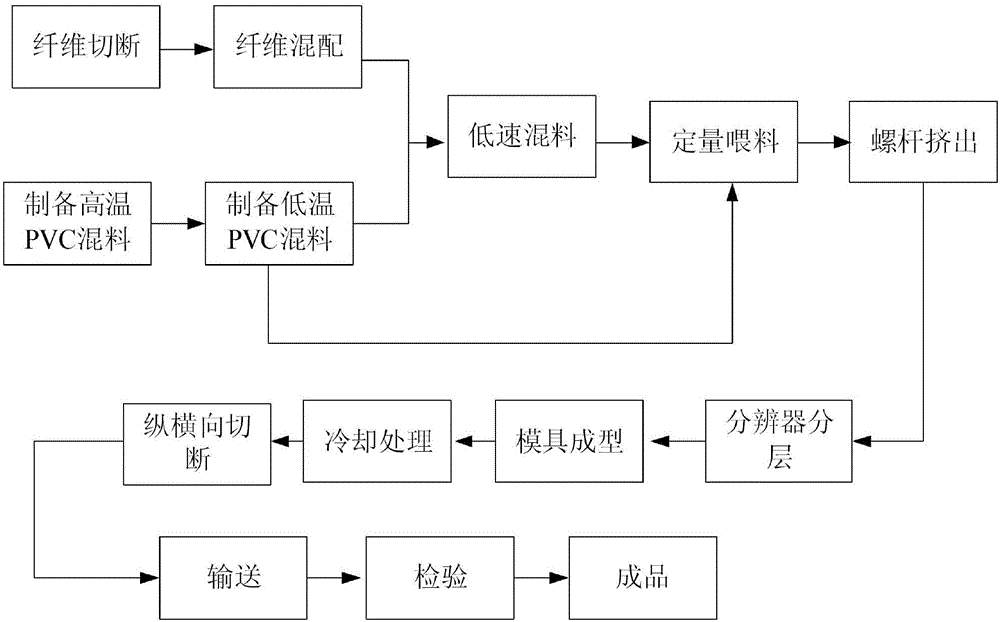

Fiber reinforced polyvinyl chloride composite floor and production process thereof

InactiveCN106836721AAddressing Thermal StabilityTroubleshoot application technology issuesSynthetic resin layered productsConstructions elementsCarbon fibersPolyvinyl chloride

The invention discloses a fiber reinforced polyvinyl chloride composite floor and a production process thereof, belonging to the technical field of new materials. Through the use of carbon fiber, basalt fiber and glass fiber as additives, the three-layer fiber reinforced polyvinyl chloride composite floor is formed by using co-extrusion process. The upper and lower surface layers are made of fiber reinforced polyvinyl chloride, and the middle layer is polyvinyl chloride flooring. Using of fiber thermal stability and scientific formula, fiber reinforced polyvinyl chloride composite floor is lighter than the stone floor, and compared with ordinary PVC plastic flooring, the fiber reinforced polyvinyl chloride composite floor does not deform after sunlight irradiation for a long time and stability is good at average temperature. Fiber reinforced polyvinyl chloride composite floor is the ideal substitute for wood and machinable wood skin compound high-grade new floor is the most popular product in international market. The application technical problem of plastic flooring is solved by fiber modification, so that the technology application performance and the product technology content are improved and additional value is added.

Owner:吉林省天誉镁林新型材料有限公司

Laminate with improved properties

InactiveUS20030092337A1Reduce Shrinkage ProblemsSuitably producedFilm/foil adhesivesRoof covering using flexible materialsFiberGlass fiber

Composites made from at least two plies are described, where one of the outer layers is a layer comprising glass fibers, and in particular is a staple glass fiber nonwoven. The layers have been bonded to one another by needling, and the extent of this needling is such that some of the fibers of the organic nonwoven emerge from the surface of the glass fiber sheet. The composite is then provided with a binder by using a rotating roll for single-side application to the glass fiber surface. The composites are particularly suitable for producing bituminized prefabricated roofing and waterproofing sheets, and as backings for coatings, e.g. PVC coatings.

Owner:JOHNSMANVILLE EUROPE GMBH

Preparation method of flame-retardant antistatic plastic liner plate

InactiveCN103910932AImprove antistatic performanceImprove flame retardant performancePolymer sciencePolypropylene

The invention relates to a preparation method of a flame-retardant antistatic plastic liner plate. The preparation method comprises following steps: 1) polypropylene, high density polyethylene, glass fiber, glass bead, citric acid, talc, calcium carbonate, a silane coupling agent, POE, sodium dodecanesulphonate, decabromodiphenylethane, conductive carbon black, an anti-oxidant, and dicapryl phthalate are taken; 2) the raw materials above are mixed, and a mixture is obtained via stirring; 3) the mixture is delivered into a screw pelletizer for granulation so as to obtain plastic particles; and 4) the plastic particles are subjected to plasticizing using an extruder, are delivered into a mould, and then are subjected to pressing, demoulding, and burr removing so as to obtain the flame-retardant antistatic plastic liner plate. The flame-retardant antistatic plastic liner plate possesses excellent antistatic property and flame resistance, is capable of maintaining relatively high tensile property, is long in service life, is excellent in dry crack resistance, and wet resistance, and is especially suitable for using in severe environments such as environment with mine water and environment with high corrosivity.

Owner:中实洛阳机械工程科技有限公司

Low dielectric glass and fiber glass

Glass compositions are provided that are useful in a variety of applications including, for example, electronics applications, reinforcement applications, and others. Some embodiments of glass compositions can provide desirable dielectric constants, desirable dissipation factors, and / or desirable mechanical properties while also having desirable fiber forming properties.

Owner:PPG IND OHIO INC

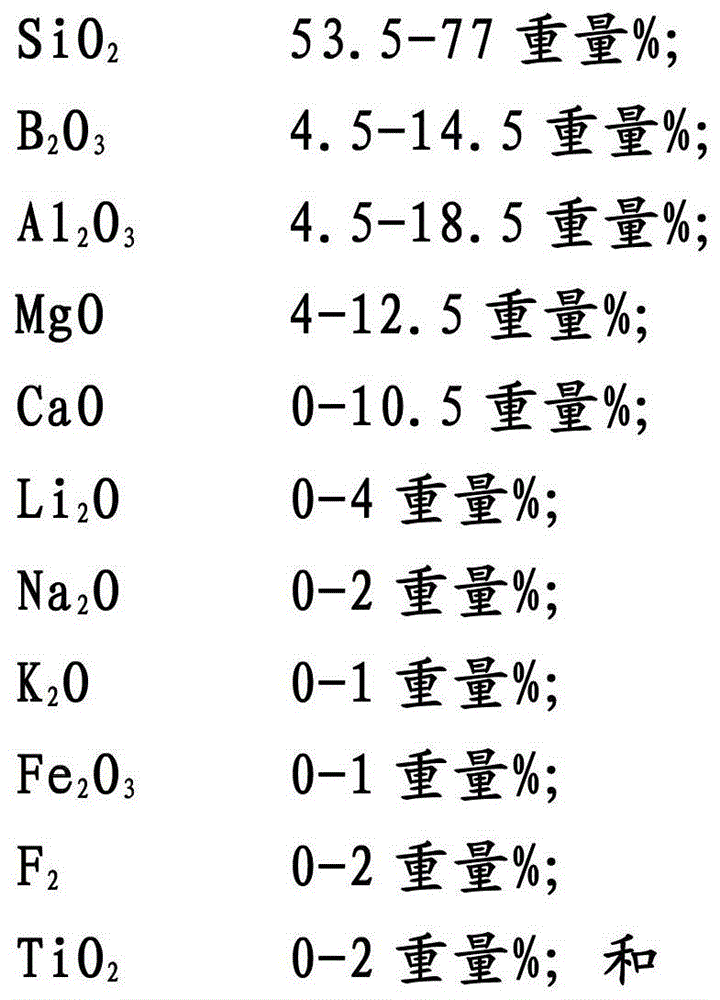

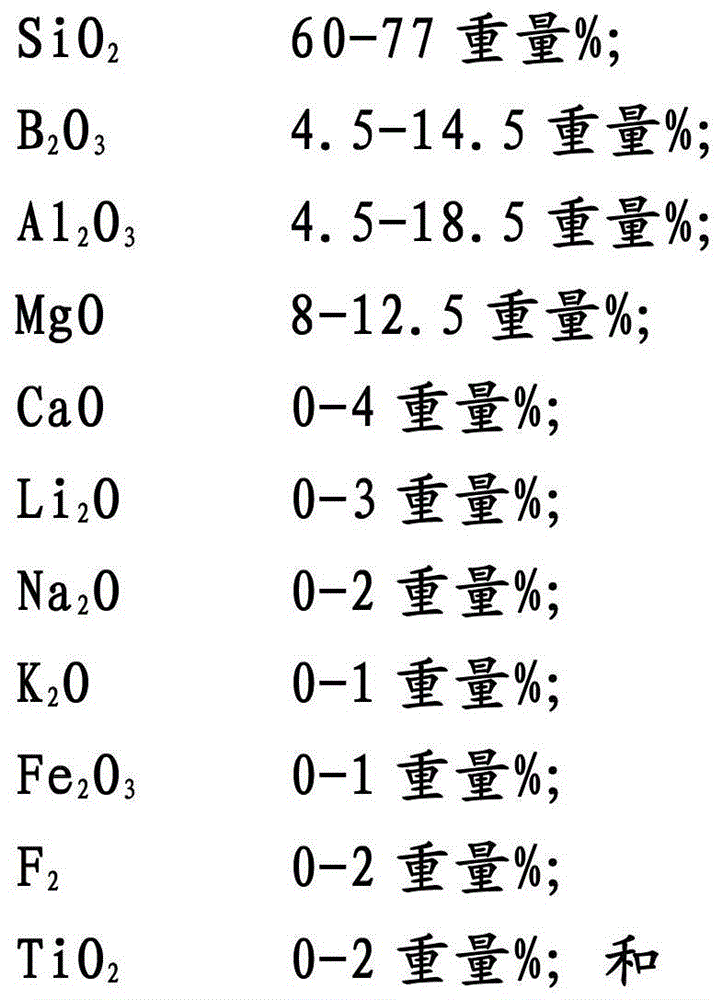

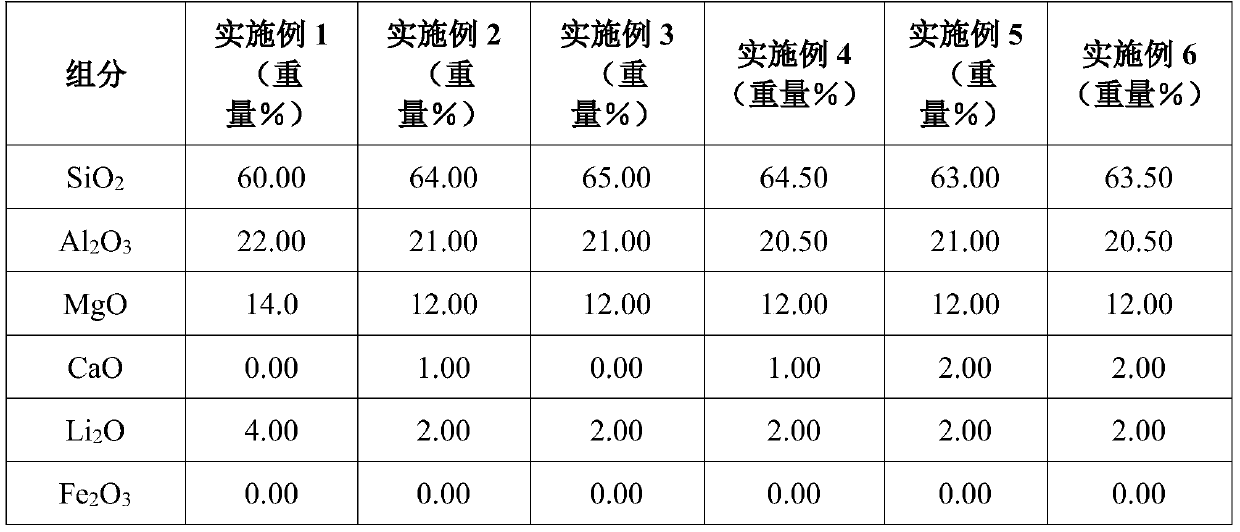

High performance fiber glass composition with improved specific modulus

The present invention relates to a high-performance fiber glass composition with improved specific modulus. The glass fibers formed from the composition of the present invention can be used in applications requiring high rigidity and have a specific modulus between 34 and 40 MJ / kg. Such applications include woven fabrics and aerospace structures used in forming wind turbine blades.

Owner:OCV INTELLECTUAL CAPITAL LLC

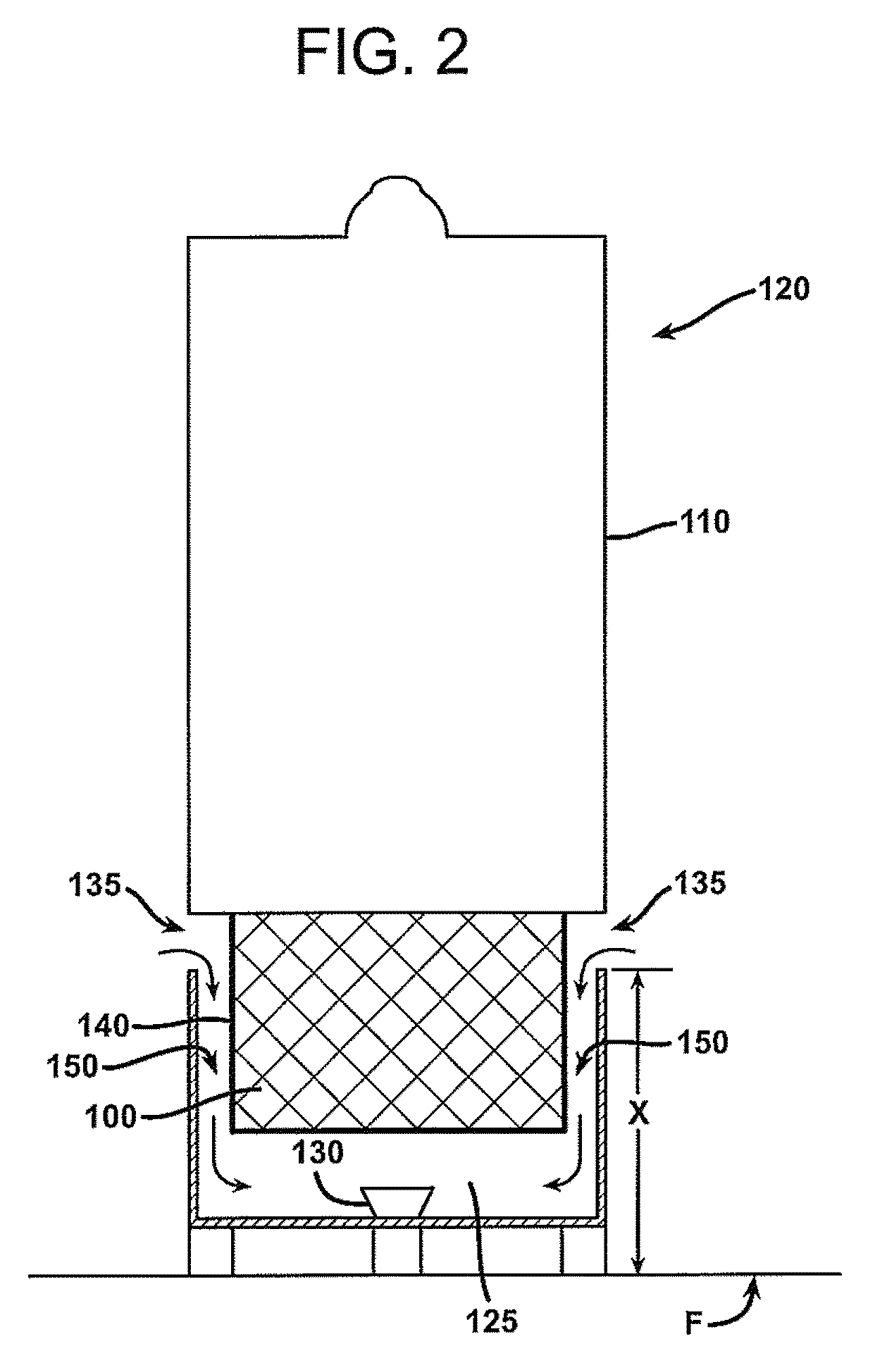

Thin rotary-fiberized glass insulation and process for producing same

A method of forming a needled rotary fiberglass glass insulation product is provided. The formation of the needled insulation product may be conducted in a continuous in-line process in which the fibers are rotary formed, a binder is sprayed onto the hot fibers, the fibers are collected onto a conveyor and formed into a fiberglass pack, the fiberglass pack is passed through the oven, and the cured insulation blanket is passed through a needling apparatus. The reduction in thickness and increased density caused by the needling process permits the production of lower thickness and higher density insulation products. In particular, the needled insulation product may have a thickness of less than about 0.75 inches and a density from about 1 pcf to about 10 pcf. The needled insulation product may be utilized in household appliances, water heaters, and HVAC equipment.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

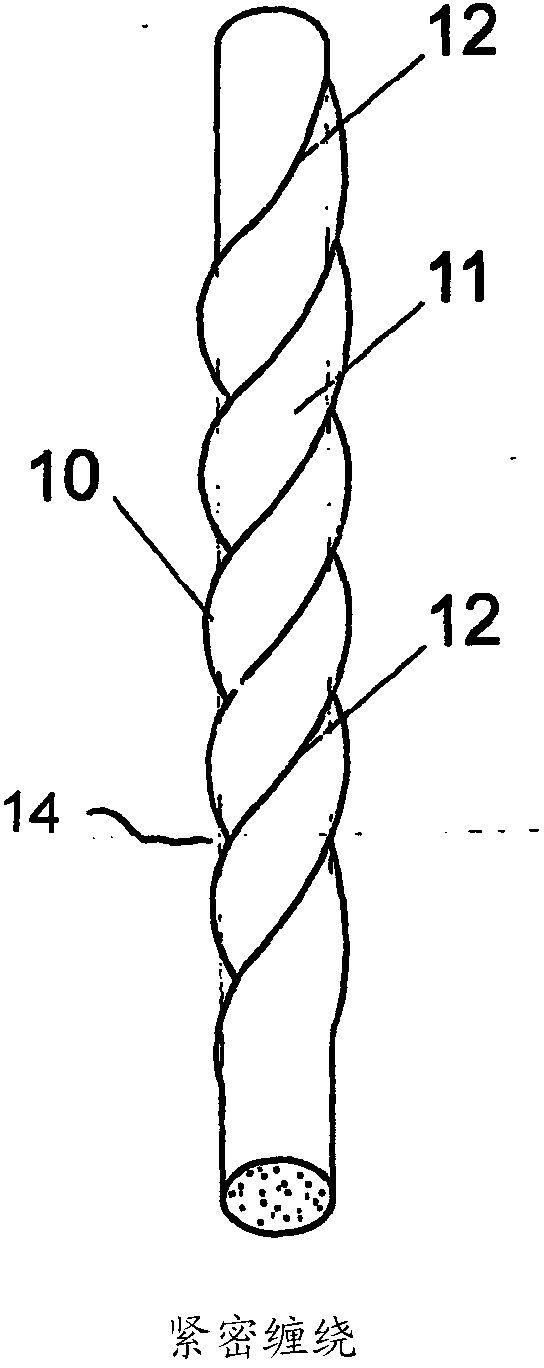

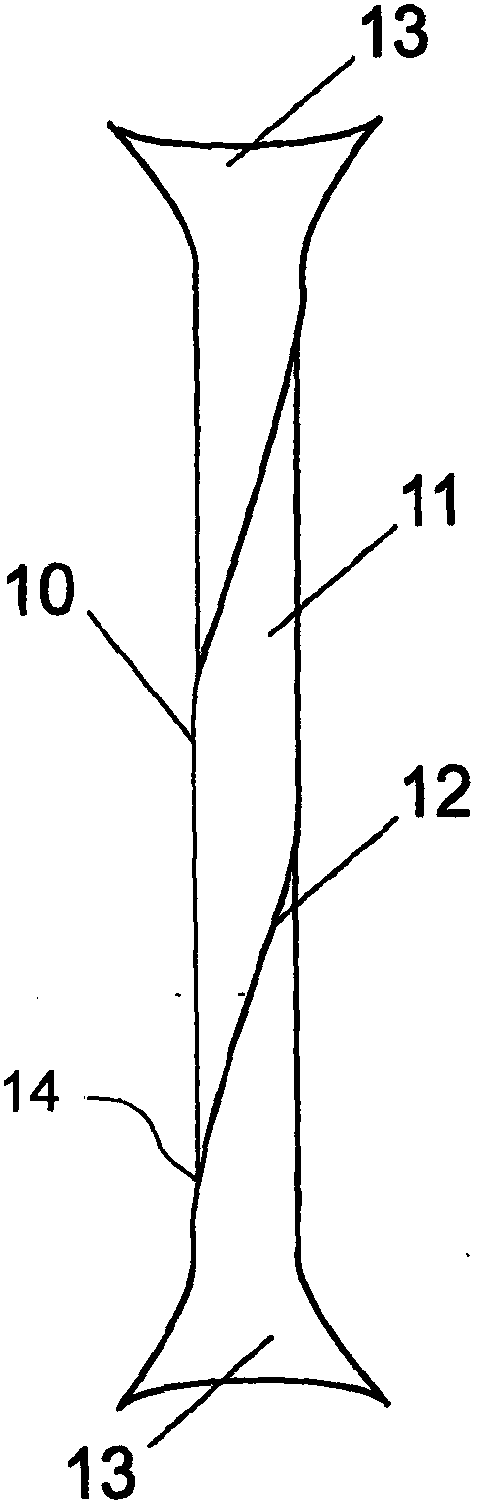

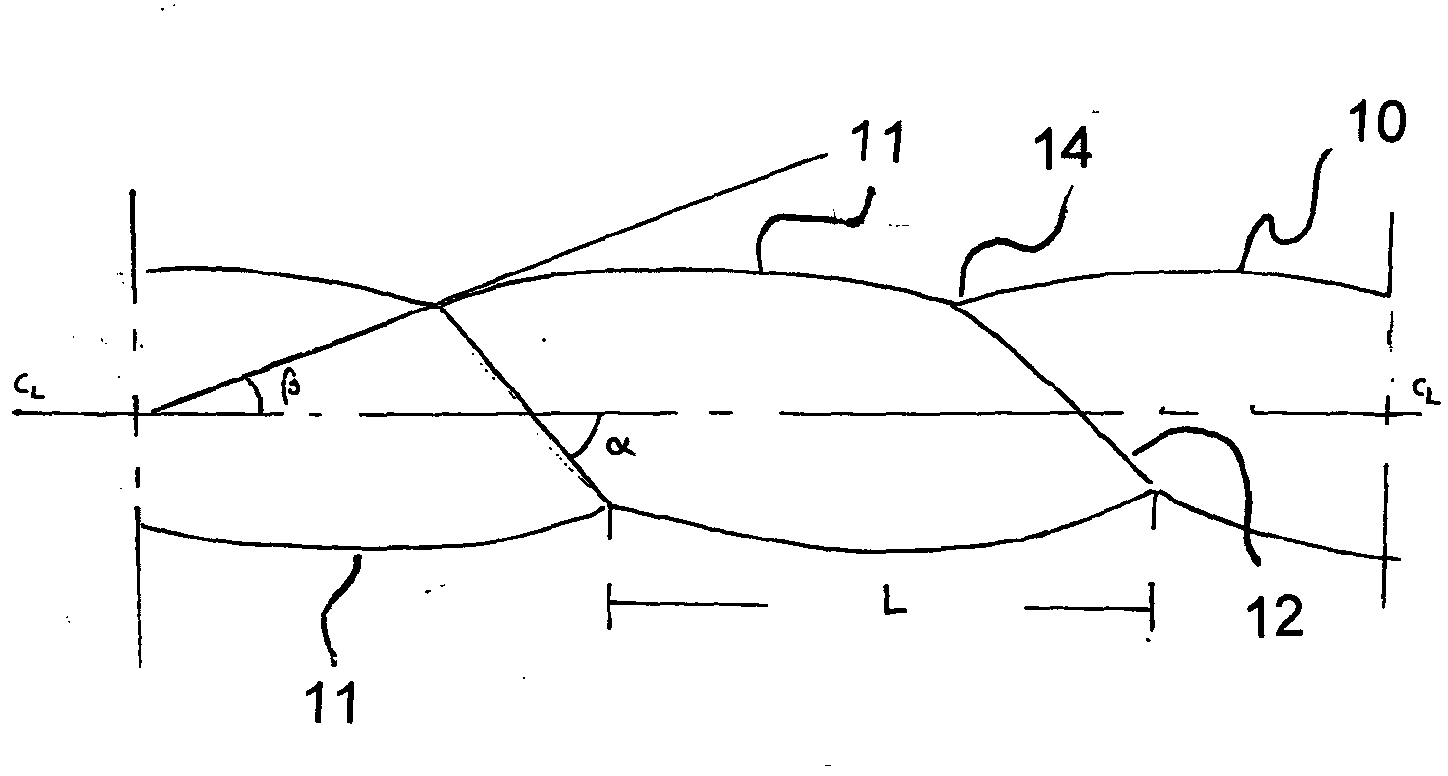

Reinforcement bar and method for manufacturing same

ActiveCN103180258ACorrosion resistanceAlkaline resistantBuilding reinforcementsThin material handlingGlass fiberCarbon fibers

The invention relates to reinforcement bars for concrete structures, comprising a large number of continuous, parallel fibers, preferably made of basalt, carbon, glass fiber, or the like, embedded in a cured matrix, the bars preferably having an average length of 20 mm to 200 mm, and an average diameter of 2 mm to 10 mm, each bar being made of at least one fiber bundles comprising a number of parallel, preferably straight fibers having a cylindrical cross section and said bars being provided with a surface shape and / or texture which contributes to good bonding with the concrete. At least a part of the surface of each bar being deformed prior to or during the curing stage of the matrix by means of: a) one or more strings of an elastic or inelastic, but tensioned material being helically wound around said at least one bundle of parallel, straight fibers prior to curing of the matrix in which the fibers are embedded, maintaining the fibers in an parallel state during curing and providing an uneven external surface in a longitudinal direction of the reinforcement bars, and / or b) at least one deformed section and / or at least one end of each reinforcement bar; thereby producing a roughened surface. The invention also relates to a method for manufacturing reinforcement bars and for use of such short fibers.

Owner:REFORCETECH LTD

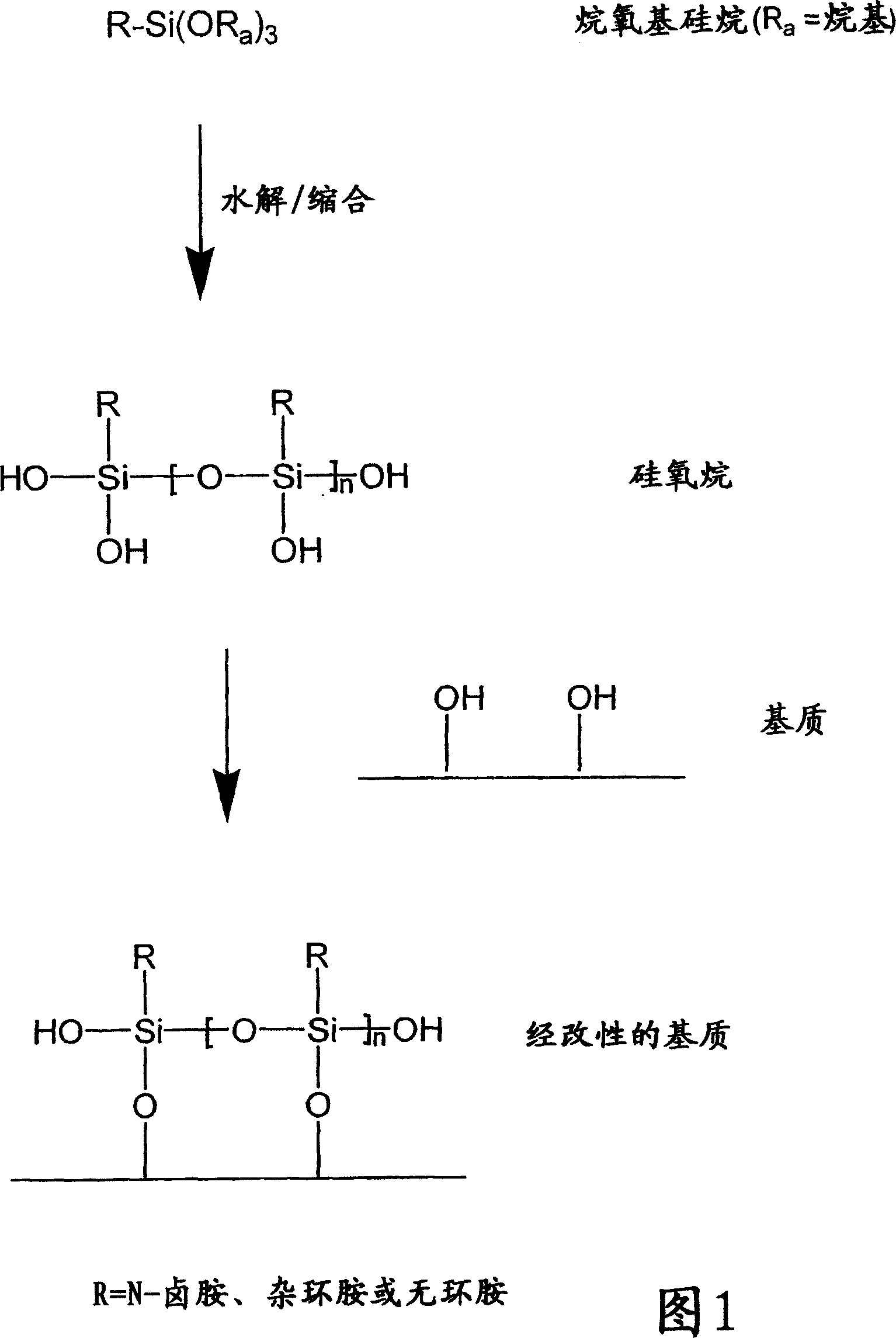

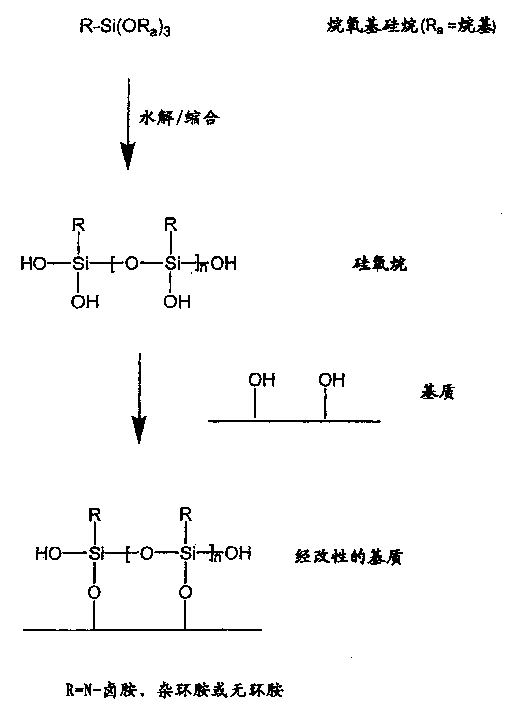

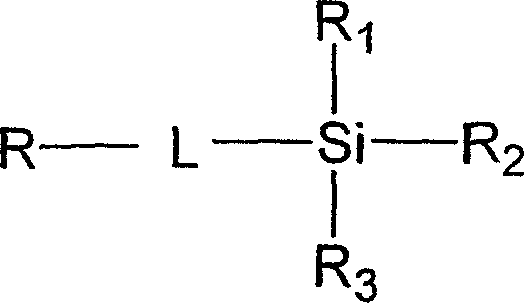

N-halamine siloxanes for use in biocidal coatings and materials

InactiveCN1675227AGroup 4/14 element organic compoundsThin material handlingCellulosePolymer science

Owner:AUBURN UNIV +1

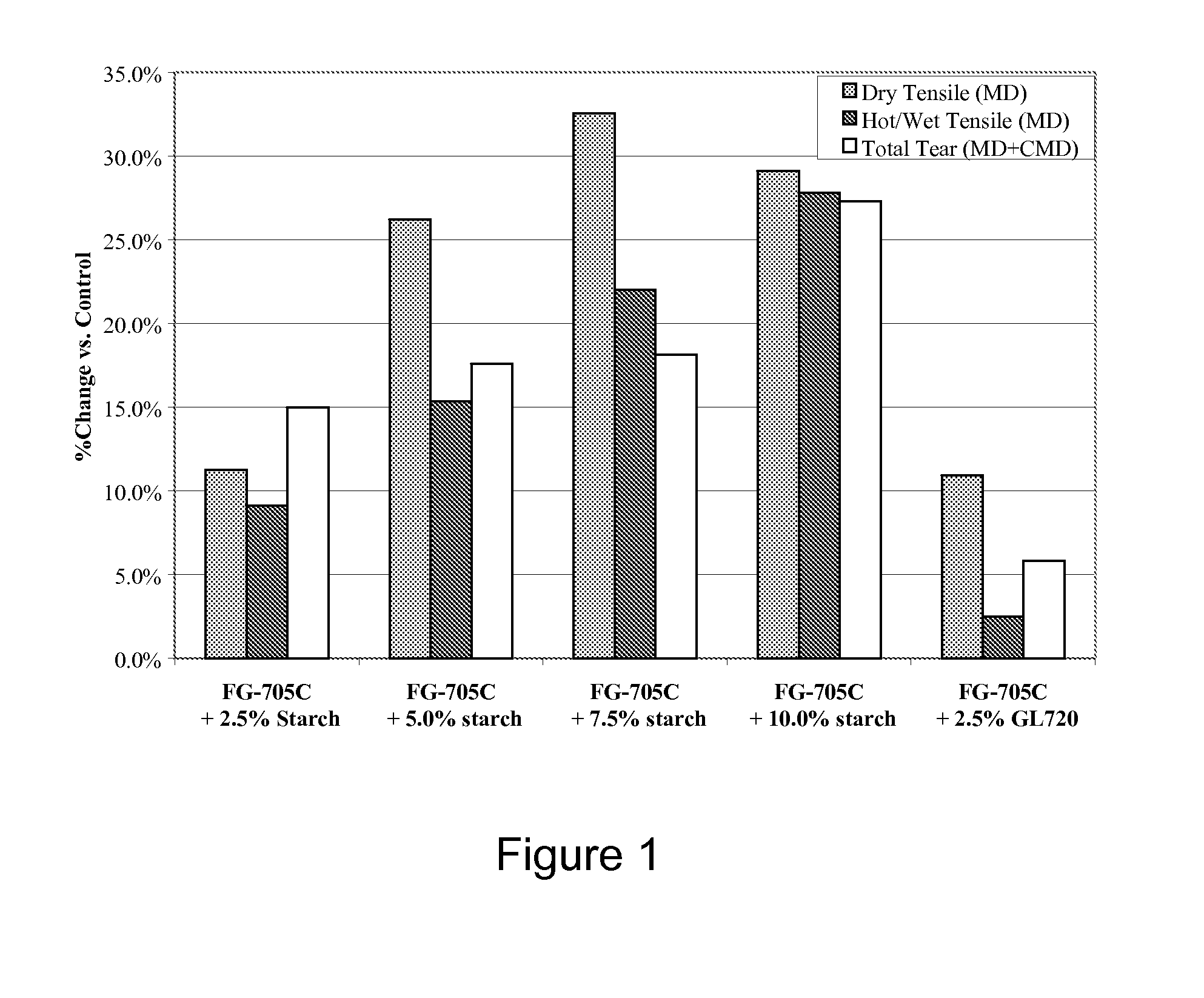

Modified urea-formaldehyde binders for non-woven fiber glass mats

ActiveUS20130130582A1High strengthSimple materialPaper coatingGlass/slag layered productsFiber-reinforced compositeFibrous Glass

Urea-formaldehyde (UF) resin binder compositions modified with a starch are described. The binder compositions may include about 1 wt. % to about 10 wt. % of a starch. In addition, fiber reinforced composites are described. The composites may include organic or inorganic fibers and a polymer matrix formed from a binder composition. The binder composition may include a UF resin and about 1 wt. % to about 10 wt. % of a starch.

Owner:JOHNS MANVILLE CORP

Reinforced polyester compositions for high dielectric performance

InactiveUS20090043033A1Excellent dielectric propertiesImprove mechanical propertiesWindings insulation materialTransformersFiberPolyester

The present invention relates to the use of polyester compositions made by melt blending a mixture comprising at least one thermoplastic polyester polymer and a combination of fibrous glass fillers having a non-circular cross-sectional aspect ratio of greater than at or about 4, mica and conventional glass fillers for applications where high dielectric performance and good mechanical properties are simultaneously required.

Owner:EI DU PONT DE NEMOURS & CO

Composite-glass-fiber-reinforced gypsum board and manufacturing method thereof

ActiveCN106220118AImprove mechanical propertiesEnhanced interface bindingGlass making apparatusGlass fiberSolvent

The invention discloses a composite-glass-fiber-reinforced gypsum board and a manufacturing method thereof. The manufacturing method comprises the following steps: (1) preparing glass fibers; (2) pretreating the glass fibers; (3) weighing graphene quantum dots, and preparing a 0.1-1 mg / ml dispersion solution, wherein the solvent is water, acetone or dimethylsulfoxide; carrying out ultrasonic agitation on 80-100ml of the graphene quantum dot dispersion solution, adding the pretreated glass fibers, carrying out ultrasonic agitation at half of the speed, and impregnating for 30-60 minutes; taking out the glass fibers, cleaning, and drying for later use; (4) preparing graphene-modified composite glass fibers; and (5) preparing the composite-glass-fiber-reinforced gypsum board. According to the composite-glass-fiber-reinforced gypsum board, the strength of the glass-fiber-reinforced gypsum board is effectively improved, and the water absorptivity is lowered.

Owner:蚌埠傲创知识产权运营有限公司

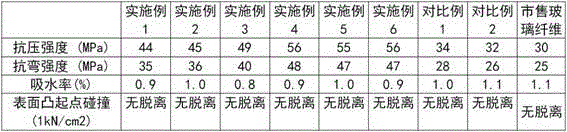

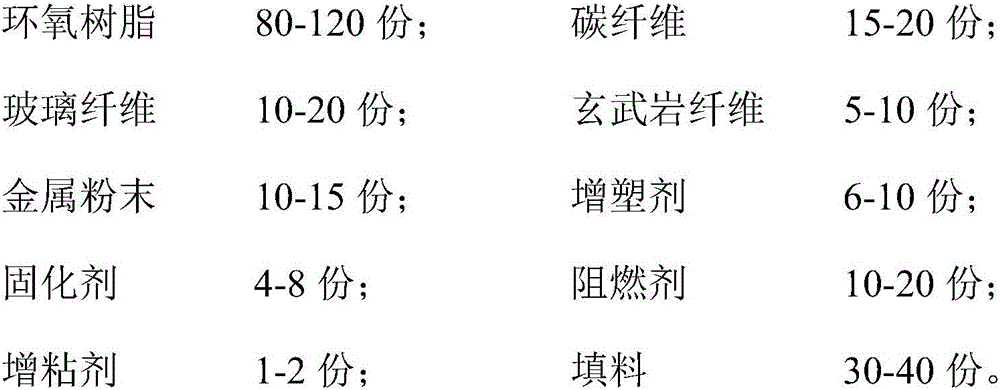

Glass steel tile back and production process thereof

The invention provides a glass steel tile back and a production process thereof. The glass steel tile back is prepared from epoxy resin, carbon fiber, glass fiber, basalt fiber, metal powder, a plasticizer, a curing agent, a flame retardant, a tackifier and packing. Due to reasonable proportions of the specific raw materials, the tensile strength of the tile back can be increased to 550-600MPa from conventional 370-500MPa, so that bent parts of the tile back can be effectively prevented from cracking, and the security of the tile back in the brake process is ensured; in addition, the glass steel tile back provided by the invention is excellent in corrosion resistance and high temperature resistance, a surface treatment procedure of the tile back can be avoided in actual production of a brake tile, the production efficiency can be improved, the applicable environment of the brake tile can be widened, and the service life of the brake tile can be prolonged.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

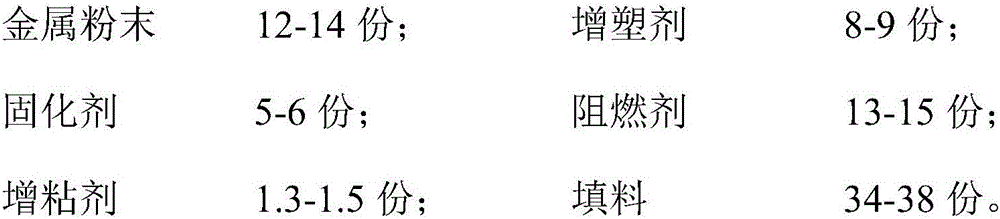

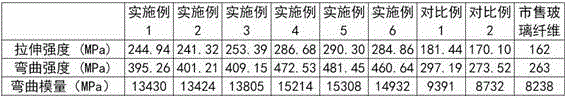

Graphene modified glass fiber reinforced resin composite material and preparation method thereof

The invention discloses a graphene modified glass fiber reinforced resin composite material and a preparation method thereof. The preparation method comprises the following steps that 1, glass fibers are prepared; 2, the glass fibers are pretreated; 3, graphene quantum dots are weighed and prepared into a dispersion solution of which the concentration ranges from 0.1 mg / ml to 1 mg / ml, the solvent is water or acetone or dimethyl sulfoxide, ultrasonic stirring is conducted on 80 ml-100 ml of graphene quantum dot dispersion solution, the pretreated glass fibers are added into the graphene quantum dot dispersion solution, the speed of ultrasonic stirring is decreased by half, soaking is conducted for 30 min to 60 min, and the glass fibers are cleaned and dried for use; 4, a graphene modified glass fiber reinforcement is prepared and modified with a silane coupling agent; 5, resin base materials are composited, and the graphene modified glass fiber reinforced resin composite material is obtained. The prepared graphene modified glass fiber reinforced resin composite material has a more excellent mechanical property.

Owner:江苏泰斯鸿科技有限公司

Long-acting antimicrobial glass fiber air filtering paper and preparation method thereof

ActiveCN106223121AIncrease the areaImprove bindingWater-repelling agents additionSynthetic cellulose/non-cellulose material pulp/paperLong actingChemistry

The invention discloses long-acting antimicrobial glass fiber air filtering paper and a preparation method thereof. The preparation method comprises the following steps: (1) preparing glass fibers; (2) pretreating the glass fibers; (3) preparing silver-loaded glass fibers; (4) coating porous graphene; (5) preparing silver / titanium dioxide-loaded antimicrobial glass fibers; (6) preparing the glass fiber filtering paper. By the method provided by the invention, the glass fibers are more effectively coated with graphene, silver and titanium dioxide in a uniform and dispersive manner, and the interaction area and the interface bonding strength of the glass fibers are further increased, so that the mechanical property of the glass fiber filtering paper is more excellent and the strength and the stiffness of the material are greatly improved; the composite material has an excellent antimicrobial property due to the antimicrobial characteristics of silver and titanium dioxide.

Owner:泰安三英新材料股份有限公司

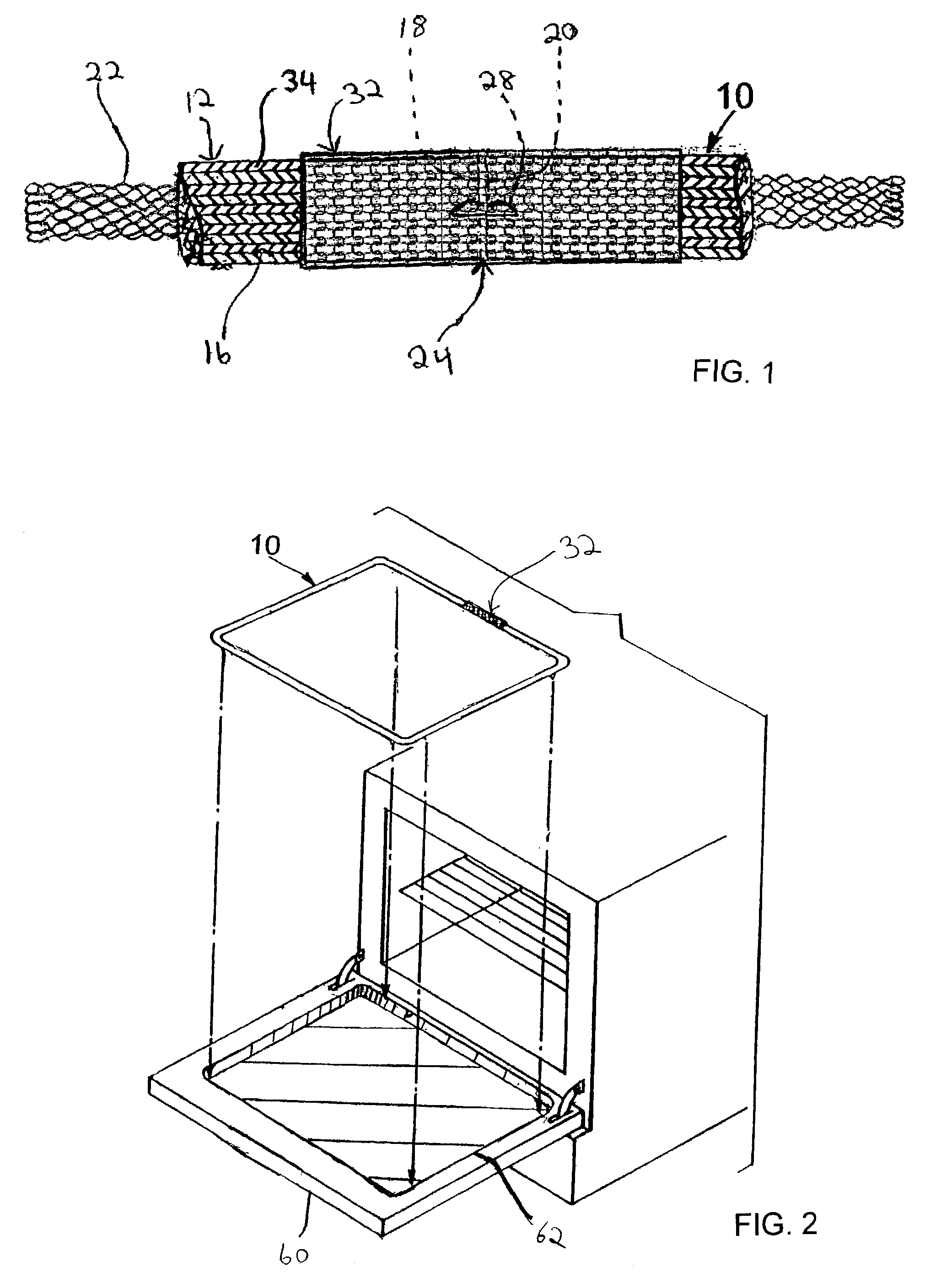

Rope gasket with termination

The present invention is a gasket comprising a length of rope formed at least substantially by a plurality of interwoven fibrous glass yarns and having at least two ends, and a soft wire mesh termination sleeve placed around and attached to the rope member at the joint that conforms to the shape of the gasket joint.

Owner:DAVLYN MFG

Thermosetting engine oil filter paper and preparation method thereof

PendingCN112160188ALarge lengthUniform lengthPaper coatingReinforcing agents additionPolymer scienceAramid

The invention provides thermosetting engine oil filter paper which comprises a paper filter layer and a resin layer, and the paper filter layer is coated with the resin layer; the paper filter layer is prepared from the following raw materials in percentage by mass: 10%-30% of coniferous wood fibers, 25%-50% of mercerized pulp fibers, 0%-15% of cotton linter fibers, 20%-40% of PET fibers, 0%-10% of aramid fibers, 0%-5% of glass fibers, 0%-0.1% of a dry strength agent, 0.5%-1.5% of a wet strength agent and 0.1% of a dispersing agent; and the resin layer is thermosetting phenolic resin. The invention further provides a preparation method of the thermosetting engine oil filter paper. The engine oil filter paper disclosed by the invention has the advantages of good strength, temperature resistance and hydrophobicity, small pore size, high air permeability and excellent filtering performance.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com