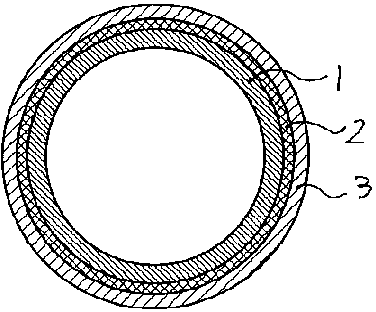

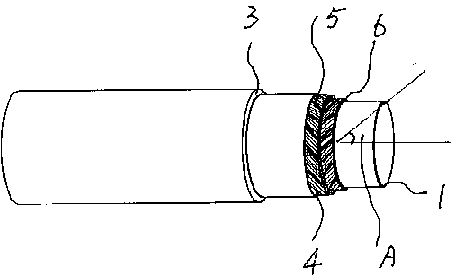

Coiled plastic composite pipe reinforced with fibre

A technology of reinforced plastics and composite pipes, applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., to achieve the effect of benefiting human health and reducing air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The constituent materials of the inner tube layer of the composite pipe are: 80 parts by weight of nylon 6, 10 parts by weight of short glass fibers, 9 parts by weight of linear low-density polyethylene, 0.6 parts by weight of antioxidant 1098, and 0.2 parts by weight of coupling agent KH-570 ;

[0029] The constituent materials of the anticorrosion protection layer of the composite pipe: 95 parts by weight of high-density polyethylene 7600M, and 5 parts by weight of carbon black masterbatch.

Embodiment 2

[0031] The constituent materials of the inner tube layer of the composite pipe are: 75 parts by weight of nylon 6, 15 parts by weight of short glass fibers, 12 parts by weight of linear low-density polyethylene, 0.8 parts by weight of antioxidant 1098, and 0.3 parts by weight of coupling agent KH-580 ;

[0032] The constituent materials of the anticorrosion protection layer of the composite pipe: 94 parts by weight of high-density polyethylene 7600M, 6 parts by weight of carbon black masterbatch and 8 parts by weight of short glass fibers.

Embodiment 3

[0034] The constituent materials of the inner tube layer of the composite pipe are: 90 parts by weight of nylon 6, 12 parts by weight of glass fiber, 6 parts by weight of linear low-density polyethylene, 1.0 parts by weight of antioxidant 168, and 0.1 parts by weight of coupling agent KH-580;

[0035] The constituent materials of the anticorrosion protective layer of the composite pipe: 92 parts by weight of high-density polyethylene 7600M, 7 parts by weight of carbon black masterbatch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com