High performance fiber glass composition with improved specific modulus

A glass composition and a technology for the composition, which can be applied to glass manufacturing equipment, wind turbines in line with the wind direction, and manufacturing tools, etc., can solve problems such as process interruption, loss of transparency of glass, and reduced productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

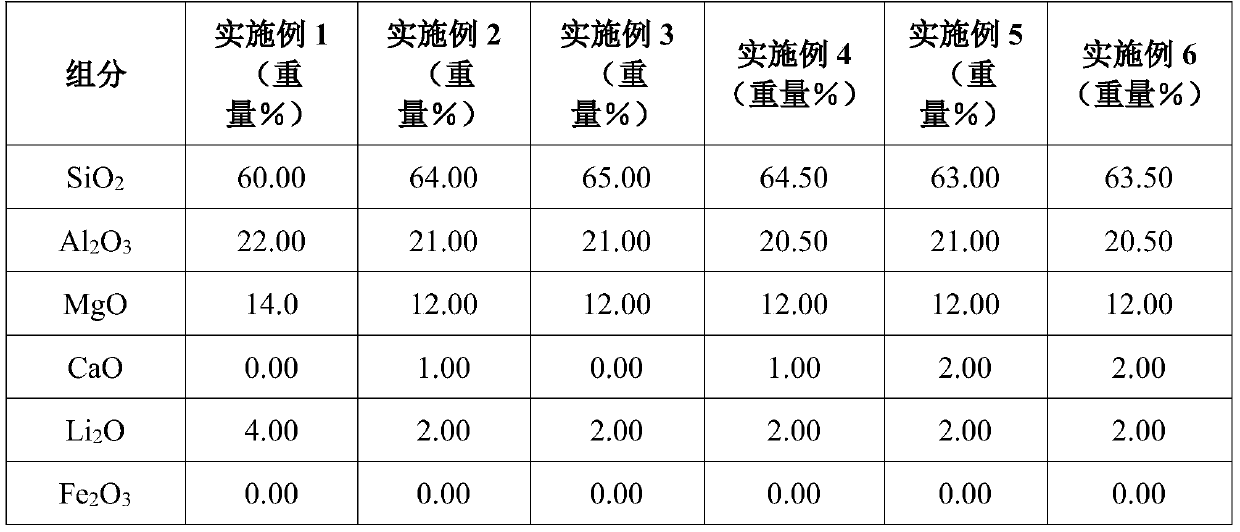

[0082] Exemplary glass compositions according to the present invention were prepared by mixing the batch components in proportionate amounts to achieve a final glass composition having the oxide weight percents set forth in Tables 1-8 below.

[0083] The raw materials were melted in a platinum crucible in an electrically heated furnace at a temperature of 1,650° C. for 3 hours.

[0084] Fiberization temperature was measured using the rotating cylinder method as described in ASTM C965-96 (2007) entitled "Standard Practice for Measuring Viscosity of Glass Above the Softening Point", the contents of which are incorporated herein by reference. By exposing the glass to a temperature gradient in a platinum alloy boat for 16 hours as described in ASTM C829-81 (2005) entitled "Standard Practices for Measurement of Liquidus Temperature of Glass", the contents of which are incorporated herein by reference. Measure the liquidus temperature. Density is measured by the Archimedes method a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com