Antibacterial glass fiber air filter paper and preparation method thereof

An air filter paper and glass fiber technology, applied in glass manufacturing equipment, filter paper, filtration and separation, etc., can solve the problems such as the inability of nano-silver and glass fiber to be closely combined, large ventilation, easy to agglomerate, etc., to increase the interaction Area and interfacial adhesion, improving strength and stiffness, and the effects of excellent antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

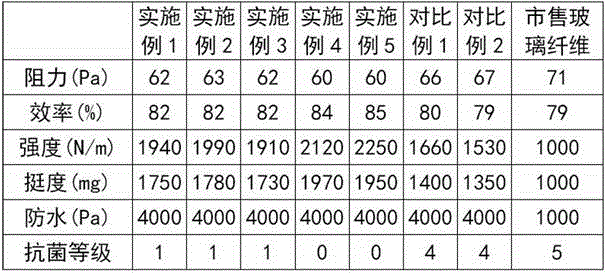

Examples

Embodiment 1

[0022] A preparation method for antibacterial glass fiber air filter paper, comprising the steps of:

[0023] (1) Preparation of antibacterial glass fiber, comprising the following steps:

[0024] (1) Preparation of glass fiber: After crushing and mixing 54.4% SiO2, 15% B2O3, 0.6% Na2O, 12% Al2O3 and 18% CaO, put it in a 400mL corundum crucible, melt it with a silicon-molybdenum rod resistance furnace, and feed The temperature is 1370°C, the melting and clarification temperature is 1450±10°C, it is released at 1200°C, poured into a mold, sent into a muffle furnace, and annealed at 500°C to obtain glass; the prepared glass is heated to a drawing viscosity temperature of 1050 ℃, drawn into glass fibers of a specific diameter;

[0025] (2) Glass fiber pretreatment: After taking 45 parts of glass fiber for phase separation, carry out acid leaching treatment in 100ml of HCl solution with a concentration of 1mol / L. Dissolve the Na2O-B2O3 phase in acid, add 5ml of NH4Cl solution wi...

Embodiment 2

[0036] A preparation method for antibacterial glass fiber air filter paper, comprising the steps of:

[0037] (1) Preparation of antibacterial glass fiber, comprising the following steps:

[0038](1) Preparation of glass fiber: After crushing and mixing 54.4% SiO2, 15% B2O3, 0.6% Na2O, 12% Al2O3 and 18% CaO, put it in a 400mL corundum crucible, melt it with a silicon-molybdenum rod resistance furnace, and feed The temperature is 1370°C, the melting and clarification temperature is 1450±10°C, it is released at 1200°C, poured into a mold, sent into a muffle furnace, and annealed at 500°C to obtain glass; the prepared glass is heated to a drawing viscosity temperature of 1050 ℃, drawn into glass fibers with a specific diameter;

[0039] (2) Glass fiber pretreatment: After taking 45 parts of glass fiber for phase separation, carry out acid leaching treatment in 100ml of HCl solution with a concentration of 1mol / L. Dissolve the Na2O-B2O3 phase in acid, add 5ml of NH4Cl solution w...

Embodiment 3

[0050] A preparation method for antibacterial glass fiber air filter paper, comprising the steps of:

[0051] (1) Preparation of antibacterial glass fiber, comprising the following steps:

[0052] (1) Preparation of glass fiber: After crushing and mixing 54.4% SiO2, 15% B2O3, 0.6% Na2O, 12% Al2O3 and 18% CaO, put it in a 400mL corundum crucible, melt it with a silicon-molybdenum rod resistance furnace, and feed The temperature is 1370°C, the melting and clarification temperature is 1450±10°C, it is released at 1200°C, poured into a mold, sent into a muffle furnace, and annealed at 500°C to obtain glass; the prepared glass is heated to a drawing viscosity temperature of 1050 ℃, drawn into glass fibers with a specific diameter;

[0053] (2) Glass fiber pretreatment: After taking 45 parts of glass fiber for phase separation, carry out acid leaching treatment in 100ml of HCl solution with a concentration of 1mol / L. Dissolve the Na2O-B2O3 phase in acid, add 5ml of NH4Cl solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com