Low dielectric glass and fiber glass

A fiber and glass technology, used in printed circuits, electrical components, circuit substrate materials, etc., can solve the problem of high fiber molding temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

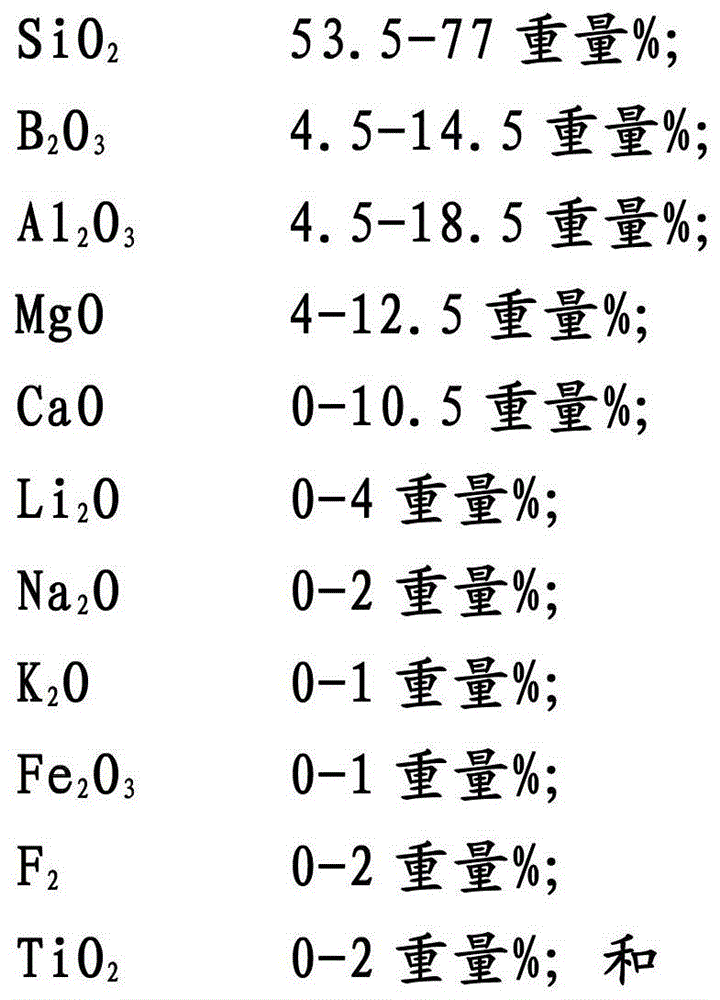

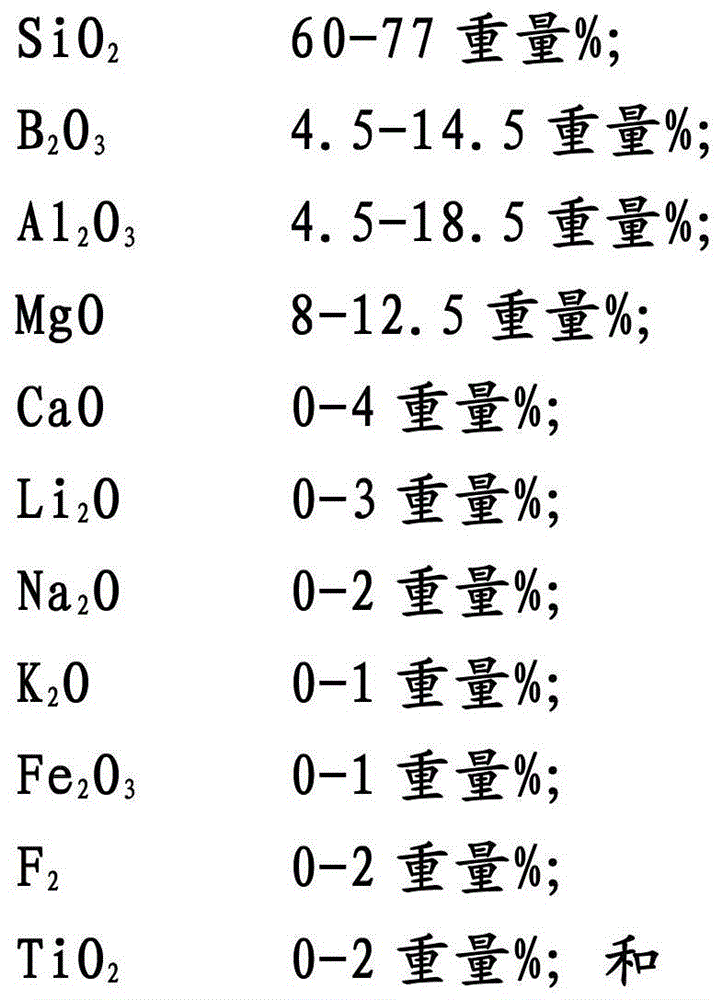

[0065] In order to reduce D k and D f , including SiO with low electric susceptibility in the composition of the present invention 2 and B 2 o 3 is useful. Although B 2 o 3 itself will melt at low temperature (350°C), but it is unstable to moisture attack in ambient air, so pure B 2 o 3 fibers cannot be practically used in PCB laminates. SiO 2 and B 2 o 3 Both are network formers, and mixtures of the two will produce significantly higher fiber forming temperatures than E-glass, as well as D-glass. In order to reduce the fiber forming temperature, MgO and Al can be included 2 o 3 , to replace some SiO 2 . Calcium oxide (CaO) and SrO can also be used in combination with MgO, but they are not as desirable as MgO since both have higher polarizability than MgO.

[0066] In order to reduce the batch cost, the B 2 o 3 Use at lower concentrations than in D-glass. However, including enough B 2 o 3 to prevent phase separation in the glass melt, thereby providing bet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com