Thermosetting engine oil filter paper and preparation method thereof

A kind of oil filter paper, thermosetting technology, applied in the field of filter paper, can solve the problems of unable to meet the requirements of long-term work of the oil filter, unable to coordinate filtration efficiency and dirt holding capacity, poor hydrophobicity of the oil filter paper, etc., to achieve low tightness, Low pore size, good aging resistance and temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

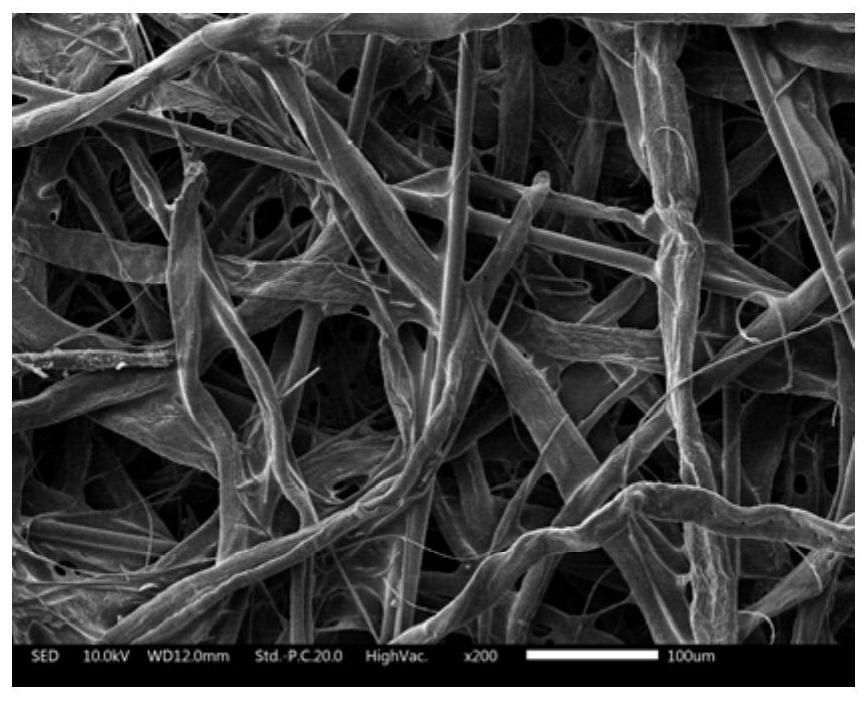

Image

Examples

Embodiment 1

[0032] A thermosetting machine oil filter paper, comprising a paper filter layer and a resin layer, the resin layer is wrapped on the paper filter layer; and the paper filter layer is made up of the raw materials of the following mass fraction: coniferous wood fiber 20% , mercerized pulp fiber 40%, cotton linter fiber 8%, PET fiber 29.42%, glass fiber 2%, dry strength agent CPAM 0.06%, wet strength agent PAE0.5%, dispersant PEO 0.02%; the resin layer is Thermosetting phenolic resin.

[0033] The preparation method of above-mentioned thermosetting machine oil filter paper, comprises the following steps:

[0034] Step 1, beating softwood fiber, mercerized pulp fiber and cotton linter fiber respectively to obtain corresponding slurry;

[0035] Step 2. Mix the slurry obtained in step 1 with PET fiber and glass fiber, and decompose to obtain the mixed slurry, and add dry strength agent CPAM, wet strength agent PAE and dispersant PEO at the same time;

[0036] Step 3, the mixed sl...

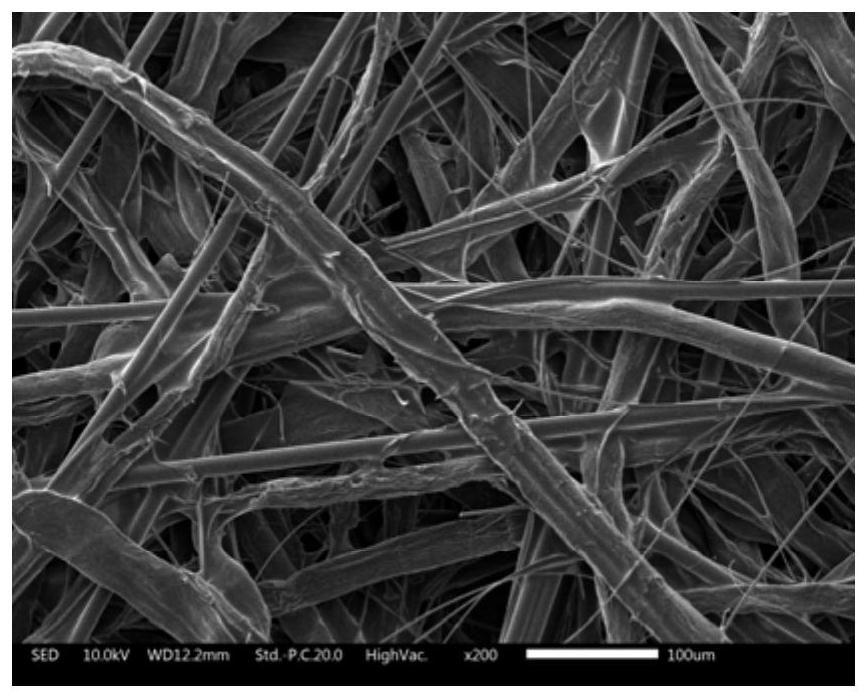

Embodiment 2

[0040] A thermosetting machine oil filter paper, comprising a paper filter layer and a resin layer, the resin layer is wrapped on the paper filter layer; and the paper filter layer is made up of the raw materials of the following mass fraction: coniferous wood fiber 20% , mercerized pulp fiber 47%, cotton linter fiber 5%, PET fiber 18.93%, aramid fiber 5%, glass fiber 3%, dry strength agent CPAM 0.04%, wet strength agent PAE 1%, dispersant PEO 0.03% ; The resin layer is thermosetting phenolic resin.

[0041] The preparation method of above-mentioned thermosetting machine oil filter paper, comprises the following steps:

[0042] Step 1, beating softwood fiber, mercerized pulp fiber and cotton linter fiber respectively to obtain corresponding slurry;

[0043] Step 2. Mix the slurry obtained in step 1 with PET fiber, aramid fiber and glass fiber, and decompose to obtain the mixed slurry. At the same time, add dry strength agent CPAM, wet strength agent PAE and dispersant PEO;

...

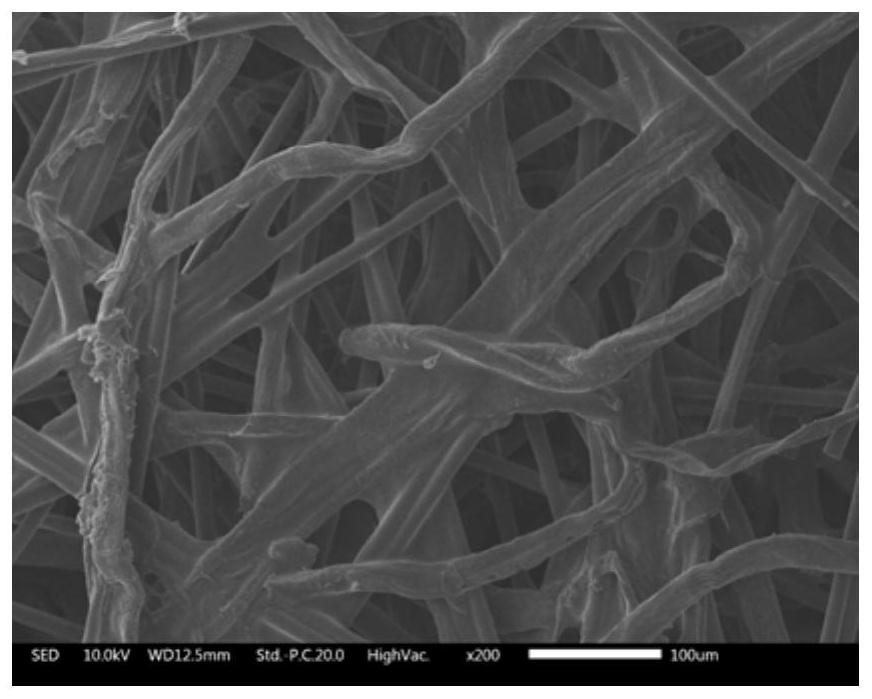

Embodiment 4

[0056] A kind of thermosetting machine oil filter paper, comprises paper quality filter layer and resin layer, and described resin layer is wrapped on described paper quality filter layer; And described paper quality filter layer is made up of the raw material of following mass fraction: coniferous wood fiber 18% , mercerized pulp fiber 35%, cotton linter fiber 12%, PET fiber 24.42%, aramid fiber 7%, glass fiber 3%, dry strength agent CPAM 0.04%, wet strength agent PAE 0.5%, dispersant PEO 0.04%; The resin layer is thermosetting phenolic resin.

[0057] The preparation method of above-mentioned thermosetting machine oil filter paper, comprises the following steps:

[0058] Step 1, beating softwood fiber, mercerized pulp fiber and cotton linter fiber respectively to obtain corresponding slurry;

[0059] Step 2. Mix the slurry obtained in step 1 with PET fiber, aramid fiber and glass fiber, and decompose to obtain the mixed slurry. At the same time, add dry strength agent CPAM,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com