Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86 results about "1,3-Butadiene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

1,3-Butadiene is the organic compound with the formula (CH₂=CH)₂. It is a colorless gas that is easily condensed to a liquid. It is important industrially as a monomer in the production of synthetic rubber. The molecule can be viewed as the union of two vinyl groups. It is the simplest conjugated diene.

Method for preparing 1,3-butadiene from normal butene by using continuous-flow dual-bed reactor

InactiveCN101980992AHigh activityActivity maximizationHydrocarbon by dehydrogenationCatalystsDehydrogenationFixed bed

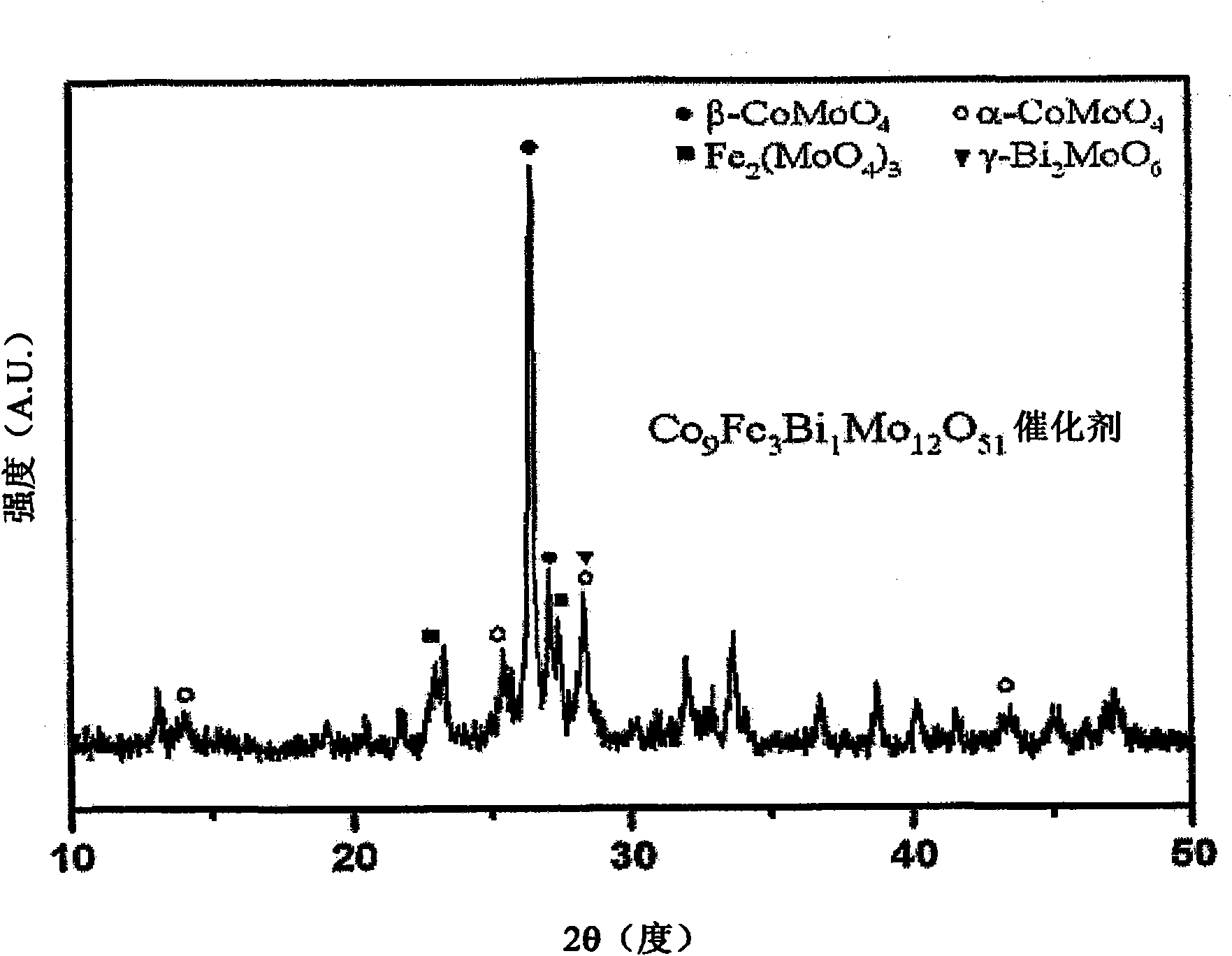

The present invention relates to a method for preparing 1,3-butadiene by an oxidative dehydrogenation of normal butene through the use of a continuous-flow dual-bed reactor which is designed in such a manner that a fixed bed reactor thereof is filled with two types of catalysts and two catalyst layers are not physically mixed. More particularly, the present invention relates to a method for preparing 1,3-butadiene through an oxidative dehydrogenation of normal butene using a C4 mixture, as a reactant, containing normal butene and normal butane, by using a continuous-flow dual-bed reactor employing a multi-component bismuth molybdate-based catalyst and a ferrite-based catalyst which have activations different from one another for the oxidative dehydrogenation of the isomers (1-butene, trans-2-butene, cis-2-butene) of normal butene.

Owner:SK INNOVATION CO LTD +1

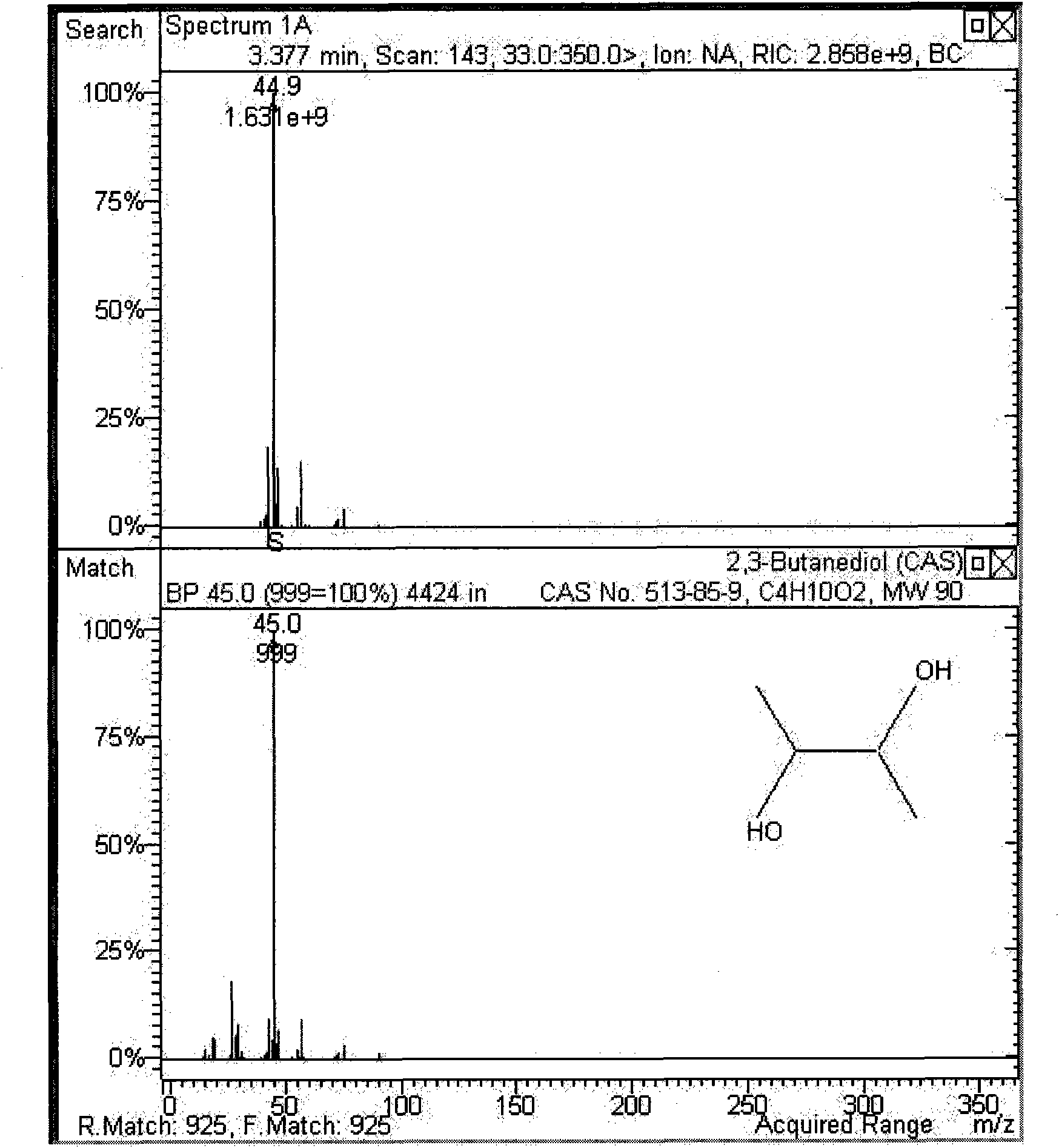

Environmentally-friendly breeding of bacillus subtilis for producing 2,3-butanediol by fermentation with glucose substrate

InactiveCN101851598AImprove protectionHigh utilization rate of raw materialsBacteriaMicroorganism based processesChemical synthesisPolyester

2,3-BDO is important industrial chemicals and a medicinal precursor, for example, the 2,3-BDO can form 1,3-butadiene through dehydration and can be used for synthesizing rubber, polyester and polyurethane; the esterified 2,3-BDO is a precursor of synthetic polyimine, and can be applied to medicaments, cosmetics, washing liquor liquid and the like; and in addition, the 2,3-BDO can also be used as a flavor substance to be added into distilled spirit and cream. The 2,3-BDO can be prepared by a chemical synthesis method and a microorganism production method, and due to a special structure of 2,3-butanediol, in the chemical method for producing the 2,3-butanediol, the 2,3-butanediol is mainly prepared by hydrolyzing four-carbon hydrocarbon generated during the splitting decomposition of petroleum at the high temperature and under the high pressure and has the disadvantages of high cost, complicated processes and difficult operation, so the large-scale industrial production is difficult to realize all the time. With the increasing rise in oil price, people pay close attention to the production of the 2, 3-butanediol by using the microbial fermentation method and the developmental research of derivatives thereof gradually. The fermentation method for producing the 2,3-butanediol has the following advantages that: firstly, the fermentation method has the superiority in cost, and the chemical method has high production cost; secondly, the fermentation method has an environmental-friendly characteristic, and the 2,3-butanediol is used as an organic synthesis intermediate to occupy markets of a number of compounds and other petroleum chemicals, has wide prospect, obvious social and environmental benefits, and is particularly favorable for the extensive application of the products; and thirdly, in the fermentation method for producing the 2,3-butanediol, renewable resources are used as raw materials, so the fermentation method does not depend on the petroleum chemicals.

Owner:JIANGNAN UNIV

Polymeric composition for seals and gaskets

InactiveUS20050182193A1Excellent combination of propertyLow compression setSynthetic resin layered productsThin material handlingElastomerPolymer science

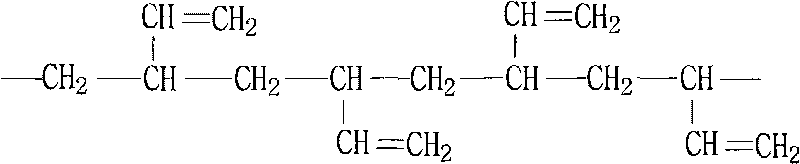

The present invention relates to a polymeric composition which has an excellent combination of properties for use in making seals and gaskets for utilization in appliances, automotive applications, and building applications, such as window glazing gaskets. These polymeric compositions offer excellent dimensional stability, low compression set, outstanding sealing characteristics, low temperature flexibility, heat resistance and ultra-violet light resistance. The present invention more specifically discloses a polymeric composition having excellent characteristics for utilization in manufacturing seals and gaskets including dimensional stability, low compression set and outstanding sealing characteristics, said polymeric composition being comprised of a blend of (A) a thermoplastic resin selected from the group consisting of polypropylene, polyethylene, poly phenylene ether, polystyrene, and styrene containing copolymer resins, (B) an elastomeric polymer selected from the group consisting of block copolymer comprising a first polymeric block that is comprised of repeat units that are derived from a vinyl aromatic monomer and a second block that is comprised of repeat units that are derived from a conjugated diolefin monomer, wherein the repeat units in the second block are hydrogenated, and wherein the repeat units in the second block are elastomeric in nature, and a crosslinked olefinic elastomer, (C) a high molecular weight crosslinked diene elastomer comprised of repeat units that are derived from conjugated diene monomer selected from the group consisting of 1,3-butadiene and isoprene, wherein the high molecular weight diene elastomer has a weight average molecular weight of at least about 200,000, and (D) an oil.

Owner:THE GOODYEAR TIRE & RUBBER CO

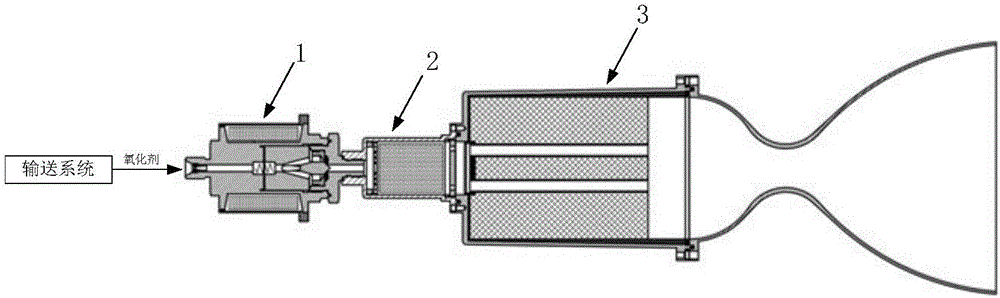

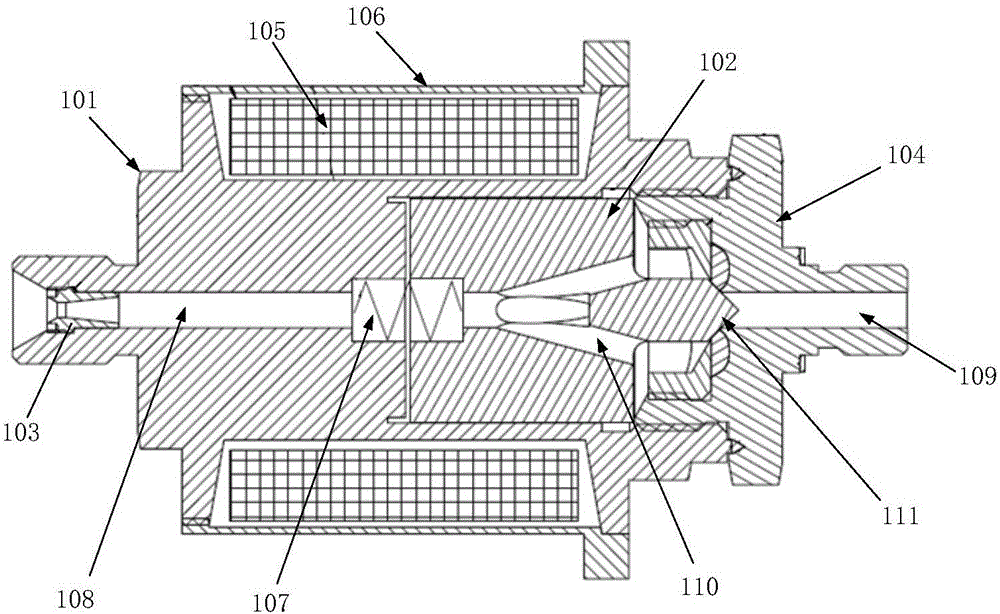

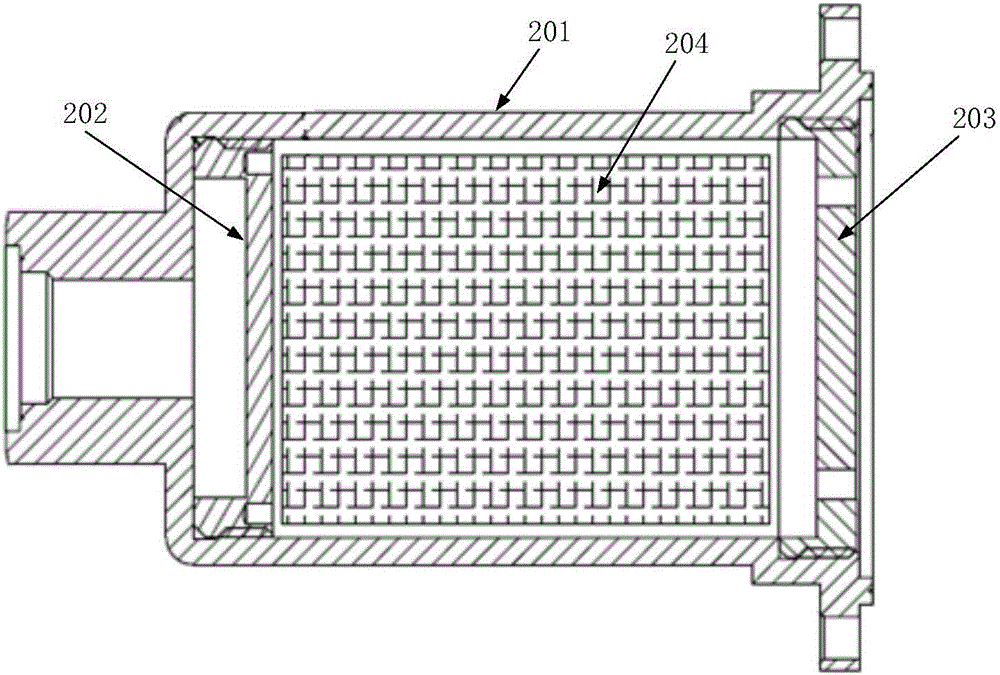

Solid-and-liquid attitude-control rocket engine

ActiveCN106194502ASimple structureImprove reliabilityRocket engine plantsCombustion chamberSolenoid valve

The invention discloses a solid-and-liquid attitude-control rocket engine. The solid-and-liquid attitude-control rocket engine comprises an oxidizing agent conveying system, a direct-action solenoid valve, a honeycomb-type catalytic bed, a combustion chamber and a spraying pipe, wherein the conveying system is used for supplying hydrogen peroxide by adopting a nitrogen extrusion mode; the supplying amount of the hydrogen peroxide is controlled by the direct-action solenoid valve, so that rapid response of the solid-and-liquid attitude-control rocket engine can be realized; the honeycomb-type catalytic bed is adopted for catalyzing, and an oxidizing agent is resolved to generate high-temperature oxygen which enters the combustion chamber through a spraying and jetting panel; and six passages are formed in the middle part of an end-burning grain, and the high-temperature oxygen reaches a grain section through the above passages and generates action with 1-3 butadiene which is a product of decomposition of HTPB, so that the engine starts to work. According to the solid-and-liquid attitude-control rocket engine, double-mode work is adopted, and the advantages of a single-unit attitude-control rocket engine of simple structure and high reliability and the advantages of a double-unit attitude-control rocket engine of high specific impulse and rapid switching-on and switching-off are combined; besides, the structure is simple; cost is low; safety is high; and the solid-and-liquid attitude-control rocket engine is environment-friendly.

Owner:BEIHANG UNIV

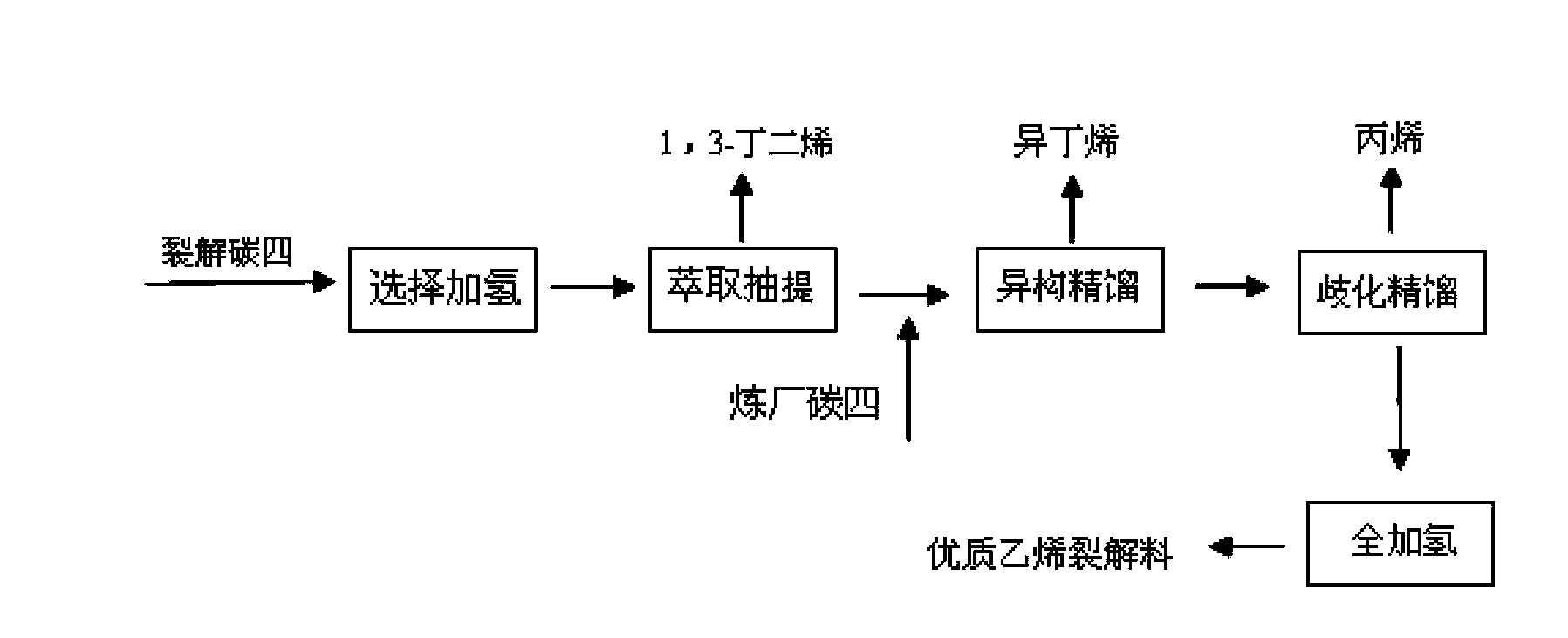

Method for increasing utilization value of mixed C4

ActiveCN103382147AHigh chemical added valueIncrease added valueHydrocarbon by hydrogenationHydrocarbon by metathesis reactionIsomerizationAlkyne

The invention relates to a method for increasing the utilization value of mixed C4. The method comprises the following steps: cracking C4, carrying out selective hydrogenation for removal of alkynes and allowing vinylacetylene and 1-butyne to produce 1,3-butadiene and 1-butylene through hydrogenation, wherein the content of alkynes in hydrogenation products is less than 15*10<-9>; subjecting obtained materials to extraction and rectification so as to allow 1,3-butadiene to be separated from other C4 fractions, mixing residual C4 material flow with C4 produced in a refinery plant, subjecting obtained mixed C4 to a hydroisomerization reaction so as to allow 1-butylene in the mixed C4 to be isomerized into 2-butylene and separating isomerization products so as to obtain an isobutene product; and introducing residual C4 material flow into a disproportionation unit, allowing 2-butylene in the residual C4 material flow and ethylene to undergo disproportionation so as to produce propylene, carrying out separation and allowing unreacted ethylene and residual C4 material flow to undergo full hydrogenation so as to enable all the unsaturated hydrocarbons to undergo hydrogenation saturation. According to the method, the content of alkenes in the hydrogenation products is lower than 1%, and the products can be used as high-quality ethylene cracking materials.

Owner:PETROCHINA CO LTD

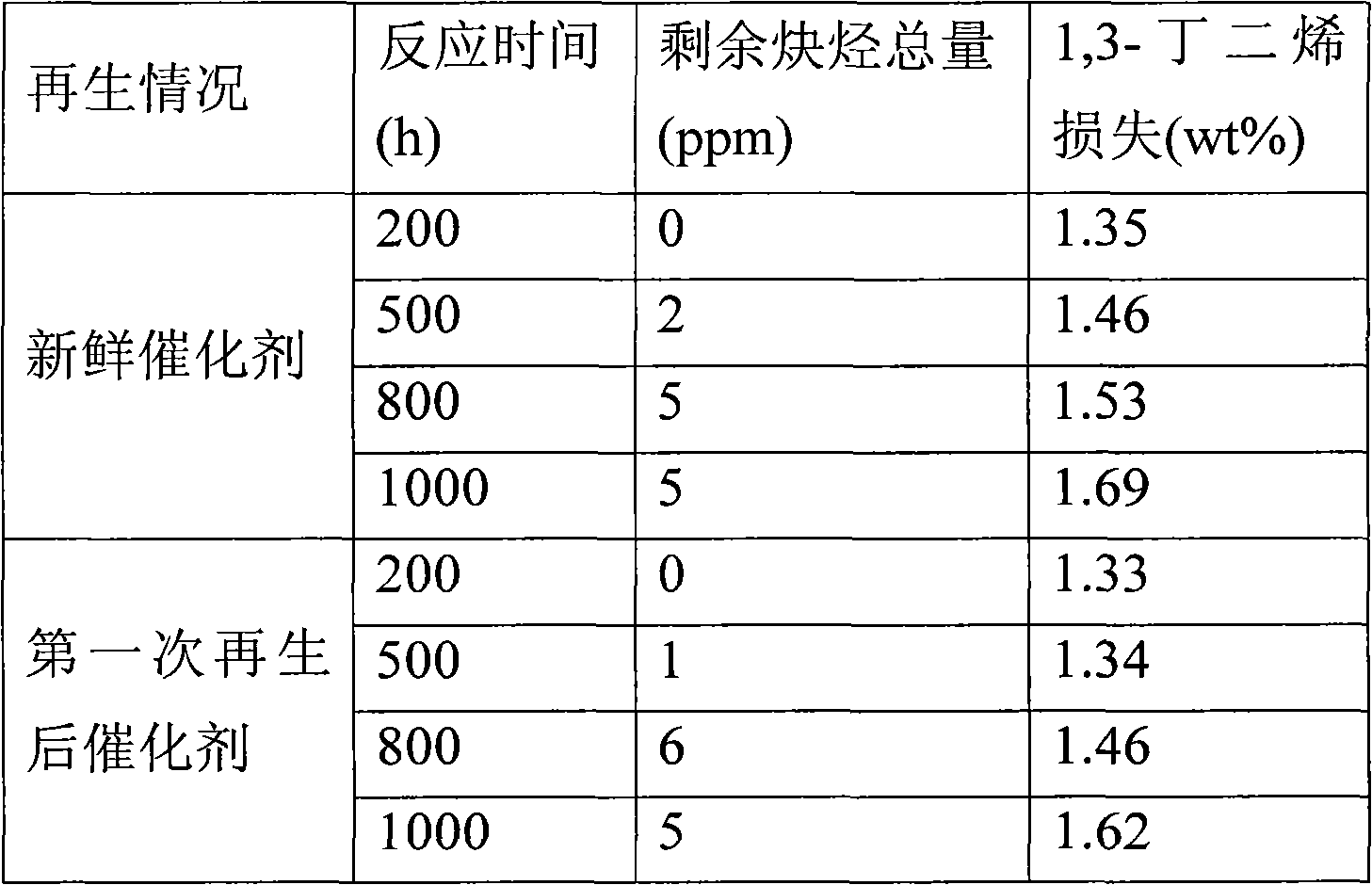

1, 3-butadiene production process by C4 selective hydrogenation

ActiveCN102731240AExtended service lifeLow total alkyne contentHydrocarbon purification/separationHydrocarbonsRare-earth elementHydrogen

The 1, 3-butadiene production process of the invention belongs to olefin production technology, and aims to solve problems of diseconomy and unsafety of a traditional butadiene extraction method. In the presence of a catalyst, a (two stage) fixed bed reactor is employed. Process conditions include: an entrance temperature of 30-60 DEG C, pressure of 0.6-2.0 MPa, carbon four liquid space velocity of 10-60 h <-1>, and hydrogen acetylene ratio of 0.2-10. The catalyst consists of an alumina carrier, 0.01-1wt% of Pd, 0.01-5wt% of Pb and one or several rare earth elements selected from La, Pr and Nd with a total content of 0.01-10wt%. The method lowers total alkynes in the C4 fraction to ppm level, and has little butadiene loss and realizes repeatedly recycled butadiene, so as to solve a ''bottleneck'' problem of the traditional butadiene production; besides, a secondary extraction can be canceled to greatly improve processing ability of the butadiene unit. Therefore, the method has high industrial application value.

Owner:CHINA PETROLEUM & CHEM CORP +1

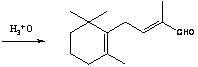

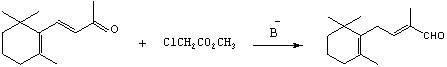

Preparation method of C-14 enol ether

InactiveCN102180774AThe reaction route is simpleRaw materials are easy to obtainEther preparationDimethyl methylphosphonateDiethyl methylphosphonate

The invention relates to a preparation method of C-14 enol ether. The C-14 enol ether is an intermediate of vitamin A, and the chemical name of the C-14 enol ether is 1-methoxy-2-methyl-4-(2,6,6-trimehtyl-1-cyclohexene-1-ly)-1,3-butadiene. The preparation method comprises the step of carrying out Wittig-Horner condensation reaction on beta-irisone as shown in a formula 4 and diethyl methylphosphonate as shown in a formula 8 at the temperature of minus 40-30 DEG C in an ether solvent or dipolar aprotic solvent in the presence of alkali so as to prepare the C-14 enol ether as shown in a formula7. According to the preparation method, reaction route is simple, and raw materials are simple and available.

Owner:SHAOXING UNIVERSITY

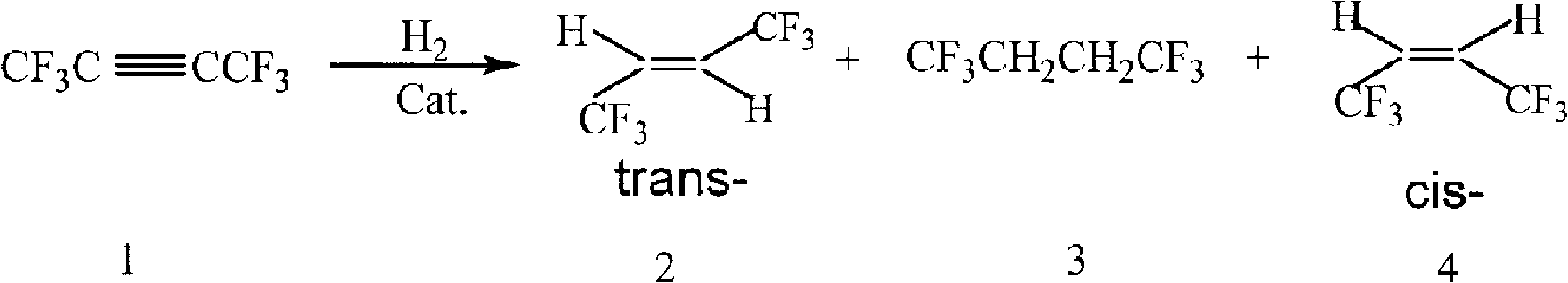

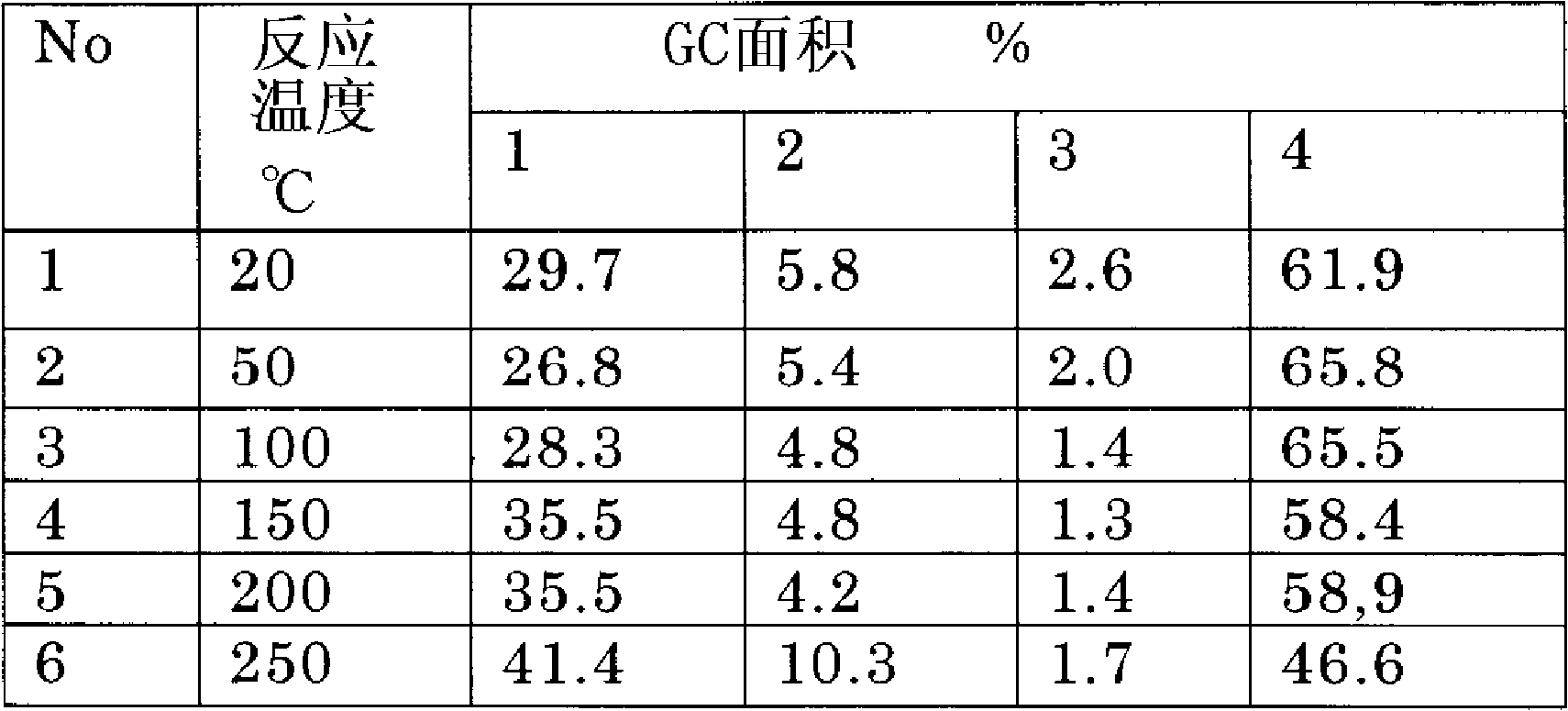

Method for producing fluorine compound

ActiveCN102933534AEfficient preparationOrganic chemistry methodsCatalyst regeneration/reactivationIsomerizationHydrogen

Provided is a method for producing 1,1,1,4,4,4-hexafluoro-2-butene that is efficient and appropriate for a flow-through reaction. Cis-1,1,1,4,4,4-hexafluoro-2-butene is obtained by isomerization of hexafluoro-1,3-butadiene using a catalyst and then continuous catalytic hydrogen reduction, and in addition cis-1,1,1,4,4,4-hexafluoro-2-butene can be obtained efficiently by carrying out all steps by means of a flow-through catalytic reaction.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Mixed manganese ferrite catalysts, method of preparing thereof and method of preparing 1,3-butadiene using thereof

ActiveCN101896267ASimple structureThe synthesis steps are simpleHeterogenous catalyst chemical elementsCatalystsHybrid typeHigh concentration

The present invention provides a method of producing a mixed manganese ferrite catalyst, and a method of preparing 1,3 -butadiene using the mixed manganese ferrite catalyst. Specifically, the present invention provides a method of producing a mixed manganese ferrite catalyst through a coprecipitation method which is performed at a temperature of 10 - 40 DEG C, and to a method of preparing 1,3 -butadiene using the mixed manganese ferrite catalyst through an oxidative dehydrogenation reaction, in which a C4 mixture containing n-butene, n-butane and other impurities is directly used as reactants without performing additional n-butane separation process or n-butene extraction. The present invention is advantageous in that 1,3-butadiene can be prepared directly using a C4 mixture including n-butane at a high concentration as a reactant through an oxidative hydrogenation reaction without performing an additional n-butane separation process, and 1,3-butadiene, having high activity, can be also obtained in high yield for a long period of time.

Owner:SK INNOVATION CO LTD +1

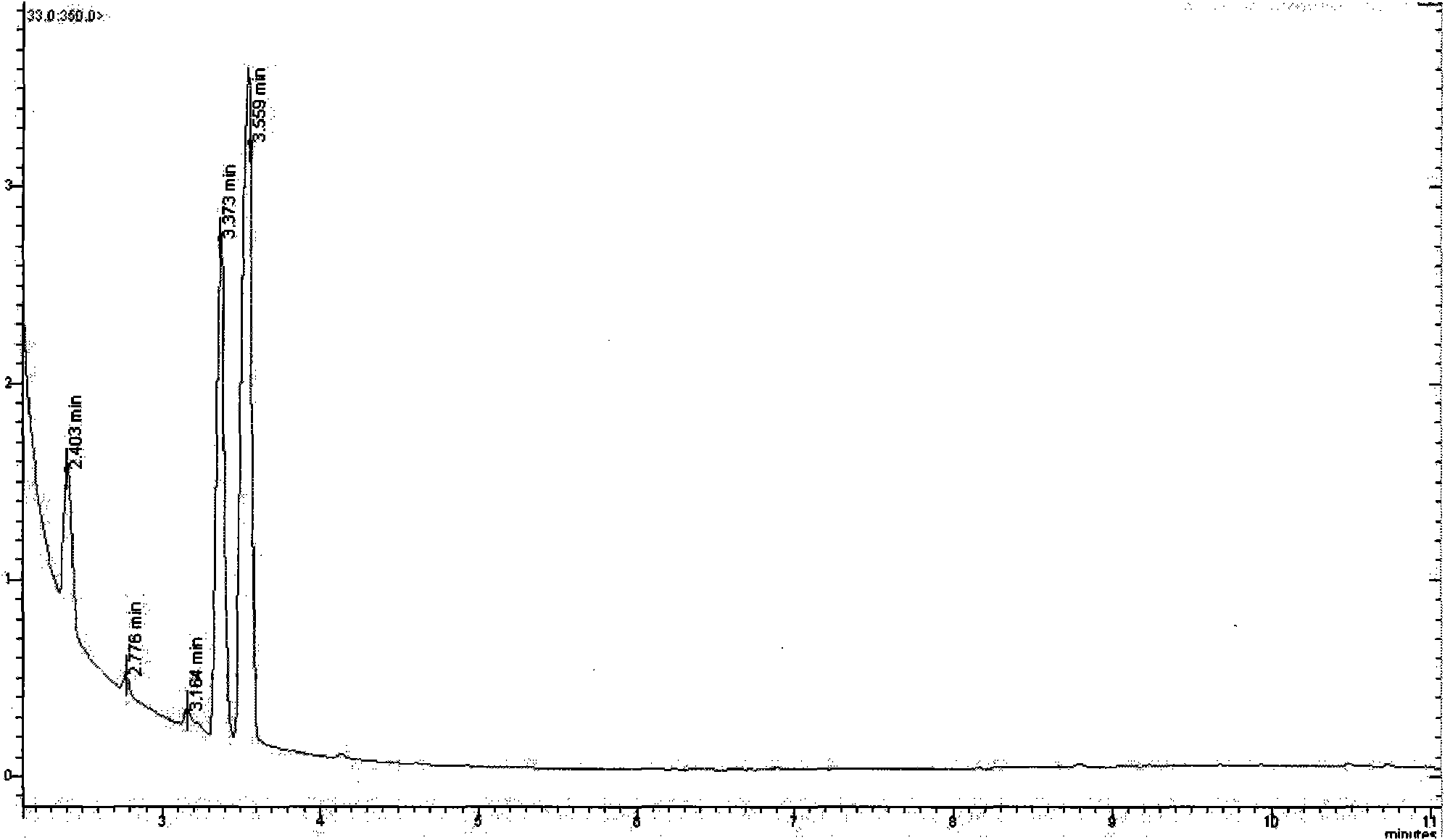

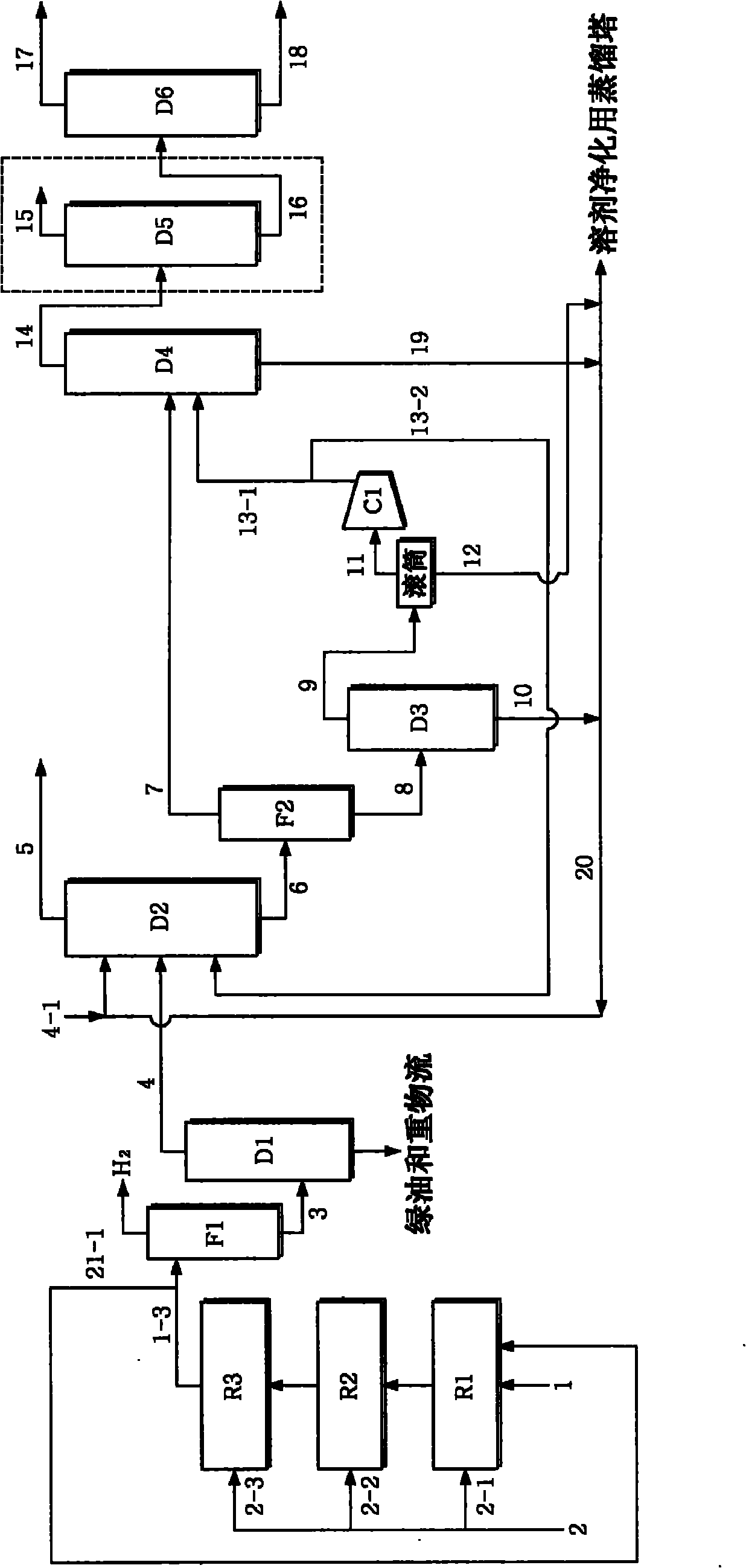

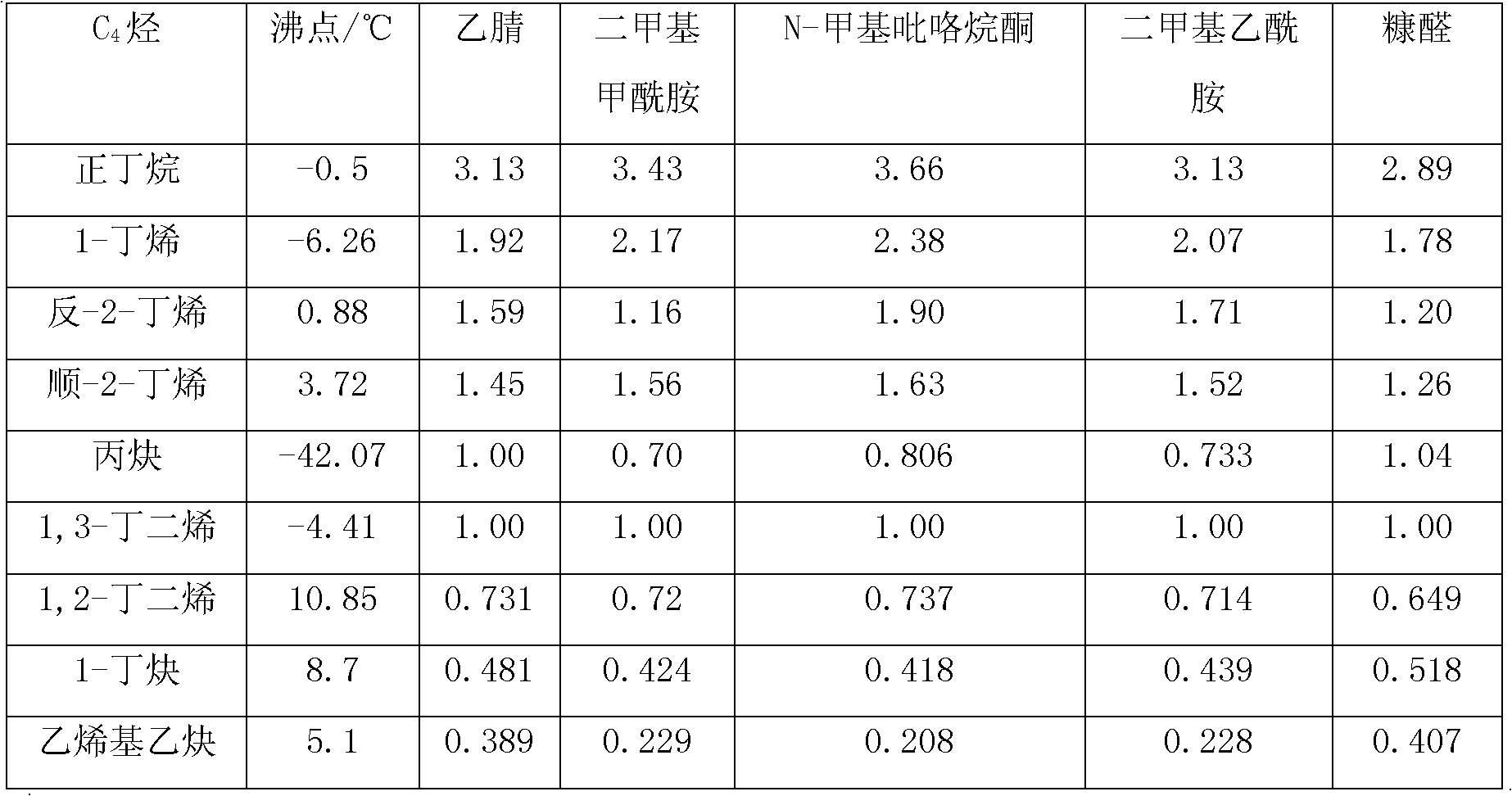

Process for 1,3-butadiene separation from crude C4 stream with acetylene converter

ActiveCN101821361AReduce accumulation timeReduce logistics lossDistillation purification/separationTreatment with hydrotreatment processesVinylacetyleneButene

Disclosed is a method of recovering 1,3 -butadiene from a C4 stream containing butane, isobutane, 2-butene, 1-butene, isobutene, butadiene and acetylene. The process of recovering highly pure 1,3 -butadiene includes acetylene conversion for selectively converting acetylene through liquid-phase hydrogenation, so that the acetylene content is decreased to 70 wt ppm or less, and 1,3 -butadiene extraction using an extractive distillation column, a pre-separator, a solvent stripping column, a solvent recovery column, and a purification column. Through the acetylene conversion, the concentration of vinylacetylene is decreased to 70 wt ppm or less, after which 1,3-butadiene is recovered using only one extractive distillation column, thereby considerably decreasing the degree of utility and the loss of streams in the course of extraction. The number of units necessary for the process is decreased, thus remarkably reducing the time during which impurities can accumulate in a processing unit.

Owner:SK INNOVATION CO LTD

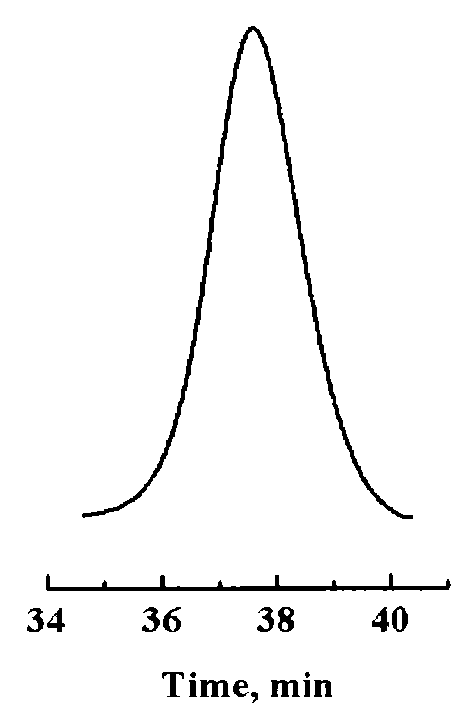

Method for preparing polybutadiene

The invention provides a method for preparing polybutadiene, which comprises: adding a 1,3-butadiene monomer and a catalyst into an alkane solvent in a molar ratio of 100-4,000:1 to perform polymerization to obtain reaction solution; and extracting polybutadiene from the reaction solution by using ethanol. A method for preparing the catalyst comprises: mixing a rare earth compound, butadiene, isoprene and alkylaluminium to perform a reaction to obtain a mixed solution; adding a chloride into the mixed solution to perform a reaction to obtain the catalyst. In the invention, the rare earth compound three-component homogeneous phase catalyst is used for catalyzing the reaction and part of the 1,3-butadiene monomer is pre-polymerized to serve as part of the catalyst, so an active center of the reaction is formed to stabilize polymerization; and by controlling the molar ratio of the 1,3-butadiene monomer to the catalyst, the polybutadiene with low molecular weight and narrow molecular weight distribution is prepared.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

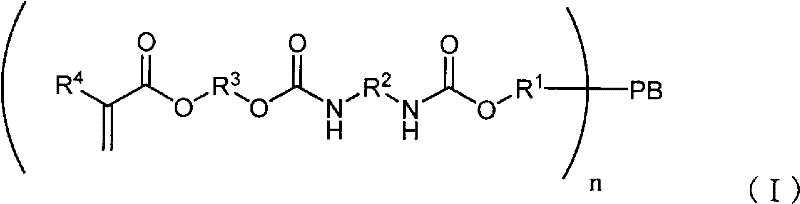

Rubber composition and pneumatic tire

InactiveUS20140187707A1Improve fuel economyImprove wet grip performanceSpecial tyresPolymer scienceNitrogen

Provided are: a rubber composition that improves fuel economy and wet grip performance together while maintaining the balance between them; and a pneumatic tire whose component (in particular tread) includes the rubber composition. The invention relates to a rubber composition containing: a rubber component containing a copolymer; silica; and a diene rubber gel bearing a hydroxyl group, wherein the copolymer is obtained by copolymerization of 1,3-butadiene, styrene, and a compound represented by formula (I) below, has an amino group at a first chain end and a functional group containing at least one atom selected from the group consisting of nitrogen, oxygen, and silicon at a second chain end, and has a weight average molecular weight of 1.0×105-2.5×106, and the diene rubber gel has a Tg of −40 to −10° C., and is present in an amount of 10-30 parts by mass per 100 parts by mass of the rubber component;

Owner:SUMITOMO RUBBER IND LTD

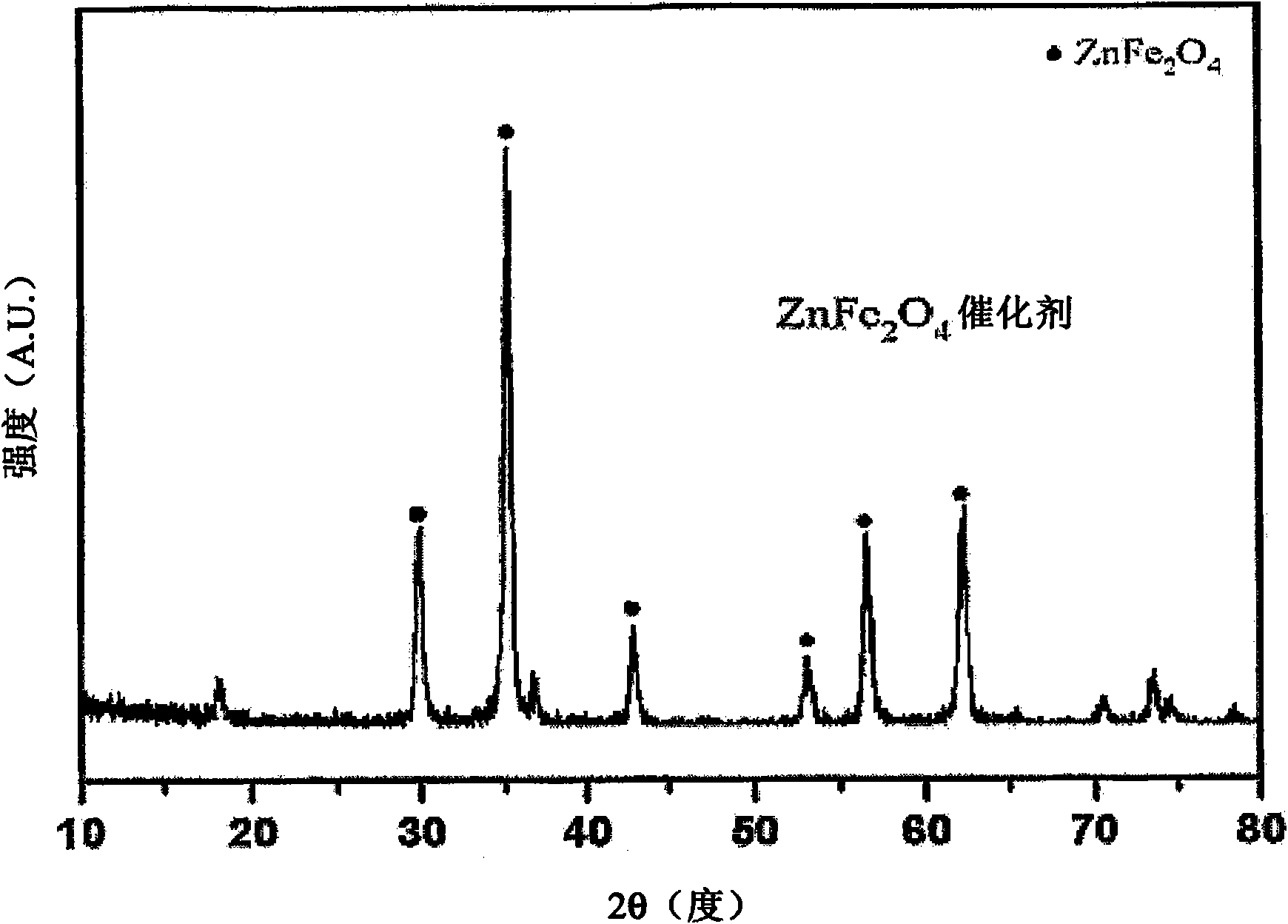

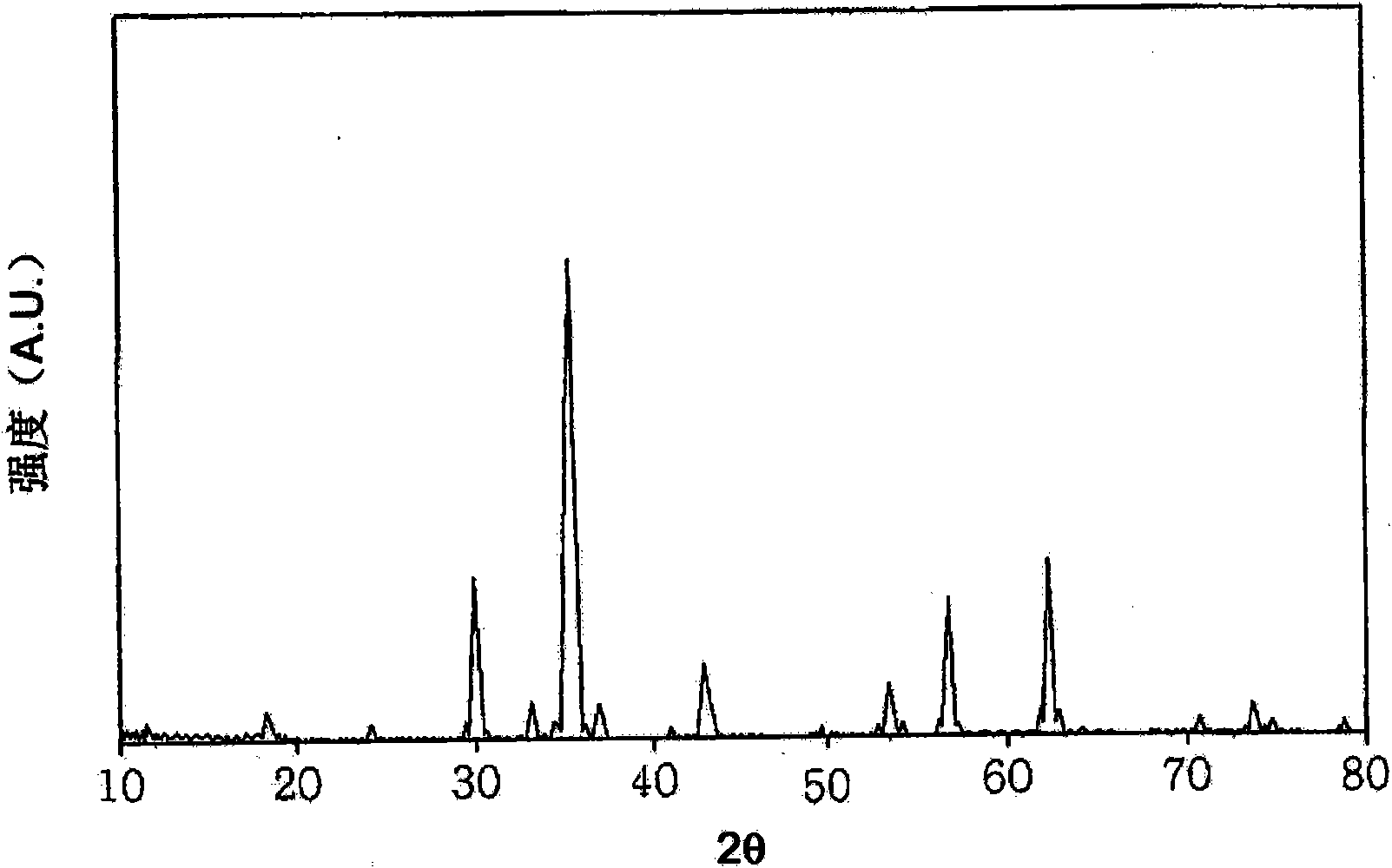

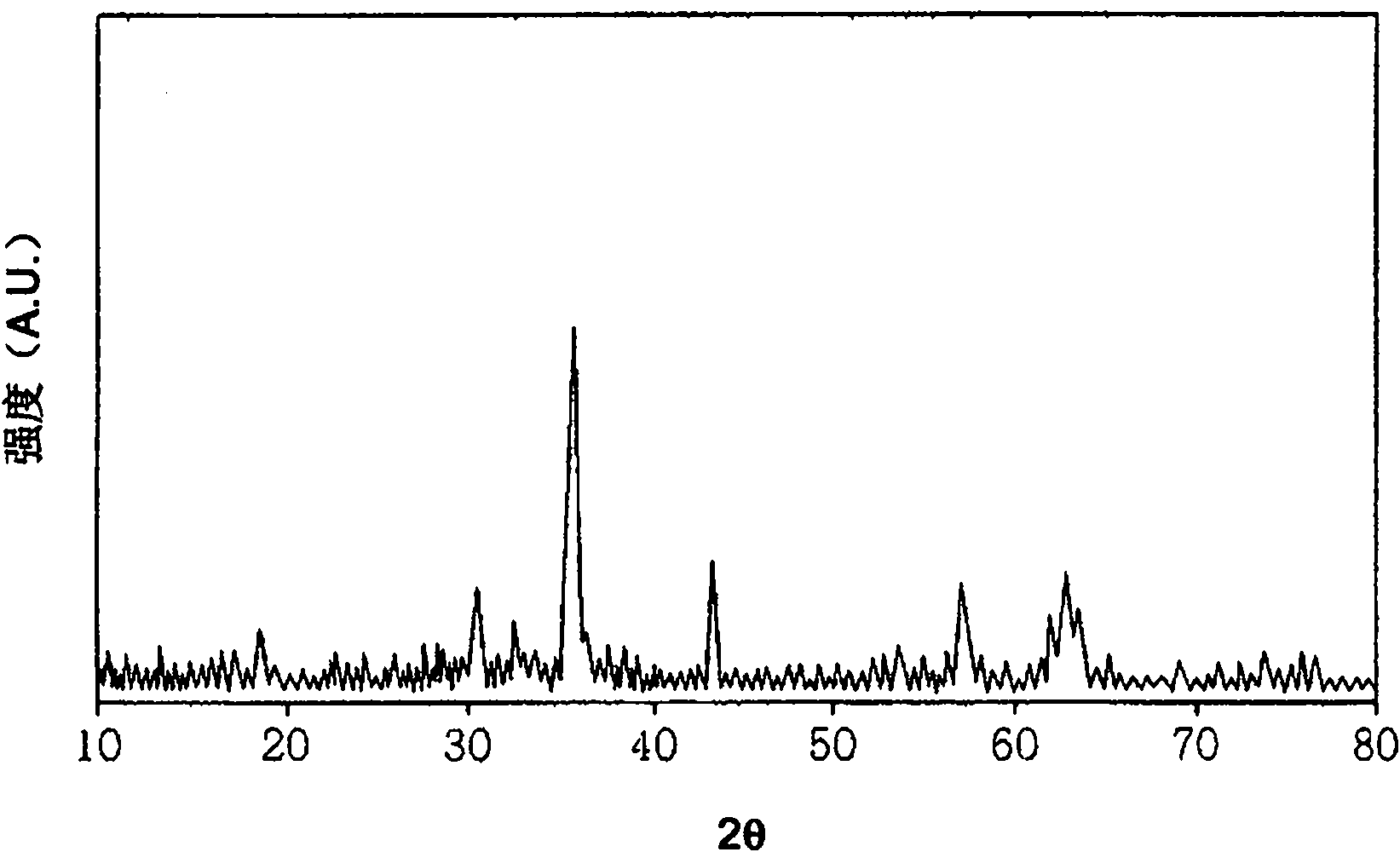

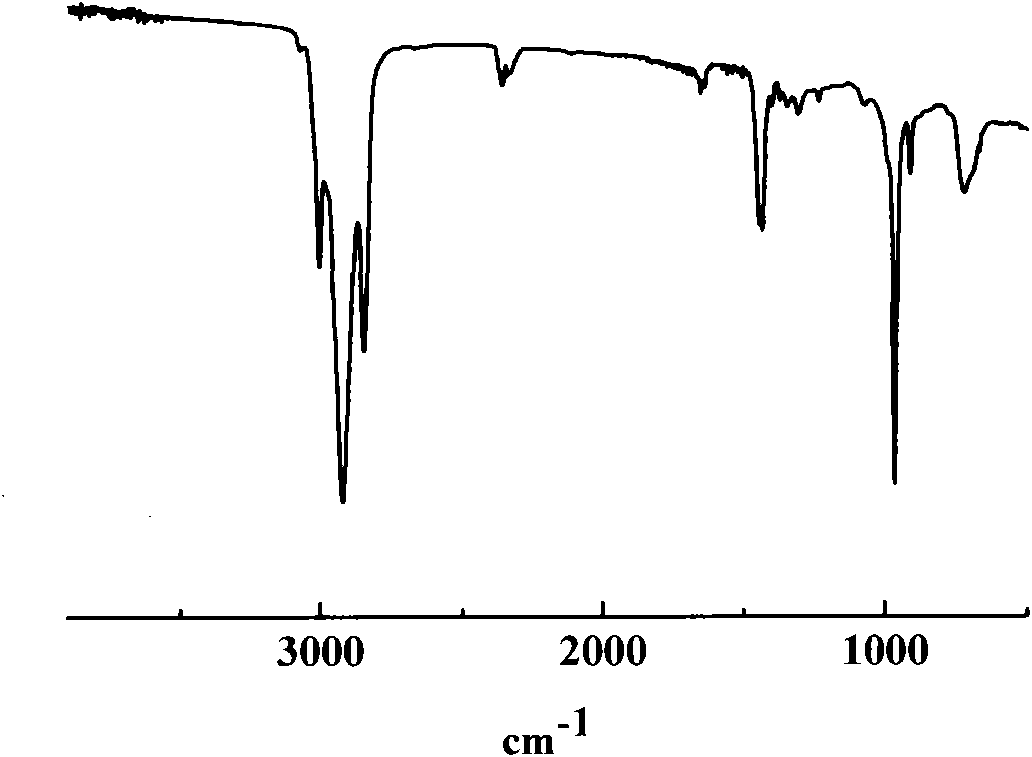

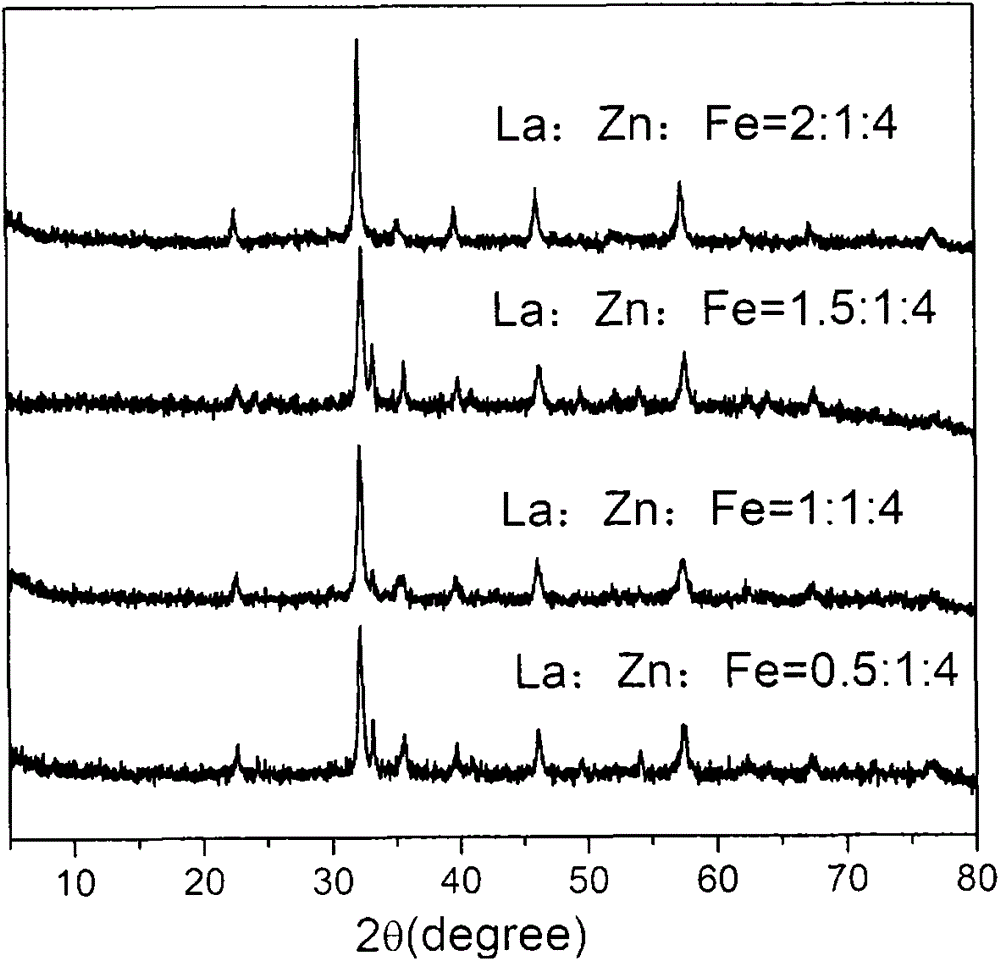

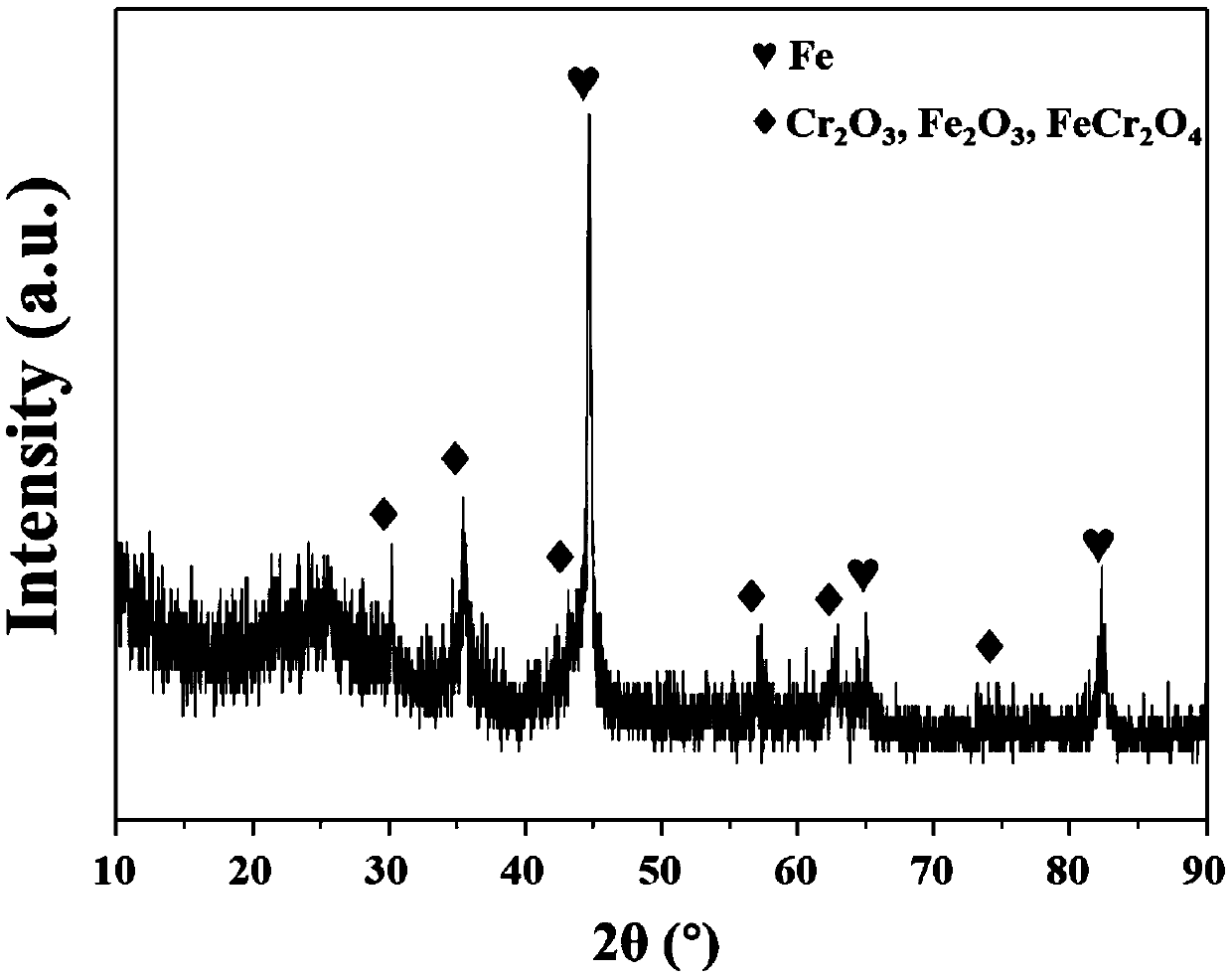

Method for preparing rare-earth modified zinc-iron composite oxide catalyst and application of catalyst in reaction of preparing butadiene from butene

ActiveCN103551157AEasy to synthesizeThe synthesis steps are simpleHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsButeneRare earth

The invention relates to a rare-earth modified zinc-iron composite oxide catalyst, a method for preparing the rare-earth modified zinc-iron composite oxide catalyst, and an application of the rare-earth modified zinc-iron composite oxide catalyst in preparing 1,3-butadiene. Specifically, the invention relates to the rare-earth modified zinc-iron composite oxide catalyst which is generated from an alkali solution by using a coprecipitation method, wherein the composite oxide catalyst is used for producing the 1,3-butadiene with high additional values by adopting the butene as a reactant. Due to adoption of the composite oxide catalyst, the yield of the 1,3-butadiene is higher than that of the conventional ferrate (ZnFe2)4), and the temperature for reaction is low.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Lithium separation material preparation method

ActiveCN105294922ANot easy to loseImprove adsorption capacityOther chemical processesMaterials preparationLithium

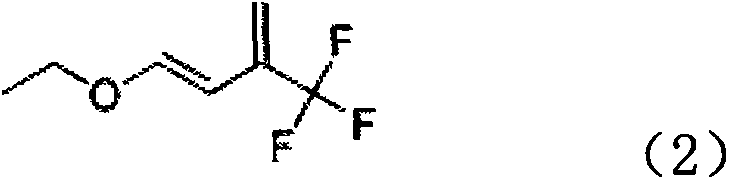

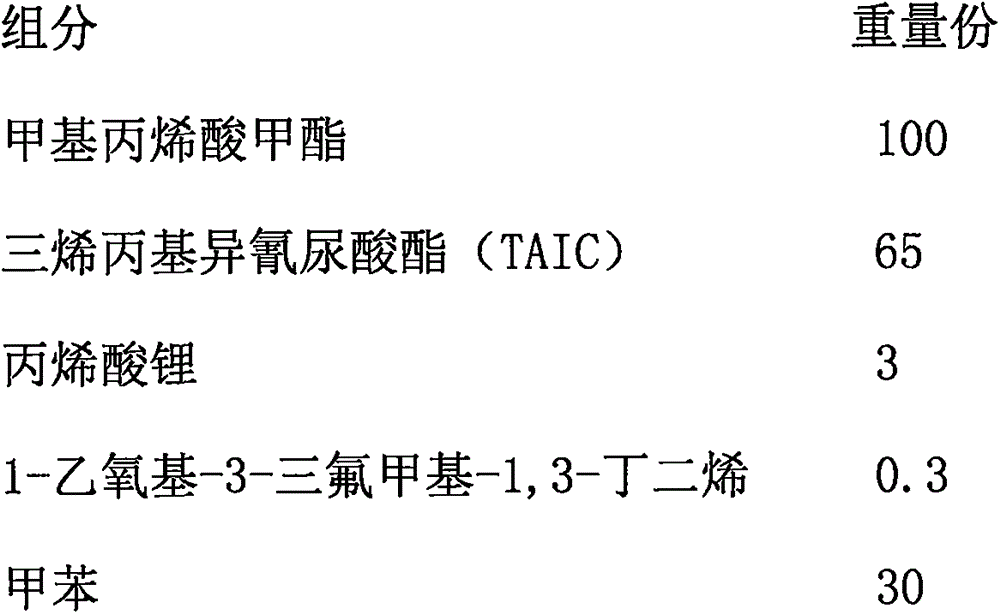

The invention provides a lithium separation material preparation method. According to the lithium separation material preparation method, small quantities of lithium acrylate and 1-ethoxy-3-trifluoromethyl-1,3-butadiene are introduced as a comonomer for polymerization, and a lithium ion is combined into the framework of acrylic resin in a chemical bond mode to be combined with diene and triene groups, so that the probability of loss is low and the adsorbability of a lithium separation material can be improved.

Owner:浙江迪特西科技有限公司

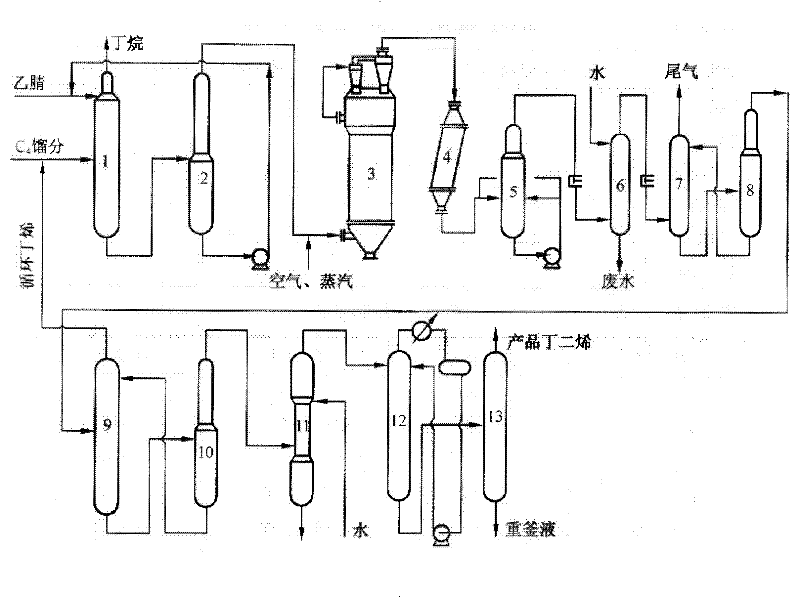

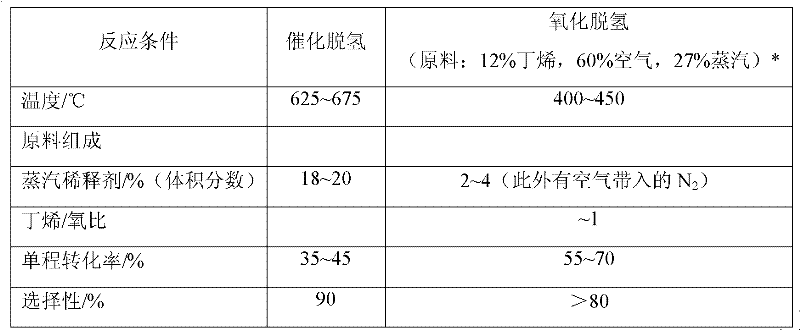

Production method for producing 1,3-butadiene by performing oxidative dehydrogenation on butylene

InactiveCN102391062AControl oxygen contentHydrocarbonsHydrocarbon preparationDehydrogenationAntimony

The invention discloses a process flow for producing 1,3-butadiene by performing oxidative dehydrogenation on butylene. A major secondary reaction in the butylene oxidative dehydrogenation process is a deep oxidation reaction of butylene and 1,3-butadiene serving as a product thereof, and carbon monoxide, carbon dioxide and oxygen-containing compounds such as aldehyde, copper, acid and the like are mainly generated in the reaction. A catalyst industrially used in the oxidative dehydrogenation process of butylene consists of bismuth molybdate, multi-component molybdate, oxides of tin and antimony, tin and phosphorus and the like, and ferrite, ferric chromate and the like. In the process, an appropriate oxygen / butylene ratio is controlled, the oxygen content of tail gas is controlled, and the residual oxygen in a reactant is 0.3-0.5 percent (volume fraction). The production method is one of the best methods for preparing high-purity 1,3-butadiene.

Owner:天津东方宜信物流有限公司

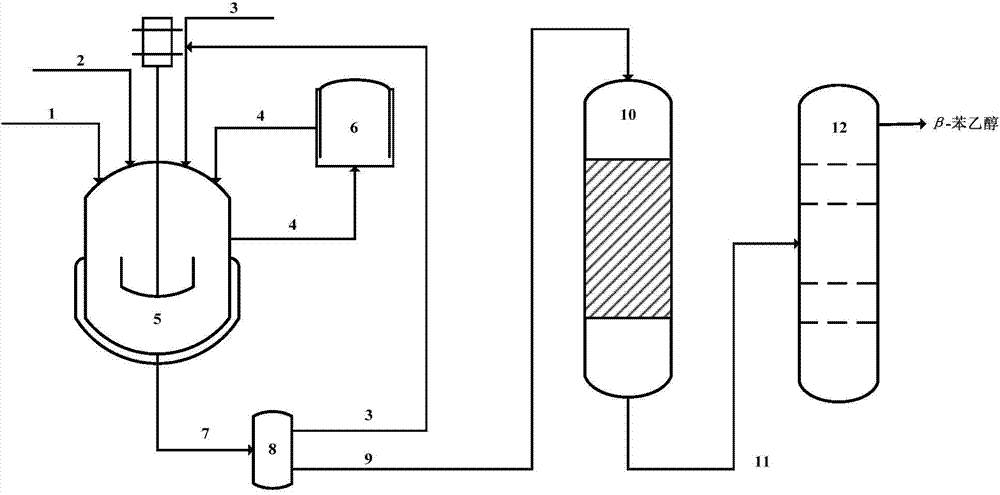

Method for preparing beta-phenethyl alcohol

ActiveCN104744216AGuaranteed water solubilityGood water solubilityOrganic compound preparationHydroxy compound preparationDehydrogenationPhenethyl alcohol

The invention discloses a method for preparing beta-phenethyl alcohol. According to the method, acetic acid-3-butene-1-alcohol ester and 1,3-butadiene are adopted as raw materials, and the preparation of beta-phenethyl is finished by adopting Diels-Alder, hydrolysis and dehydrogenation reactions. lewis acid supported by fullerol as a carrier is adopted as the catalyst for the Diels-Alder reaction, the atom utilization rate is high, the total yield can reach 87%-95%, the purity of products can reach 99.92wt%-99.98wt%, and an oxidation reaction process and a high-pressure hydrotreatment reaction process are not adopted, so that the production process is safe and environmentally friendly.

Owner:WANHUA CHEM GRP CO LTD

Insoluble sulfur efficient stabilizer and preparation method thereof

The invention discloses an insoluble sulfur efficient stabilizer and a preparation method thereof, and belongs to the field of fine chemicals and advanced materials. The chemical structural formula of the efficient stabilizer is as follows. The insoluble sulfur efficient stabilizer is made of raw materials of alkyl sodium xanthate and 2-chloromethyl-1, 3-butadiene or benzyl chloride. The insoluble sulfur efficient stabilizer can be used in polymerization, sharp quenching, extraction, oil charge and other links of production of insoluble sulfur, and can obviously improve stability of the insoluble sulfur.

Owner:WUXI HUASHENG RUBBER TECHN

Utilization method of waste gas discharged from butadiene extracting apparatus

ActiveCN102336626AImprove securityAchieve boostSolidificationLiquefactionHydrogenation reactionAlkyne

The invention discloses a utilization method of waste gas discharged from a butadiene extracting apparatus. According to the method, waste gas is subject to a reaction with hydrogen; alkyne in the waste gas is subject to a selective hydrogenation reaction, such that diolefins is produced; the reaction product is delivered back to the butadiene extracting apparatus, and 1,3-butadiene can be recovered. According to the invention, a compressor technology and a cold box technology are adopted, such that a problem of butadiene tail gas utilization difficulty is solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

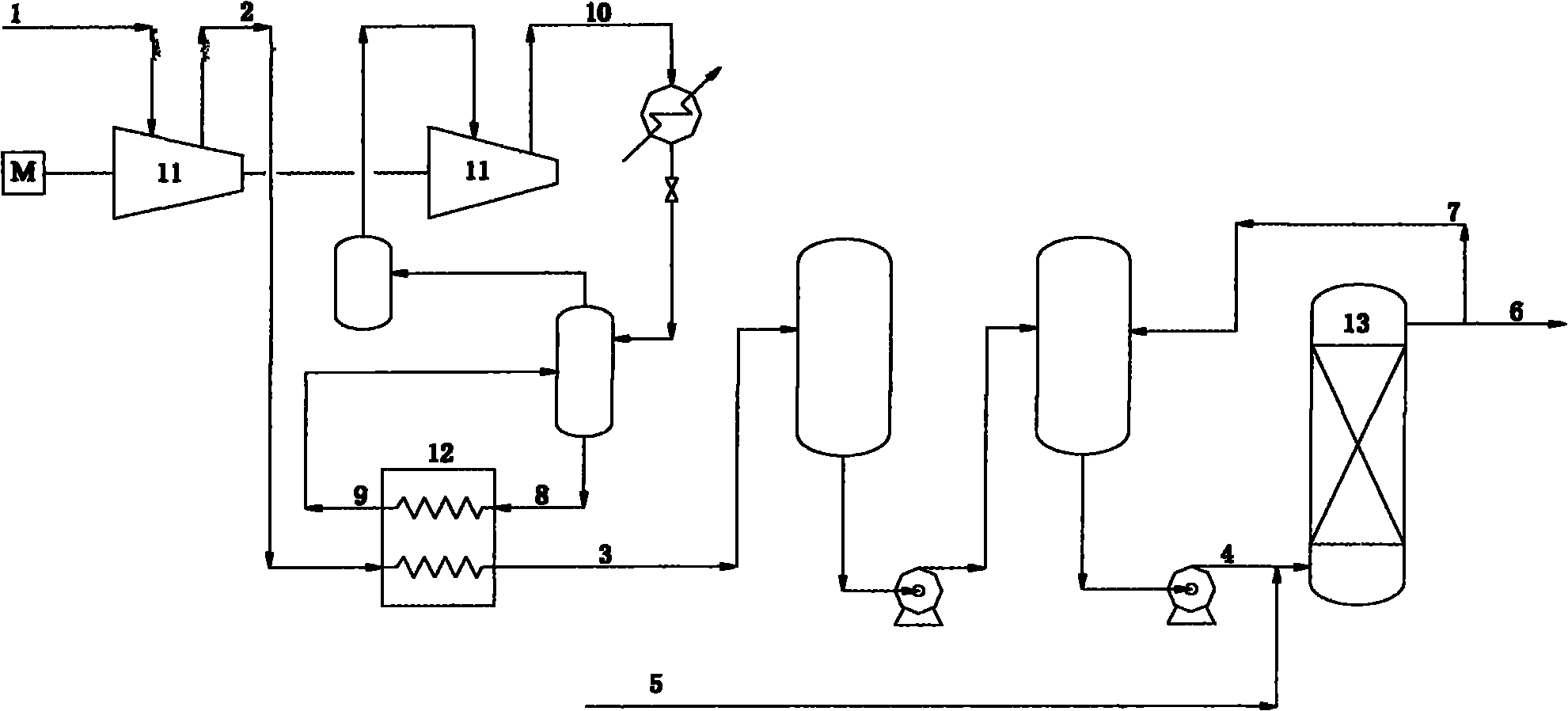

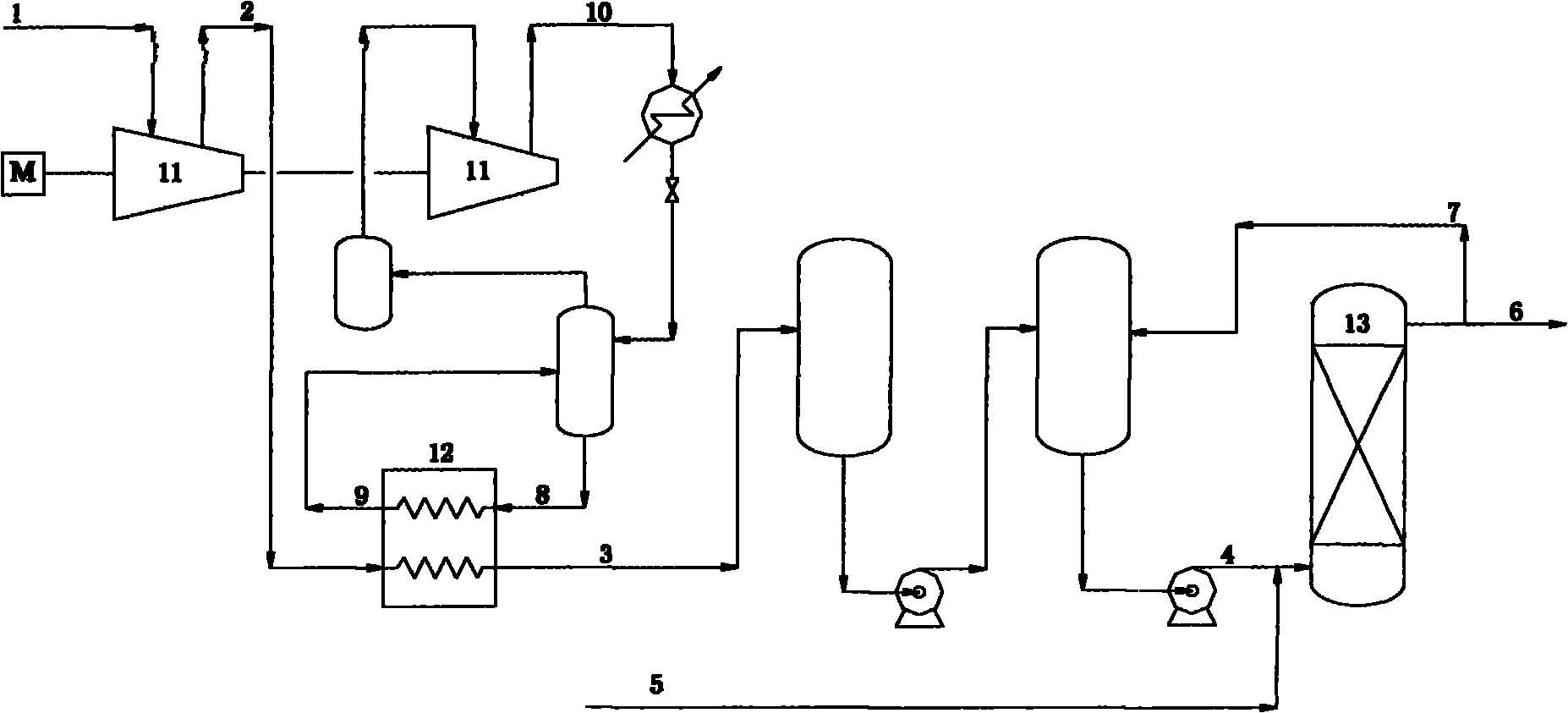

Method for extracting high-purity 1,3-butadiene by using N-methylpyrrolidone

InactiveCN102329185AImprove solubilityGood choiceDistillation purification/separationExtractive distillation1,3-Butadiene

The invention discloses a technological process for separating and refining high-purity 1,3-butadiene by an N-methylpyrrolidone extractive distillation method. The invention is characterized in that N-methylpyrrolidone containing a small amount of water is used as a solvent to carry out absorption twice and rectification twice, thereby obtaining the polymer-grade 1,3-butadiene. The yield of the product 1,3-butadiene is up to 98.5%, the purity is 99.8-99.9%, and the alkyne content is lower than 50 mu g / g. The method disclosed by the invention has the advantages of reasonable technique and simpleness, and is an ideal technology for purifying 1,3-butadiene.

Owner:天津东方宜信物流有限公司

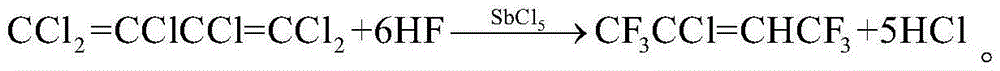

Method of gas phase synthesis of 1,1,1,4,4,4-hexafluoropropylene-2-chlorine-2-butene

The invention discloses a method of gas phase synthesis of 1,1,1,4,4,4-hexafluoropropylene-2-chlorine-2-butene. Gas-phase hexachloro-1,3-butadiene and gas-phase hydrofluoric acid serve as main materials, under the action of one or more mixtures of catalysts of AlF3, CrF3, ZnF2, SbF3 and SbF5, the gas-phase hexachloro-1,3-butadiene and the gas-phase hydrofluoric acid are introduced into a gas-phase reactor made of 316L stainless steel, continuous gaseous phase fluorination is conducted, the reaction temperature is controlled to range from 220 DEG C to 820 DEG C, the retention time of a reaction ranges from 0.1 s to 10 s, the molar ratio of hexachloro-1,3-butadiene to the hydrofluoric acid is 1 to 6-14, and a target product 1,1,1,4,4,4-hexafluoropropylene-2-chlorine-2-butene is obtained by conducting cooling, purification and rectification on a product obtained through a reaction. The method of the gas phase synthesis of the 1,1,1,4,4,4-hexafluoropropylene-2-chlorine-2-butene has the advantages of being simple in process, low in cost, high in yield, capable of achieving continuous production, suitable for industrial production and the like.

Owner:JUHUA GROUP TECH CENT

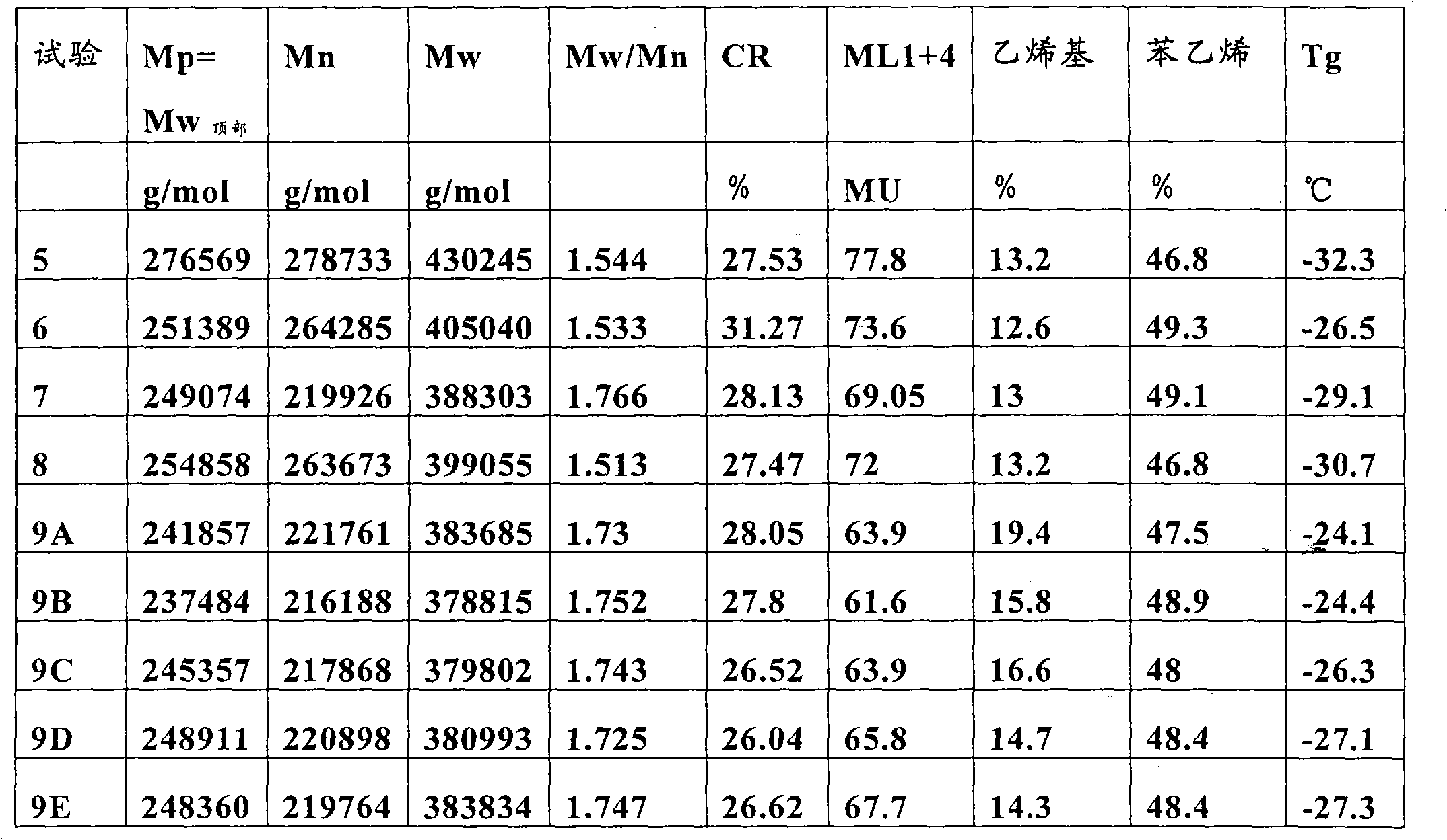

Styrene-butadiene polymers with styrene gradient and methods of making same

The invention provides a process for polymerizing a polymer comprising monomeric units derived from styrene and 1,3-butadiene, said process comprising: A) adding less than 60 weight percent of the total amount of the butadiene used in the polymerization, to a reactor comprising the total amount of styrene used in the polymerization and solvent; B) adding at least one initiator to the reactor, and allowing the reaction to proceed for a time t; and C) adding the remaining amount of butadiene to the reactor in two or more separate additions; and wherein for each butadiene addition, the amount of subsequent butadiene added is less than, or equal to, the amount of butadiene added in the immediately prior addition; and wherein for each butadiene addition, the butadiene is added over a time, tnc, and after each addition, the reaction is allowed to proceed for a time, tnr, wherein n is the number of the butadiene addition, and for each addition, n is independently greater than, or equal to, 1.

Owner:TRINSEO EURO GMBH

Method for producing N-methyl-N-vinylacetamide having improved stability and polymerizability

InactiveCN101910117AEasy to inhibit polymerizationStable and stableOrganic compound preparationCarboxylic acid amide separation/purificationN-methylacetamide1,3-Butadiene

Owner:RESONAC HOLDINGS CORPORATION

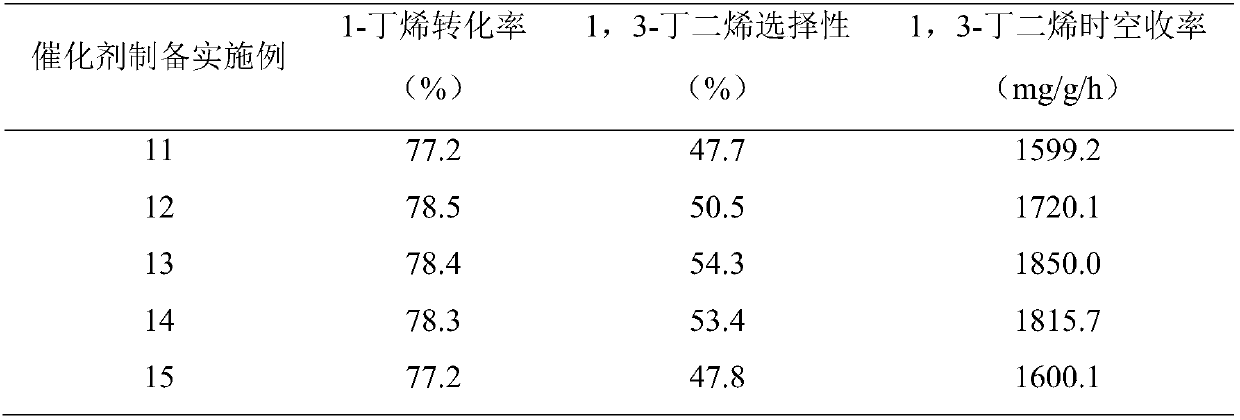

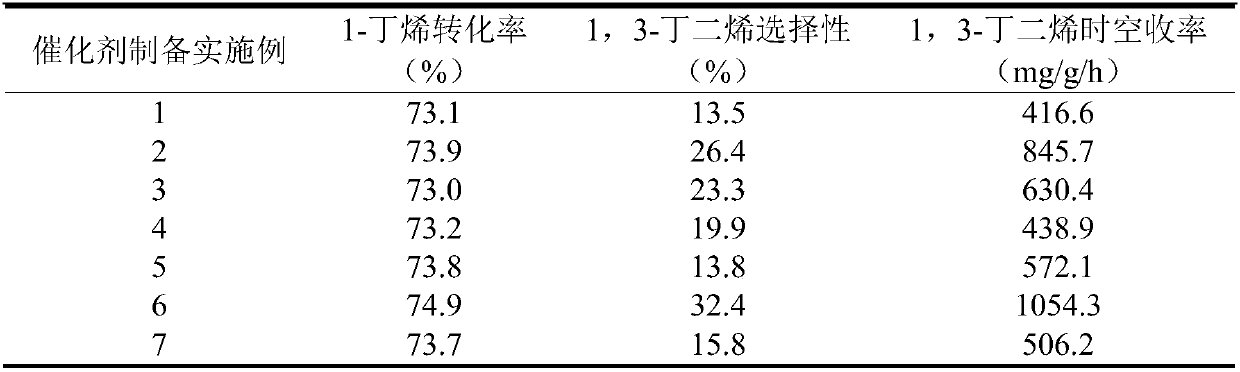

High-efficiency catalyst for preparing 1,3-butadiene by using carbon dioxide to oxidize 1-butene to dehydrogenate and preparation method thereof

ActiveCN109647400AHigh selectivityImprove stabilityCatalystsHydrocarbon preparation catalystsOxygenElectron

The invention discloses a high-efficiency catalyst for preparing 1,3-butadiene by using carbon dioxide to oxidize 1-butene to dehydrogenate and a preparation method thereof, a carrier and an oxidizingacid are mixed for heating and stirring to obtain a mixture, the mixture is washed with deionized water to be neutral, and dried to obtain a granular sample, the granular sample is mixed with a soluble ferric salt, one or two same-period metal soluble salt and an alkali metal salt, deionized water is added to uniformly disperse, heating is performed to remove water to obtain a granular sample, heat preservation roasting is performed on the granular sample at 500-600 DEG c, and the granular sample is naturally cooled to room temperature. Compared with the prior art, activated carbon is adoptedas a catalyst carrier to prepare an iron-based catalyst, due to the fact that the activated carbon is large in specific surface area, rich in pore channels, and good in conductivity, and has rich andadjustable oxygen-containing groups on the surface, compared with a traditional aluminum oxide supported iron-based catalyst, active component iron oxide can be effectively dispersed, agglomeration and sintering of the active component can be avoided, the transmission capacity of electrons in the catalyst can be improved, so that the activity, the selectivity and the stability of the catalyst areimproved.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for catalyzing selective hydrogenation of 1,3-butadiene with PdAgNi/N-C catalyst

ActiveCN108786879AHigh activityImprove stabilityHydrocarbon by hydrogenationHeterogenous catalyst chemical elementsButadiene DioxideHydrogenation reaction

The invention discloses a method for catalyzing selective hydrogenation of 1,3-butadiene with a PdAgNi / N-C catalyst. The method is characterized by comprising the following steps: firstly, putting a PdAgNi / N-C catalyst into a tubular reactor, increasing the temperature of a catalyst bed layer to 30-60 DEG C, further introducing a mixed gas of 1,3-butadiene and hydrogen into the reactor, and carrying out a reaction at pressure of 1.5-3.2MPa and an air speed of 1.0-4.0hour<-1>. By adopting the method, PdAgNi / N-C is adopted as a catalyst, selective hydrogenation of 1,3-butadiene is carried out with the catalyst, the content of 1,3-butadiene in a product is less than 900ppb, the content of butane is less than 2.3%, and high catalysis activity can be still maintained after the catalyst is continuous operated for 100 hours.

Owner:安徽工大化工科技有限公司

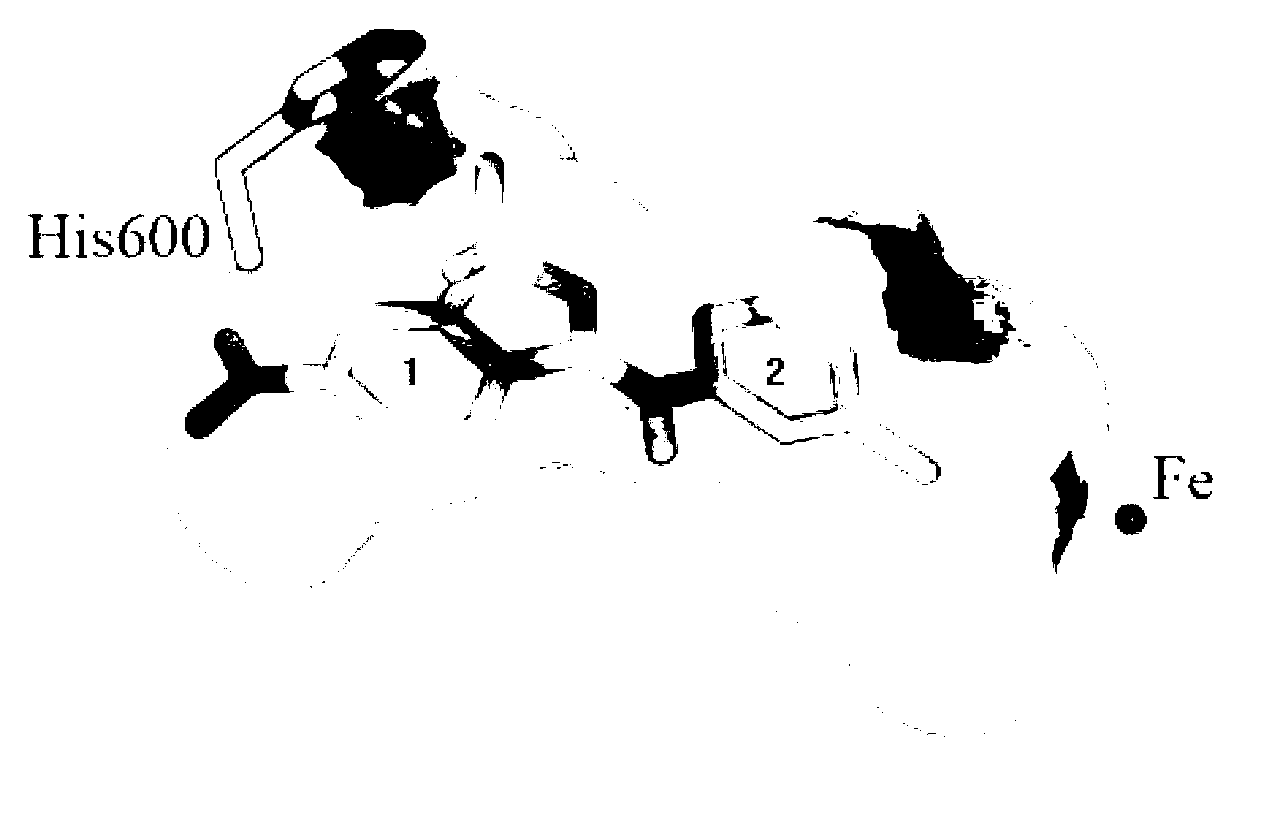

Catalyst composition for preparing 1,2-polybutadiene, and preparation method for 1,2-polybutadiene

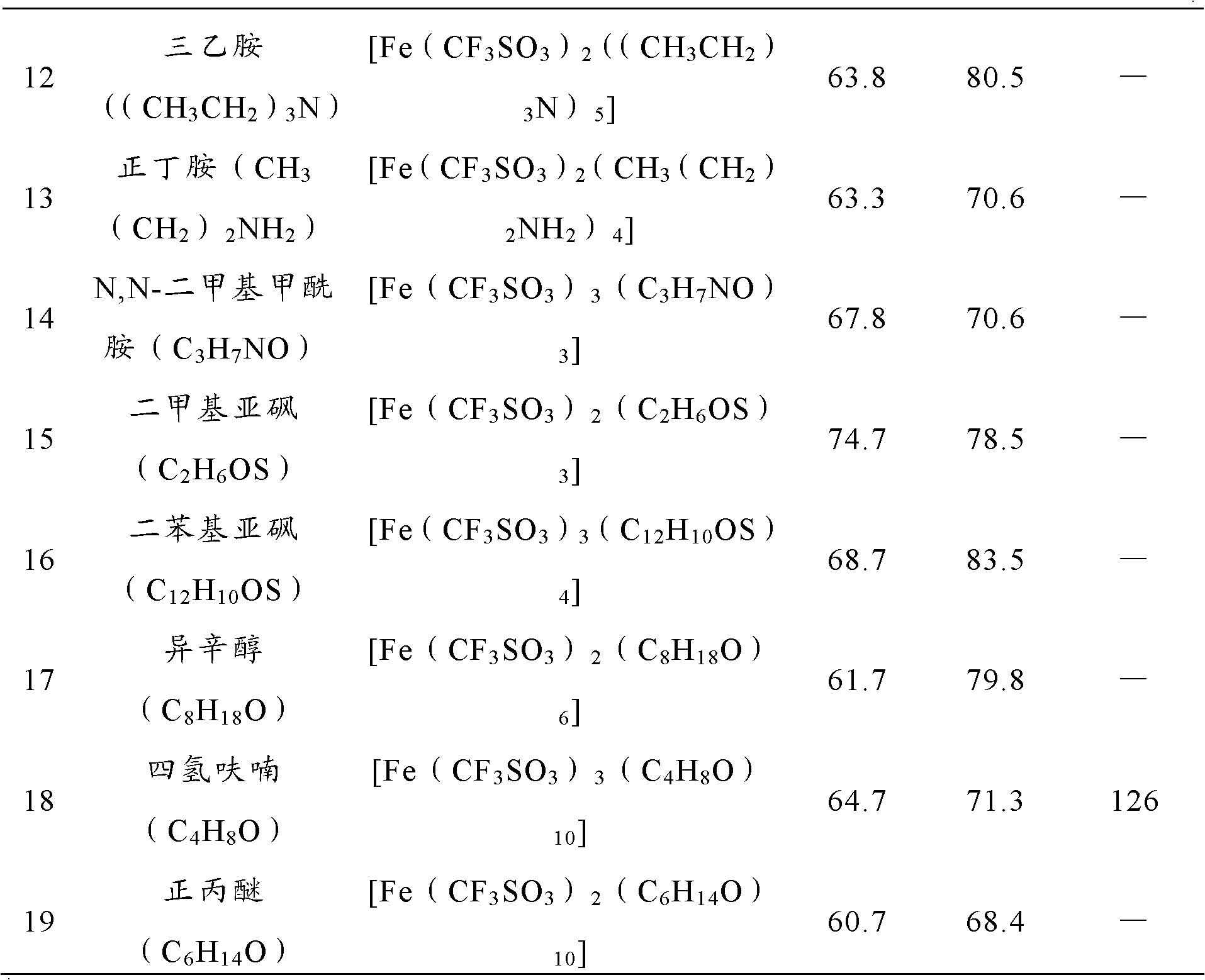

The invention provides a catalyst composition for preparing 1,2-polybutadiene. The catalyst composition comprises alkyl aluminum, and iron complex with the chemical formula shown as a formula (I): [Fe(CF3SO3)x(L)y], wherein L is ligand which is a phosphorus compound, a nitrogenous compound, a sulfur compound, or an oxygen compound; x is 2 or 3; and y is more than or equal to 1 and less than or equal to 10. The catalyst composition has high catalytic activity at high temperature, has a wide application temperature range, and can be produced industrially. The invention also provides a preparation method for the 1,2-polybutadiene. The preparation method comprises the following steps of: performing polymerization on 1,3-butadiene in an organic solvent under the action of the catalyst composition for preparing the 1,2-polybutadiene to obtain the 1,2-polybutadiene. A small amount of the catalyst composition is adopted in the preparation method, a preparation process is stable, a reaction condition is mild, and the method is easy to operate and low in production cost.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

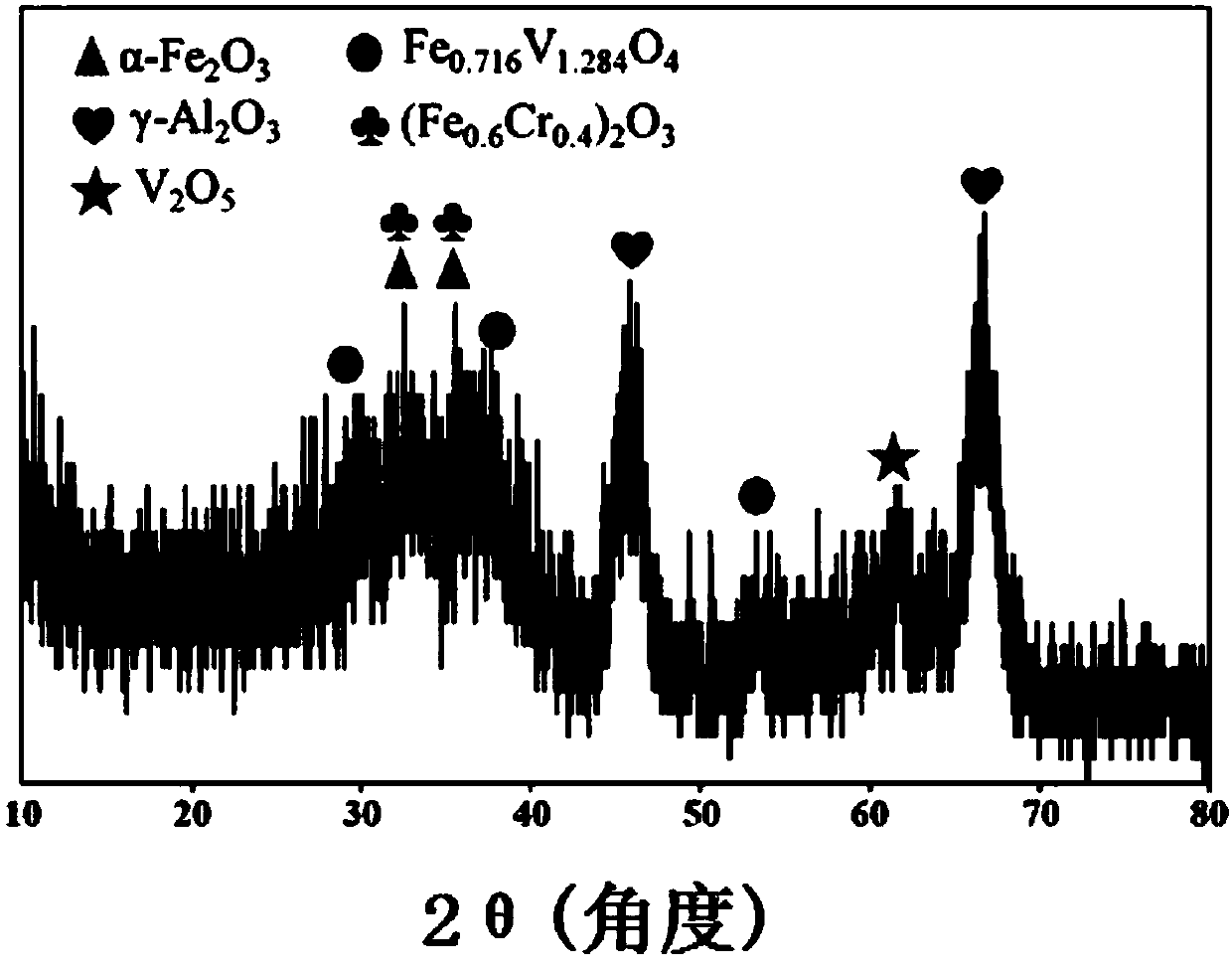

High-efficiency catalyst for preparing 1,3-butadiene by using carbon dioxide to oxidize 1-butene to dehydrogenate and preparation method thereof

ActiveCN109647402AImprove liquidityHigh activityHeterogenous catalyst chemical elementsCatalystsLattice oxygenEfficient catalyst

The invention discloses a high-efficiency catalyst for preparing 1,3-butadiene by using carbon dioxide to oxidize 1-butene to dehydrogenate and a preparation method thereof, wherein the catalyst consists of a carrier and an active component, a compound oxide of metal iron and a doping element is taken as the active component, and a precipitation roasting mode is adopted for preparation. The catalyst disclosed by the invention can be used for preparing for preparing 1,3-butadiene by using carbon dioxide to oxidize 1-butene to dehydrogenate, and is high in activity, good in selectivity, good instability and low in preparation cost, and the preparation method is simple in process. Compared with a traditional aluminum oxide loaded iron oxide catalyst, the crystal lattice oxygen fluidity and the crystal lattice oxygen content of the catalyst can be effectively improved, so that the activity and the stability of the catalyst are improved.

Owner:TIANJIN UNIV OF SCI & TECH

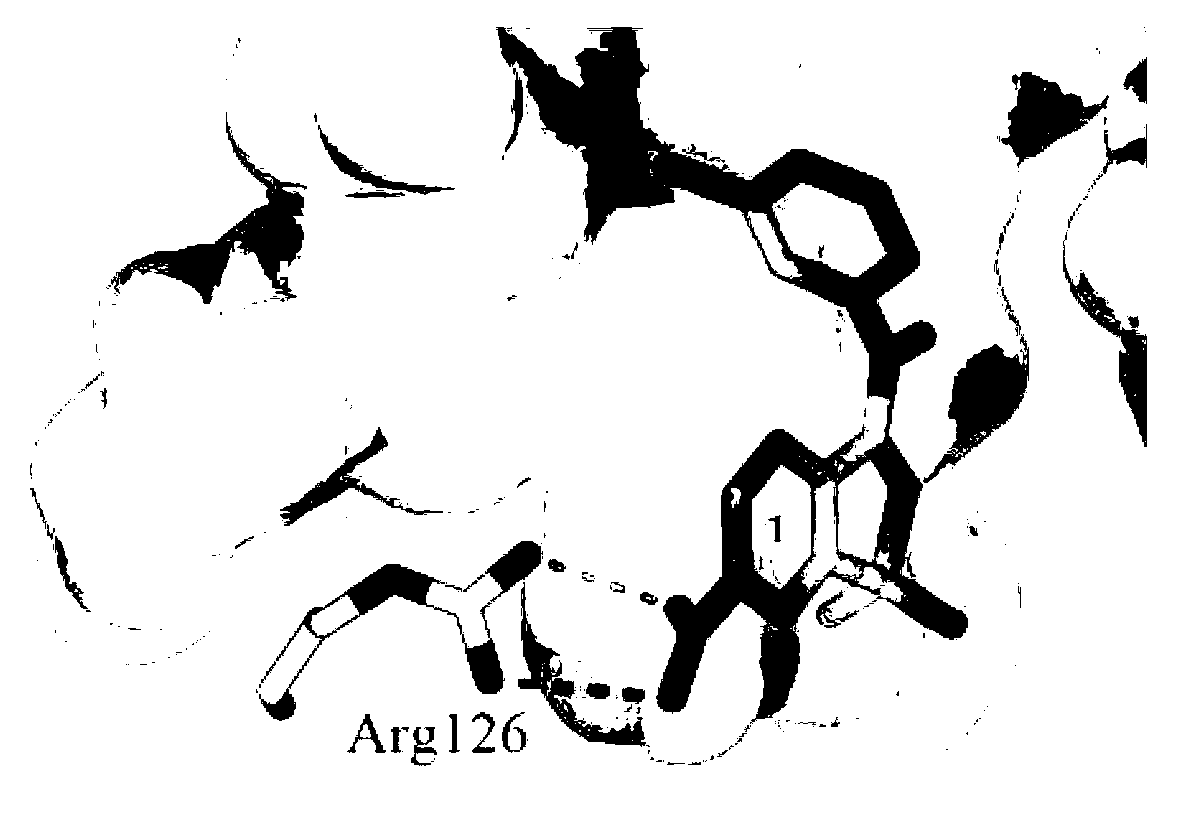

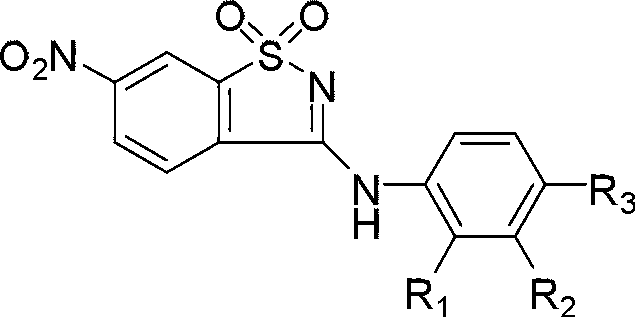

Benzisoxa thiazoles 5-LOX and mPGES-1 inhibitor and application

The invention discloses a benzisoxa thiazole compound which is used as a double-function inhibitor of 5-lipoxygenase (5-LOX) and prostaglandin E synthetase (mPGES-1), and the compound has the structure shown in the formula IV, wherein, R1, R2 and R3 represent hydrogen, alkyl, alkyloxy or halogen respectively, or R2 and R1 or R3 form a ring, thereby representing 1, 3-butadiene subunit. The external and whole blood enzyme activity test of the compound for 5-LOX and mPGES-1 confirms that the compound has the double-function inhibition activity for 5-lipoxygenase and prostaglandin E synthetase, and can be used for preparing medicaments for treating and preventing various inflammations.

Owner:PEKING UNIV

Method for preparing syndiotactic poly1,2-butadiene thermoplastic elastomer

The invention relates to a method for preparing a syndiotactic poly1,2-butadiene thermoplastic elastomer, which comprises the following steps: initiating the polymerization of 1,3-butadiene monomer in hexane solution of a synthetic rubber through the addition of 1,2-configurational units by using iron catalysts to form a uniform blend of 1,2-butadiene and synthetic rubber, wherein the catalysts comprise iron isooctanoate or iron naphthenate, diethyl phosphate, triisobutyl aluminium and aluminium triethyl; the adding sequence of the catalysts is that any components are combined or two aluminum alkyls are mixed first and then combined with the other two components optionally; in a polymerization system, every 1,000 millilitres of hexane solution contains 90 to 140 grams of 1,3-butadiene monomer, and the adding amount of the rubber is 0.1 to 25 grams; and the polymerization initiating temperature is 60 to 90 DEG C. The blend has the properties of the typical thermoplastic elastomers and can be used for modifying thin films, shoe soles, tubular materials, rubbers and plastics.

Owner:PETROCHINA CO LTD

Process for preparing nickel series low mooney viscosity high cis-1, 4,-polybutadiene rubber

InactiveCN1196723CHigh tensile strengthDoes not affect conversion ratePolymer scienceMooney viscosity

The preparation process of nickel-based low Mooney high-cis 1,4-polybutadiene rubber is a solution polymerization reaction of 1,3-butadiene in a polymerization solvent, and the catalyst is a nickel-based catalyst. The nickel-based The catalyst is a Ni-Al-B three-way catalyst. The main technical feature is to add a molecular weight regulator D in the polymerization system. D can be a hydroxyl-containing compound or an olefin. By adjusting its addition amount and adjusting the Al / B ratio Prepare a low Mooney butadiene rubber with a Mooney viscosity of 25 to 40. At the same time, add a coupling agent C to the polymerization system. C is a divinyl compound, so that the prepared low Mooney butadiene rubber maintains a high tensile strength. It achieves the same strength as butadiene rubber with a Mooney viscosity of 40-50, and has a lower gel content, less than 0.5%.

Owner:CHINA PETROLEUM & CHEM CORP

Method for producing polybutadiene

ActiveCN102549023AImprove use valueIncreased tensile shear forcePhotomechanical apparatusConjugated diene hydrocarbon adhesivesBoiling pointReaction temperature

In the disclosed method for producing polybutadiene by means of anionic polymerization at a low temperature, polybutadiene having diverse physical properties is produced by means of controlling the microstructure thereof. The method for producing polybutadiene by means of anionic polymerization from 1,3-butadiene under the presence of a polymerization initiator and under reaction temperature conditions no higher than the boiling point of butadiene is characterized by being performed under the presence of a potassium salt in an aprotic polar solvent or a mixed solvent of an aprotic polar solvent and a nonpolar solvent. The potassium salt is preferably potassium t-butoxide, and the solvent is preferably a mixed solvent of tetrahydrofuran and hexane. The polybutadiene obtained thereby can be used in an adhesive composition and in a plate production material composition used in flexographic printing plates.

Owner:NIPPON SODA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com