Method for preparing polybutadiene

A technology for polybutadiene and butadiene is applied in the field of preparation of polybutadiene, and can solve the problems of inapplicability of low molecular weight polybutadiene, low efficiency and low efficiency of lithium-based catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a preparation method of polybutadiene, comprising: adding 1,3-butadiene monomer and catalyst into an alkane solvent in a molar ratio of 100 to 4000:1 for polymerization reaction to obtain Reaction solution; use ethanol to condense polybutadiene from the reaction solution. The catalyst is obtained by the following preparation method: the rare earth compound, butadiene and aluminum alkyl are mixed for reaction to obtain a mixed solution, and chloride is added to the The reaction is carried out in the mixed solution to obtain the catalyst.

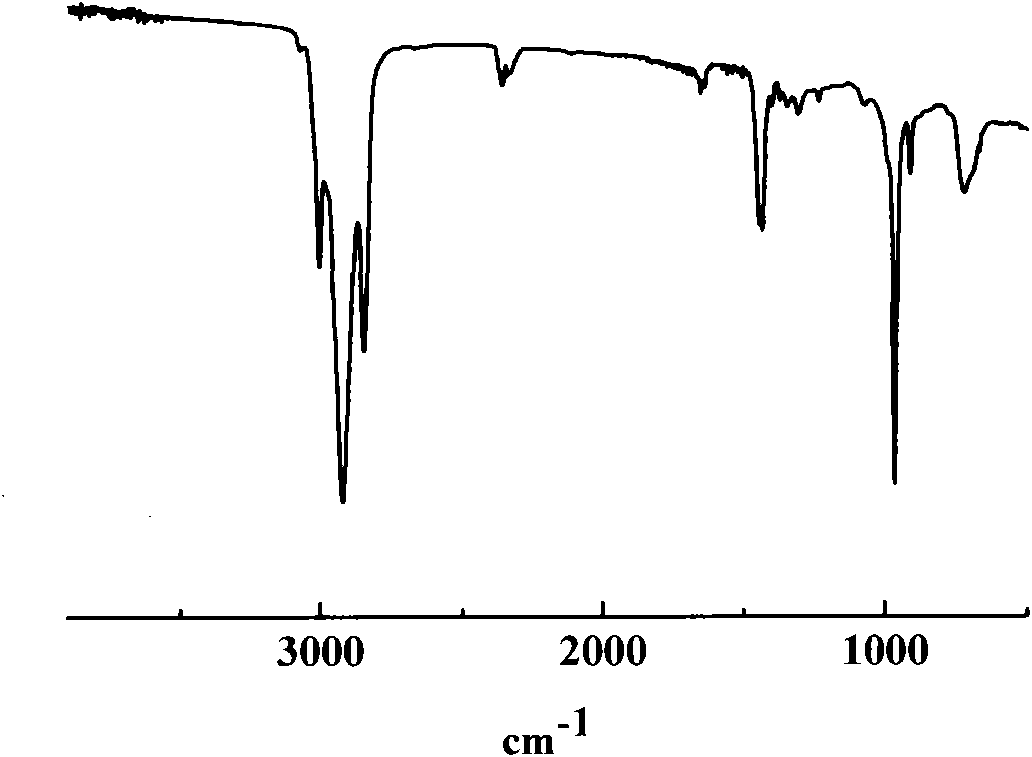

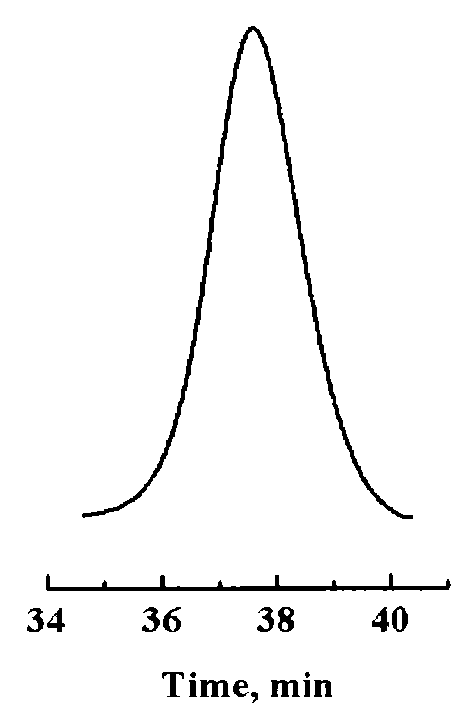

[0027] The invention uses an anionic coordination polymerization mechanism to prepare polybutadiene with low molecular weight and narrow molecular weight distribution, and the polymerization environment is a solution. The catalyst used in the preparation method of the present invention is preferably a three-component homogeneous catalyst of rare earth compounds, and the raw materials include: rare earth compounds...

Embodiment 1

[0034] Under the protection of nitrogen, add neodymium neodecanoate, butadiene and diisobutylaluminum hydride to the dry catalyst reaction flask in sequence, and react at 50°C for 5 minutes, then add dimethyldichlorosilane, and then add dimethyldichlorosilane at 25 The reaction was carried out at ℃ for 30 minutes to obtain a rare earth catalyst for butadiene polymerization. In preparing the catalyst raw materials, the molar ratio of neodymium neodecanoate, butadiene, diisobutylaluminum hydride and dimethyldichlorosilane is 1:10:20:2.0.

[0035] Under nitrogen protection, 20 mL of a hexane solution of 1,3-butadiene monomer was added to a dry 50 mL reaction flask. Then add the prepared rare earth catalyst. The molar ratio of catalyst to 1,3-butadiene monomer is 1:400. Polymerization was carried out at 50°C. After 4 hours of polymerization reaction, terminate with ethanol solution containing 0.01 g / mL anti-aging agent 264. Coagulation with ethanol yields low molecular weight ...

Embodiment 2

[0041] Under the protection of nitrogen, add neodymium neodecanoate, butadiene and diisobutylaluminum hydride in sequence to the dry catalyst reaction bottle, and react at 50°C for 5 minutes, then add chlorobutylaluminum, and then add chlorobutylaluminum at 25°C The reaction was carried out for 30 minutes to obtain a rare earth catalyst for butadiene polymerization. In preparing the catalyst raw materials, the molar ratio of neodymium neodecanoate, butadiene, diisobutylaluminum hydride and chlorobutylaluminum is 1:10:20:2.0.

[0042] Under nitrogen protection, 20 mL of a hexane solution of 1,3-butadiene monomer was added to a dry 50 mL reaction flask. Then add the prepared rare earth catalyst. The molar ratio of catalyst to 1,3-butadiene monomer is 1:400. Polymerization was carried out at 50°C. After 4 hours of polymerization reaction, terminate with ethanol solution containing 0.01 g / mL anti-aging agent 264. Coagulation with ethanol yields low molecular weight butadiene. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com