Utilization method of waste gas discharged from butadiene extracting apparatus

An extraction device and butadiene technology, which is applied in the field of utilization of alkyne-rich waste gas from a butadiene extraction device, can solve the problems of difficult utilization of butadiene tail gas, achieve equipment investment savings, strong raw material adaptability, The effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

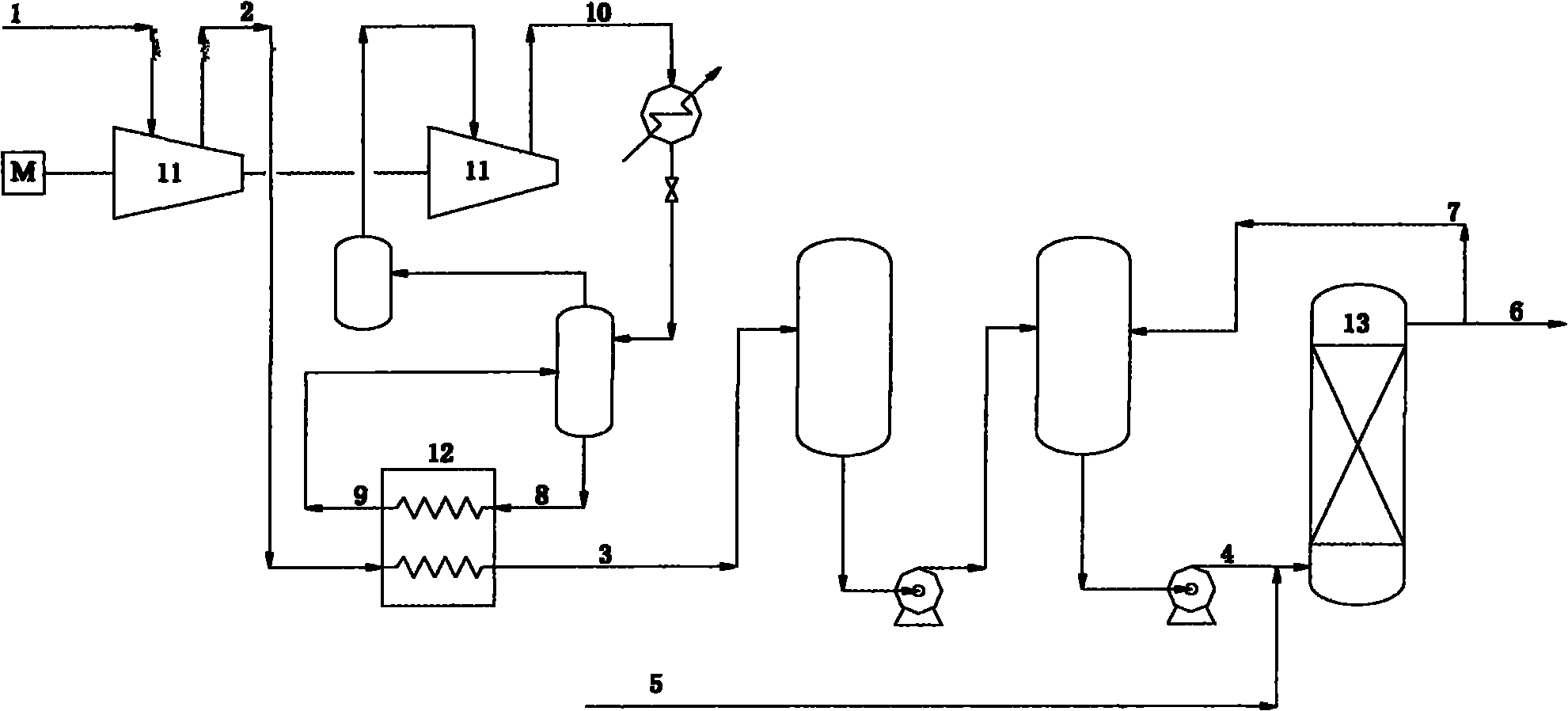

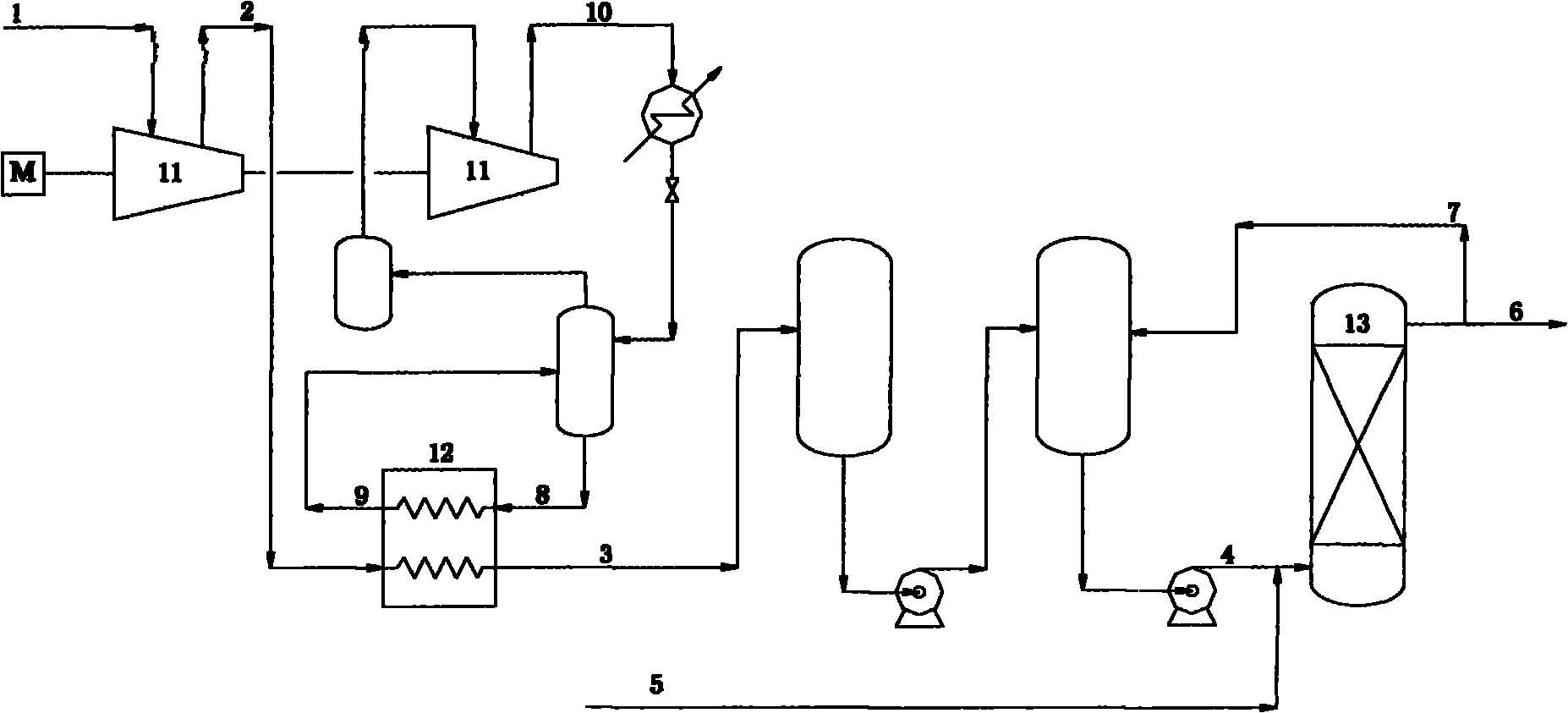

[0040] 1. Boost: Exhaust gas 1 from the butadiene extraction unit (main composition: 7.82% butene, 43.76% butadiene, 47.1% ethyl acetylene and vinyl acetylene, both in mass percentage), flow rate 1080kg / h, pressure 0.1MPa (absolute pressure, the same below). The exhaust gas enters a section of the compressor 11, the pressure of the exhaust gas stream 2 at the outlet of the compressor is 0.17MPa, and the temperature is 64.3°C. The exhaust gas enters the cold box for heat exchange and turns into a liquid phase. 5.1°C;

[0041] 2. Reaction: The liquid phase C43 enters the mixing tank after being dehydrated, and mixes with the recycle stream 7 from the hydrogenation product. The flow rate of the recycle stream is 8640kg / h. After boosting the pressure by the booster pump, a certain amount of hydrogen is added 5. Enter the reactor 13 to react. The reaction conditions are: temperature 40°C, pressure 2.0MPa, hydrogen / alkyne molar ratio 1.5, liquid volume space velocity 15h -1, a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com