Styrene-butadiene polymers with styrene gradient and methods of making same

A technology of polymer and butadiene, applied in the field of styrene-butadiene polymer with styrene gradient and its preparation, can solve the problems of small glass transition temperature, no glass transition temperature and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

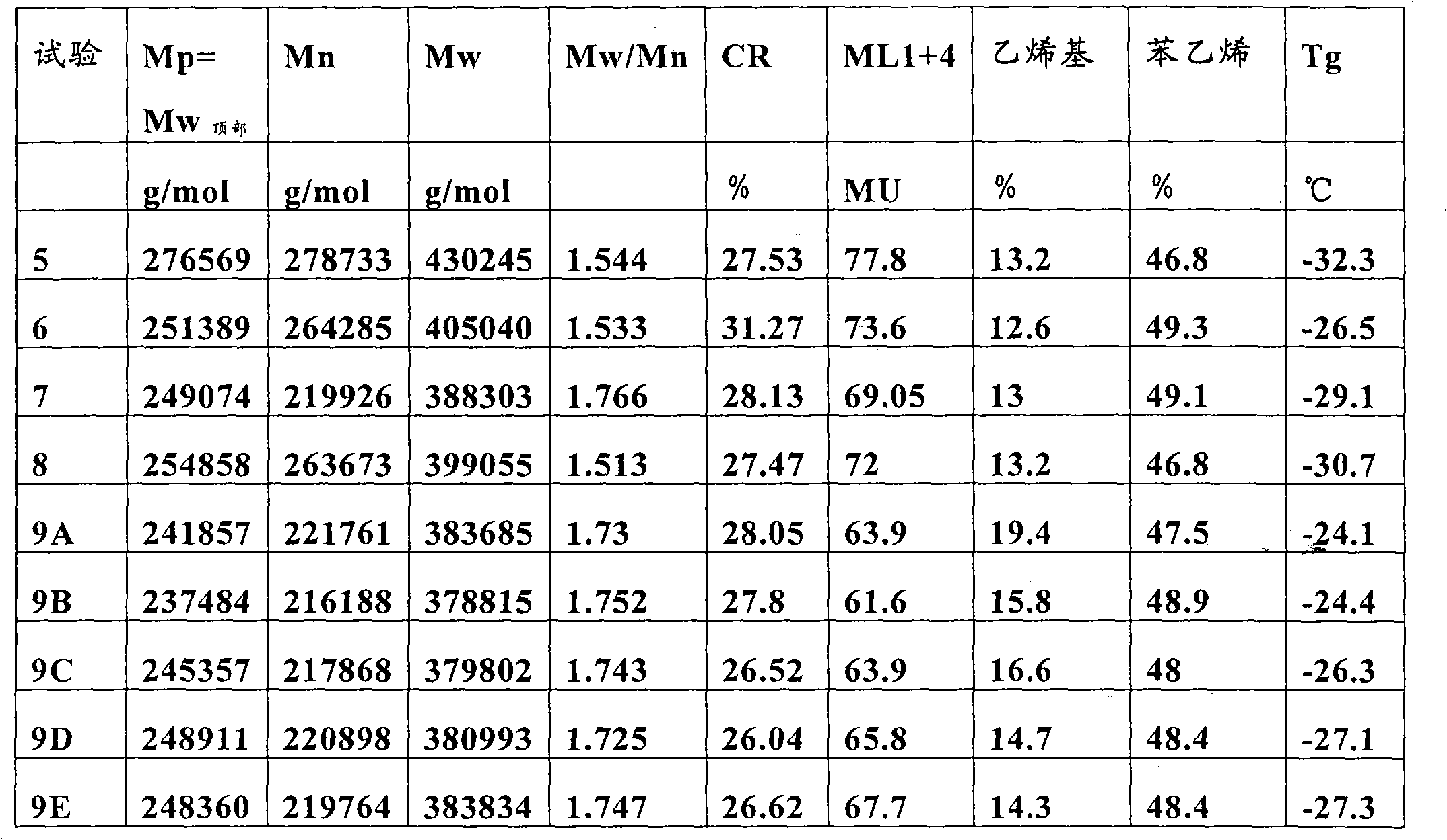

Examples

Embodiment 1

[0125] Example 1 (TT17)

[0126] Cyclohexane (m CH,0 =4980g), butadiene (m BD,0 =245.51g), styrene (m St,0 =510.92g) and tetramethylethylenediamine (TMEDA (2.86 mmol respm TMEDA,0 = 13.6 g of a solution in cyclohexane)) was charged to a 10-liter reactor under a nitrogen atmosphere, and the mixture was heated to 55° C. while stirring. Secondly, 4.704 mmoles of n-butyllithium (in cyclohexane m NBL,T = 12.69 g of solution) was added dropwise to the mixture (reaction with impurities) until the color of the reaction mixture changed to yellow (titration step). Then, 6.487 millimoles of n-butyllithium (solution in cyclohexane: m NBL,P = 17.5 g) was charged immediately by pump to initiate polymerization. The charge start time of "6.487 mmoles of n-butyllithium" was used as the start time of the initial polymerization reaction.

[0127] The initial polymerization step was characterized as a typical batch polymerization without any additional reactants charged. Starting after "6...

Embodiment 2

[0131] Example 2 (TT18)

[0132] Example 1 was repeated with the following changes: TMEDA (5.179 mmol) was used in the initial charge.

Embodiment 3

[0133] Example 3 (TT15)

[0134] Example 1 was repeated with the following changes: instead of 2.86 mmoles of TMEDA, "4.59 mmoles of TMEDA" was included in the initial charge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com