Method of gas phase synthesis of 1,1,1,4,4,4-hexafluoropropylene-2-chlorine-2-butene

A gas-phase synthesis and butene technology, applied in halogen substitution preparation, organic chemistry, etc., can solve the problems of expensive raw materials, difficult separation, low selectivity, etc., to achieve improved yield and selectivity, rich sources of raw materials, and safe operation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

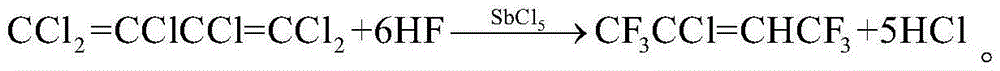

Image

Examples

Embodiment 1

[0025] Put a certain amount of catalyst AlF into a stainless steel gas phase reactor made of 316L material and a pipe diameter φ of 10mm 3 , raising the temperature to 240 °C. Add hexachloro-1,3-butadiene and HF respectively into the steam heater to vaporize them. Add the steam of hexachloro-1,3-butadiene into the meteorological reactor with a metering pump, and the flow rate is 20ml / min; add the HF vapor into the fixed bed with a metering pump, and the flow rate is 160ml / min (that is, hexachloro-1, The molar ratio of 3-butadiene to HF is 1:8), and the residence time of the reaction is 1s. The product is introduced into a condenser to be condensed and purified by rectification. The yield of 1,1,1,4,4,4-hexafluoro-2-chloro-2-butene was 82.5% and the selectivity was 90.7%.

Embodiment 2

[0027] Put a certain amount of catalyst AlF into a stainless steel gas phase reactor made of 316L material and a pipe diameter φ of 10mm 3 , raising the temperature to 320 °C. Add hexachloro-1,3-butadiene and HF respectively into the steam heater to vaporize them. Add the steam of hexachloro-1,3-butadiene into the fixed bed with a metering pump, and the flow rate is 20ml / min; add the HF vapor into the fixed bed with a metering pump, and the flow rate is 160ml / min (that is, hexachloro-1,3 - The molar ratio of butadiene to HF is 1:8), and the residence time of the reaction is 2.5s. The product is introduced into a condenser to be condensed and purified by rectification. The yield of 1,1,1,4,4,4-hexafluoro-2-chloro-2-butene was 84.2%, and the conversion was 92%.

Embodiment 3

[0029] Put a certain amount of catalyst SbF into a stainless steel gas phase reactor made of 316L material and a pipe diameter φ of 10mm 3 , raising the temperature to 400 °C. Add hexachloro-1,3-butadiene and HF respectively into the steam heater to vaporize them. Add the steam of hexachloro-1,3-butadiene into the fixed bed with a metering pump, and the flow rate is 20ml / min; add the HF vapor into the fixed bed with a metering pump, and the flow rate is 200ml / min (that is, hexachloro-1,3 - The molar ratio of butadiene to HF is 1:10), and the residence time of the reaction is 4s. The product is introduced into a condenser to be condensed and purified by rectification. The yield of 1,1,1,4,4,4-hexafluoro-2-chloro-2-butene was 85.8%, and the conversion was 95.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com