Production method for producing 1,3-butadiene by performing oxidative dehydrogenation on butylene

A technology for oxidative dehydrogenation and production methods, which is applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., and can solve problems such as corrosion, reduction of effective utilization of raw materials, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

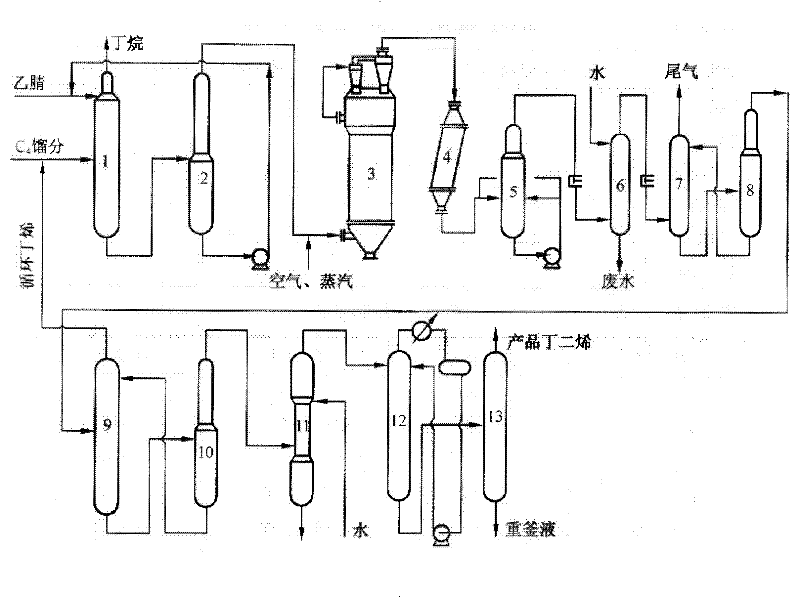

[0018] Butene is industrially adopted for oxidative dehydrogenation, wherein the catalyst used is bismuth molybdate process control suitable oxygen / ene ratio, and controls the oxygen content in the tail gas, and the residual oxygen in the reactant is at 0.5% (volume fraction), flow process See figure 1 .

Embodiment 2

[0020] With industrial butene, adopt oxidative dehydrogenation, wherein the catalyst used is ferrite; process control suitable oxygen / ene ratio, and control the oxygen content in the tail gas, the residual oxygen in the reactant is 0.45% (volume fraction), see process figure 1 .

Embodiment 3

[0022] With industrial butene, adopt oxidative dehydrogenation, wherein used catalyst is iron chromic acid; Process controls the suitable oxygen / ene ratio, and controls the oxygen content in the tail gas, residual oxygen is at 0.5% (volume fraction) in the reactant, see process figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com