Production technology of steel used for pipe line steel electrode

A technology for production process and steel for welding rods, which is applied in the direction of improving process efficiency, manufacturing converters, etc., can solve the problems of less than 50% smelting rate, difficult to control, low temperature, etc., and achieves the effect of improving the smelting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiment of the production process of steel for pipeline steel electrode of the present invention is the production process of steel H08GX for pipeline steel electrode, which successively includes converter steelmaking process, argon station refining process, continuous casting process; argon station refining process, continuous casting process All using traditional techniques.

[0028] The converter steelmaking process is basically the same as the traditional process, the difference lies in the following specific process parameters of the converter steelmaking process:

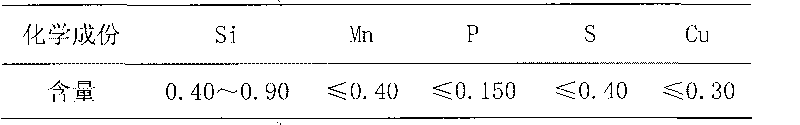

[0029] (1), molten iron pretreatment: S removal, molten iron weight: 100 to 110 tons, into the furnace molten iron, the weight percentage content of S is ≤0.003%; the molten iron composition control range is:

[0030]

[0031] (2) 10-15 tons of pretreated molten iron and scrap steel are sent into the converter, and the end point of the converter is controlled, specifically: tapping temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com