Preparation method of low-cost titanium alloy

A titanium alloy, low-cost technology, applied in the field of low-cost titanium alloy preparation, can solve the problem of not being able to effectively reduce the cost of parts, and achieve the effects of improving density, reducing production costs, and good plasticity and fatigue properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

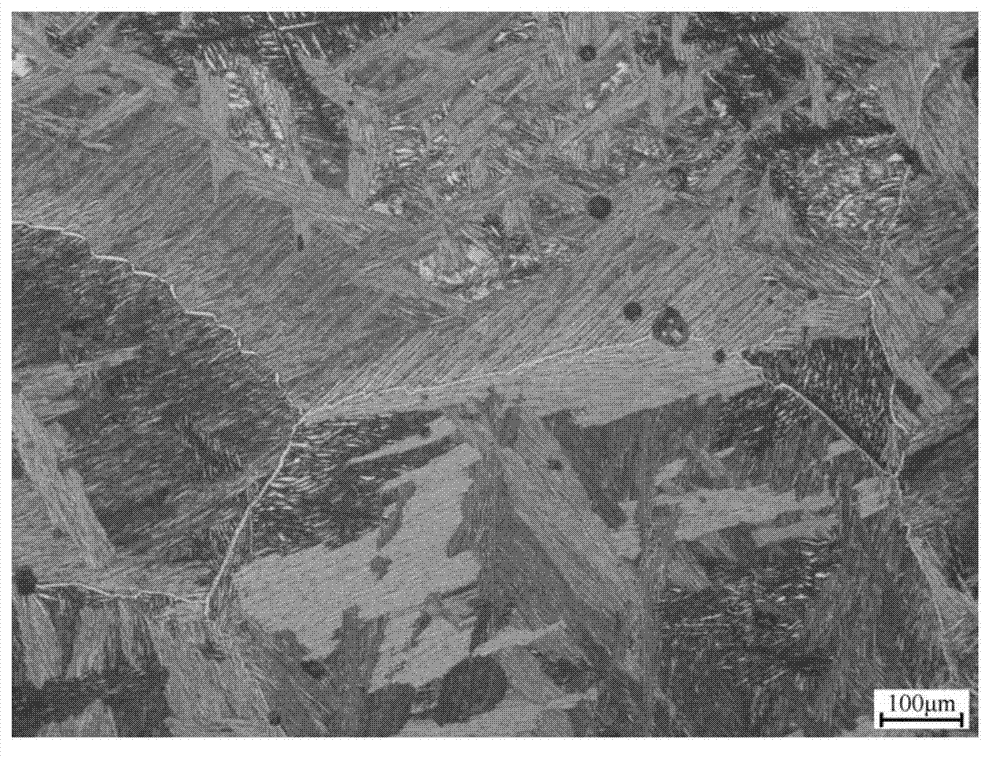

Embodiment 1

[0022] Step 1. According to the nominal composition of the Ti-1.5Fe-2.5Mo alloy, titanium powder and MoFe master alloy powder are placed in a mixer according to the proportion and mixed evenly to obtain a mixed powder; the Fe in the Ti-1.5Fe-2.5Mo alloy The mass percentage content of Mo is 1.5%, the mass percentage content of Mo is 2.5%, and the balance is Ti and other unavoidable impurities; the hydrogen mass percentage content of the titanium powder prepared by hydrodehydrogenation method is not more than 0.001% The pure titanium powder has an average particle size of 45 μm and an oxygen mass content of 2800 ppm; the average particle size of the MoFe master alloy powder is 30 μm, and the oxygen mass content of the MoFe master alloy powder is 3000 ppm;

[0023] Step 2. Put the mixed powder described in step 1 into a Φ50mm×200mm cold isostatic pressing rubber sleeve, and perform cold isostatic pressing under the condition that the pressing pressure is not less than 200MPa to ob...

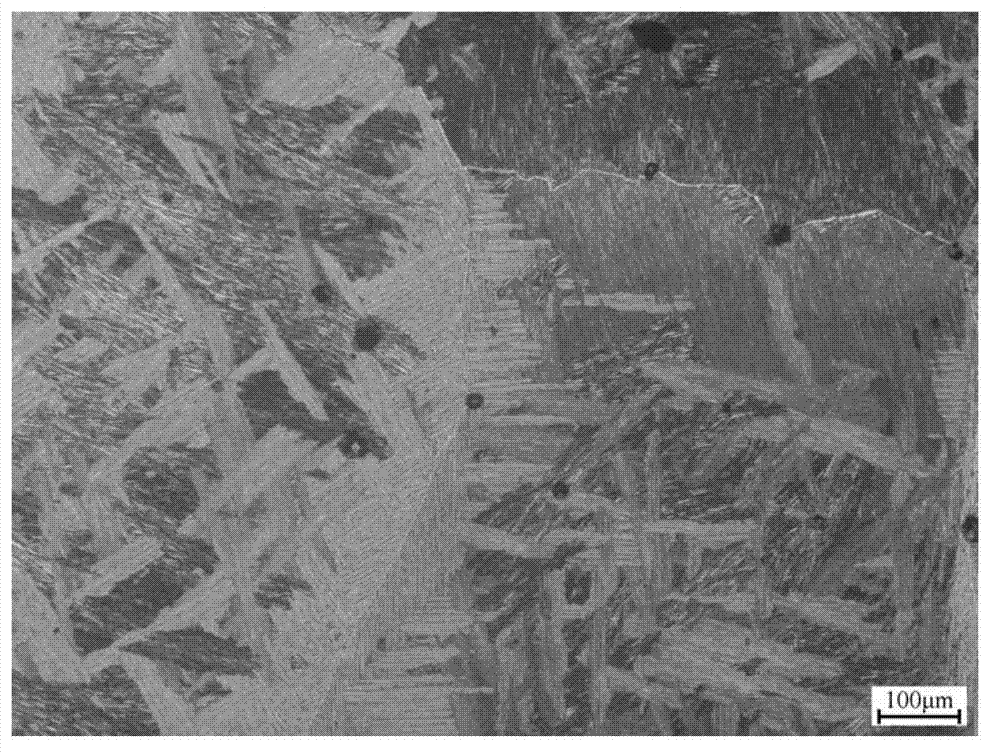

Embodiment 2

[0028] Step 1. According to the nominal composition of the Ti-1.5Fe-2.5Mo alloy, titanium powder and MoFe master alloy powder are placed in a mixer according to the proportion and mixed evenly to obtain a mixed powder; the Fe in the Ti-1.5Fe-2.5Mo alloy The mass percentage content of Mo is 1.5%, the mass percentage content of Mo is 2.5%, and the balance is Ti and other unavoidable impurities; the hydrogen mass percentage content of the titanium powder prepared by hydrodehydrogenation method is not more than 0.001% The pure titanium powder has an average particle size of 53 μm and an oxygen mass content of 2400 ppm; the average particle size of the MoFe master alloy powder is 60 μm, and the oxygen mass content of the MoFe master alloy powder is 2500 ppm;

[0029] Step 2. Put the mixed powder described in step 1 into a Φ50mm×200mm cold isostatic pressing rubber sleeve, and perform cold isostatic pressing under the condition that the pressing pressure is not less than 200MPa to ob...

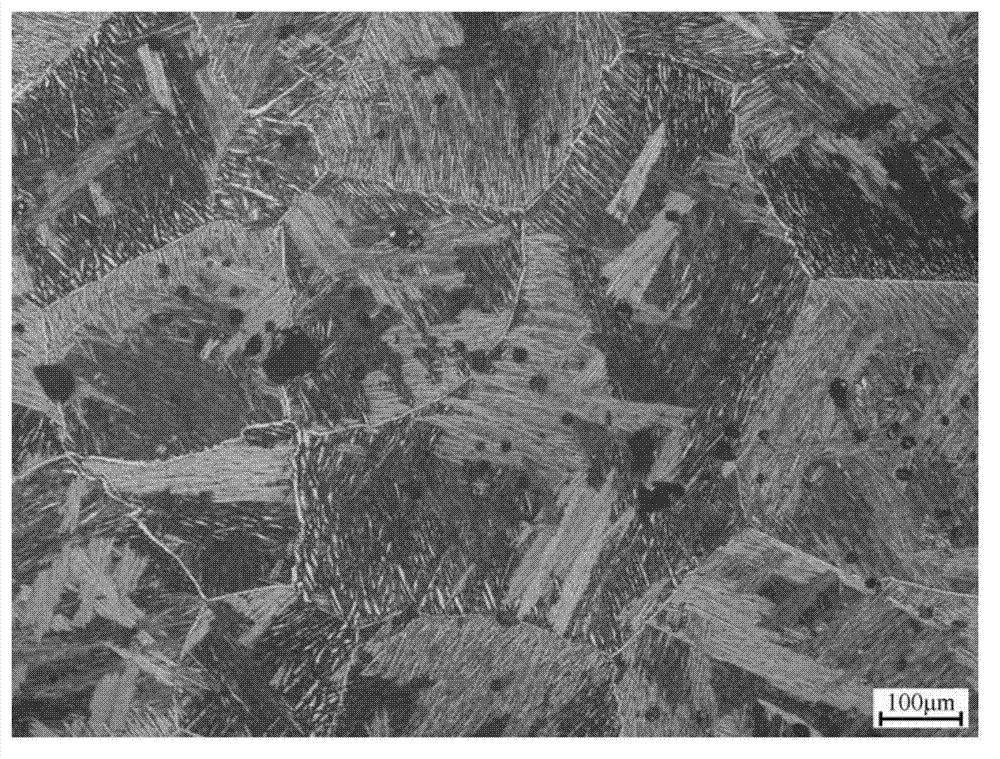

Embodiment 3

[0034] Step 1. According to the nominal composition of the Ti-1.5Fe-2.5Mo alloy, titanium powder and MoFe master alloy powder are placed in a mixer according to the proportion and mixed evenly to obtain a mixed powder; the Fe in the Ti-1.5Fe-2.5Mo alloy The mass percentage content of Mo is 1.5%, the mass percentage content of Mo is 2.5%, and the balance is Ti and other unavoidable impurities; the hydrogen mass percentage content of the titanium powder prepared by hydrodehydrogenation method is not more than 0.001% The pure titanium powder has an average particle size of 80 μm and an oxygen mass content of 1700 ppm; the average particle size of the MoFe master alloy powder is 74 μm, and the oxygen mass content of the MoFe master alloy powder is 1000 ppm;

[0035]Step 2. Put the mixed powder described in step 1 into a Φ50mm×200mm cold isostatic pressing rubber sleeve, and perform cold isostatic pressing under the condition that the pressing pressure is not less than 200MPa to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com