Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70results about How to "Solve delamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

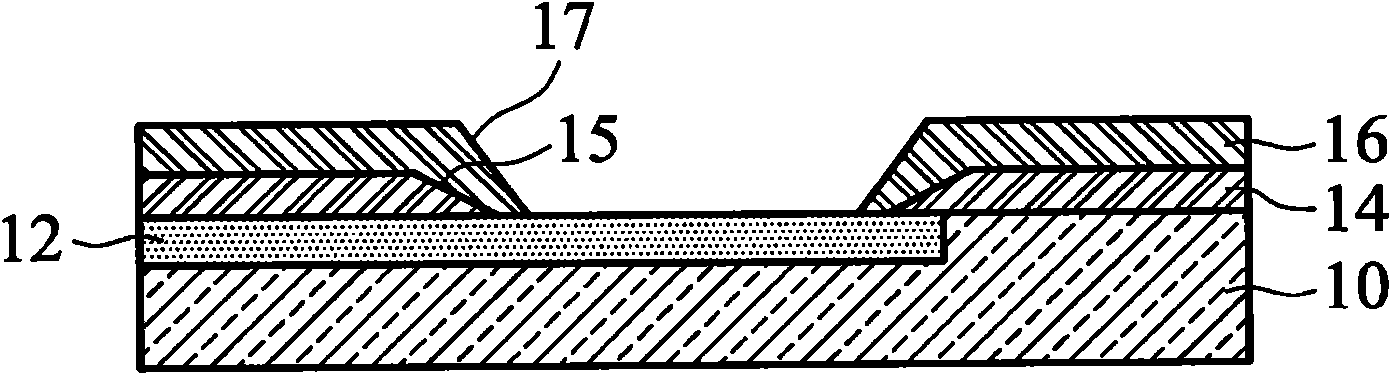

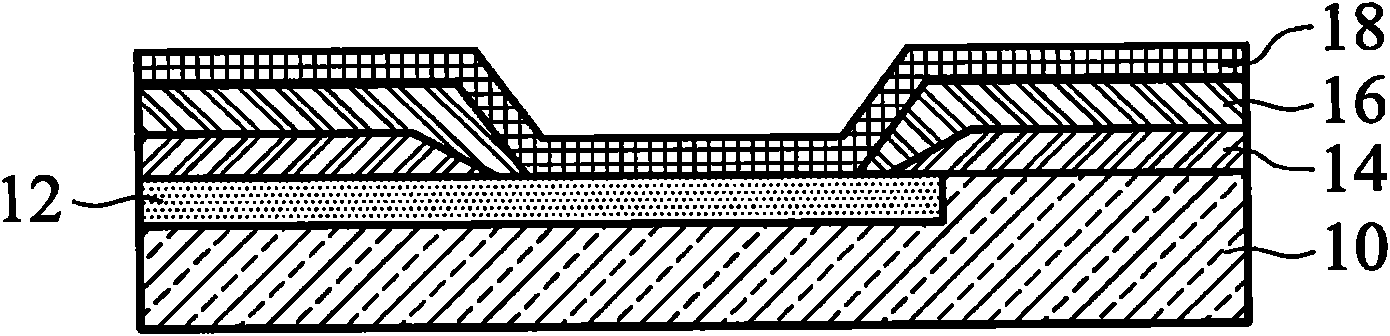

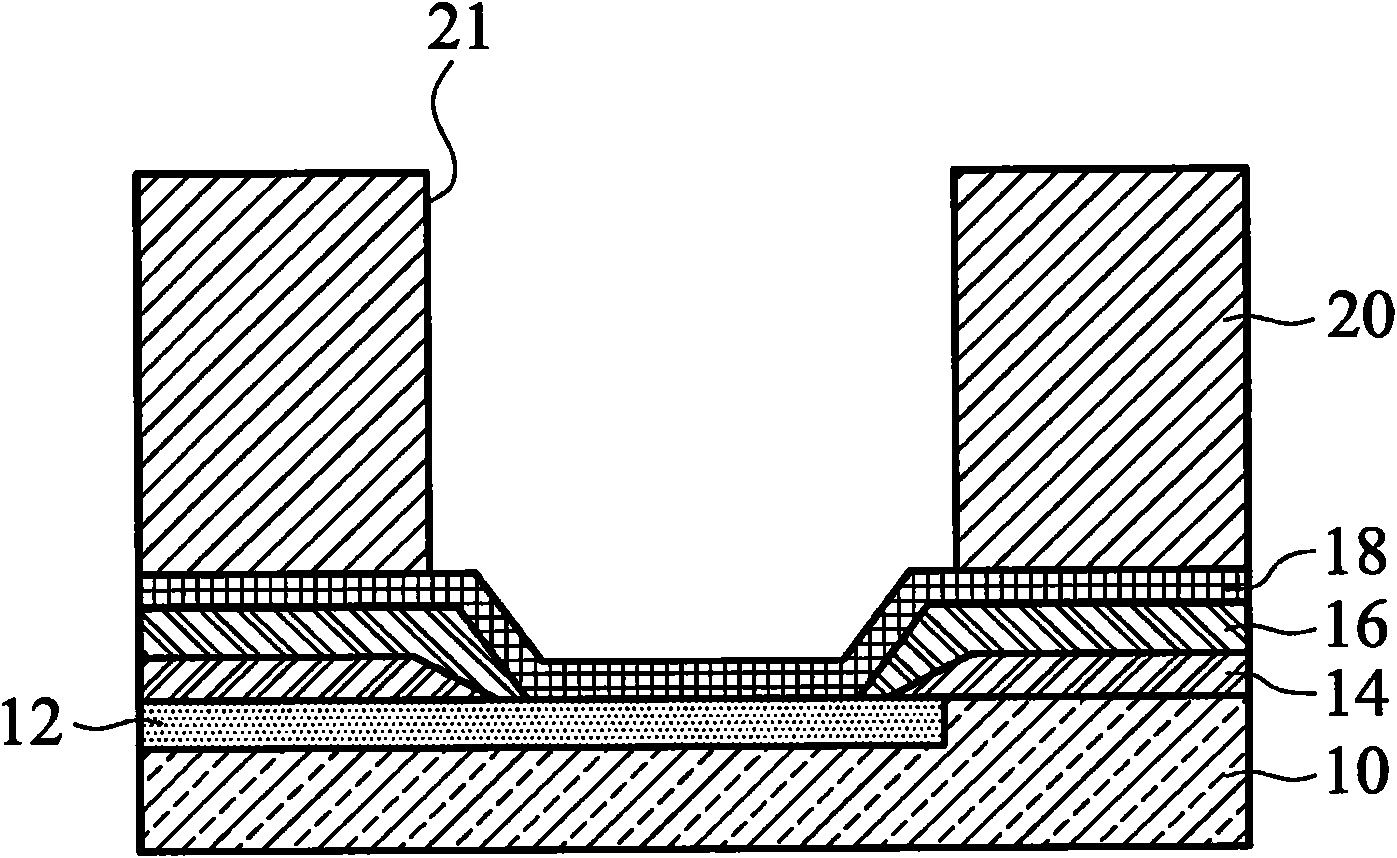

Integrated circuit element and forming method of bumping block structure

ActiveCN102237316APrevent oxidationExcellent adhesionSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorFilling materials

The invention provides an integrated circuit element and a forming method of a bumping block structure. The integrated circuit element comprises a semiconductor substrate, a bumping block metal layer disposed on the semiconductor substrate, a copper column which is disposed on the bumping block lower metal layer and has a side wall surface and an upper surface, and a protection layer which is disposed on the side wall surface and the upper surface of the copper column. The protection layer is a nickel-containing layer, including phosphor with content being less than 0.01 weight%. The invention provides a copper column bumping block, having a side wall protection layer formed by an electrolytic metal layer. The electrolytic metal layer is an electrolytic nickel layer, an electrolytic gold layer, an electrolytic copper layer or an electrolytic silver layer, preventing the copper column side wall from oxidation, and increasing the adhesion strength between the copper column side wall and the bottom filler materials formed afterwards. The bumping block can prevent stress to be concentrated on one point, resolving the problem that the bumping blocks are peeled off or delaminated from the copper column side wall.

Owner:TAIWAN SEMICON MFG CO LTD

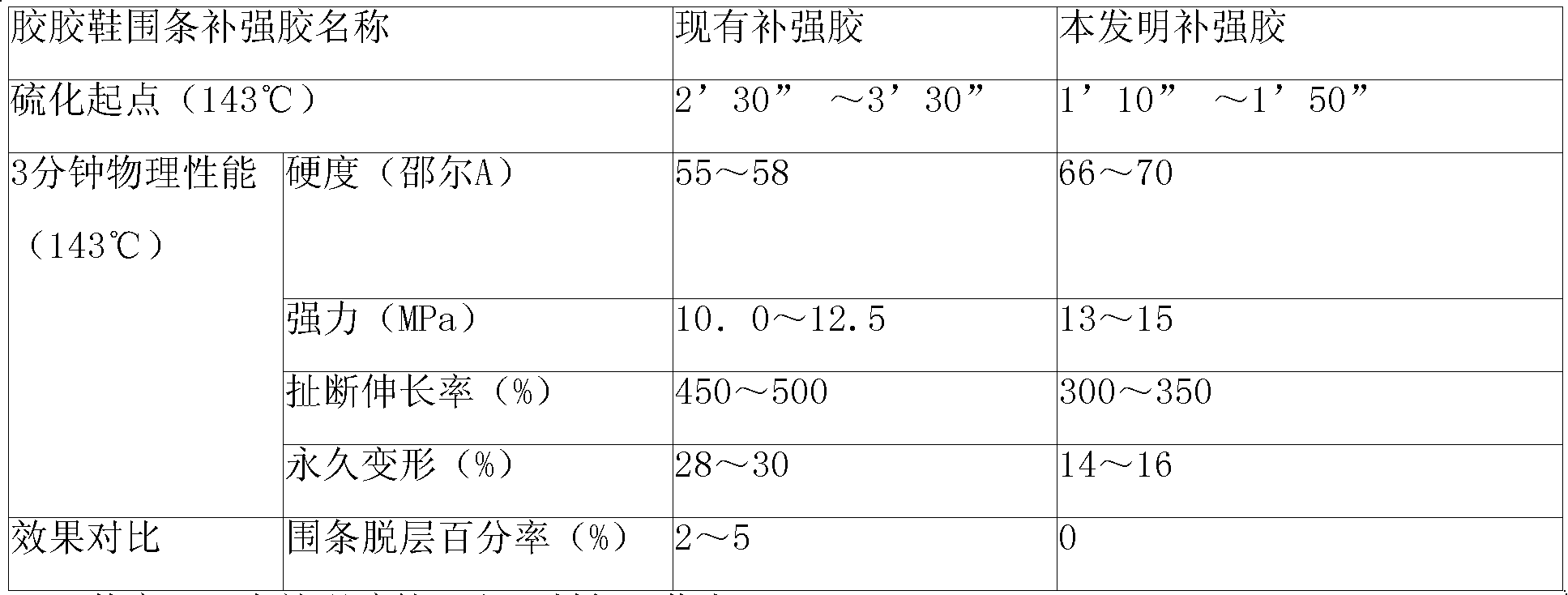

Ultra-low-temperature fast-curing reinforcing glue for rubber shoes and preparation method thereof

ActiveCN101225194AIncrease the speed of cross-linking and settingSolve delaminationWeltsUpperPolymer scienceVulcanization

The invention discloses an ultra low temperature fast vulcanization strengthening adhesive used by rubber shoes and a preparation method of the strengthening adhesive, which is characterized in that: firstly, natural rubber is masticated to form masticated rubber, product A is obtained by mixing the masticated rubber and the synthetic rubber, the product B is obtained by mixing the polyethylene glycol and the silica, the product C is obtained by mixing the vulcanizing agent, the vulcanization accelerator and the vulcanization active agent; the product A is put into the rubber refiner to be refined for 0.5 to 1 minute, the product C is added into the rubber refined and keep on refining for 2 to 5 minutes, and then softener is added into the refiner to be refined homogenously, when the discharged material reaches the flattening machine, the supplementary re-processing is carried out to obtain the rubber compound, at last sulfur is added into the rubber compound to obtain the ultra low temperature fast vulcanization strengthening adhesive. The preparation method of the strengthening adhesive has the advantages that: the prescription of the strengthening adhesive materials are improved, the crosslinking stress of the strengthening adhesive is enhanced, thus, the crosslinking stress is ensured to be larger than the rebound force of the outsole plus the expansive force produced by the foaming sponge, and the crosslinking calibration speed is increased; meanwhile, the rubber foxing delamination problem is totally avoided.

Owner:JIHUA 3537 SHOE MAKING

Method for preparing polyethylene type adhesive resin for multilayer co-extrusion barrier package

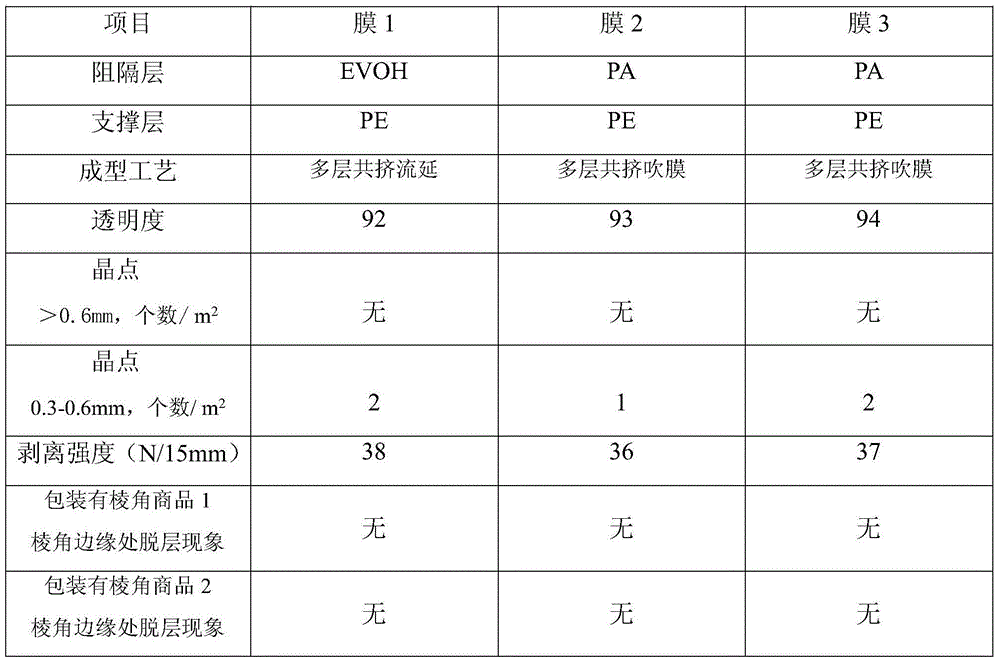

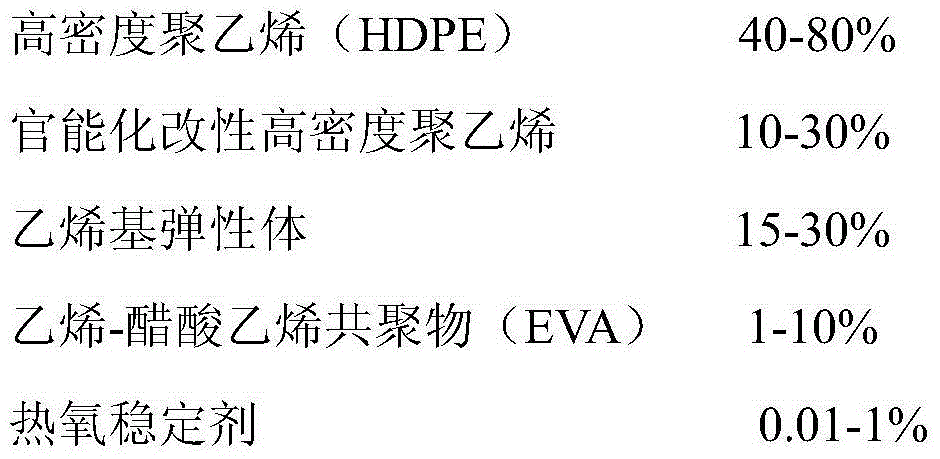

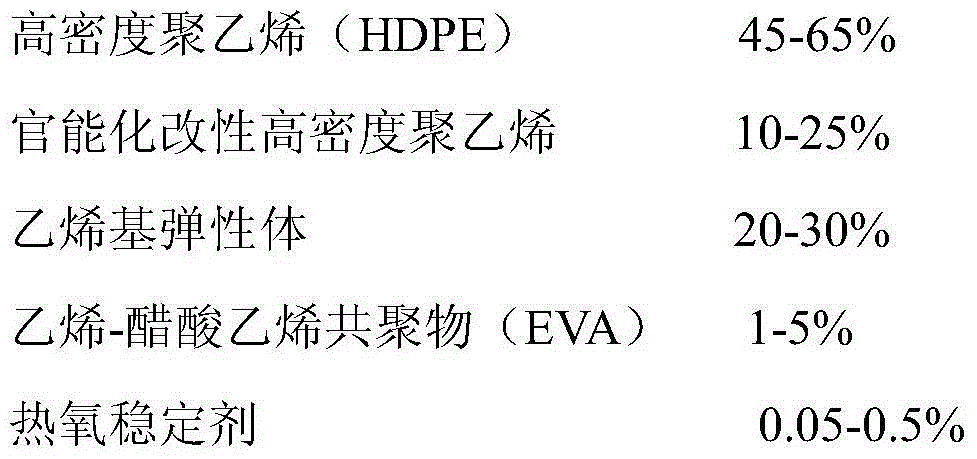

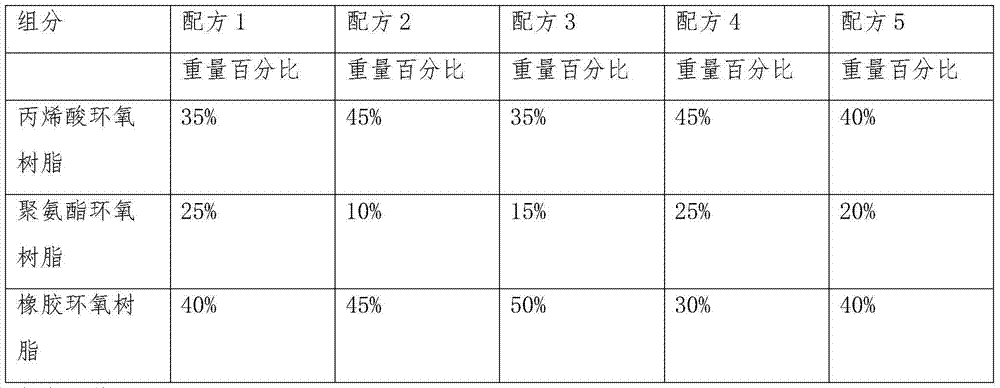

The invention discloses a polyethylene type adhesive resin for multilayer co-extrusion barrier package. The polyethylene type adhesive resin comprises the following formula raw materials in percentage by weight: 40-80 percent of high density polyethylene (HDPE), 10-30 percent of functionalization modified high density polyethylene, 15-30 percent of vinyl elastomer, 1-10 percent of ethylene vinyl acetate copolymer (EVA), 0.01-1 percent of hot oxygen stabilizer. The polyethylene type adhesive resin is prepared by the following steps: performing a plasticizing and blending process by adopting a twin-screw extruder, extruding, and granulating, thereby obtaining the product. The adhesive resin disclosed by the invention is used for an adhesive layer of a polyethylene (PE) / nylon (PA) or polyethylene (PE) / ethylene-vinyl alcohol copolymer (EVOH) multilayer co-extrusion barrier package film (sheet) and is excellent in processability, high in transparency, high in heat resistance and fewer in grain points, is particularly excellent in adhesive performance, and a good adhesive layer material is provided for the field of polyethylene type multilayer co-extrusion barrier package.

Owner:HEYUAN PLG MATERIALS

Binding material of anti-skidding layer of road surface and preparation method

ActiveCN103756617ASimple production processSave energyNon-macromolecular adhesive additivesPaving detailsEpoxyRoad surface

The invention discloses a binding material of an anti-skidding layer of a road surface and a preparation method. The binding material is composed of the following components in percentage by weight: 40%-60% of epoxy resin, 15%-25% of a curing agent, 0.5%-1% of toner and 24%-35% of quartz sand. The binding material has excellent mechanical performance, deformation performance and endurance quality and has a consistent color.

Owner:道仑(重庆)新材料技术有限公司

Preparation method of polypropylene type bonding resin for multi-layer coextrusion barrier packaging

ActiveCN104371597AEasy to processHigh transparencyLaminationLamination apparatusElastomerHeat resistance

The invention discloses a preparation method of polypropylene type bonding resin for multi-layer coextrusion barrier packaging. The raw materials include (by weight percent) 50% to 80% of polypropylene random copolymer, 10% to 30% of functionalized modified atactic polypropylene, 10% to 30% of propylene based elastomer, 1% to 10% of styrene block copolymer and 0.01% to 1% of thermal oxygen stabilizer. The resin is obtained in extruded and granulated manners through a double screw extruder by the plasticating and blending process. The bonding resin is applied to the bonding layers of polypropylene (PP) / Niron (PA) or polypropylene (PP) / ethylene vinyl alcohol copolymer (EVOH) multi-layer coextrusion barrier packaging films (pieces), the processing performance is fine, the transparency is high, thermal resistance is fine, fisheye is few, the bonding performance is excellent, and a good bonding layer material is provided in the field of polypropylene type multi-layer coextrusion barrier packaging.

Owner:HEYUAN PLG MATERIALS

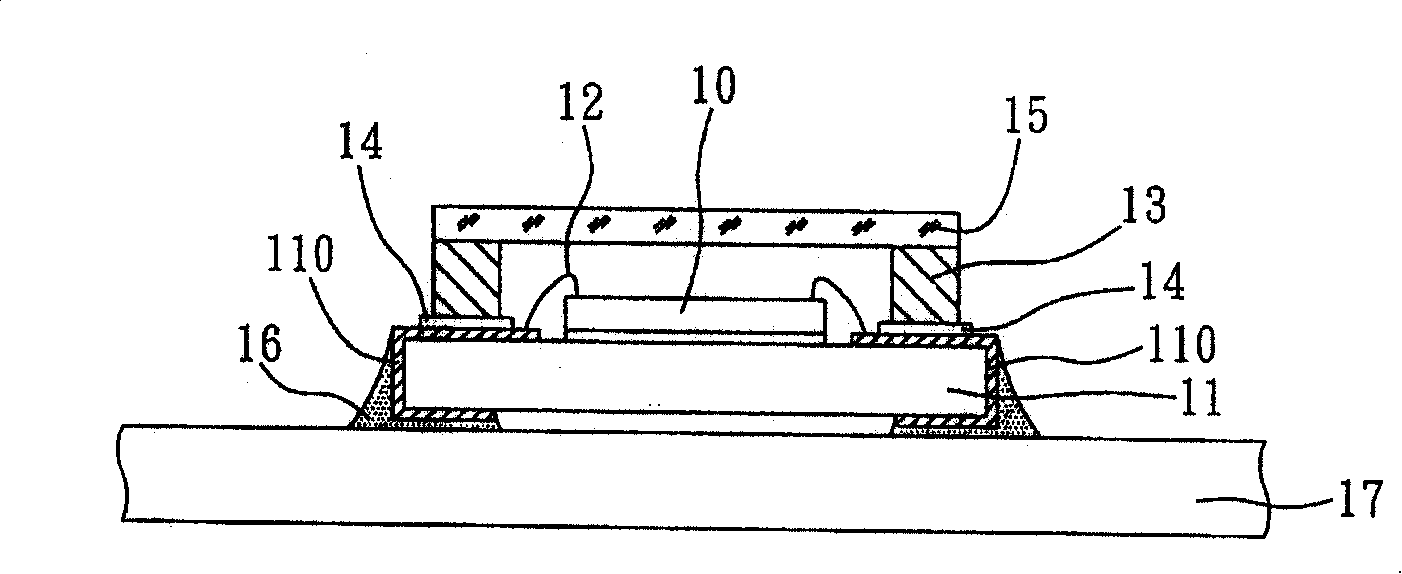

Flip-chip type semiconductor packaging structure and chip bearing member

InactiveCN101114622ASolve delaminationEffective protectionSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

A flip-chip typed semiconductor packaging structure with the related chip carrier is essentially characterized in that an edge of chip linking area of the chip carrier is provided with a groove which can be placed around the edges of the chip linking area or in the corner of the chip linking area, thus soft filler with low young modulus can fill the groove in order to be in connection with the flip-chip typed semiconductor chip in the chip linking area, and the filler with low young modulus absorbs thermal stress in order to avoid delamination between the filling glue at bottom of the chip and the chip.

Owner:SILICONWARE PRECISION IND CO LTD

Sunlight hollow board and manufacturing method thereof

InactiveCN101298940AFully utilizeSolve delaminationSolar heating energySolar heat devicesUltravioletUv absorber

The invention relates to a sunlight plate (polycarbonate plate), particularly a sunlight hollow plate; the invention also relates to a method for preparing the sunlight hollow plate, which is characterized by including a sunlight hollow plate body, a ultraviolet absorber protective layer, wherein the ultraviolet absorber protective layer is formed on the surface of the sunlight hollow plate body through the coextrusion with the thickness of 30-50 micron. The method for preparing the sunlight hollow plate is characterized by high temperature melt extruding the PC main materials and the ultraviolet absorber in the extruder, converging in the mould, shaping through the calibration table, annealing. The sunlight hollow plate by the method of the invention not only solves the delamination desquamation problems, but also makes full use of the ultraviolet absorber, which reduces the production cost.

Owner:SHANGHAI HUILI TUVGAL SHEETAB

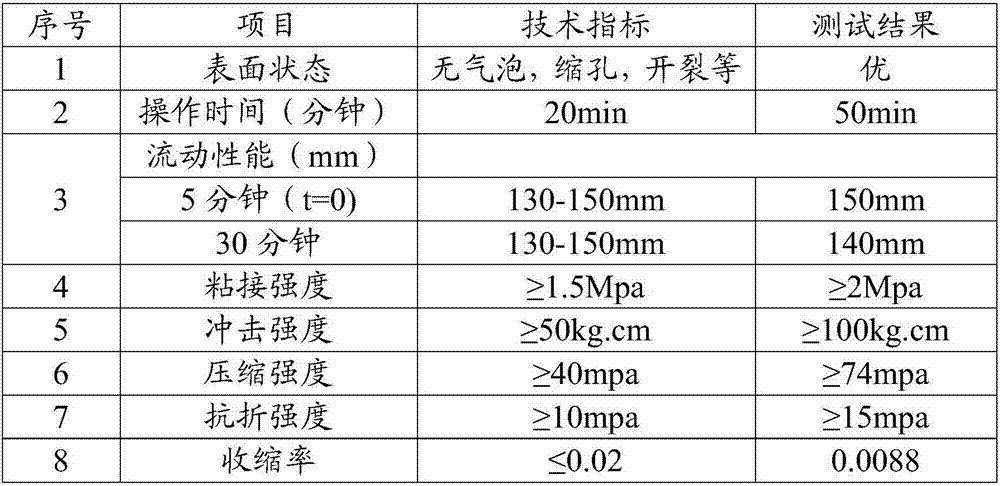

Waterborne epoxy composite cement mortar material as well as preparation and construction methods thereof

The invention discloses a waterborne epoxy composite cement mortar material. The material comprises a component A, a component B and a component C in the mass ratio being (0.5-1.5): (1-3): (12-18), wherein the component A is a waterborne epoxy emulsion, the component B is prepared from, in parts by weight, 3-10 parts of water, 3-10 parts of a curing agent and 0.01-0.1 parts of a defoaming agent, and the component C is prepared from 30-60 parts of quartz sand, 20-40 parts of cement, 0.1-0.5 parts of a water reducer, 0.2-1.0 part of an additive and 0.1-1.0 part of a defoaming agent. The material is green, environment-friendly and low in cost, has good matching performance in concrete, can be cured in humid interfaces and has reinforcement and permeation resistance functions, the problem that traditional floor coatings peel or have bubbles is solved, the one-time forming thickness can reach 2 mm or above, basic planes are easy to level, and construction is easy. The invention further discloses preparation and construction methods of the material. The preparation condition is mild, the method is simple and suitable for large-scale industrial production, the construction process is simple and feasible, and the construction cost is low.

Owner:深圳市威尔地坪材料有限公司

Curved shallow-crossing linking structure carbon fiber/copper fiber carbon-based friction material and preparation method thereof

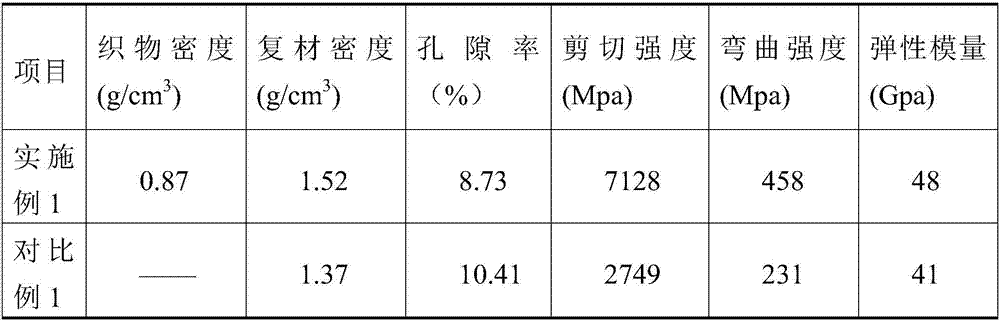

InactiveCN105803637AOvercoming Delamination ProblemsIncreased interlaminar shear strengthCarbon fibresWoven fabricsWeft yarnCopper

The invention discloses a curved shallow-crossing linking structure carbon fiber / copper fiber carbon-based friction material and a preparation method thereof.The preparation method of the friction material comprises the following steps that 1, preparation of a curved shallow-crossing linking structure carbon fiber / copper fiber preform is conducted and includes (1) warp yarn preparation, (2) weft yarn preparation, (3) warping, (4) drafting and denting, (5) weaving and (6) take-up and let-off; 2, CVI deposition is performed: the carbon fiber / copper fiber perform is arranged in a CVI system for deposition to prepare the friction material.Long carbon fibers and copper fibers are mixed and woven for preparation of the friction material, the advantages of the two types of fibers are fully played and the shortcomings of the fibers are overcome to achieve the effect of overcoming their own shortcomings by learning from their strong points.

Owner:JIANGNAN UNIV

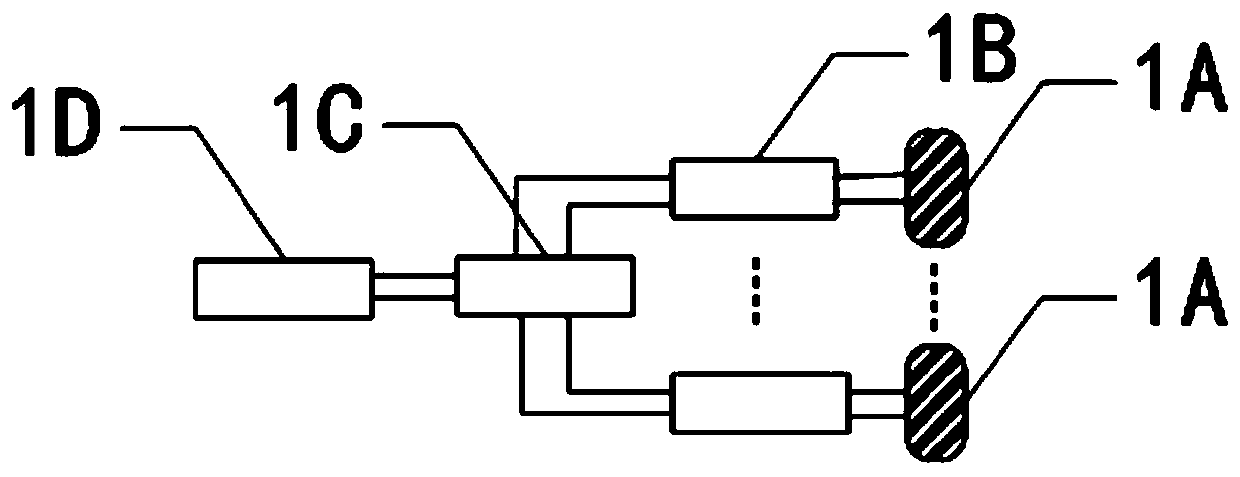

Satellite-borne SAR dual-polarized microstrip radiation sub-array antenna

ActiveCN111180868AImprove isolationImproved cross-polar performanceAntenna arraysRadiating elements structural formsAntenna polarizationTelecommunications

According to the invention, the antenna polarization requirement of a multi-information-amount satellite-borne SAR imaging system is met, reasonable unit layout combination is adopted, the problem ofmutual coupling between two polarization energies of the sub-array is isolated by using the metallized through holes, the defects of poor cross polarization and poor port isolation of a satellite-borne active phased array radiation sub-array are overcome, the space environment adaptability and reliability of the radiation sub-array are fully considered, and the aspects of material selection processing, processing selection, structural design layout and the like are fully emphasized, so that the radiation sub-array has the advantage of large-scale engineering application.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

Deep-crosslinked-structure carbon-fiber-reinforced phenolic-resin-base friction material and preparation method thereof

ActiveCN105038116AImprove flexural strengthIncreased shear strengthOther chemical processesInterlaminar shearUltimate tensile strength

The invention discloses a deep-crosslinked-structure carbon-fiber-reinforced phenolic-resin-base friction material. The preparation method of the friction material comprises the following steps: preparing a deep-crosslinked-structure carbon fiber prefabricated body, preparing a matrix colloidal liquid, and preparing the friction material, wherein the friction materials is prepared by immersing the deep-crosslinked-structure carbon fiber prefabricated body in the colloidal liquid and carrying out die pressing treatment. The stitching warp penetrates through the friction material in the whole thickness direction to form the three-dimensional structure, thereby overcoming the defect of delamination and increasing the interlaminar shear strength. The friction material has the advantages of excellent structural designability, excellent integral impact resistance and excellent fatigue resistance. The preparation method has the advantages of simple technique and low production cost, and is convenient for popularization.

Owner:JIANGNAN UNIV

Special color heat-pressing label for resin grinding wheel

The invention discloses a special colored hot-press label of a resin grinding wheel. The special colored hot-press label comprises a black paperboard or a copper printing paper substrate, a bottom layer, a pattered oil layer and a protective layer, wherein the bottom layer, the pattered ink layer and the protective layer are offset-printed on the substrate. Aiming at realizing small color change amplitude after a finished product label and the grinding wheel are sintered and vulcanized together, ink for the pattered ink layer is scientifically prepared from materials, such as polydimethylsiloxane phenolic resin, a chemical corrosion resisting agent, an anti-friction agent, tung oil, organic pigment, and the like, crude ink is modified, the high-temperature softening point of the ink layeris improved, the adhesive film hardness of the surface of the ink layer is increased, and an adhesive film gap on the surface of the ink layer is sealed. The special colored hot-press label has the advantages that: a brand name and various technical data of the grinding wheel are printed with various colors of ink by utilizing the appropriate substrate and then die-cut and formed, and directly hot-pressed on the surface of the substrate in the production process of the grinding wheel, and the grinding wheel is discharged from a furnace after dried in a high-temperature vulcanizing kiln for 30h at 186 DEG C, therefore, the mark of the label is very distinct, not powdered and obscure, and the color change amplitude is less than 10 percent.

Owner:郑州市晶森彩印有限公司

Gluing method for avoiding delaminating between foam plastic core and metal envelope

InactiveCN106142814AQuality assuranceReduce repair rate and scrap rateLamination ancillary operationsCosmonautic vehiclesAirplaneManufacturing quality

The invention belongs to the field of aircraft composite material manufacturing and relates to a bonding method for solving the delamination of a foam plastic core and a metal skin. In the method of the invention, the foamed plastic core and the metal skin are bonded by laying high-strength glass cloth and brushing epoxy resin glue, and then realize the bonding and curing between the two by vacuum pressure. The invention can solve the frequent delamination problem after the foam plastic core and the metal skin are glued together in the closed structure of the aircraft, effectively guarantee the quality of parts manufacturing, and greatly reduce the repair rate and scrap rate of such parts , and easy to implement, wide adaptability and low cost.

Owner:SHAANXI AIRCRAFT CORPORATION

Module, manufacturing method thereof, camera and electronic device

InactiveCN109218582AEasy to fall offResolve fragmentationTelevision system detailsColor television detailsEngineeringUltimate tensile strength

The invention is applicable to the technical field of a camera, and provides a lightweight and thin module and a manufacturing method thereof, a camera and an electronic device. The module comprises acircuit board, an image sensor, a middleware and an optical filter, wherein the optical filter is directly fixed on the top surface of the photosensitive area of the image sensor. The embodiment eliminates the base in the prior art and directly fixes the filter on the top surface of the photosensitive area of the image sensor, thereby saving components and reducing the filter attaching process, and avoiding the problem of tilting the base and the middleware in the installation process. As for that module design, since there is no base, the space of the module in the vertical direction is saveby 0.3 to 0.5 mm, so that the module is lighter and thin. In addition, since the image sensor itself is fixed on the circuit board, the image sensor can provide sufficient bearing strength to the filter, thereby improving the bearing capacity of the module when impacted by external forces, and making the filter not easy to fall off or break.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Artificial stone wood combined colorful environment friendly stone furniture table-board and method of producing the same

InactiveCN101508554ASolve delaminationSolve warpingSynthetic resin layered productsLaminationTechnical standardFirming agent

The invention discloses a man-made colored and environment-friendly stone furniture table-board combining stone and wood and a manufacturing method thereof. Ethyl methyl ketone is taken as a firming agent, cobalt naphthenate solution is taken as an accelerator, unsaturated polyester resin and talc powder are taken as binders and waste slabs are taken as basal layers and the table-board is manufactured by certain processes. The table-board successfully solves the technical problems of delamination, upwarping, bending and deformation of the existing man-made stone and saves over 60% of chemical raw materials, thereby greatly lowering the cost of the product, and the surface hardness and lustrousness meet the national relevant technical standards. The table-board is free from delamination, upwarping, bending and deformation and has the advantages of beautiful design, bright color, durability, low cost, light weight, high strength, bending resistance, changing waste into valuable and environment protection. Various flower patterns can be designed based on the requirements. The luxurious rate and decorative effect of the table-board is superior to the natural stone and is a super top-quality building decoration material.

Owner:江孟东

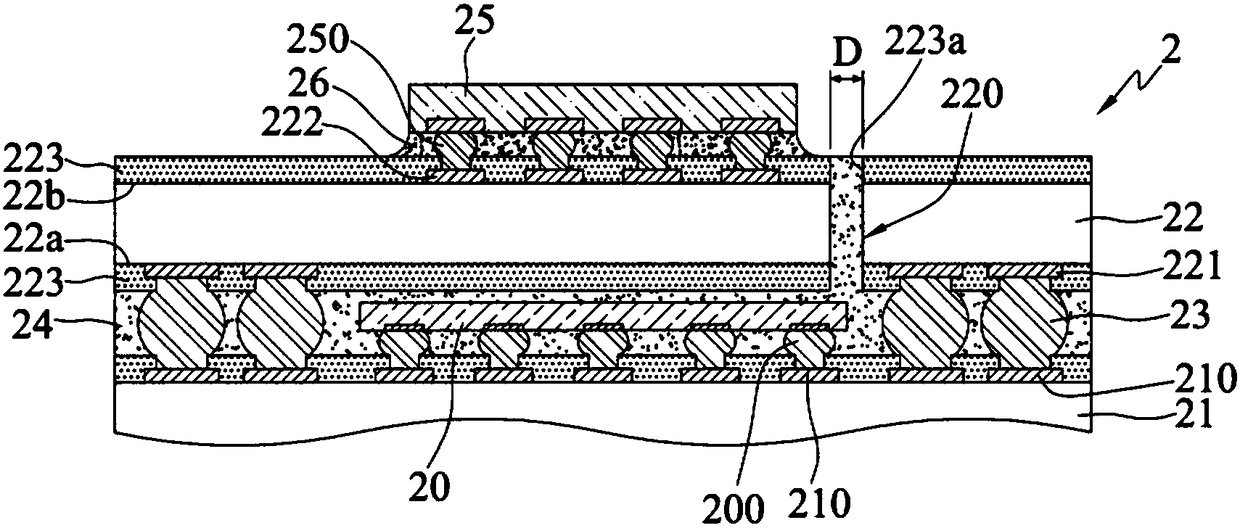

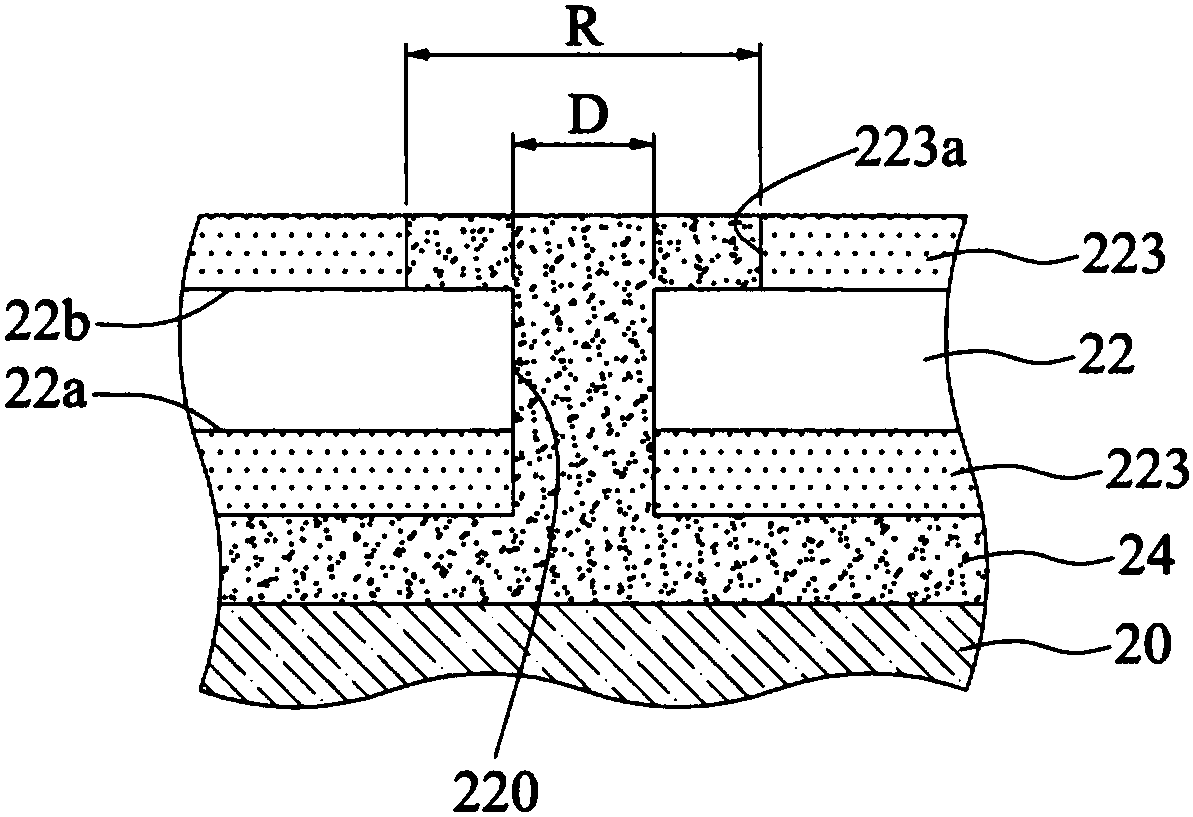

Package stack structure

ActiveCN108074881AIncrease contact areaImprove bindingSemiconductor/solid-state device detailsSolid-state devicesEngineering

A package stack structure is provided, including a first substrate, a second substrate stacked on the first substrate, and an encapsulant formed between the first substrate and the second substrate. Athrough hole is formed to penetrate the second substrate and allow the encapsulant to be filled therein, thereby increasing the contact area and hence strengthening the bonding between the encapsulant and the second substrate.

Owner:SILICONWARE PRECISION IND CO LTD

Current collection layer structure of solid oxide fuel cell

InactiveCN104766983ASimple structureExpensive to fixSolid electrolyte fuel cellsFuel cell detailsNanometreEngineering

The invention discloses a current collection layer structure of a solid oxide fuel cell. The current collection layer structure comprises a current collection layer skeleton structure and a current collection layer active structure, wherein the current collection layer active structure is infiltrated inside the current collection layer skeleton structure, and the current collection layer active structure consists of nano particles. The current collection layer structure of the solid oxide fuel cell is simple in structure, the problem that the traditional metal current collection layer is expensive in price can be solved, the stripping problem caused by mismatching of heat expansion coefficients between the ceramic current collection layer and the cell can be solved, the preparation cost is low, and the current collection layer structure is easy to realize.

Owner:昆山艾可芬能源科技有限公司

Binder composition for semiconductor device and binder sheet for semiconductor device

InactiveCN1821337AExcellent electrical reliabilityGood adhesionFilm/foil adhesivesAldehyde/ketone condensation polymer adhesivesEpoxyDynamic viscoelasticity

The present invention provides one kind of adhesive composition with excellent performances, especially high adhesion capacity and excellent heat tolerance, for semiconductor device and adhered sheet for semiconductor device. The adhesive composition for semiconductor device contains epoxy resin, phenolic resin, and ethylene copolymer containing ethylene and unsaturated carboxylic acid with functional group capable of reacting with the epoxy resin or its derivative. The adhesive composition has its dynamic viscoelasticity before curing measured to have lowest molten viscosity of 400-50,000 Pa.s.

Owner:TOMOEGAWA PAPER CO LTD

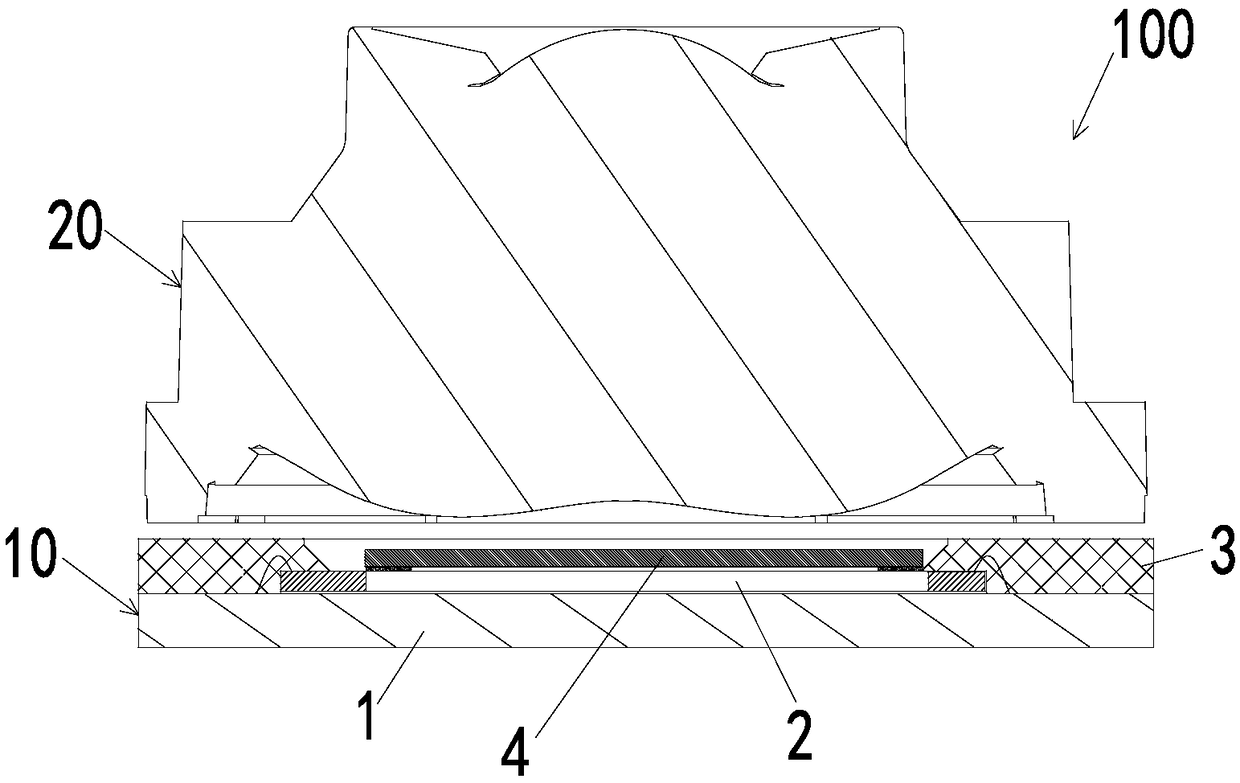

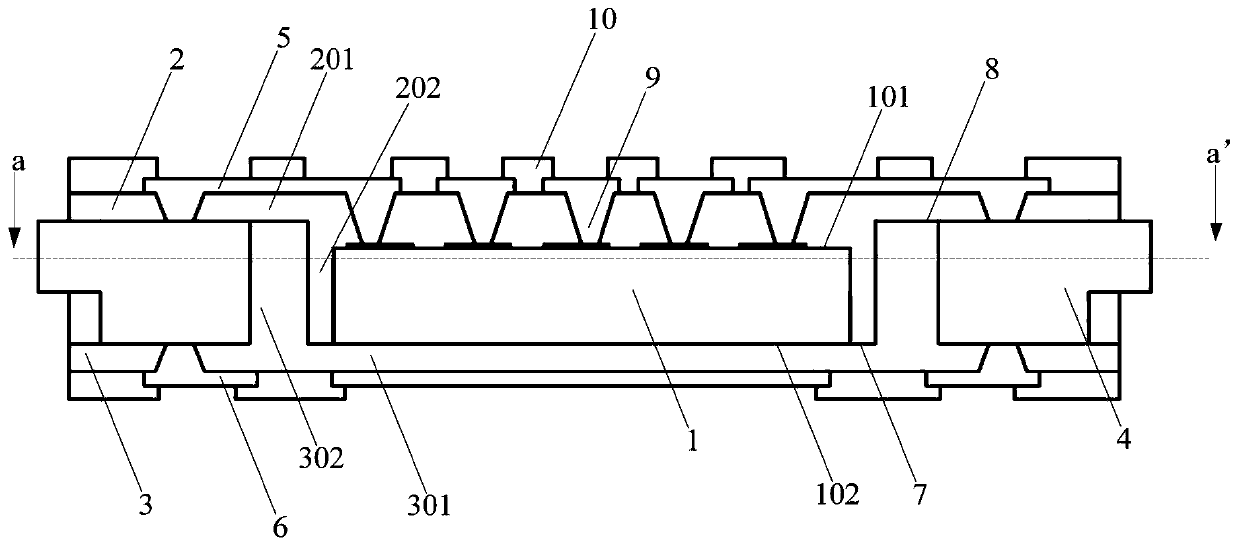

Power module, chip embedded packaging module and preparation method

ActiveCN111415908ASolve delaminationAvoid delaminationSemiconductor/solid-state device detailsPrinted circuit aspectsMechanical engineeringPower module

The invention provides a power module, a chip embedded packaging module and a preparation method. The chip embedded packaging module comprises a chip which is provided with a first surface and a second surface which are oppositely arranged; a first plastic part which comprises a first covering part and a first protrusion, wherein the first covering part wraps at least one part of the first surfaceof the chip, the first protrusion wraps the side face of the chip, and the surface where the top end of the first protrusion is located and the second surface of the chip are located are located on the same plane; a second plastic part which comprises a second covering part and a second protrusion, wherein the second covering part covers at least one part of the second surface of the chip, the second protrusion is arranged on the side face of the chip, and the surface where the top end of the second protrusion is located and the second surface of the chip are not located on the same plane. Therefore, a non-equal-height discontinuous interface structure is formed between the surface where the top end of the second protrusion is located and the second surface of the chip, a delamination expansion path at the edge position of the chip is cut off, and delamination initiation is effectively inhibited.

Owner:DELTA ELECTRONICS SHANGHAI CO LTD

Manufacturing method of corrosion-resistant high-flame-retardant silicon core pipe

The invention discloses a corrosion-resistant high-flame-retardant silicon core pipe which is prepared from, by weight, 230-320 parts of n-paraffin hydrocarbon, 195-225 parts of high-density polyethylene, 35-45 parts of dodecene, 135-145 parts of methyl hydrogen silicone oil, 25-30 parts of hydroxy stearic acid, 75-85 parts of polyolefin resin, 10-12 parts of color master batches, 6-8 parts of graphene, 3-5 parts of sodium-based bentonite, 2-4 parts of polyvinyl alcohol, 1-2 parts of zinc naphthenate, 2-4 parts of nano-boride, 3-4 parts of polyurethane, 1-2 parts of polyacrylic acid, 3-5 partsof triethyl phosphate, 2-3 parts of chlorinated paraffin, 1-2 parts of antioxidants, 5-7 parts of glycerol and 7-9 parts of deionized water. By the aid of the formula, the corrosion-resistant high-flame-retardant silicon core pipe has high wear resistance, high flame resistance and high reliability, overall consistency is improved, and the problem of delaminating is avoided. In addition, variousreactants with different functions are added, so that reaction is sufficient, various composition effects of the pipe are maximally achieved, and finally, the pipe is quite high in overall performance.

Owner:RONGCHENG PIPE IND

A preparation method of polypropylene type adhesive resin for multilayer co-extruded barrier packaging

ActiveCN104371597BEasy to processHigh transparencyLaminationLamination apparatusElastomerHeat resistance

Owner:HEYUAN PLG MATERIALS

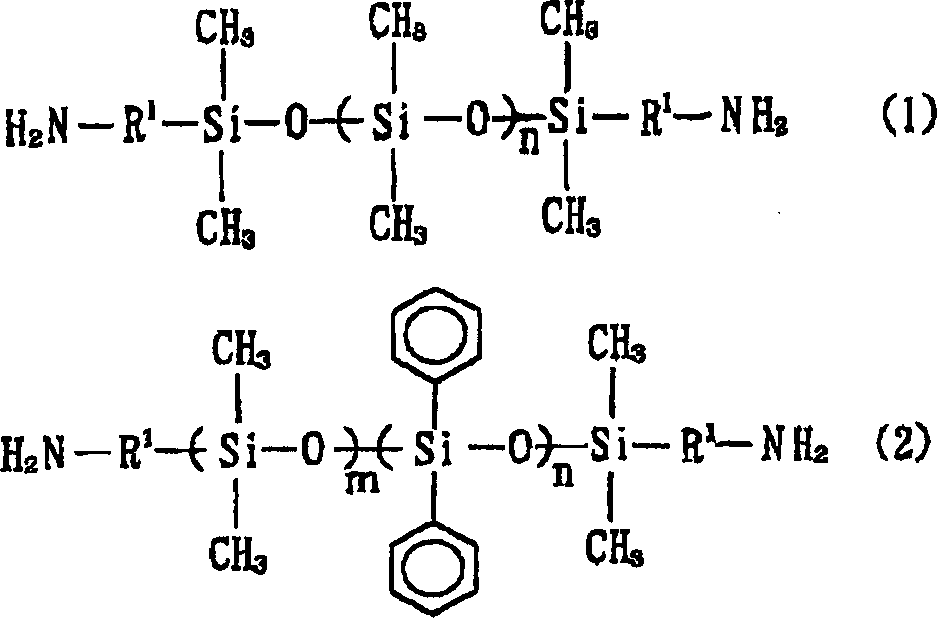

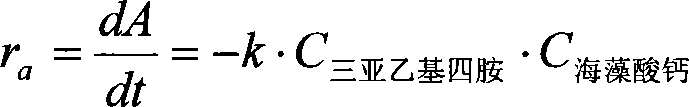

Reinforcement method for yeast cell immobilization

InactiveCN101117632AImprove salt resistanceHigh mechanical strengthFungiOn/in organic carrierYeastCalcium alginate

The present invention relates to a strengthening method for the immobilization of saccharomyecte cells in the bioengineering technical field. The present invention is characterized in that a immobilized granule forms the fortified and immobilized yeast spherical bead through the process of trien and then through the process of glutaraldehyde after the calcium-alginate-immobilized yeast spherical bead is formed; the immobilized yeast spherical bead has good chemical intensity, whose index can reach 95.32 percent, and also has good physical intensity, whose index can reach 132.3 kg per square centimeters. Moreover, the fermentation performance of the granule is stable, and the service life is longer.

Owner:SHANGHAI JIAO TONG UNIV

Wind power generation monitoring system based on distributed vibration optical fibers

PendingCN114459594ASolve delaminationSolve crackingSubsonic/sonic/ultrasonic wave measurementCharacter and pattern recognitionEngineeringFan blade

The invention relates to a distributed vibration optical fiber-based wind power generation monitoring system, which is characterized in that an optical fiber is arranged in a fan blade in a production link, and adopts the following method: (1) an optical fiber signal is converted into a vibration signal through a photoelectric conversion part, and the detection length of the optical fiber is obtained through the vibration signal; (2) the broken fiber judgment module judges whether fiber relaying occurs or not according to the vibration signal; (3) carrying out feature extraction on the vibration signal, and meanwhile, carrying out further sound restoration to obtain environmental sound information features; the vibration energy features and the environment sound information features are subjected to feature training through a decision tree forest according to application requirements, and effective features are stored in a historical feature library; and (4) performing state judgment and output by performing a feature matching algorithm on the historical feature library in the operation process, and performing reminding when detecting that the state is abnormal. The occurrence of fiber breakage is detected according to the change of the length of the optical fiber, and the problem of intelligent monitoring of the conditions of delamination, cracks, abrasion and the like of the fan blade is solved.

Owner:WUXI KEY SENSOR PHOTONICS TECH

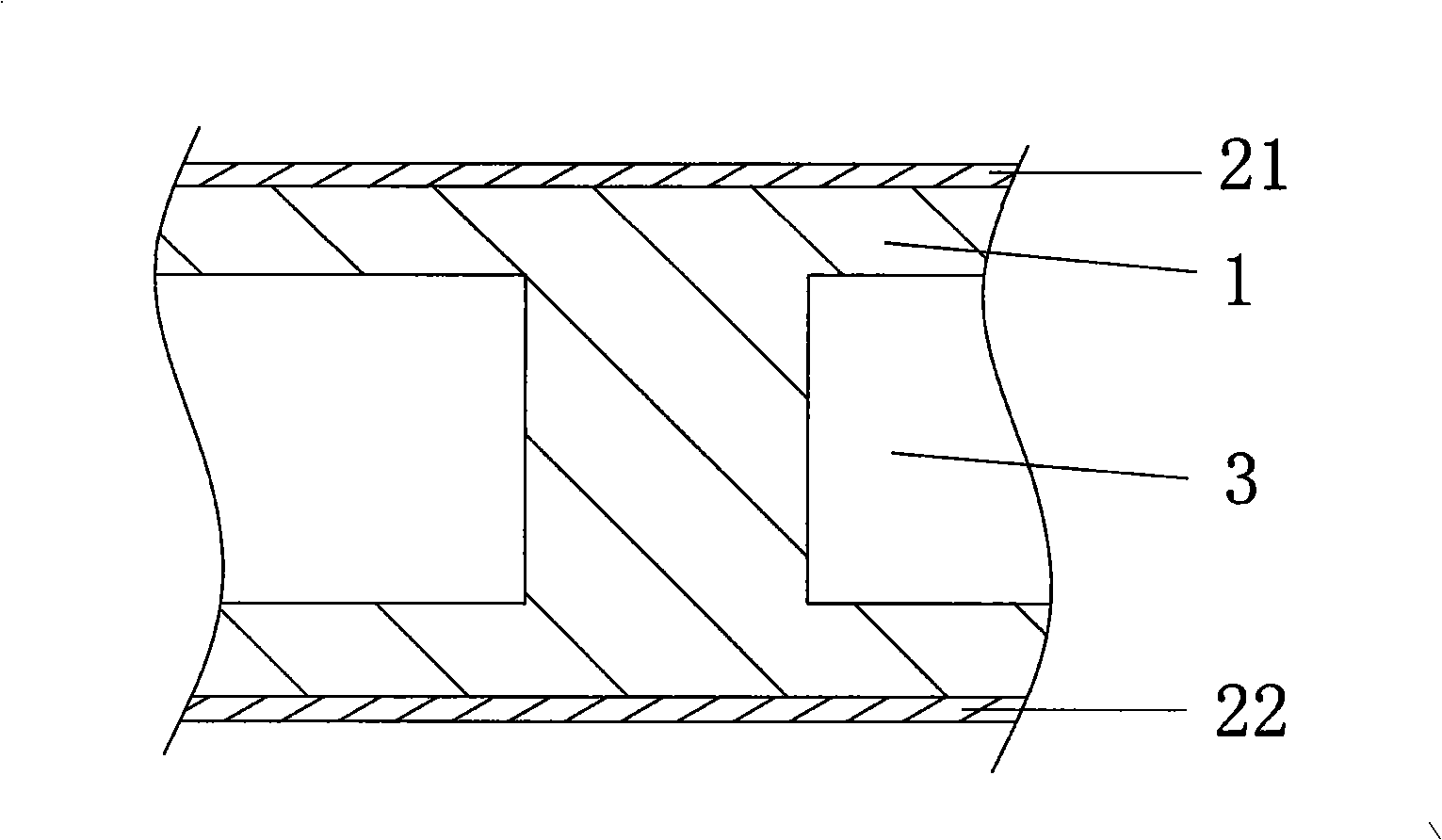

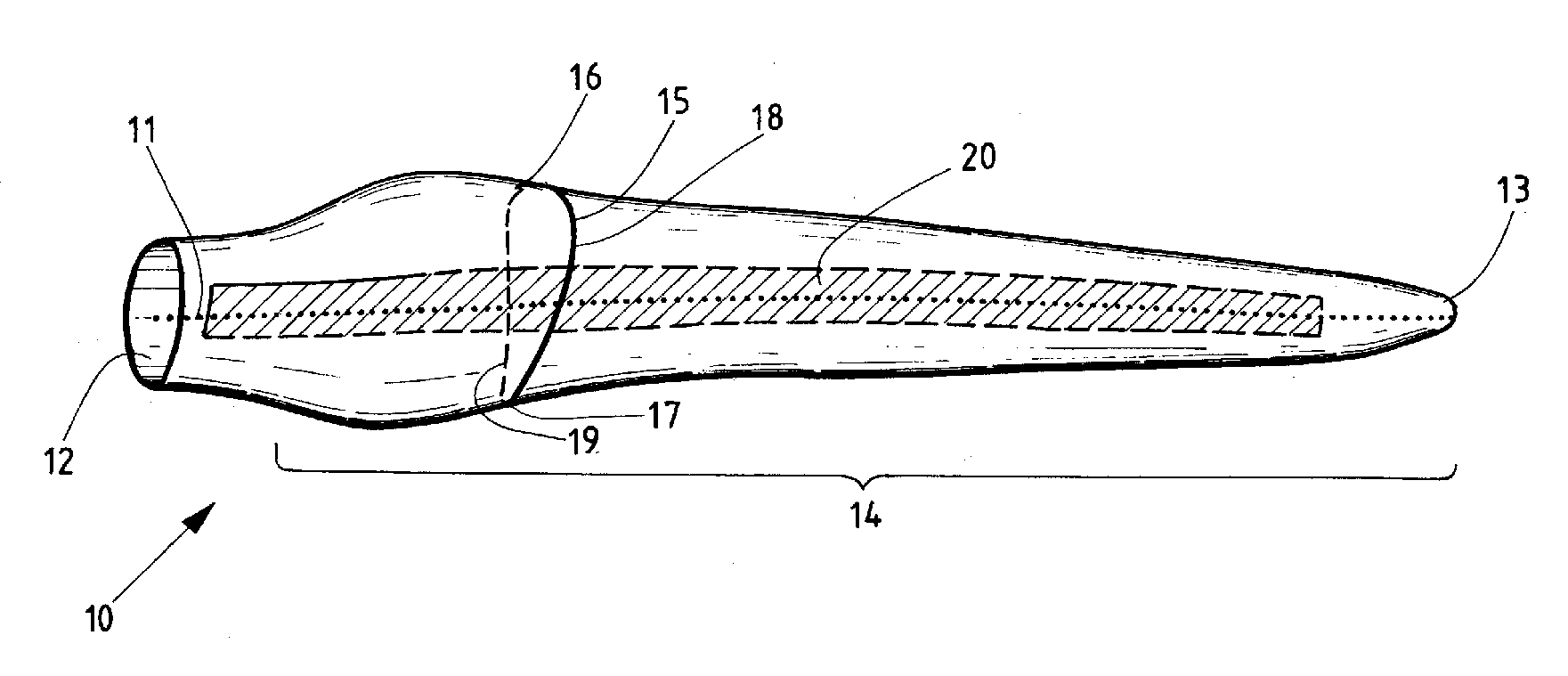

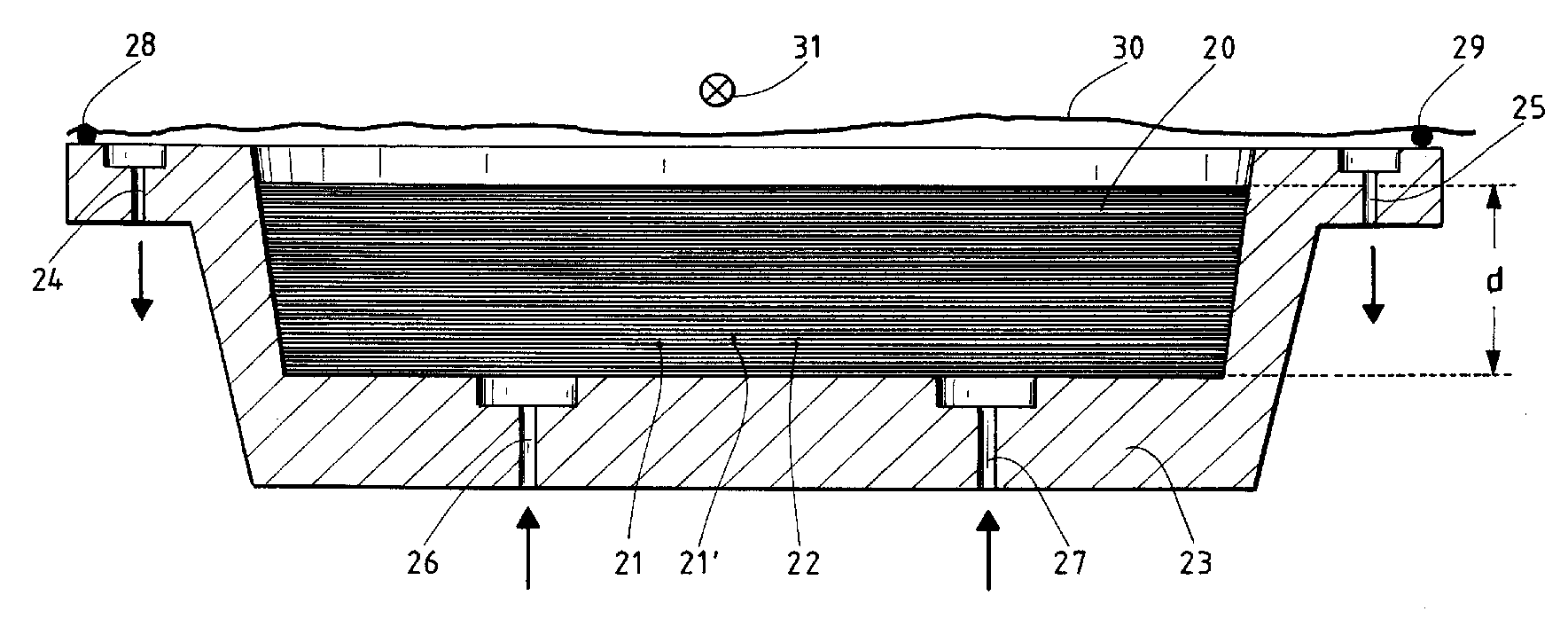

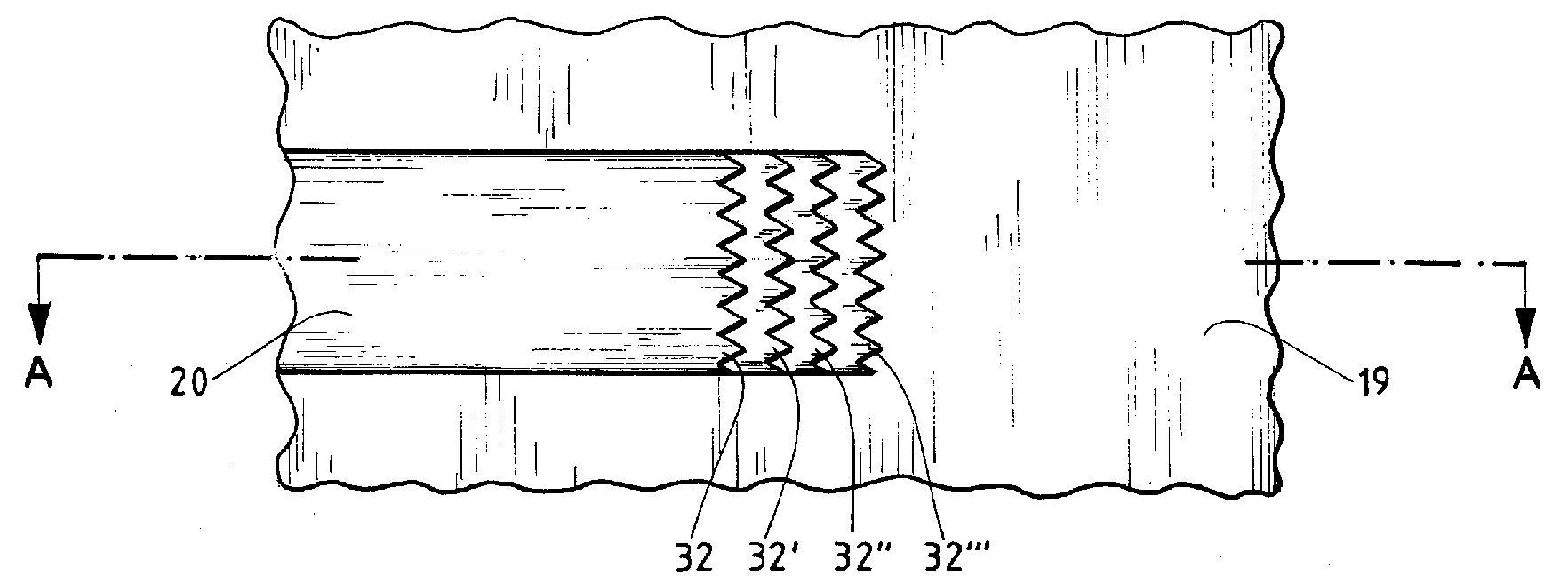

Belt of rotor blade of wind power plant

InactiveCN102086846AAvoid delaminationSolve delaminationEngine manufactureFinal product manufactureEngineeringWind power

The present invention relates to a belt (20) of a rotor blade (10) of a wind power plant, including a plurality of fiber-reinforced individual layers which are interconnected by a resin. The belt is characterized in that at least one fiber-reinforced individual layer of the belt has a longitudinal stiffness of more than 50,000 N / mm with a thickness of more than 0.9 mm.

Owner:REPOWER SYST AG

Preparation method for high-temperature-resistant laminated composite zirconium dioxide-niobium material

InactiveCN103590035ASolve delaminationVacuum evaporation coatingSputtering coatingZirconium hydrideNiobium

The invention relates to a preparation method for a high-temperature-resistant laminated composite zirconium dioxide-niobium material. The preparation method comprises the following steps: preprocessing of a niobium sheet, zirconium plasma injection, drawing of a zirconium dioxide film on the surface of the niobium sheet through the sol-gel method, and high-temperature sintering. The invention has the advantages that through the vacuum metal plasma injection technology, the metallic element zirconium is injected into the pickled and etched niobium metal test sheet according to a certain amount of energy and dosage, so as to solve the problem that the zirconium dioxide film easily cracks due to the large differences between niobium and zirconium dioxide in ion size as well as between coefficients of thermal expansion; the niobium metal test sheet is covered by the zirconium dioxide film through the vertical drawing method of a zirconium sol-gel solution; the niobium sheet and the zirconium dioxide film are subjected to high-temperature annealing and sintering together to prepare the high-temperature-resistant laminated composite zirconium dioxide-niobium material. According to the composite zirconium dioxide-niobium material, the niobium sheet and the zirconium dioxide film are directly compounded in a laminated manner, so that the high-temperature-resistant property of the niobium sheet and the zirconium dioxide film is preserved. Therefore, the composite zirconium dioxide-niobium material achieves a very good application potential in the high-temperature field.

Owner:TIANJIN UNIV

A 2.5-dimensional carbon fiber woven preform reinforced resin-based friction material

The invention discloses a 2.5 dimensional carbon fiber woven prefabricated part reinforced resin matrix friction material. The friction material is formed by combining and curing 2.5 dimensional carbon fiber woven prefabricated parts serving as reinforced structures and matrix resin glue. The specific preparation process comprises the steps of pretreatment of carbon fibers, preparation of the 2.5 dimensional carbon fiber woven prefabricated parts, preparation of the matrix resin glue and preparation of the friction material. According to the friction material, the carbon fibers are subjected to the pretreatment, and thus the carbon fibers are excellent in strength elongation property and weavability. Attachment warps penetrate through the material in the whole thickness direction, three-dimensional structures are formed, the delaminating problem is solved, the interlaminar shear strength is improved, the mechanical properties are outstanding, and the service life is prolonged; meanwhile, the preparation process is simple, and a product is low in porosity, uniform and compact, flat and clean in surface, low in production cost and easy to popularize.

Owner:JIANGNAN UNIV

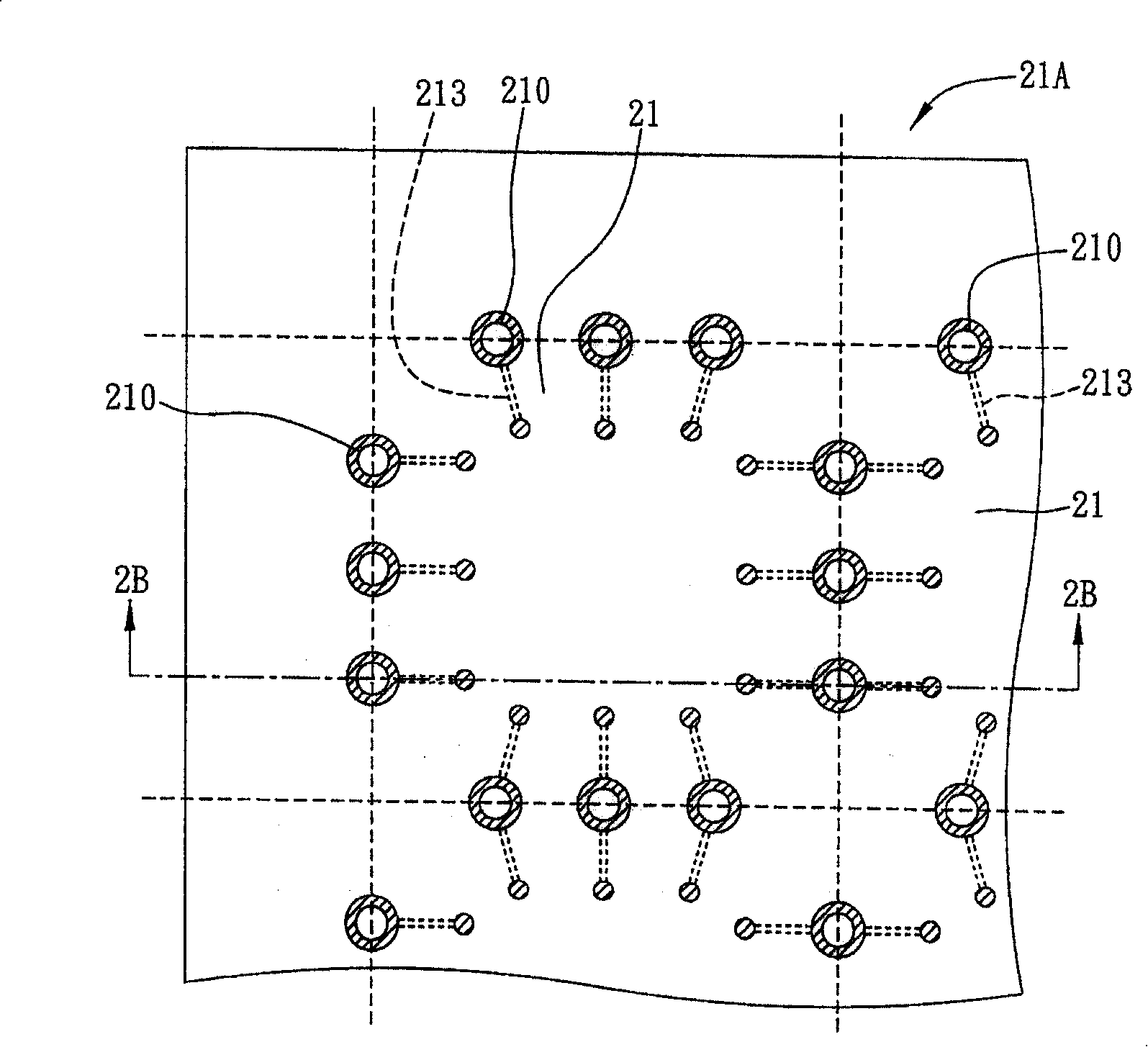

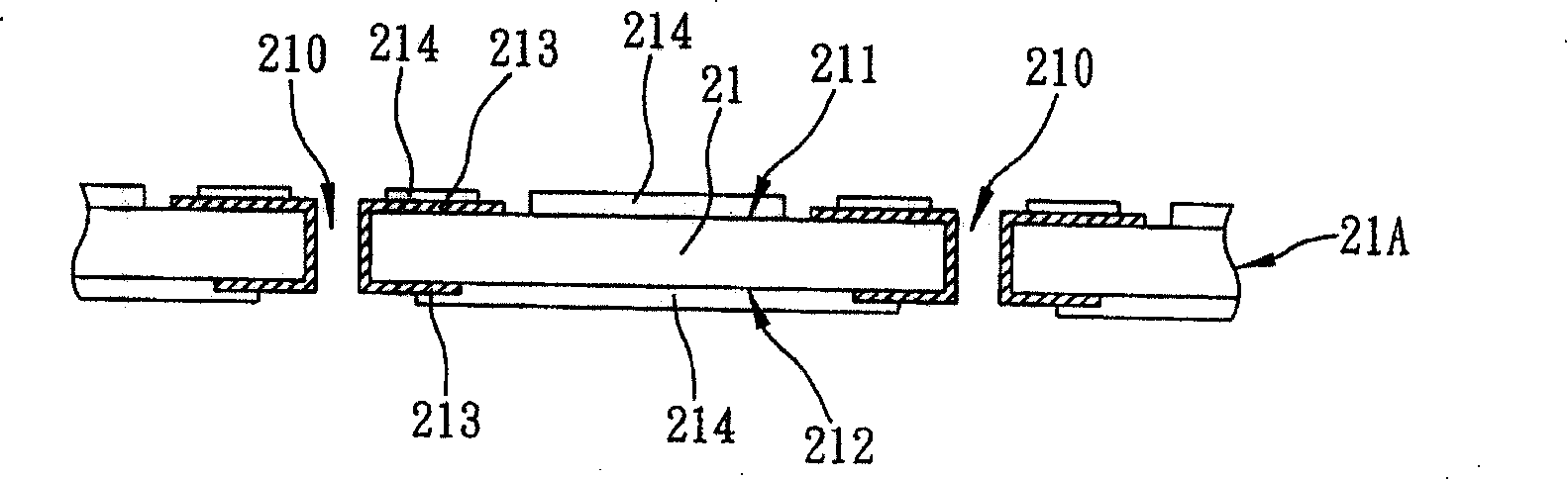

Sensing type packaging part and manufacturing method thereof

InactiveCN101231959APrevent leakageSolve delaminationSemiconductor/solid-state device detailsSolid-state devicesElectric propertiesEngineering

The invention discloses a sensitive packaging part and a manufacturing method thereof. The invention provides a baseplate pattern assembly sheet with a plurality of baseplates which are arranged in array. A plurality of via holes of electric property are arranged between adjacent baseplates, which are filled with and covered with conducting materials. Dam structures covering the conducting materials are formed between adjacent baseplates on the baseplate pattern assembly sheet. The via holes are filled and covered with such conducting materials as soldering tin to prevent the material constituting the dam structure from being drained onto the other surface of the baseplates through via holes. In addition, a tape is not required to be covered on the via holes in advance. The invention eliminates the problem that the tape absorbs moisture which results in separation of the dam structures and the baseplates. Subsequently, sensitive chips can be electrically connected in areas enclosed by the dam structures on the baseplates; transparent units covering the sensitive chips are connected to the dam structures. In the subsequent cutting process, a plurality of sensitive packaging parts are got by means of cutting between the baseplates.

Owner:SILICONWARE PRECISION IND CO LTD

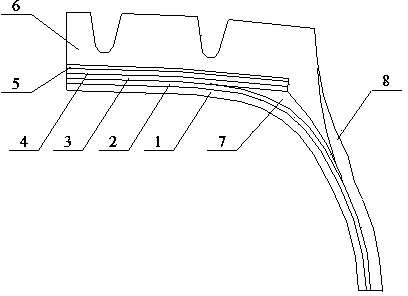

Radial tire with belt work ply cords arranged at 90 degrees in circumferential direction

InactiveCN104354537AReduce shear stressSolve delaminationPneumatic tyre reinforcementsStrain energyEngineering

The invention provides a radial tire with belt work ply cords arranged at 90 degrees in the circumferential direction. The radial tire is characterize in that the lower side of a shoulder wedge is connected with a carcass ply, the upper side of the shoulder wedge is connected with a first belt ply and tread rubber respectively, sidewall rubber is connected with the side surface of the tread rubber, and both the first belt ply and a second belt ply are arranged at 90 degrees. According to the radial tire, a section curve is usually parallel to a tread design curve; the work plies circumferentially arranged at 90 degrees are orthogonal to a carcass at 0 degree in the radial direction, and basic features of an orthogonal tire are formed. Compared with existing various steel wire belt ply structures, the radial tire has the advantages that the maximum value of the strain energy density in rubber parts in a crown area is reduced by 50%-80% and is moved to an area near the shoulder surface greatly beneficial to heat radiation from space among the belt plies or end areas on two sides, and the mass loss problems such as early shoulder separation, crown separation, separation, crown burst and the like which usually occur easily during use of a tire adopting the radial tire structure can be effectively solved.

Owner:王友善

Vertical honeycomb sandwich plate, preparation method and sandwich plate connecting method

PendingCN109383077AImprove carrying capacityHigh bonding strengthLayered productsVehicle componentsHoneycombEngineering

The invention discloses a vertical honeycomb sandwich plate, a preparation method and a sandwich plate connecting method. The vertical honeycomb sandwich plate comprises an upper face plate, a lower face plate, an upper glue layer, a lower glue layer, a honeycomb layer arranged between the upper glue layer and the lower glue layer as well as a plurality of upright columns connected with the upperface plate and the lower face plate respectively, wherein honeycomb holes of the honeycomb layer are vertical to the face plates. During preparation, a honeycomb core is arranged in a sleeving mannerafter one ends of the plurality of upright columns are fixedly connected with the lower face plate, the upper face plate is connected and fixed with the other ends of the upright columns, the upper glue layer and the lower glue layer are poured respectively, and the honeycomb sandwich plate is prepared. According to the sandwich plate connecting method, sandwich plates can be connected by arranging overlap edges or adopting solid square tubes. The honeycomb sandwich plate is low in density, light in weight and high in specific strength, specific stiffness, bearing capacity, vibration damping,sound insulation and heat insulation, and bonding strength between the core and the face plates is high; meanwhile, the method is simple, the operability is high, and the cost is low; besides, the connecting strength of the sandwich plates is high.

Owner:JIANGSU UNIV OF SCI & TECH

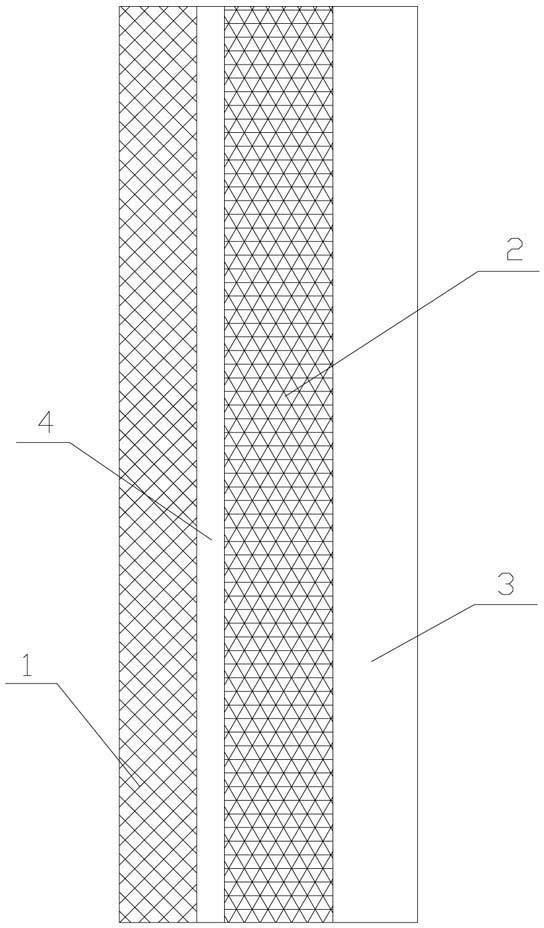

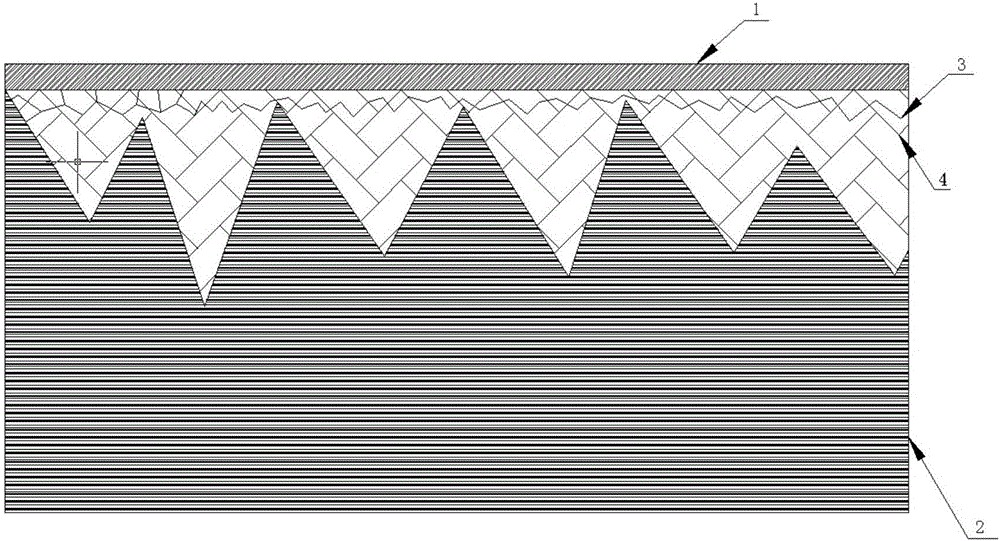

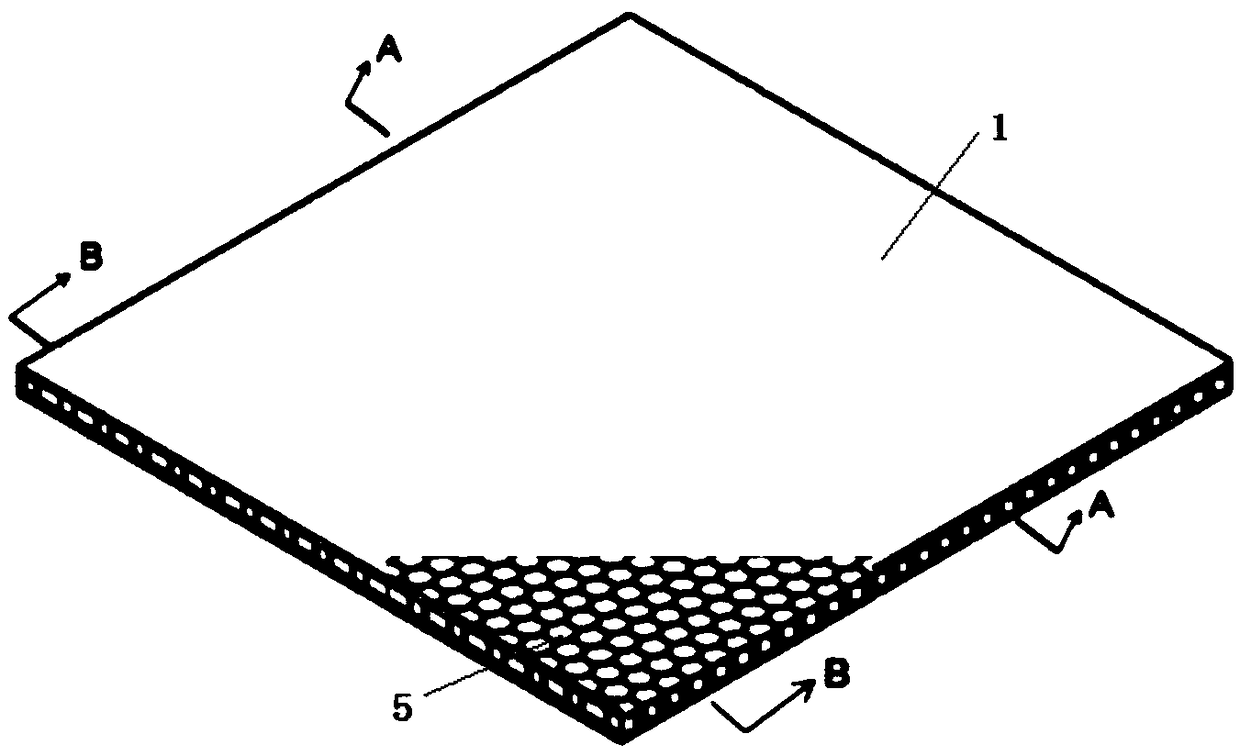

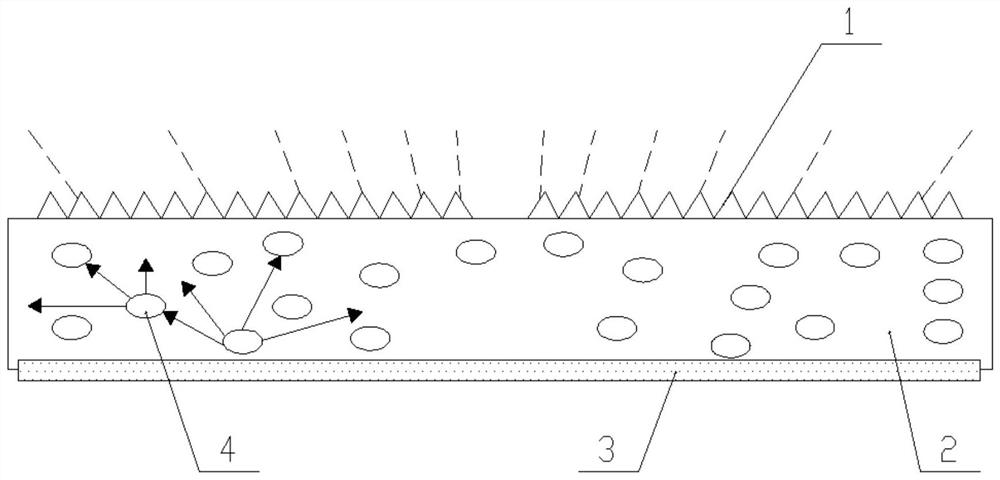

Diffusion and brightening composite optical film and preparation method thereof

ActiveCN113504591AReduce use costIncrease productivityPrismsDiffusing elementsThin membraneChemistry

The invention provides a diffusion and brightening composite optical film and a preparation method thereof, the diffusion and brightening composite optical film is prepared by co-extruding and compounding a diffusion layer with a diffusion microstructure function and a brightening layer with a brightening functional structure, and the problems that in the coating process of an existing optical diffusion film product, the production efficiency and the quality yield of the prepared product are reduced, The result shows that the PET extrusion film cannot meet the optical requirements of high fog and high transmittance; meanwhile, a coating process is adopted, so that pollution to the environment is caused, and in the subsequent processing process, the defect that the product quality is affected by dust generated by coating falling does not occur. The use convenience and the thin film use turning-out are improved, the use cost is reduced, and the production efficiency is improved.

Owner:JIANGXI SHENGHUI OPTICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com