Module, manufacturing method thereof, camera and electronic device

A module and circuit board technology, applied in the field of cameras, can solve the problems of tilting of the camera holder assembly, easy falling off of filters, layering and falling off, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

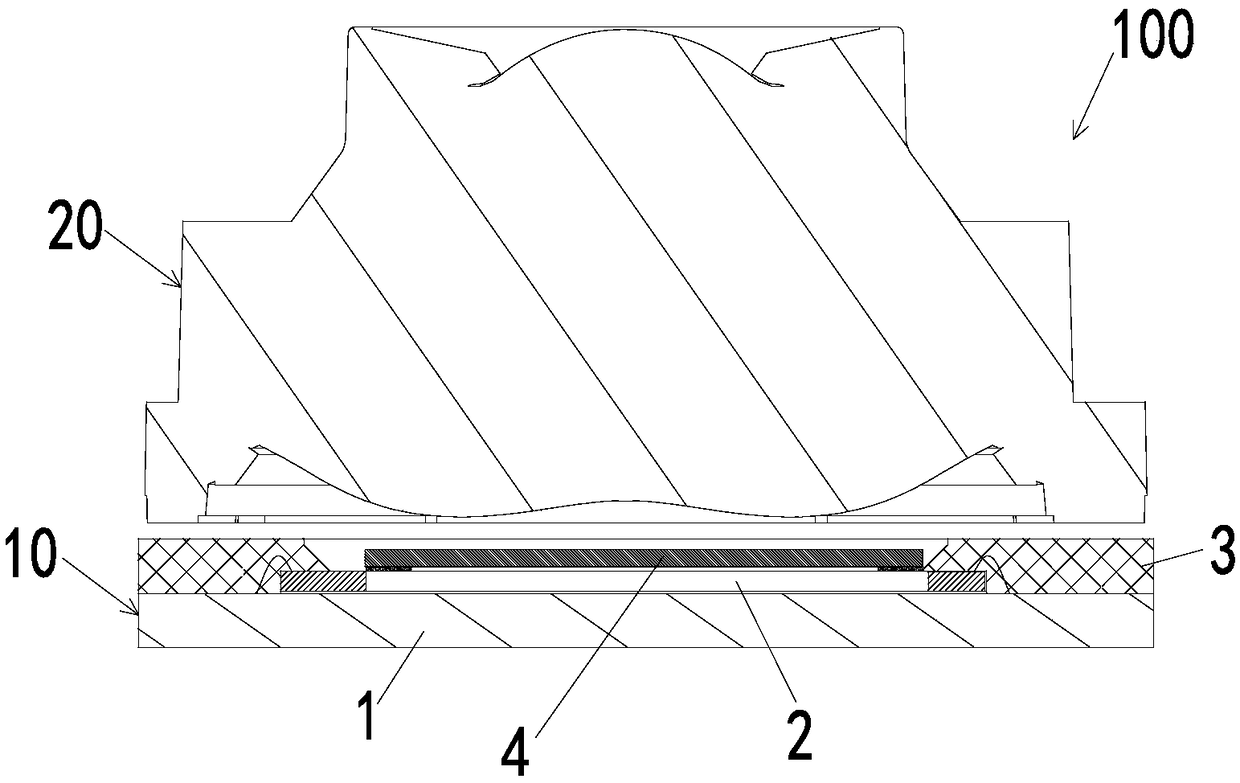

[0030] See figure 1 , which is Embodiment 1 of the present invention, provides a module 10 including a circuit board 1 , an image sensor 2 , a middleware 3 and an optical filter 4 .

[0031] The image sensor 2 is fixed on the circuit board 1 and is electrically connected to the circuit board 1 through a connecting wire 5 . See figure 2 , the middle piece 3 has a hollow area 31 and an edge area 32, the edge area 32 of the middle piece 3 is fixed on the circuit board 1, the image sensor 2 has a photosensitive area 21, and the optical filter 4 is fixed on the image sensor by an adhesive 6 2 on the top surface of the photosensitive area 21, and the position of the optical filter 4 corresponds to the photosensitive area 21 of the image sensor 2, and the image sensor 2 and the optical filter 4 are embedded in the hollow area of the middle piece 3.

[0032] In this embodiment, the optical filter 4 is made of blue glass, which can filter part of infrared rays and visible red ligh...

Embodiment 2

[0045] See Figure 5 , the main content of this embodiment is the same as that of Embodiment 1, the difference is that the image sensor 2 of this embodiment also has a non-photosensitive region 22, and the non-photosensitive region 22 is located at the outer periphery of the photosensitive region 21, and the optical filter 4 The edge area is bonded to the top surface of the non-photosensitive area 22 by means of an adhesive 6 . Since the optical filter 4 is connected to the non-photosensitive region 22 of the image sensor 2 , there is no limit to whether the light transmittance of the adhesive 6 is high or low.

[0046] Specifically, in order to make the connection between the middle piece 3 and the circuit board 1 stronger, the edge area of the top surface of the circuit board 1 is fixed with a boss 11 , and the middle piece 3 wraps the boss 11 .

Embodiment 3

[0048] See Figure 6 The main content of this embodiment is the same as that of the first embodiment, except that the filter 4 of this embodiment is bonded to the top surface of the photosensitive region 21 of the image sensor 2 through an adhesive 6 with high light transmittance. Optionally, glue with a light transmittance higher than 92% can be used as the adhesive 6 . Since the adhesive 6 with high light transmittance is used, the optical filter 4 can be bonded to the image sensor 2 in a large area, and the connection between the optical filter 4 and the image sensor 2 is very firm. Also, the adhesive 6 does not interfere with entering the image sensor 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com