Structural chromogenic finishing liquid for preparing high-stability photonic crystal, and application of structural chromogenic finishing liquid

A high-stability, structural color-producing technology, applied in dyeing, textiles, and papermaking, can solve the problems of limited printing equipment, poor printing effect, lack of adaptability, etc., and achieve green and universal applicability , easy to implement, guaranteed durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

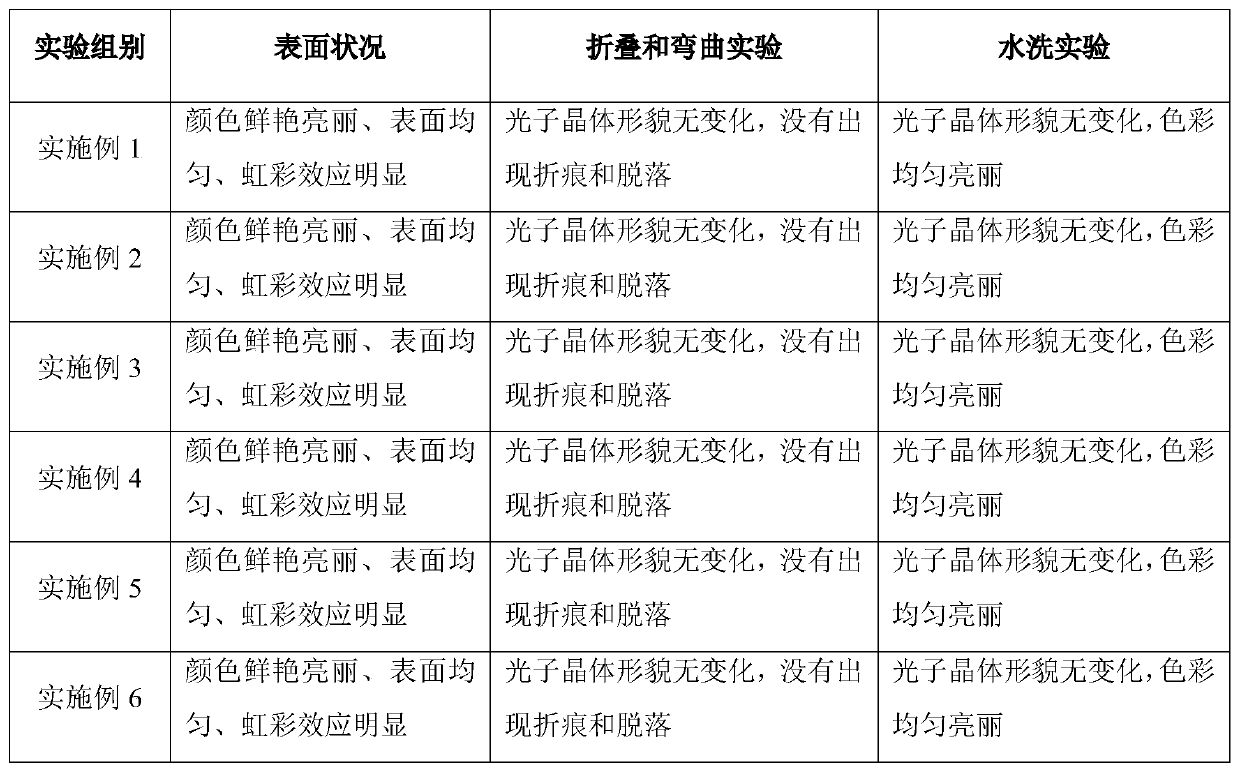

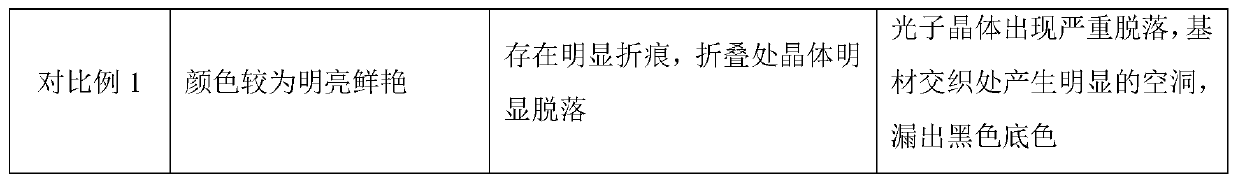

Examples

Embodiment 1

[0040]At room temperature, to 25% (in terms of solid content) particle size is 240nm, monodispersity index (PDI) is 0.05 polystyrene microspheres (PSt) colloidal microspheres, add successively account for 5% of the total mass of colloidal microspheres Structural stabilizer self-crosslinking water-based polyacrylate, 1% surfactant sodium dodecyl sulfate (SDS) and 2% thickener sodium alginate (SA), then heated and stirred at 70°C for 20min; The above prepared finishing solution was stirred at 10000r / min for 30min, then placed in a gravure printing machine, and pattern printing was carried out on the black polyester fabric base material, and the printed black polyester fabric was taken out, and then heat-baked at 80°C for 60s Bright and gorgeous, highly stable turquoise photonic crystal structure color-producing textiles can be obtained.

Embodiment 2

[0042] At room temperature, 30% (in terms of solid content) of silicon dioxide (SiO) with a particle size of 210 nm and a monodispersity index (PDI) of 0.06 2 ) in the colloidal microspheres, sequentially add the structure stabilizer self-crosslinking water-based polyurethane accounting for 3.5% of the total mass of the colloidal microspheres, 3% of the surfactant alkylphenol polyoxyethylene ether (OP-10) and 1% of the thickener Carboxymethyl cellulose (CMC), then heated and stirred at 70°C for 20 minutes; the above prepared finishing solution was stirred at a speed of 10000r / min for 30 minutes and then placed in a gravure printing machine, and pattern printing was carried out on a black silk fabric substrate. Take out the printed black silk fabric, and heat-bake it at 80°C for 60 seconds to get bright and gorgeous, highly stable color-producing textiles with blue photonic crystal structure.

Embodiment 3

[0044] At room temperature, to 40% (in terms of solid content) particle size is 350nm, monodispersity index (PDI) is 0.02 poly (styrene microspheres-methacrylic acid) (P (St-MAA)) colloidal microspheres Add successively the structural stabilizer self-crosslinking water-based polyacrylate accounting for 2% of the total mass of the colloidal microspheres, 2% of the surfactant sodium lauryl polyoxyethylene ether sulfate (AES) and 1.5% of the thickener glycerol Alcohol (GL), and then heated and stirred at 70°C for 20 minutes; the above prepared finishing solution was stirred at 10000r / min for 30 minutes, then placed in a gravure printing machine, and pattern printing was carried out on the black cotton fabric substrate, and it was taken out after printing. After the black cotton fabric has been baked at 80°C for 60 seconds, a bright and colorful, highly stable magenta photonic crystal structure color-producing textile can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com