Preparation method of multi-layered textile fabric capable of purifying air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

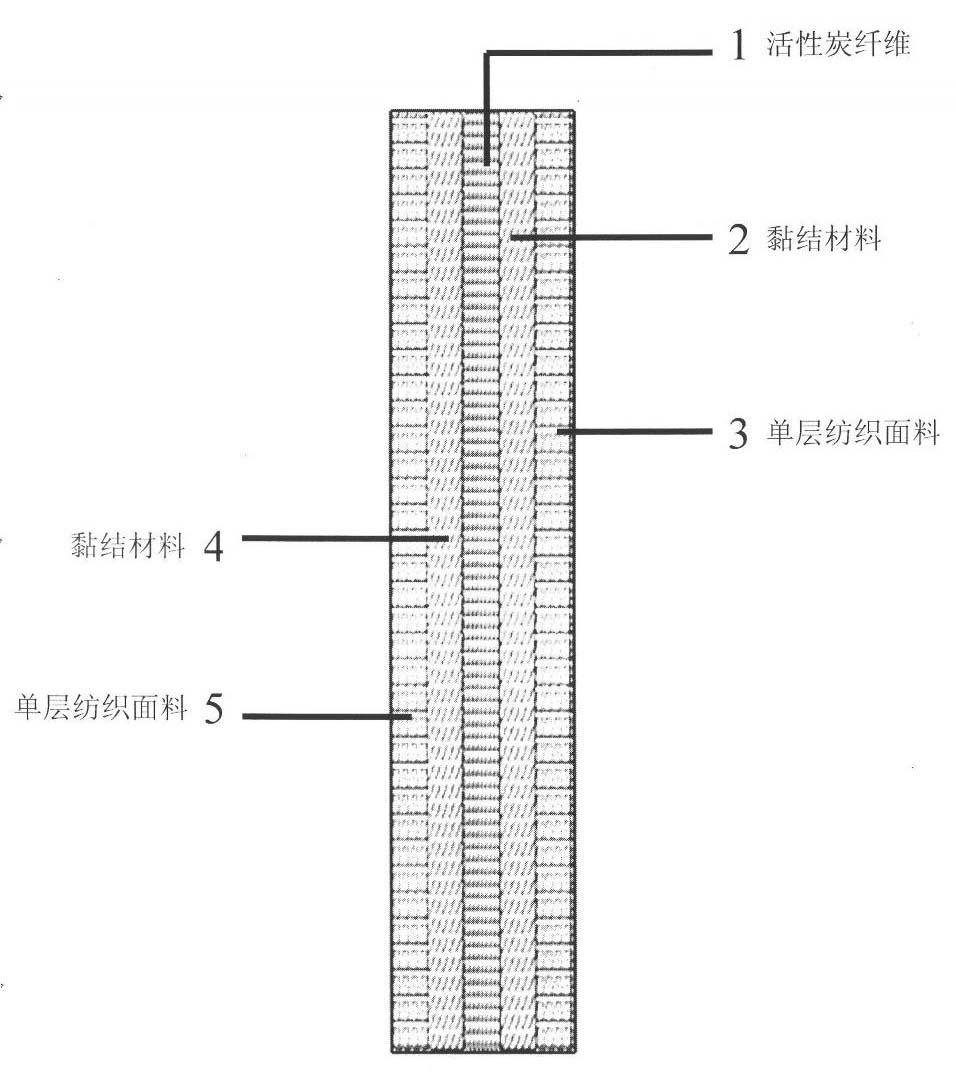

[0014] see figure 1 , the fabric is composed of activated carbon fiber 1 in the figure, bonding material 2 and bonding material 4 in the figure, single-layer textile fabric 3 in the figure and single-layer textile fabric 5 in the figure. The bonding material 2 and the bonding material 4 in the figure can be either liquid bonding materials or any material in the solid bonding materials; the single-layer textile fabric 3 and the single-layer textile fabric 5 in the figure can be pure wool material, pure cotton Any one of synthetic materials, pure fiber materials, and interwoven materials.

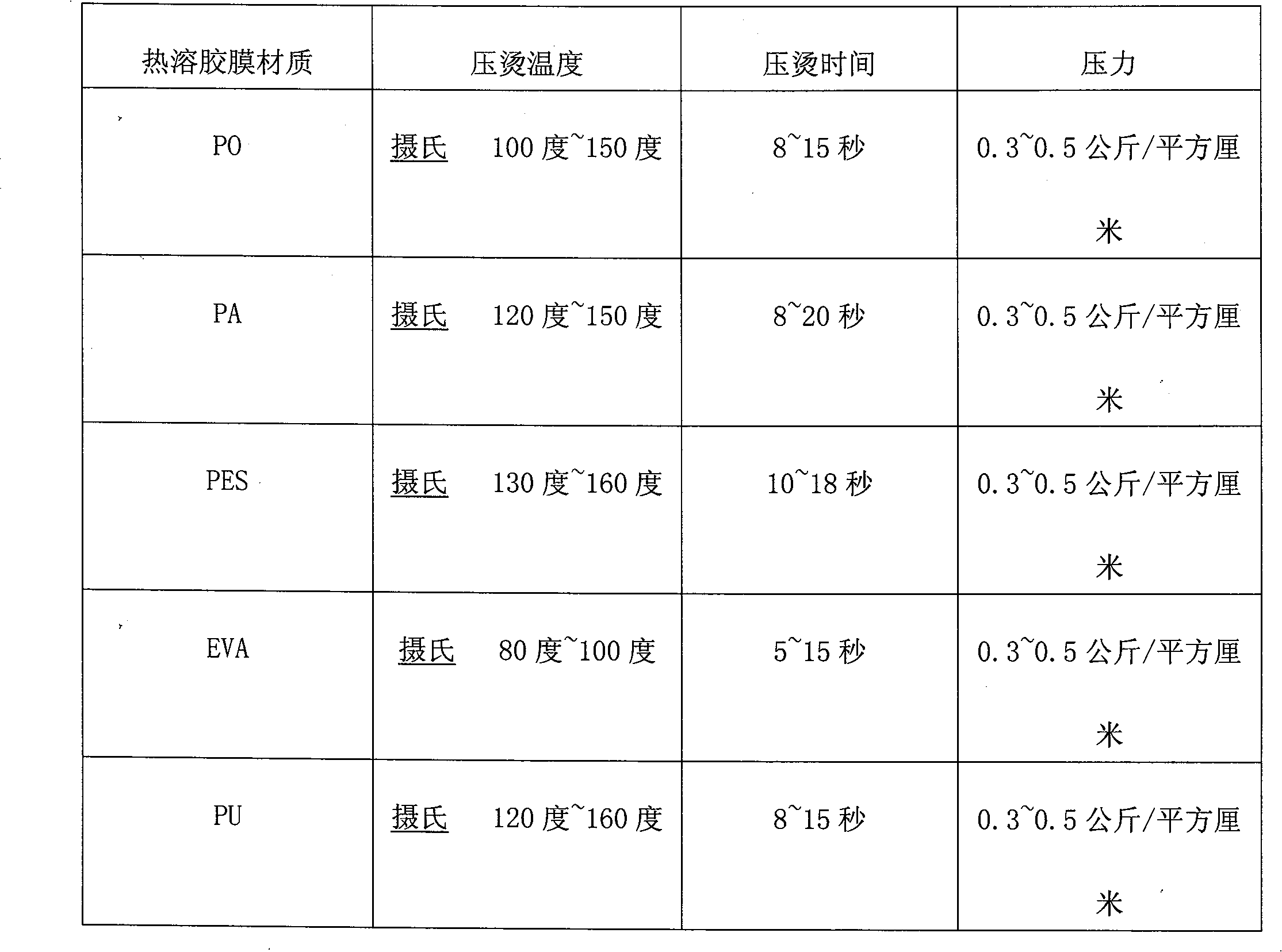

[0015] combine Figure 1 To describe an example of the specific implementation of the fabric production method, the bonding material of this example is a solid hot-melt film material. First, the single-layer textile fabric 5, the single-layer textile fabric 3, the bonding material 4, and the bonding material 2 are cut into the same width as the activated carbon fiber 1, and then the single-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com