Radial tire with belt work ply cords arranged at 90 degrees in circumferential direction

A radial tire and belt technology, applied in tire parts, reinforcement layers of pneumatic tires, transportation and packaging, etc., can solve problems such as shoulder voids, tire quality damage, and mechanical properties of the rubber compound. empty effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

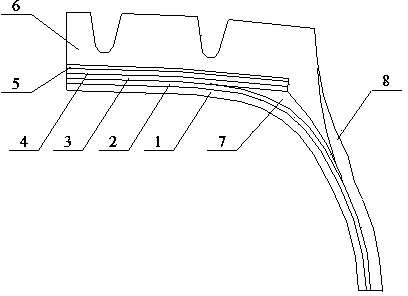

[0013] like figure 1 and figure 2 As shown, a radial tire with belt working layer cords arranged at 90 degrees in the circumferential direction involved in this embodiment includes: inner liner 1, carcass ply 2, first belt layer 3, second Belt layer 4, third belt layer 5, tread rubber 6, shoulder pad rubber 7 and sidewall rubber 8, the inner liner 1, carcass ply 2, first belt layer 3 , the second belt layer 4, the third belt layer 5 and the tread rubber 6 are sequentially connected together from the inside to the outside, the underside of the shoulder pad rubber 7 is connected with the carcass ply 2, and the tire The up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com