Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Short decolorization time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

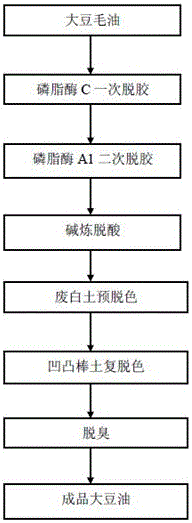

Processing method of soybean oil

InactiveCN105038977AReduce phosphorus contentRelieve pressureFatty-oils/fats refiningActivated carbonPhosphatidase

The invention discloses a processing method of soybean oil. The method comprises the following steps: 1, preparing crude soybean oil; 2, adding phosphatidase C, and carrying out primary degumming treatment to obtain primary degummed soybean oil; 3, adding phosphatidase A1, and carrying out secondary degumming treatment to obtain secondary degummed soybean oil; 4, carrying out alkali refining depickling treatment to obtain depickled soybean oil; 5, adding waste white clay to the depickled soybean oil, carrying out pre-decoloring treatment to obtain pre-decolored soybean oil, adding attapulgite and active carbon to the pre-decolored soybean oil, and carrying out re-decoloring treatment to obtain re-decolored soybean oil; and 6, carrying out deodorizing treatment on the re-decolored soybean oil to obtain finished soybean oil. The processing method of the soybean oil has the advantages of safety, environmental protection, simple process, convenient operation, low cost and high refining rate, and is suitable for soybean oil processing industrial production.

Owner:WUHAN POLYTECHNIC UNIVERSITY

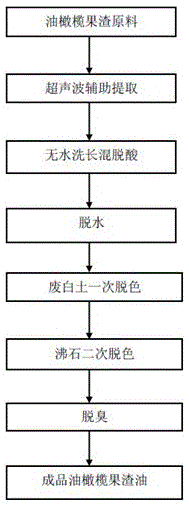

Method for ultrasonic-assisted extraction of olive pomace oil

InactiveCN105038943AEliminate the steps of deacidification and washingHigh yieldFatty-oils/fats refiningFatty-oils/fats productionUltrasonic assistedOil quality

The invention discloses a method for ultrasonic-assisted extraction of olive pomace oil. The method comprises the following steps: 1, preparing an olive pomace oil raw material; 2, adding n-hexane to the olive pomace oil raw material, and carrying out ultrasonic-assisted extraction to obtain crude olive pomace oil; 3, carrying out waterless washing long-mixing depickling treatment on the crude olive pomace oil to obtain depickled olive pomace oil; 4, dehydrating the depickled olive pomace oil to obtain dehydrated olive pomace oil; 5, respectively carrying out primary decoloring and secondary decoloring treatment on the dehydrated olive pomace oil to obtain double decolored olive pomace oil; and 6, deodorizing the double decolored olive pomace oil to obtain finished olive pomace oil. The method for ultrasonic-assisted extraction of olive pomace oil has the advantages of simple process, safety, environmental protection, high efficiency, fastness, good oil quality and high oil yield, and is suitable for small-lot production of the olive pomace oil.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Refining method of Idesia polycarpa edible oil

InactiveCN105861140AReduce contentMeet degumming requirementsFatty-oils/fats refiningFatty-oils/fats productionFiltrationEdible oil

The invention discloses a refining method of Idesia polycarpa edible oil, relating to the technical field of refining of Idesia polycarpa oil. The refining method comprises the steps of: 1) preparation of Idesia polycarparaw oil; 2) degumming treatment; 3) depickling treatment; 4) decoloring treatment; 5) debitterizing treatment; 6) deodorizing treatment; and 7) filtration to obtain the finished Idesia polycarpa oil. The refining method of the Idesia polycarpa edible oil has the advantages of safety, environment protection, high oil yield and impurity free, and improves the quality of the Idesia polycarpa oil.

Owner:四川森迪科技发展股份有限公司

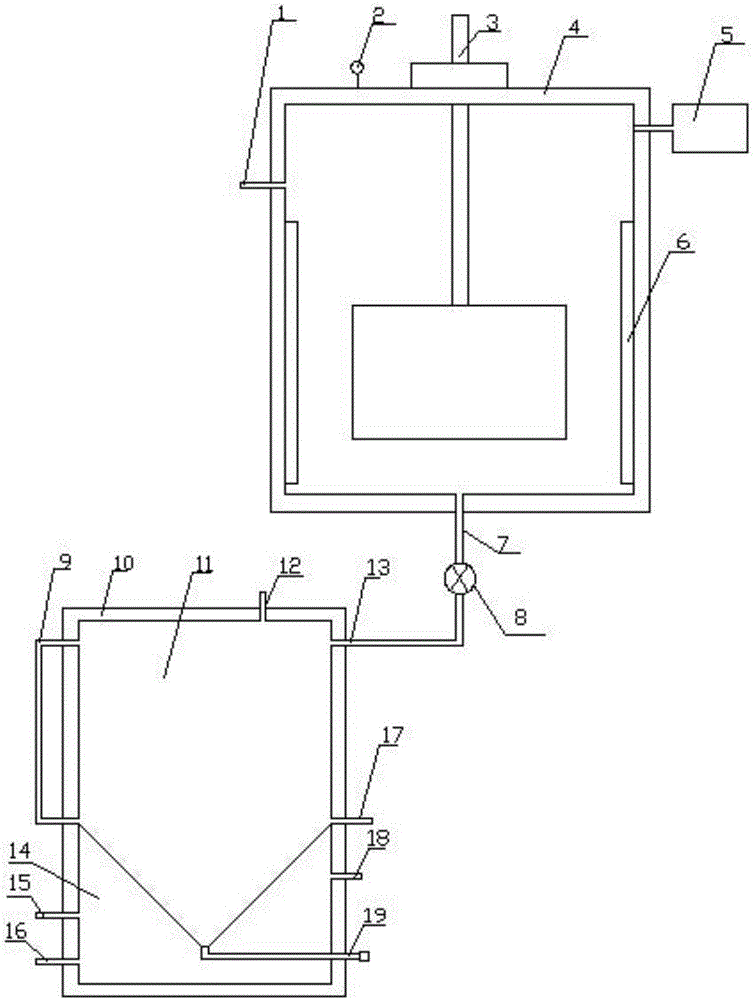

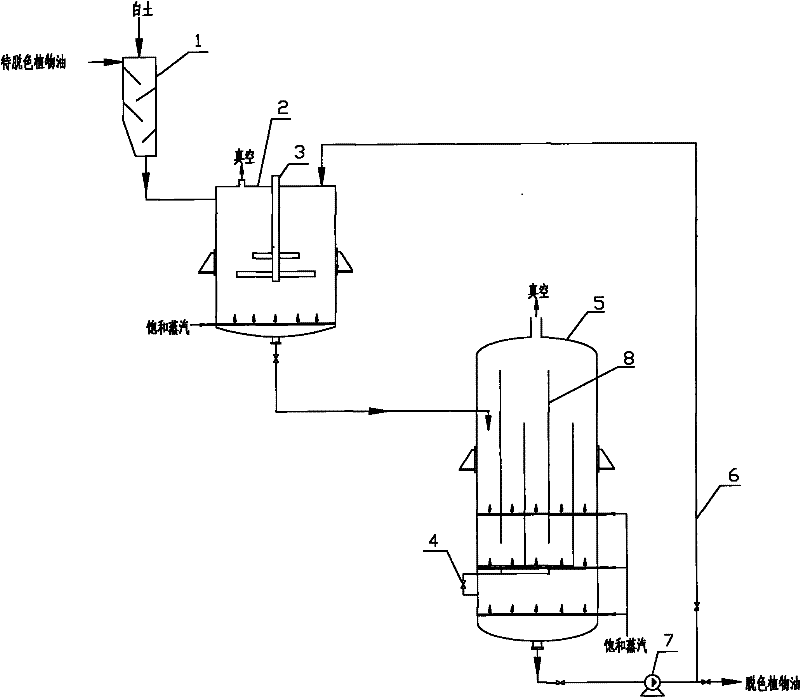

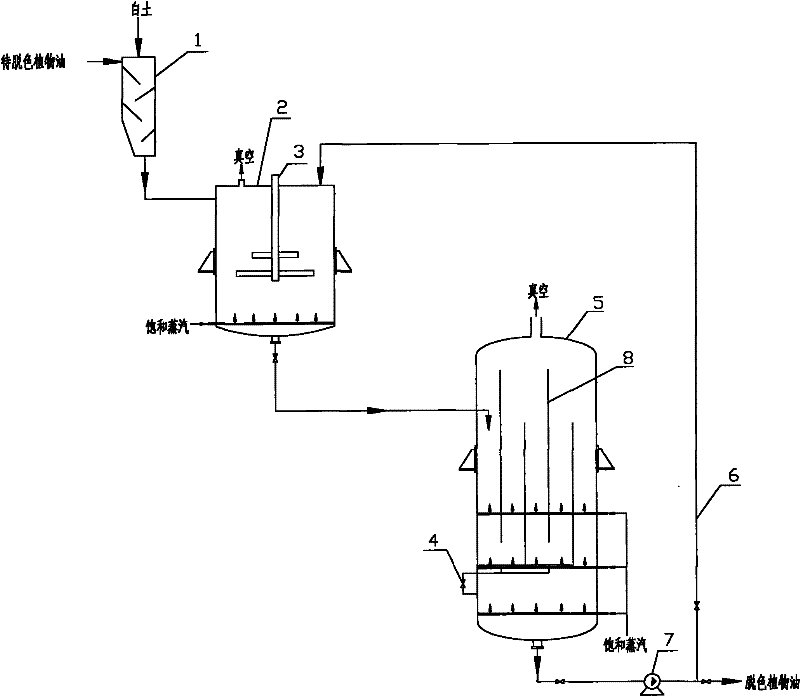

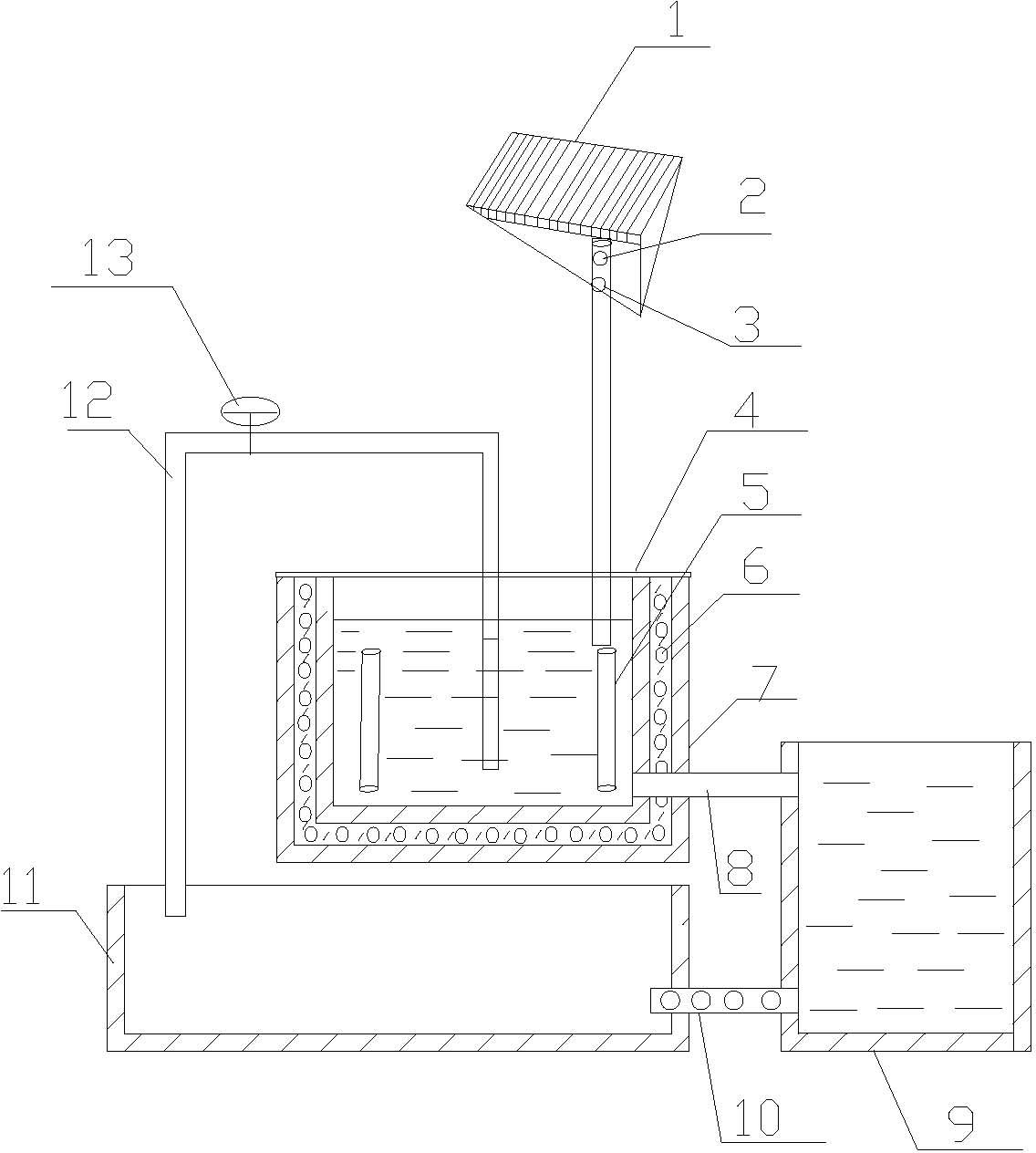

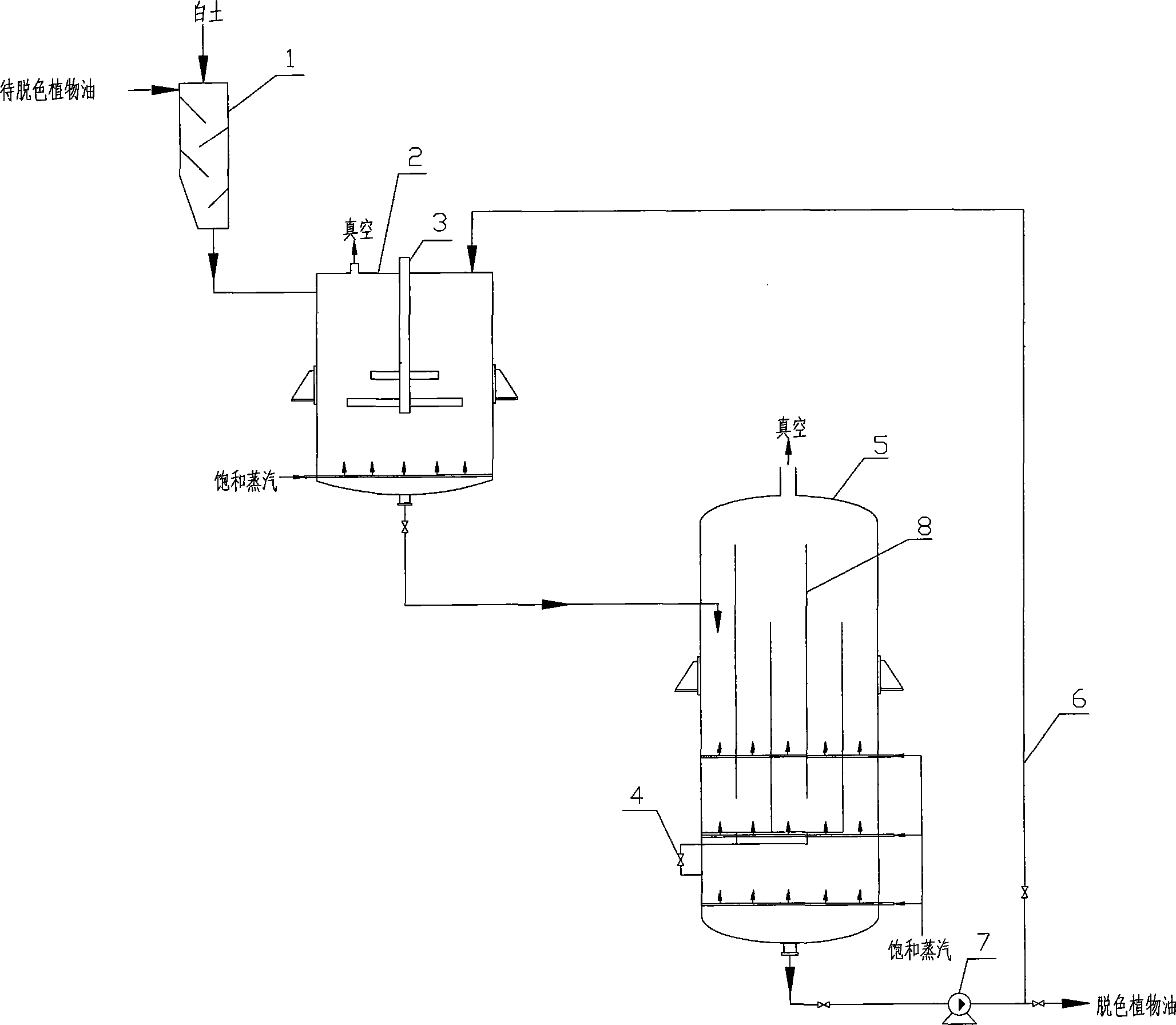

Low temperature decolouring method and device for plant oil

ActiveCN102311873AGuaranteed decolorization effectReduce lossesFatty-oils/fats refiningProcess engineeringAir stripping

The invention provided a low temperature decolouring method and a device for plant oil. Before oil enters a steam mill decolouring device, a pre-decolouring device with the combination of stripping and mechanical stirring is added, so as to improve the mixing uniformity of a decolorant and oil and minimize the decolouring time and steam amount; on the basis of guaranteeing the decolouring effect of the decolorant, low temperature decolouring is selected, thus effectively avoiding the catalysis effect of oil to the decolorant, minimizing oxidative decomposition and preventing the generation ofadverse substances.

Owner:SHANDONG BOHI INDUSTRY CO LTD +3

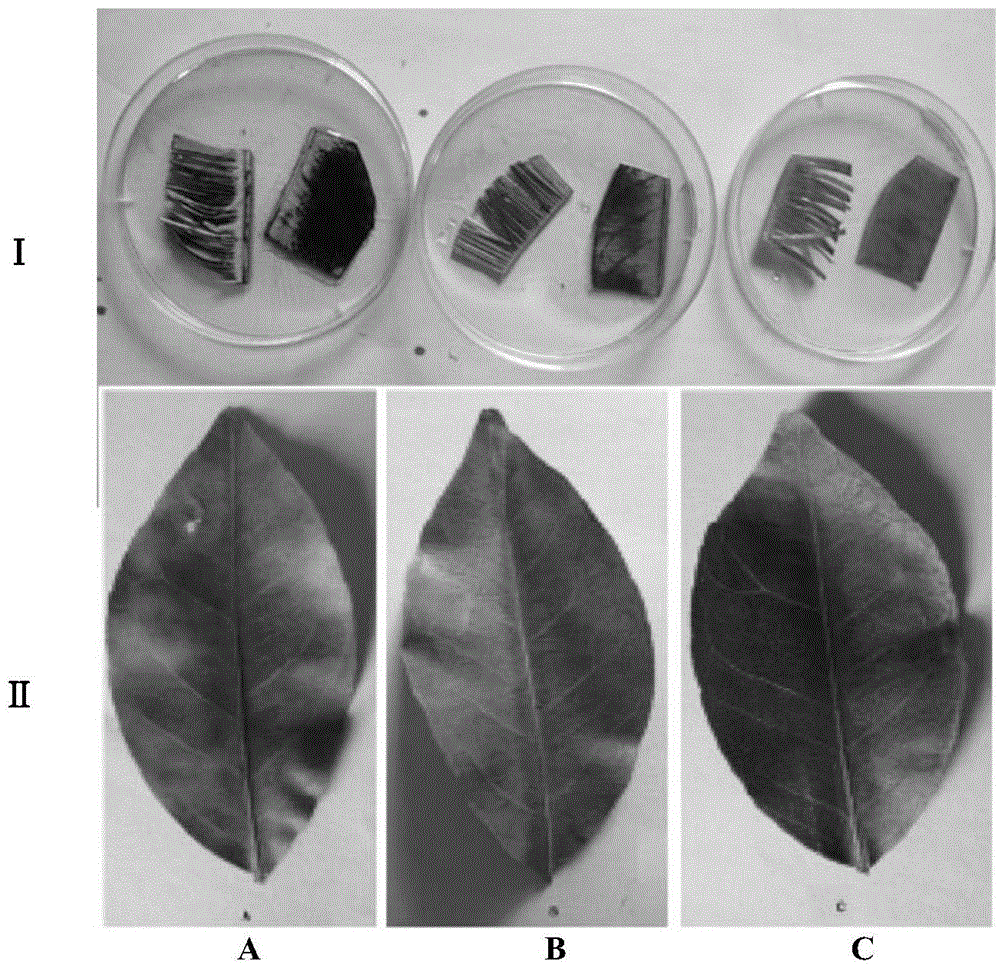

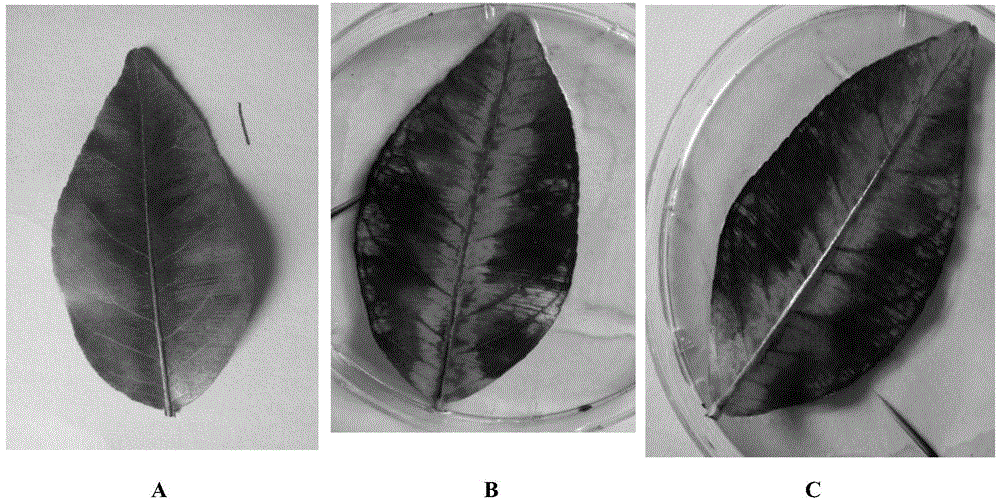

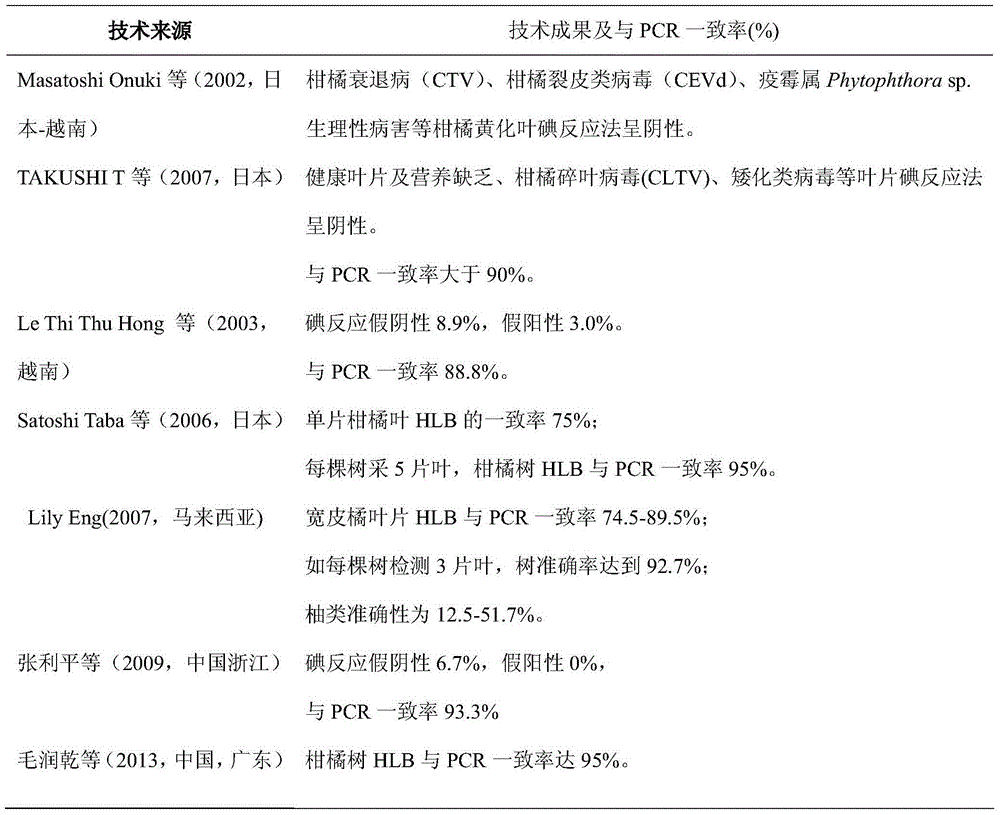

Citrus greening disease rapid detection method

InactiveCN104132938AIntegrity guaranteedClear colorMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationChange colorCitrus tree

The invention discloses a citrus greening disease rapid detection method. The method comprises the following steps: step a, polishing citrus leaves which have been subjected to a dark treatment to get rid of the wax layer on the leaf surfaces, soaking the leaves in a chlorophyll decoloring liquid until the leaves turn white; step b, color development detection: dropwise adding a starch color developing solution on the discolored leaves, and observing the color change of the leaves, if the leaves turn blue, the citrus leaves must be from a citrus tree affected by citrus greening disease, and if the leaves do not change color, the leaves are healthy. The method has the advantages of more convenient operation, shorter time, and more precise result, and can be operated by farmers themselves.

Owner:GUANGDONG INST OF APPLIED BIOLOGICAL RESOURCES

Soapnut saponin decoloring method

ActiveCN108129523AGood decolorization effectGood decolorizationSugar derivativesGlycosidesEnvironment effectRoom temperature

The invention discloses a soapnut saponin decoloring method which comprises the following steps: (1) weighing dried soapnut saponin powder, adding 0.6 times by mass of deionized water, and stirring ata room temperature to completely dissolve the soapnut saponin powder; (2) mixing composite metal hydride with acid sulfite in a mass ratio of (4:3)-(4:36) so as to obtain a composite decoloring agent; (3) adjusting the pH value of the soapnut saponin solution obtained in the step (1) to 4.5-4.6, adding the composite decoloring agent obtained in the step (2) according to a mass ratio of (100:1)-(100-5), and performing reduction decoloring for 30-80 minutes at 20-70 DEG C; (4) performing spray drying on the total soapnut saponin solution decolored in the step (3), thereby obtaining decolored saponin powder. The composite decoloring agent used in the method has a synergetic function, and the method is small in amount of the decoloring agent, good in decoloring effect, short in decoloring time, low in production cost, relatively small in environment influence caused by waste liquids and small in target product loss in the decoloring process, and has the advantages of high efficiency, timeshortening and environment protection.

Owner:JIANGXI NORMAL UNIV

Decolorizing treatment system for paulownia wood

InactiveCN102615683APromote leachingAvoid pollutionWood treatment detailsLoose filtering material filtersPaulowniaPaulownia coreana

Owner:CHINA PAULOWNIA RES CENT

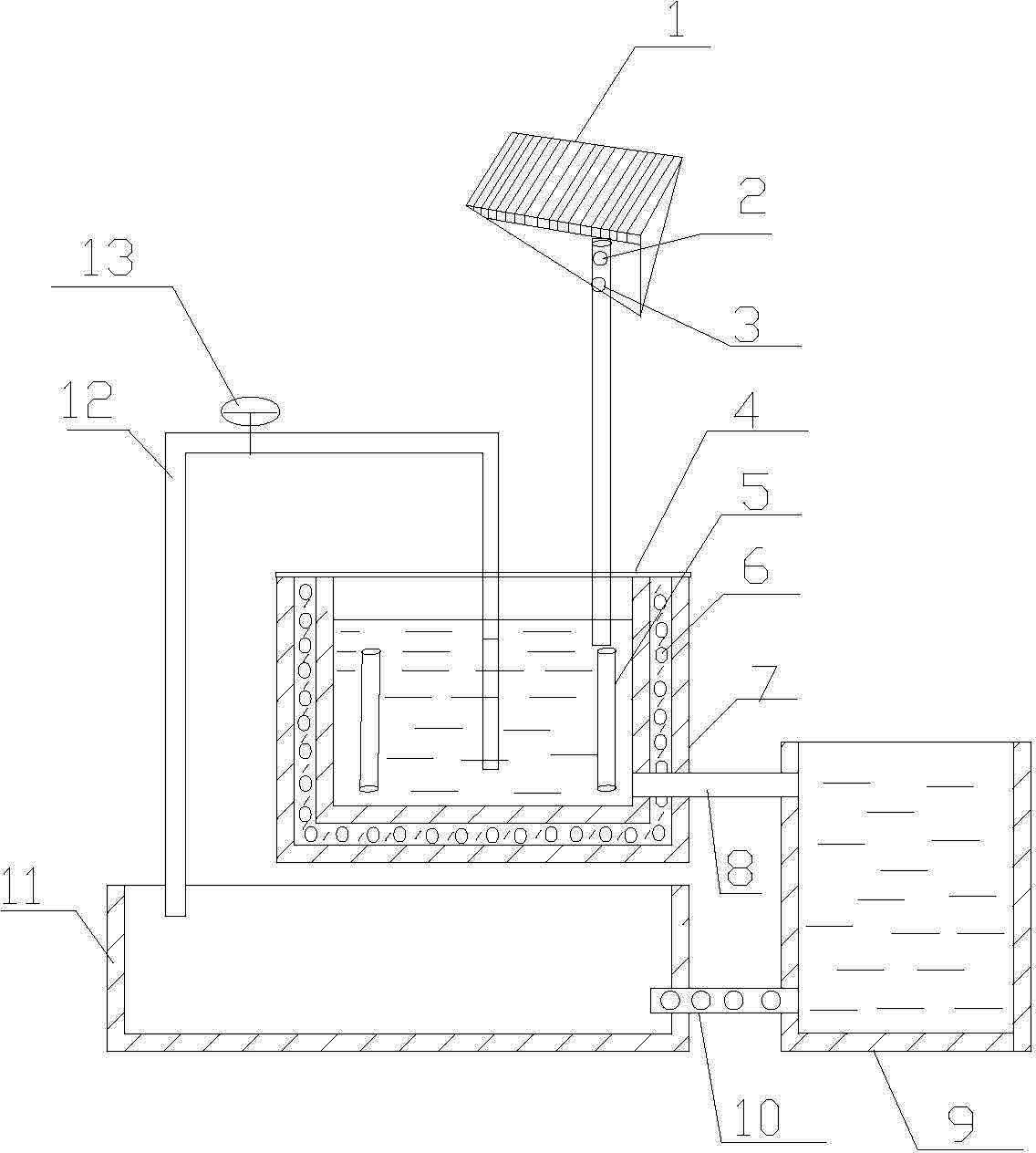

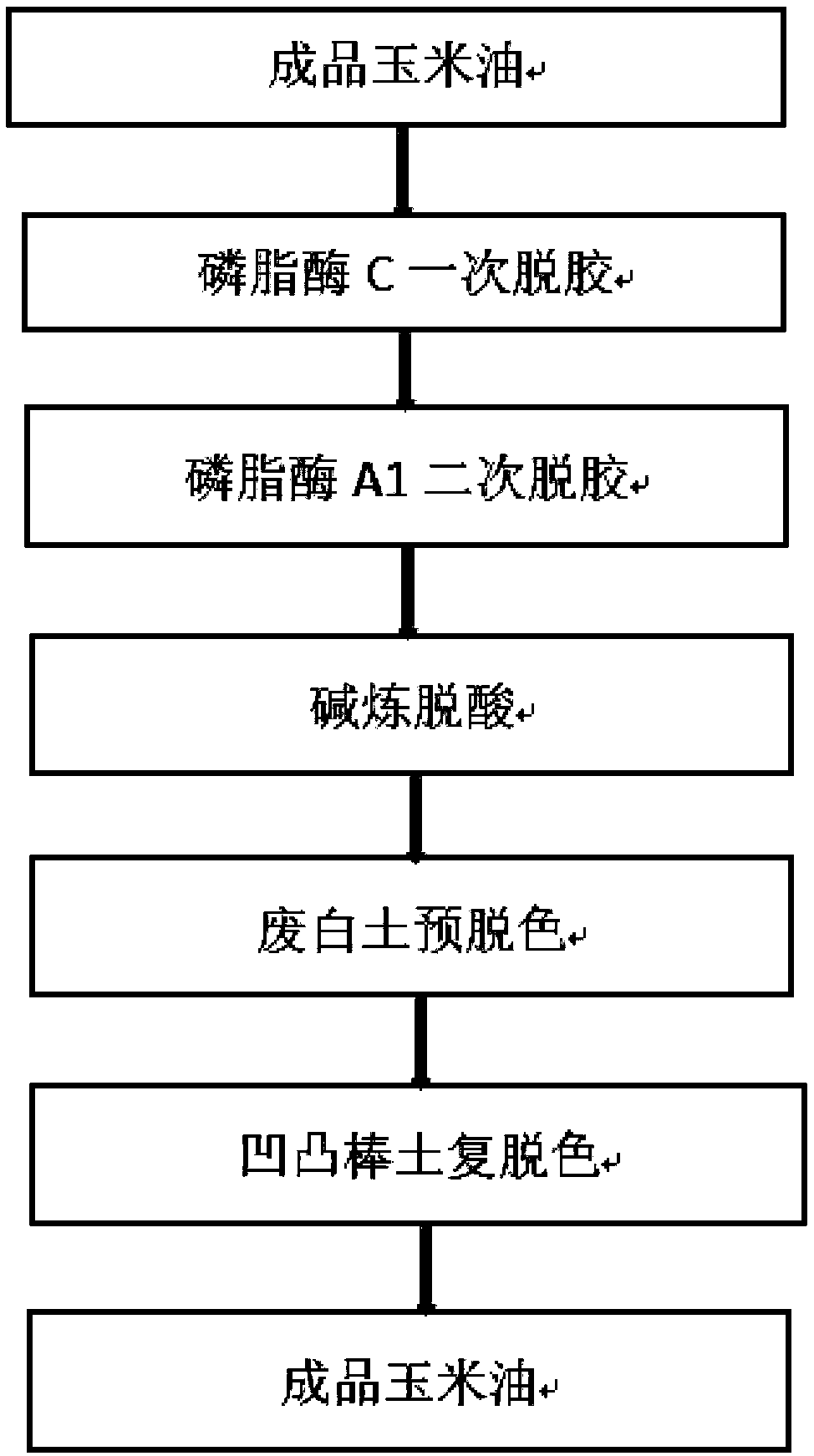

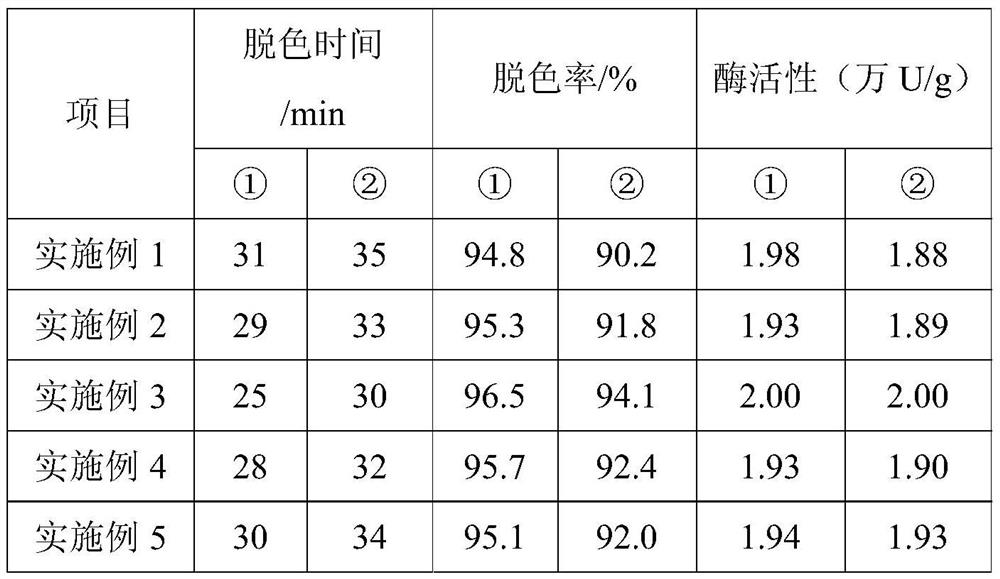

Processing method of corn oil

InactiveCN108659953AReduce phosphorus contentRelieve pressureFatty-oils/fats refiningFatty-oils/fats productionActivated carbonPhospholipases C

The invention discloses a processing method of corn oil. The processing method comprises the following steps of step 1, preparing crude corn oil; step 2, adding phospholipase C to degum for the firsttime, so as to obtain the primary degummed corn oil; step 3, adding phospholipase A1 to degum for the second time, so as to obtain the secondary degummed corn oil; step 4, performing base refining anddeacidifying on the secondary degummed corn oil, so as to obtain the deacidified corn oil; step 5, adding waste argil into the deacidified corn oil to pre-discolor, so as to obtain the pre-discoloredcorn oil; adding attapulgite and activated carbon into the pre-discolored corn oil to re-discolor, so as to obtain the re-discolored corn oil; step 6, deodorizing the re-discolored corn oil, so as toobtain the finished corn oil. The processing method of the corn oil has the advantages that the safe and environment-friendly effects are realized, the technology is simple, the operation is rapid, the cost is low, the refining rate is high, and the processing method is suitable for industrial production of corn oil.

Owner:陕西金亨祥食品科技股份有限公司

Tea saponin bio-enzyme decoloring technology

ActiveCN103864879AMild reaction conditionsShort decolorization timeSugar derivativesSteroidsMedicineSpray dried

The invention discloses a tea saponin bio-enzyme decoloring technology, and aims to solve the problems that: (1) in the prior art the decoloring process must be carried out in a strong alkaline condition, and the strong alkali will harm the operators and pollute the environment; (2) the loss of tea saponin is great and the recovery of the tea saponin is difficult because of the absorption effect. The technology comprises the following main steps: co-immobilization of laccase and glucose oxidase, preparation of a crude tea saponin solution, decoloring of crude tea saponin, and recovering of tea saponin. The technology has the advantages of mild reaction conditions, short decoloring time, and prominent decoloring effect. Moreover, the immobilized enzyme can be recycled and reutilized, the loss rate of tea saponin is low, the tea saponin powder with light color and luster can be recycled only through a spray drying technology, and the technology is simple.

Owner:HANGZHOU YIMIN PETOROCHEM

Processing technology for rapeseed oil

InactiveCN109536277AMeets moderate refining requirementsReduce degumming water consumptionFatty-oils/fats refiningEdible oils/fatsWater useOil processing

The invention discloses a processing technology for rapeseed oil. As ultrasonic waves can be adopted to assist a phospholipase C degumming process to perform degumming processing on rapeseed crude oil, the water using amount of degumming can be greatly reduced, and the generated wastewater amount can be greatly reduced as well, so that the processing technology is green and environmentally friendly; and the degumming time can be shortened to 60 min, and the processing technology can accord with the moderate refining of oils and fats. The processing technology is safe, environmentally friendly,simple, convenient in operation, low in cost, high in refining rate and suitable for the industrial production of rapeseed oil processing.

Owner:余握中

Process for producing gallic acid by hydrolyzing buffer solution

InactiveCN101654411AReduce dosageReduce lossesOrganic compound preparationCarboxylic compound preparationGallic acid esterCarbonization

The invention discloses a process for producing gallic acid by hydrolyzing a buffer solution, which is characterized by comprising the following steps: (1) pulverizing nutgalls; (2) adding an NaH2PO4solution into an enameled reaction kettle; (3) adding nutgall powder to evenly mix under a mixing condition; (4) slowly adding H2SO4 to obtain a pH value of 1-2; adding steam of 0.15MPA to raise the temperature to 120 DEG C; regulating and maintaining the pH value of 1-2 and the reaction time of 2-4 hours of the mixture; cooling and crystallizing after the reaction; filtering; dehydrating; decolorizing to filter; crystallizing; dehydrating; drying; and obtaining a finished product. The process for producing gallic acid by hydrolyzing a buffer solution can effectively solve the problems of incorrect control, easily excessive hydrolyzation, carbonization and other impurities when pure concentrated sulfuric acid is hydrolyzed, greatly reduce active carbon quantity of later procedures, decolorizing time, production period, excessive solid hydrolyzation and gallic acid loss caused by active carbon adsorption, increase the yield of the gallic acid and reduce the production cost.

Owner:CHONGQING RUITONG BIO CHEM

Decolorizing resin for lactase and preparation method of decolorizing resin

The invention discloses a decolorizing resin for lactase. The decolorizing resin comprises styrene, divinylbenzene, gelatin, juncus roemerianus, methyl isobutyl carbinol, hydroxyethyl methylacrylate, triallyl cyanurate, N-phenylmaleimide, chitosan, vitamin C magnesium phosphate, benzoyl peroxide, polyvinyl alcohol, tributyl phosphate, salicylic acid, hydroxyethyl methyl cellulose and a pore-foaming agent. The invention also discloses a preparation method of the decolorizing resin. The preparation method comprises the following steps of: mixing gelatin, chitosan, hydroxyethyl methyl cellulose, polyvinyl alcohol and salicylic acid to prepare a liquid phase; mixing styrene, divinylbenzene, methyl isobutyl carbinol, hydroxyethyl methylacrylate, triallyl cyanurate, N-phenylmaleimide, benzoyl peroxide, tributyl phosphate and a pore-foaming agent to prepare an oil phase; mixing the juncus roemerianus fiber with vitamin C magnesium phosphate to prepare a solid phase; and mixing the three phases to prepare the polymer. The decolorizing resin is high in decoloration efficiency, short in time and small in lactase activity loss after decoloration.

Owner:广西叁万生物科技有限公司

Stripping technology for waste denim rags

InactiveCN111411506ALow costAchieve desizing effectDry-cleaning apparatus for textilesDyeing processOrganic acidDenim

The invention relates to a stripping technology for waste denim rags. The technology includes the following steps that desizing is performed firstly, sodium chlorite and a penetrating agent are added,glacial acetic acid is added to adjust the pH to be 4.0, the temperature is increased to range from 60 DEG C to 80 DEG C and is kept for 30-45 min, then stripping is performed, trisodium phosphate, sodium chlorite and a penetrating agent are added, an organic acid is added to adjust the pH to be 4.0, the rags are soaked at room temperature for 0.5 h, then the temperature is increased at the temperature increasing speed of 1 DEG C / min for 30 min, the temperature is directly increased to 95 DEG C and is kept for 60 min after constant-speed temperature increasing is completed, then bleaching isperformed, sodium hypochlorite is added, the pH is adjusted to range from 9 to 11, the rags are soaked at room temperature for 40-80 min, dechlorinating is performed finally, hydrogen peroxide is added, a circulating pump is started, the temperature is increased to range from 50 DEG C to 60 DEG C and is kept for 30-50 min, and the rags are cleaned with hot water at the temperature ranging from 80DEG C to 90 DEG C finally. The technology is low in cost and short in stripping time, consumes few materials and can meet industrial production requirements.

Owner:澧县新伟纺织有限责任公司

De-coloring method of cotton

InactiveCN106758127AHigh whitenessFeel goodBiochemical treatment with enzymes/microorganismsGrip property fibresRoom temperaturePercent sodium chloride

The invention provides a de-coloring method of cotton. The de-coloring method comprises the specific steps: (1) loosening the cotton; stirring and scattering a pre-washing solution until the moisture of the cotton reaches 40 percent to 60 percent, wherein a pre-washing agent is prepared from 10 to 20 parts of 30 percent hydrochloric acid solution, 5 to 10 parts of 5 percent organic phosphonic acid solution, 5 to 10 parts of 8 percent sodium chloride solution and 50 to 80 parts of water; (2) washing with an enzyme: adding the pre-washed cotton into an enzyme washing agent, wherein the enzyme washing agent is prepared from 10 to 20 parts of mercerized proteinase, 10 to 20 parts of a non-ionic washing agent, 10 to 20 parts of a caustic soda flake and 80 to 100 parts of water; immersing at room temperature for 2 to 3 hours; (3) after washing with water, adding into an oxygen bleaching agent, wherein the oxygen bleaching agent is prepared from 3 to 5 parts of an oxygen bleaching stabilizer, 10 to 20 parts of hydrogen peroxide and 80 to 100 parts of water; (4) washing with the water for a plurality of times and drying. The de-coloring method of the cotton is short in period, high in efficiency and low in cost; the treated cotton has good whiteness, less weight loss, small strength loss and good hand feeling and is easy to spin and weave.

Owner:WUXI BENNIU BIOTECH CO LTD

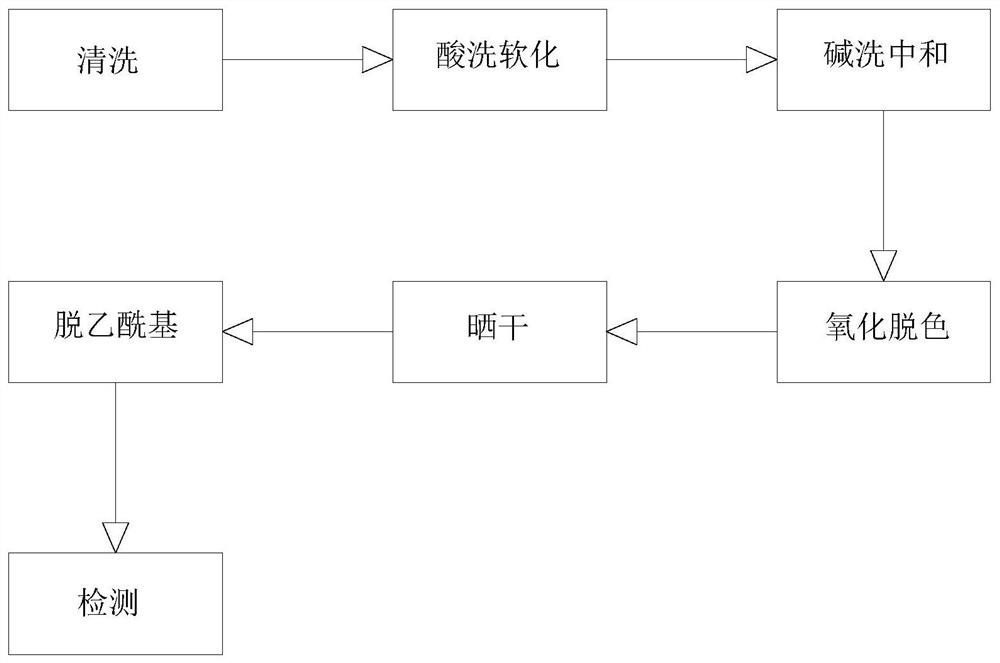

Production process for producing chitin and efficiently removing pigments

The invention discloses a production process for producing chitin and efficiently removing pigments. The production process comprises the following steps: cleaning, preparing a proper amount of shrimpshells or crab shells, soaking the shrimp shells or crab shells in clear water, brushing with a brush, pouring out water after brushing, and repeating the above steps; pickling and softening: soakingthe treated shrimp shells or crab shells in diluted hydrochloric acid according to a certain proportion for a period of time until no bubbles are generated; alkali washing and neutralizing: putting the treated shrimp shells or crab shells into a pot, putting a sodium hydroxide solution with a proper concentration into the pot, and then boiling; the production process has the beneficial effects that when the raw materials are subjected to oxidative decoloration, the raw materials and reagents are heated, so that the effect of shortening the decoloration time can be achieved, the production period of chitin is shortened, and the production efficiency of chitin is improved.

Owner:QUZHOU UNIV

Low temperature decolouring method and device for plant oil

ActiveCN102311873BGuaranteed decolorization effectReduce lossesFatty-oils/fats refiningEngineeringProcess engineering

The invention provided a low temperature decolouring method and a device for plant oil. Before oil enters a steam mill decolouring device, a pre-decolouring device with the combination of stripping and mechanical stirring is added, so as to improve the mixing uniformity of a decolorant and oil and minimize the decolouring time and steam amount; on the basis of guaranteeing the decolouring effect of the decolorant, low temperature decolouring is selected, thus effectively avoiding the catalysis effect of oil to the decolorant, minimizing oxidative decomposition and preventing the generation of adverse substances.

Owner:SHANDONG BOHI INDUSTRY CO LTD +3

A Strain of Trametes pilosae with Efficient Decolorization of Lignin

ActiveCN111979131BHigh decolorization rateGood decolorizationFungiMicroorganism based processesBiotechnologyMicroorganism

The invention discloses a strain of Trametes hirsuta X‑13 with high-efficiency decolorization of lignin, which belongs to the technical field of microbial engineering. After culturing for 11 days under the condition of ℃ and 180rpm, the decolorization rate of the bacteria to lignin can reach 52.43%. The decolorization effect of this strain on lignin-containing solution is better than that of most strains of the same species reported at home and abroad, and the decolorization time is shorter and the operation is simple. It is suitable for industrial treatment of lignin-containing waste liquid such as paper industry waste liquid .

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Method for producing natural tartaric acid from wine leftovers

ActiveCN112010745AReduce acidityImprove solubilityPreparation from carboxylic acid saltsOther chemical processesCalcium tartrateGrape wine

The invention discloses a method for producing natural tartaric acid from wine leftovers. The method comprises the following steps: adding crushed wine leftovers into pure water, adding sodium carbonate, stirring, neutralizing, and filtering to obtain a leftover filtrate; adding excessive calcium chloride into the leftover filtrate, filtering to obtain a primary precipitate, washing the primary precipitate with water, and drying to obtain a calcium tartrate precipitate; adding the calcium tartrate precipitate into a dilute sulfuric acid solution, uniformly stirring and mixing, filtering to obtain a secondary precipitate, washing the secondary precipitate with water, combining the filtered and washed solutions, adding a decolorizing agent for decolorizing, and filtering the decolorized solution; filtering to obtain filtrate; evaporating and crystallizing the filtrate to obtain primary tartaric acid; recrystallizing the primary tartaric acid, and drying to obtain natural tartaric acid; according to the method, the defects in the prior art are overcome, the process steps are few, the production process is simple, the raw material cost is low, and the purity of the produced natural tartaric acid is larger than 99.8%.

Owner:安徽皖晶生物科技有限公司

A kind of preparation method of printing and dyeing wastewater rapid decolorizer

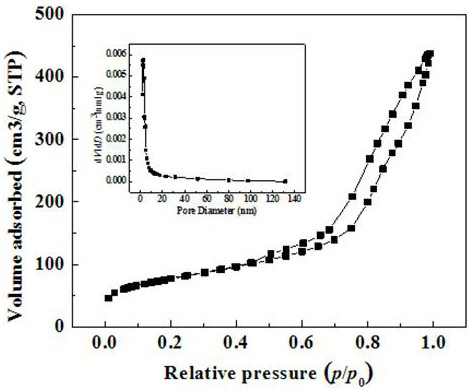

InactiveCN108435136BLarge specific surface areaStrong decolorization abilityOther chemical processesWater contaminantsPolyethylene oxideDyeing wastewater

The invention discloses a preparation method of a quick discoloring agent for dyeing and printing wastewater, wherein the quick discoloring agent is prepared through a hydrothermal process with a polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer as a template agent, sodium silicate as a raw material and a layered double hydroxide as a main component. The quick discoloring agent has large specific surface area, excellent discoloring capability and short discoloring time, and can completely remove majority of dyes within a short time.

Owner:HEZE UNIV

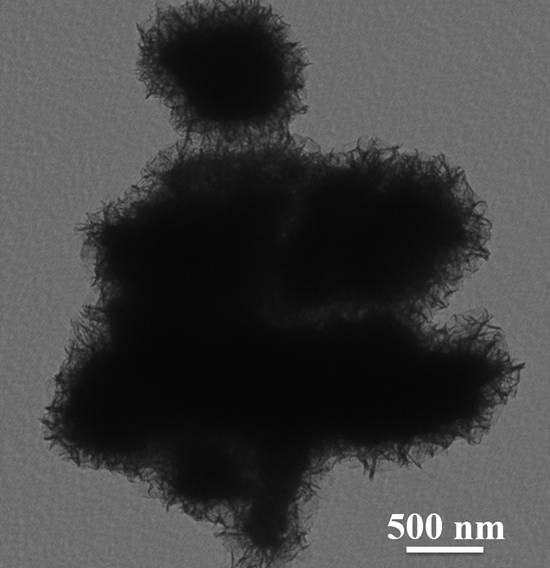

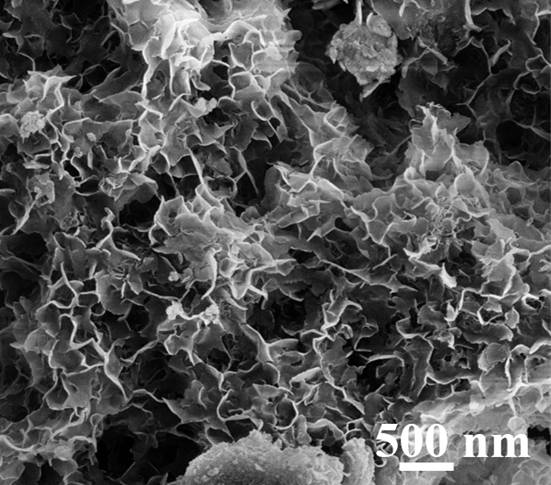

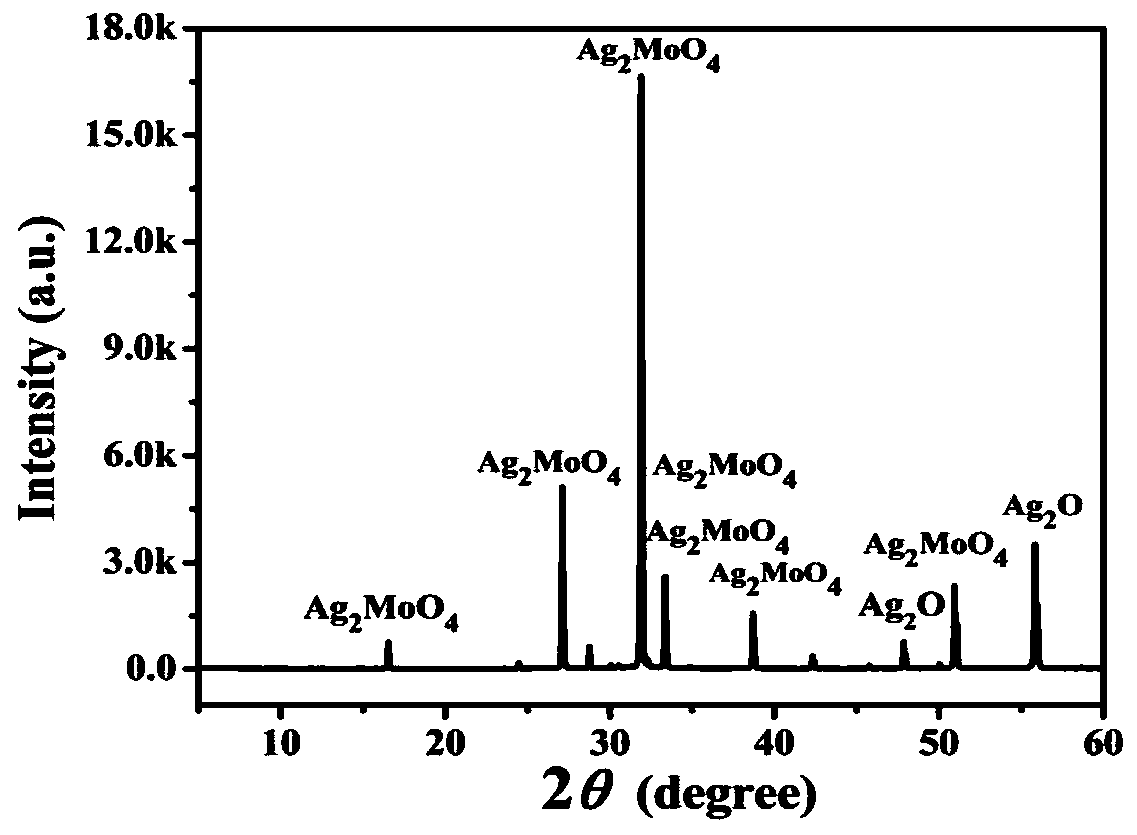

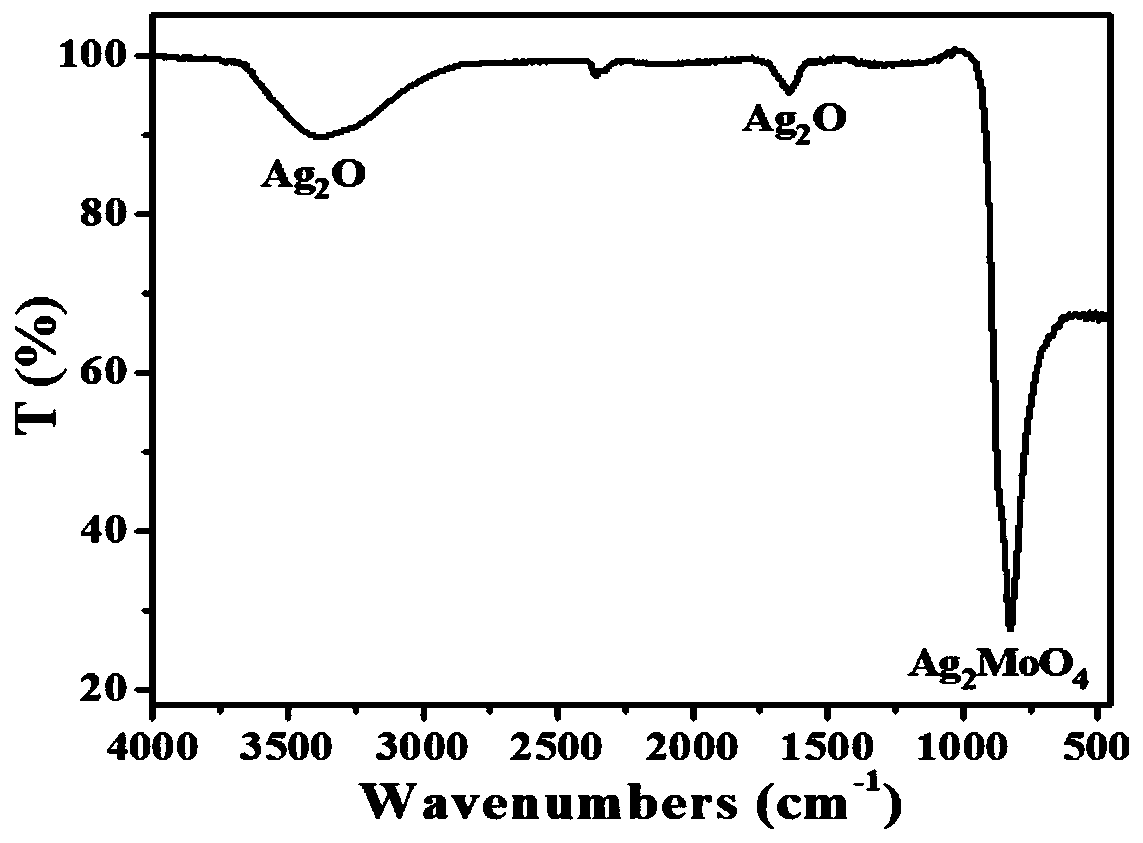

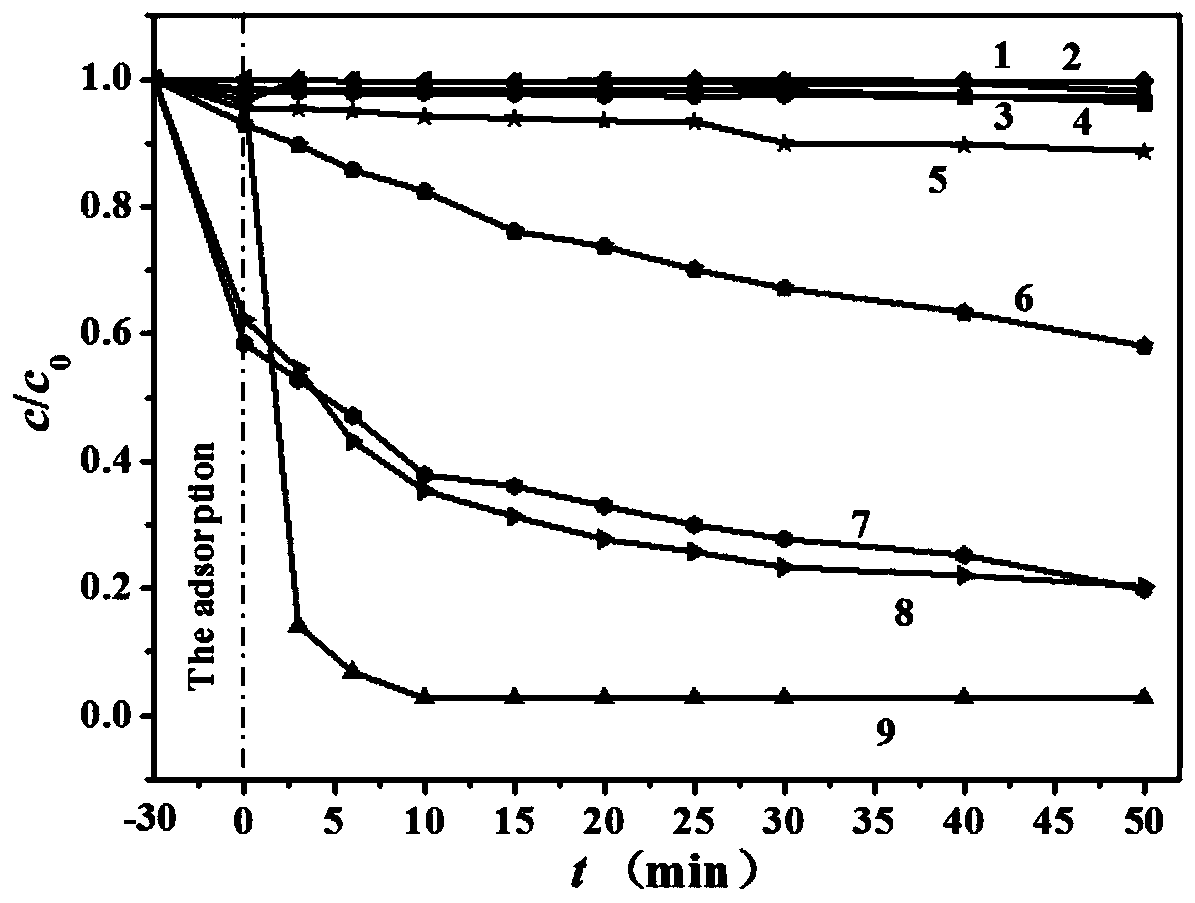

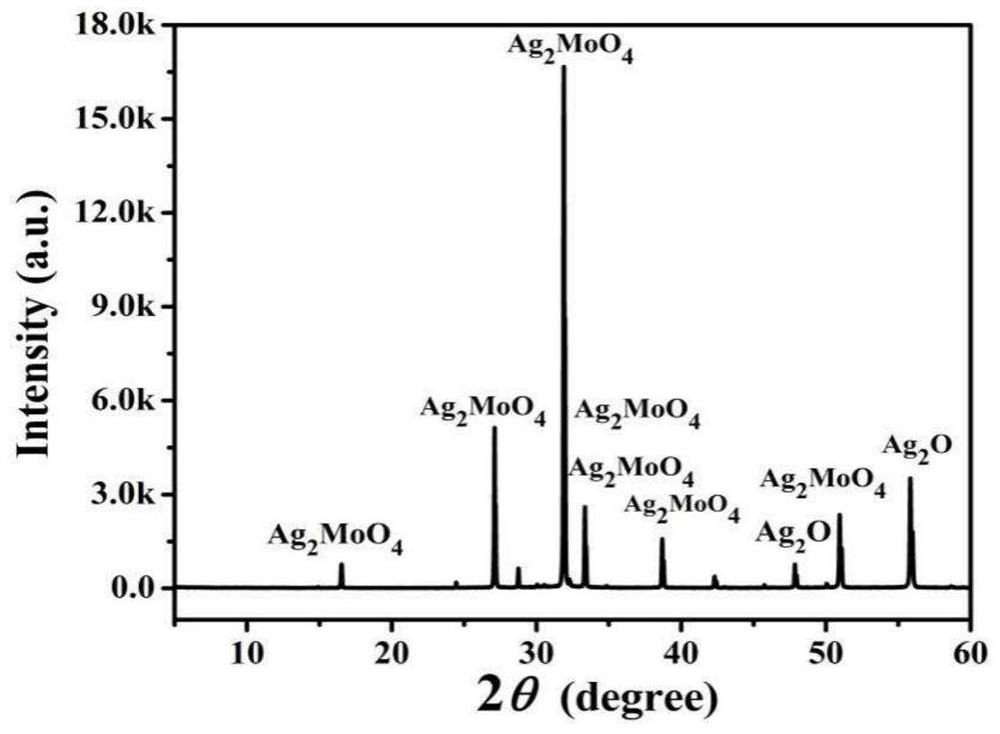

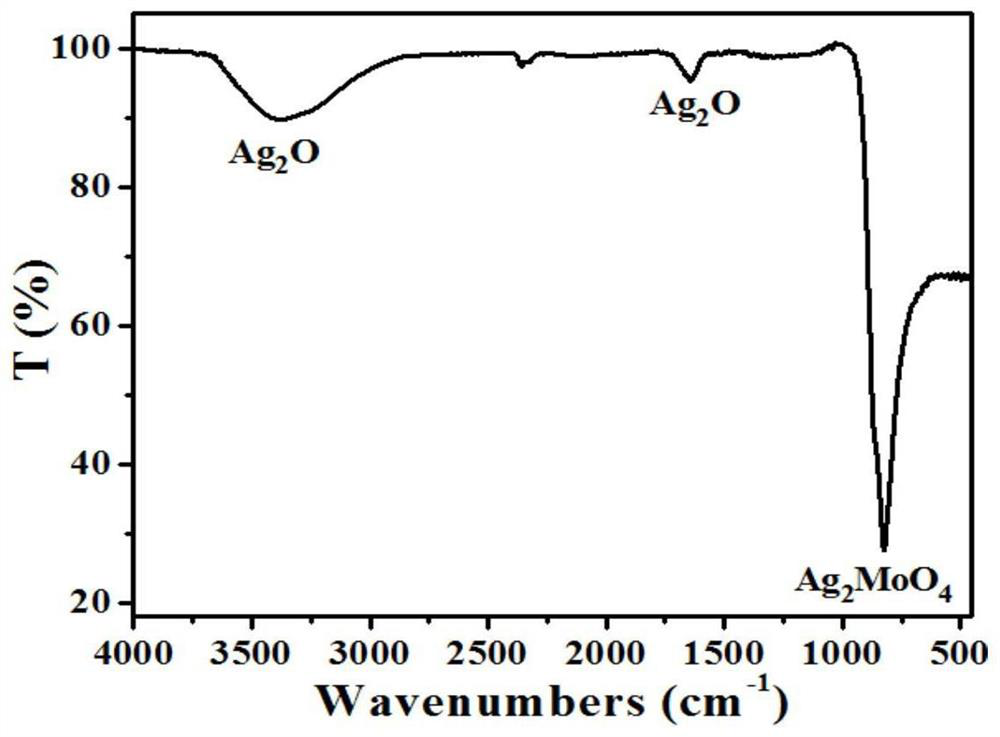

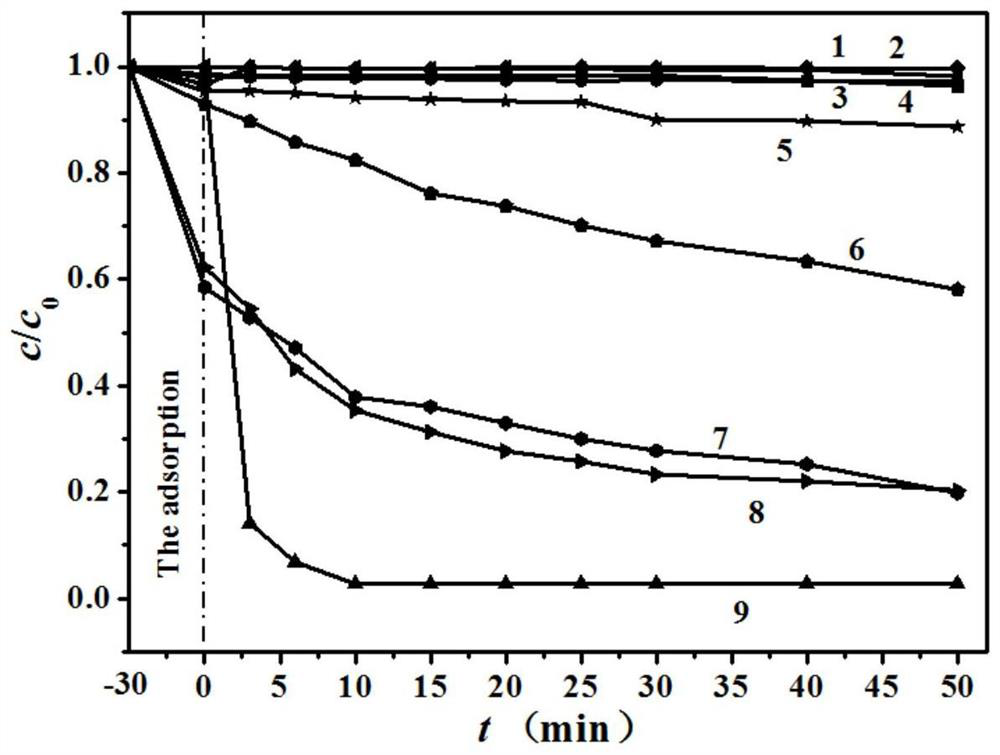

Preparation method of Ag2MoO4/Ag2O material for rapidly degrading malachite green

ActiveCN110605119AShort decolorization timeImprove decolorization efficiencyWater treatment compoundsWater contaminantsChemistrySilver oxide

The invention discloses a Fenton-like catalyst Ag2MoO4 / Ag2O material capable of rapidly degrading malachite green as well as a preparation method and application of the Fenton-like catalyst Ag2MoO4 / Ag2O material. Disodium hydrogen phosphate, sodium molybdate and silver nitrate are used as raw materials, a novel Ag2MoO4 / Ag2O Fenton-like catalyst is synthesized by utilizing a chemical precipitationmethod and cooperating with hydrothermal silver oxide self-doping, and the optimal pH of a synthesis reaction, the feeding ratio of the sodium molybdate to the silver nitrate and the conditions of thehydrothermal reaction are determined; the catalyst can be applied to efficient degradation of malachite green in a proper pH environment after being mixed with H2O2. Research finds that the decolorization rate of the Ag2MoO4 / Ag2O-H2O2 heterogeneous Fenton-like composite system on the malachite green is as high as 99.7% within 6 min. The preparation method of the photocatalyst is simple and easy to operate, has the advantages of low toxicity, low price and the like, and has very high research value in the field of organic dye degradation.

Owner:ZHAOQING UNIV

A rapidly degrading malachite green ag 2 moo 4 /ag 2 oMaterial preparation method

ActiveCN110605119BShort decolorization timeImprove decolorization efficiencyWater treatment compoundsWater contaminantsMalachite greenSodium molybdate

The invention discloses a Fenton-like catalyst Ag for rapidly degrading malachite green 2 MoO 4 / Ag 2 O material, preparation method and application thereof. Using disodium hydrogen phosphate, sodium molybdate and silver nitrate as raw materials, using chemical precipitation method, synergistic hydrothermal method to synthesize a new type of Ag by self-doping silver oxide 2 MoO 4 / Ag 2 O-type Fenton catalyst, wherein the optimum pH of the synthesis reaction, the feeding ratio of sodium molybdate and silver nitrate, and the conditions of the hydrothermal reaction are determined; the catalyst is combined with H 2 O 2 After mixing, it can be applied to efficiently degrade malachite green in a suitable pH environment. The study found that Ag 2 MoO 4 / Ag 2 O‑H 2 O 2 The decolorization rate of malachite green by the heterogeneous Fenton-like composite system is as high as 99.7% within 6 minutes. The preparation method of the photocatalyst of the invention is simple, easy to operate, has the advantages of low toxicity, low price, etc., and has very high research value in the field of degrading organic dyes.

Owner:ZHAOQING UNIV

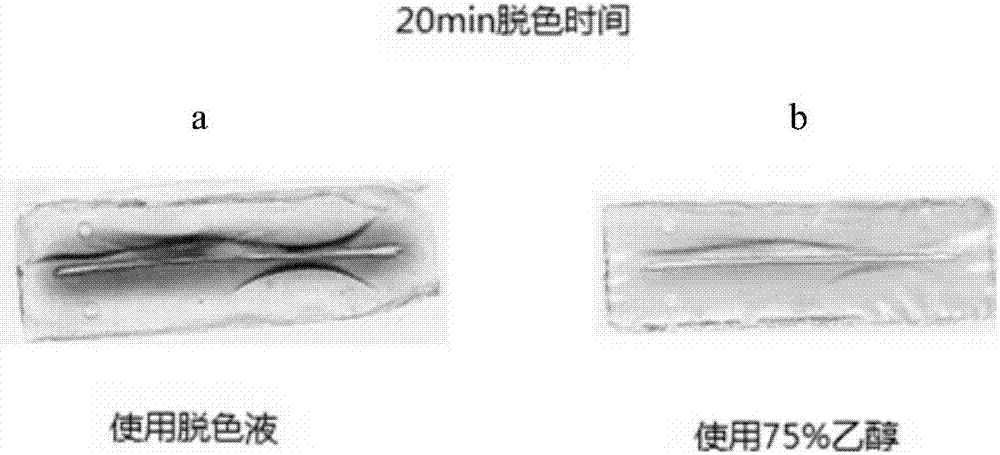

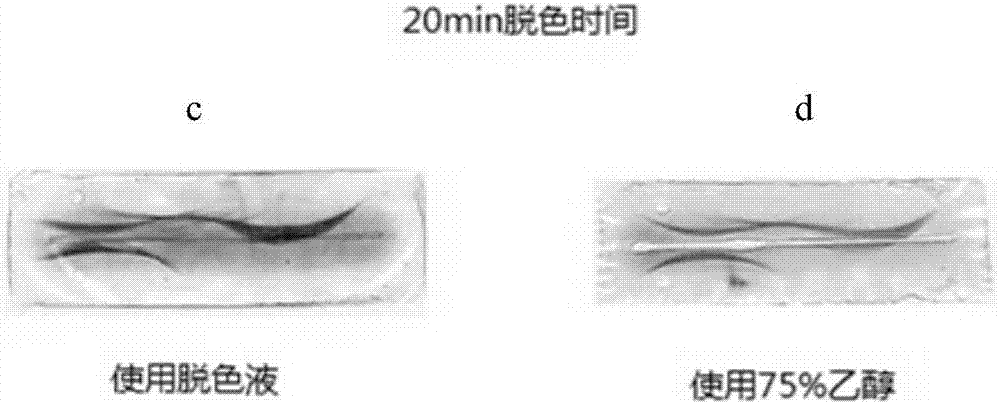

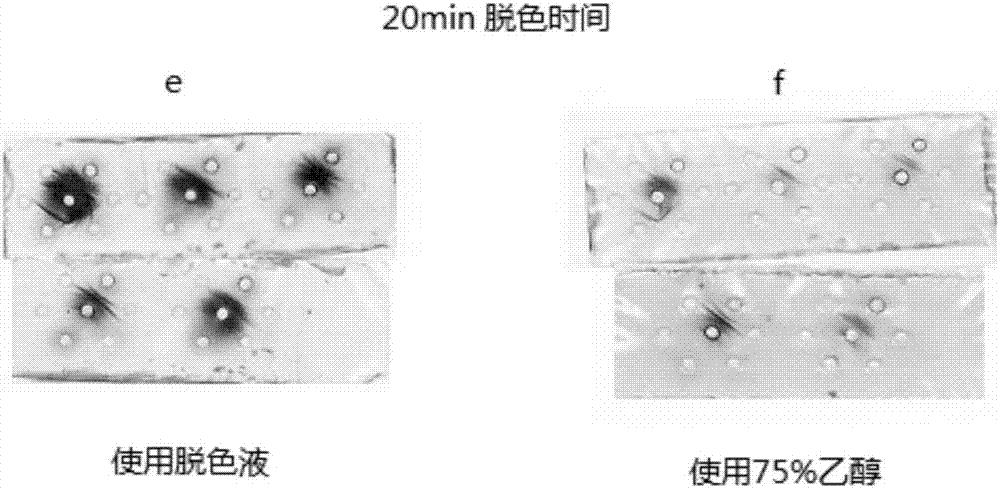

Method for rapid identification of albumin and globulin products

InactiveCN107340396AShort durationMeet the identification standardBiological testingRapid identificationBiology

The invention relates to a method for quickly identifying albumin and globulin products, which comprises the following steps: S1: punch measurement holes and control holes on an agarose gel plate, add 10 μl of product solution and bromophenol blue indicator to the measurement holes Add 1 drop of normal human serum or human plasma and 1 drop of bromophenol blue indicator solution to the control well; S2: Electrophoresis at a constant voltage of 100V for about 2 hours, and dig a 3-4mm wide depression between the measurement well and the control well Tank, add human serum antibody or human plasma antibody into the tank and spread it in a wet box; S3: fully soak the agarose gel plate with physiological sodium chloride solution, and stain it after soaking; Decolorize in the decolorization box with % ethanol, so that the background is decolorized and the precipitation line is clearly visible; S5: compare with the reference substance, and identify the protein type contained in the product solution. After using the method of the invention, the identification time for proteins is reduced from 4-5 days to 1-2 days, which greatly improves the efficiency of identification experiments.

Owner:HUALAN BIOLOGICAL ENG CHONGQING +1

A kind of decolorization method of Sapindus saponin

ActiveCN108129523BGood decolorization effectGood decolorizationSugar derivativesGlycosidesSulfite saltSulfate

Owner:JIANGXI NORMAL UNIV

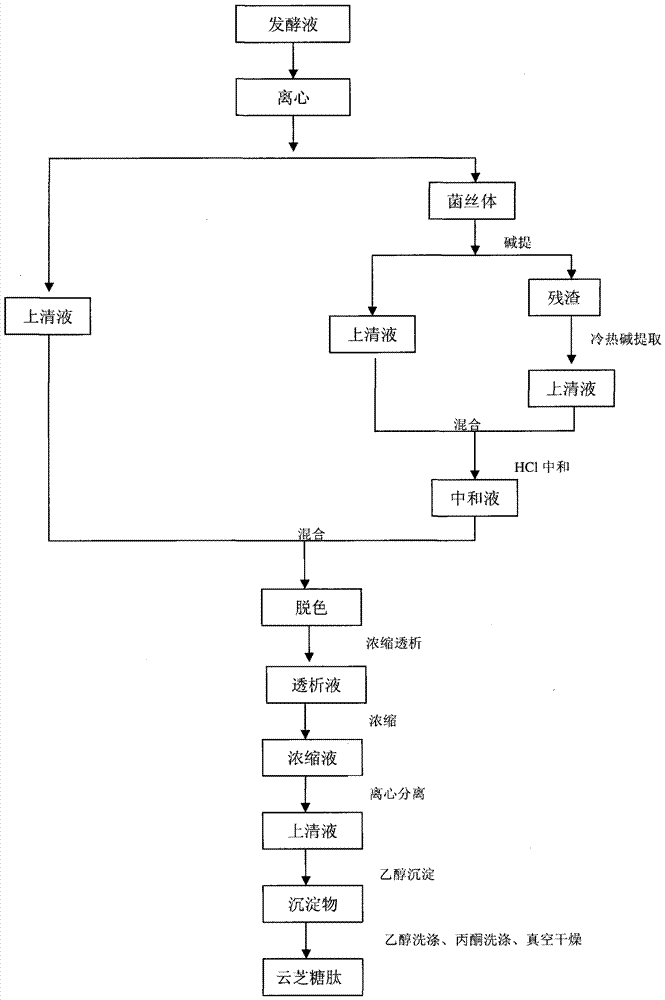

A kind of method for the preparation of Yunzhi glycopeptide

The invention discloses a preparation method of Yunzhi glycopeptide, which belongs to the category of biotechnology. The present invention not only extracts the extracellular glycopeptides in the fermentation broth by the method of water extraction and alcohol precipitation, but also processes the mycelia through the method of alkali extraction to obtain intracellular glycopeptide substances, and regenerates the mycelium residue after alkali extraction. Extraction with cold alkali and hot alkali in turn increases the yield of intracellular glycopeptides. The total yield of Yunzhi glycopeptides can reach more than 10.50g / L, and the sugar content in the obtained Yunzhi glycopeptides reaches more than 56.00%. The content reaches more than 35.80%. The invention has the advantages of advanced technology, simple process, high yield, low cost, high product purity, etc., and is beneficial to the improvement of production technology and industrialization level of versicolor glycopeptide in my country.

Owner:中科医药行业生产力促进中心有限公司

Supported hydrochloric acid decolorizing agent as well as preparation method and decolorization process thereof

InactiveCN108383083AShort decolorization timeGood effectChlorine/hydrogen-chloride purificationChemistryIron(II) chloride

The invention relates to a novel supported hydrochloric acid decolorizing agent as well as a preparation method and a decolorization process thereof. The decolorizing agent can be used for quite effectively removing the color of industrial hydrochloric acid; the decolorized industrial hydrochloric acid is colorless transparent liquid. A reagent is prepared from an ordered mesoporous material MCM-41 (the MCM-41 treated through trimethoxysilyl propylamine and trimethylchlorosilane), 2-p-bromomethyl bipyridine, sulfurous acid, ferrous chloride, magnesium sulfate, stannous chloride, diatomite, water and ethanol. The reagent capable of being used for decolorizing hydrochloric acid, which is provided by the invention, is simple in preparation process, short in production period and low in cost,is used for decolorizing the industrial hydrochloric acid, is short in decolorization time and good in decolorization effect, and does not decrease the content of the industrial hydrochloric acid, andthe decolorizing agent can be repeatedly recovered and utilized for multiple times.

Owner:CHINA THREE GORGES UNIV

Decolorization treatment method of apple dietary fiber

ActiveCN103652828BLow viscosityLow densityFood ultrasonic treatmentFood preparationDietary fiberAlcohol

The invention discloses a decolorization treatment method of an apple dietary fiber, and belongs to the field of food processing technology. The decolorization treatment method comprises the following steps: 1) adding apple pomace into an alkaline solution, fully mixing evenly, and thus obtaining a mixed material liquid; 2) adding a polar alcohol solution into the mixed material liquid, stirring evenly, then at the temperature of 60-100 DEG C, introducing ozone, and carrying out decolorization treatment under an ultrasonic condition to obtain a decolorized mixed material liquid; and 3) adjusting the pH value of the decolorized mixed material liquid to neutral, then centrifuging, drying, crushing, sieving, and thus obtaining the decolorized apple dietary fiber. The decolorization treatment method can obtain the apple dietary fiber product having good color and luster and according with sensory requirements in the relatively short decolorization time, has the advantages of easy and simple operation and green environmental protection, and is suitable for industrialized enlargement production.

Owner:SHAANXI UNIV OF SCI & TECH

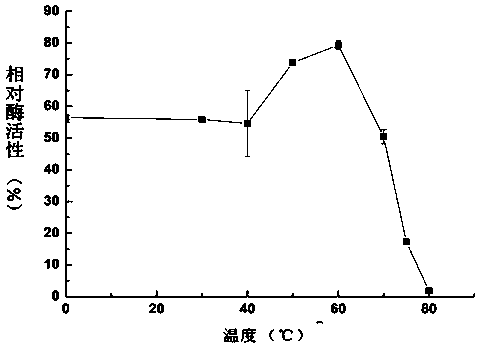

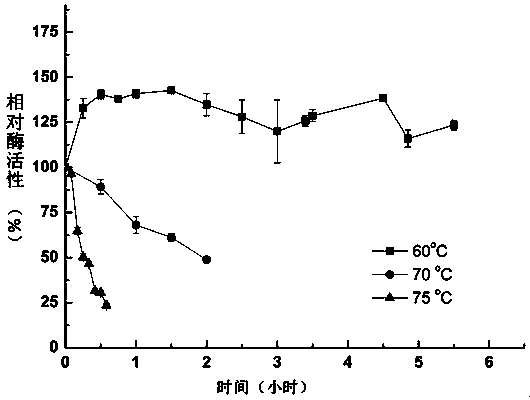

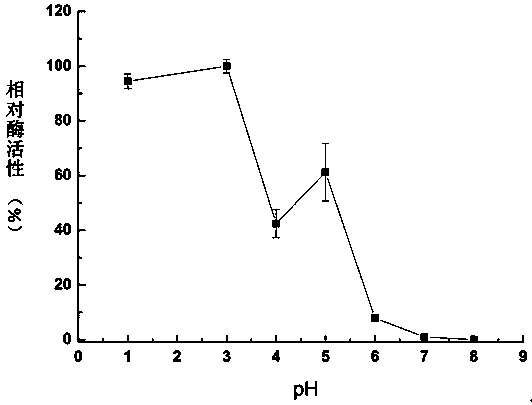

A kind of thermostable Trametes trichos laccase ttlac13 and its application

ActiveCN105505891BThe advantage of thermal stability is obviousImprove degradation efficiencyOxidoreductasesIsozymeTrametes trogii

The invention belongs to the field of applied microbiology and the technical field of bioengineering, and particularly discloses trametes trogii laccase isozyme TtLac13. The amino acid sequence of the trametes trogii laccase isozyme TtLac13 is shown in SEQ ID NO:1. When the trametes trogii laccase isozyme TtLac13 is applied to biodegradation of triphenylmethane colored and toxic substances such as peacock green and crystal violet, time is short, decoloration efficiency is high, good industrial application prospects are achieved, and good economic benefits and good social benefits can be generated.

Owner:KUNMING UNIV OF SCI & TECH

Decoloring agent for dental fluorosis

A liniment for removing the fluorine spots from tooth includes two products. The liniment A is prepared from 7 Chinese-medicinal materials including dahurian angelica root, as arum herb, Chuan-xiong rhizome, fresh tangerine peel, etc through proportional mixing, immersing in 2-8 % solution of hydrochloric acid and filtering. The liniment B is prepared from pumice through grinding, immersing in solution of sodium fluoride, and filtering. Its advantages are high speed, no damage to tooth enamel, and 100% of cure rate.

Owner:李明明

A kind of tea saponin biological enzyme decolorization process

ActiveCN103864879BMild reaction conditionsShort decolorization timeSugar derivativesSteroidsBiotechnologySaporin

Owner:HANGZHOU YIMIN PETOROCHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com