Processing method of corn oil

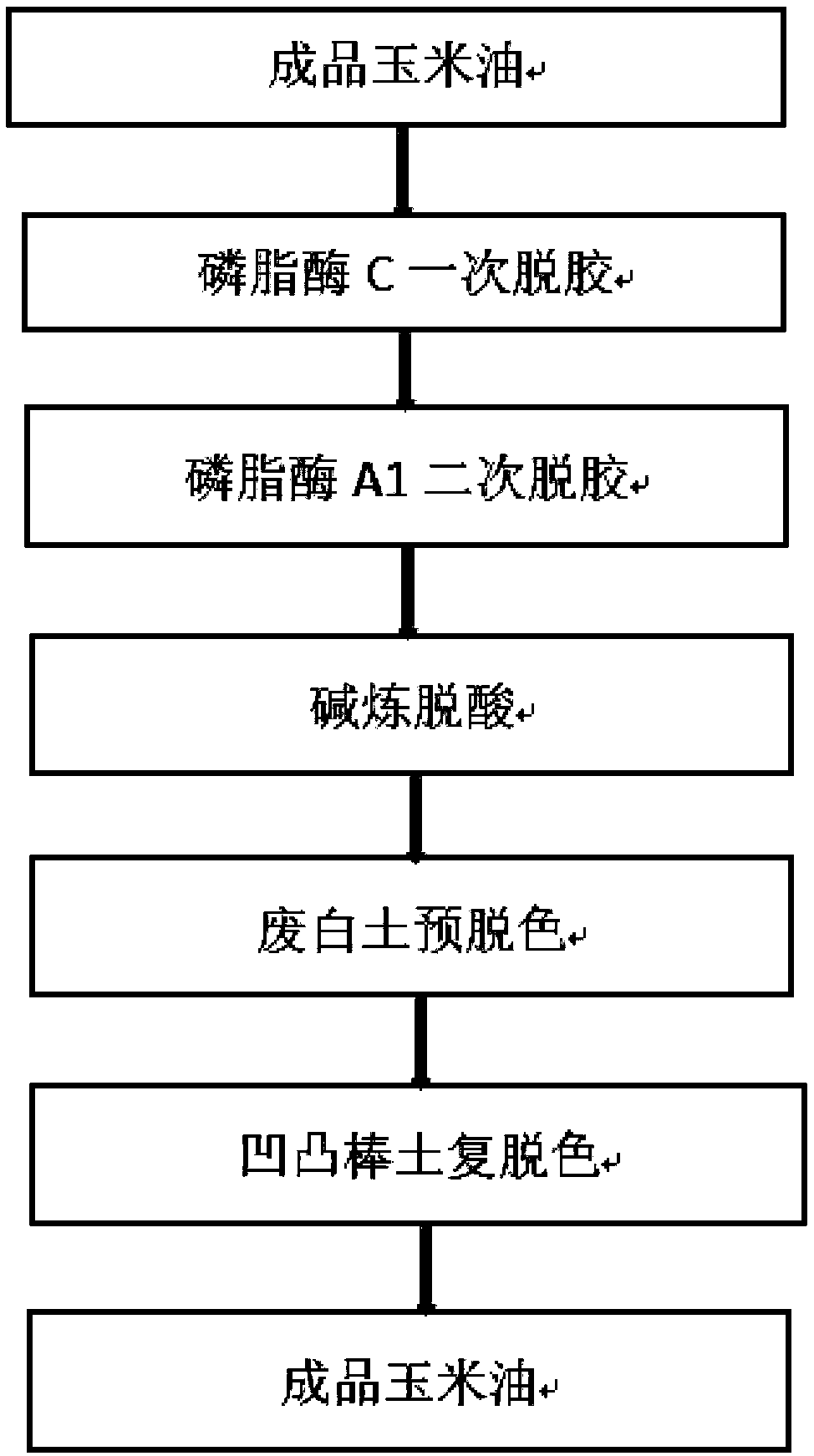

A processing method, corn oil technology, applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problems of low trans fatty acid production, processing wastewater, waste residue discharge exceeding the standard, long process line, etc., to achieve Reduce the water consumption of degumming, reduce the amount of waste water, and facilitate the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] Step 1. Preparation of crude corn oil: the crude corn oil is obtained by leaching the soybean meal. The main indicators of the crude corn oil are as follows: the phosphorus content is 0.67%, the oleic acid in the fatty acid composition is 17.7-28.0%, and the linoleic acid is 49.8-59.0%, linolenic acid 5.0-11.0%, vitamin E 90-296mg / 100g, phytosterol 0.15-0.38%;

[0023] Step 2. Heat the crude corn oil prepared in step 1 to 65-75°C, add citric acid solution with an oil weight of 0.09-0.1% and a concentration of 45%, and after homogeneous mixing, stir and keep warm at 45°C Stay for 25-35 minutes, then add phospholipase C with a concentration of 0.1%, and the addition amount is 12-16mL / kg of the oil weight, after homogeneous mixing, add soft water with an oil weight of 2-4%, stir at 45°C Insulate and perform a degumming treatment for 85-95 minutes. After the first degumming treatment is completed, inactivate the enzyme at 85-95°C for 8-12 minutes. After the enzyme inactivat...

Embodiment 1

[0029] Heat corn crude oil to 70°C, add citric acid solution with 0.1% oil weight and 45% concentration, after homogeneous mixing, stir at 45°C and keep it warm for 30 minutes, then add phospholipase with a concentration of 0.1% C, and the addition amount is 12mL / kg of the oil weight. After homogeneous mixing, add soft water with 3% oil weight, stir and keep warm at 45°C for a degumming treatment for 90 minutes, and after the first degumming treatment is completed, extinguish it at 90°C. Enzyme treatment for 10 minutes, after the end of enzyme deactivation, centrifuge to obtain oil bottoms and primary degummed corn oil; heat primary degummed corn oil to 70°C, add citric acid solution with 0.12% oil weight and 45% concentration, and wait for homogenization After mixing, stir at 45°C and keep it warm for 30 minutes, then add phospholipase A1 with a concentration of 0.1%, and the addition amount is 10mL / kg of the oil weight, after homogeneous mixing, add soft water with 2% oil wei...

Embodiment 2

[0031] Heat corn crude oil to 70°C, add citric acid solution with 0.1% oil weight and 45% concentration, after homogeneous mixing, stir at 45°C and keep it warm for 30 minutes, then add phospholipase with a concentration of 0.1% C, and the addition amount is 16mL / kg of oil weight, after homogeneous mixing, add soft water with 2% oil weight, stir and keep warm at 45°C for a degumming treatment for 90 minutes, after the first degumming treatment is completed, extinguish at 90°C Enzyme treatment for 12 minutes, after the end of enzyme deactivation, centrifuge to obtain oil bottoms and primary degummed corn oil; heat the primary degummed corn oil to 70°C, add citric acid solution with 0.12% oil weight and 45% concentration, wait until homogeneous After mixing, stir at 45°C and keep it warm for 30 minutes, then add phospholipase A1 with a concentration of 0.1%, and the addition amount is 15mL / kg of the oil weight, and add soft water with 2% oil weight after homogeneous mixing, Stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com