Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

99 results about "Phospholipase A1" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

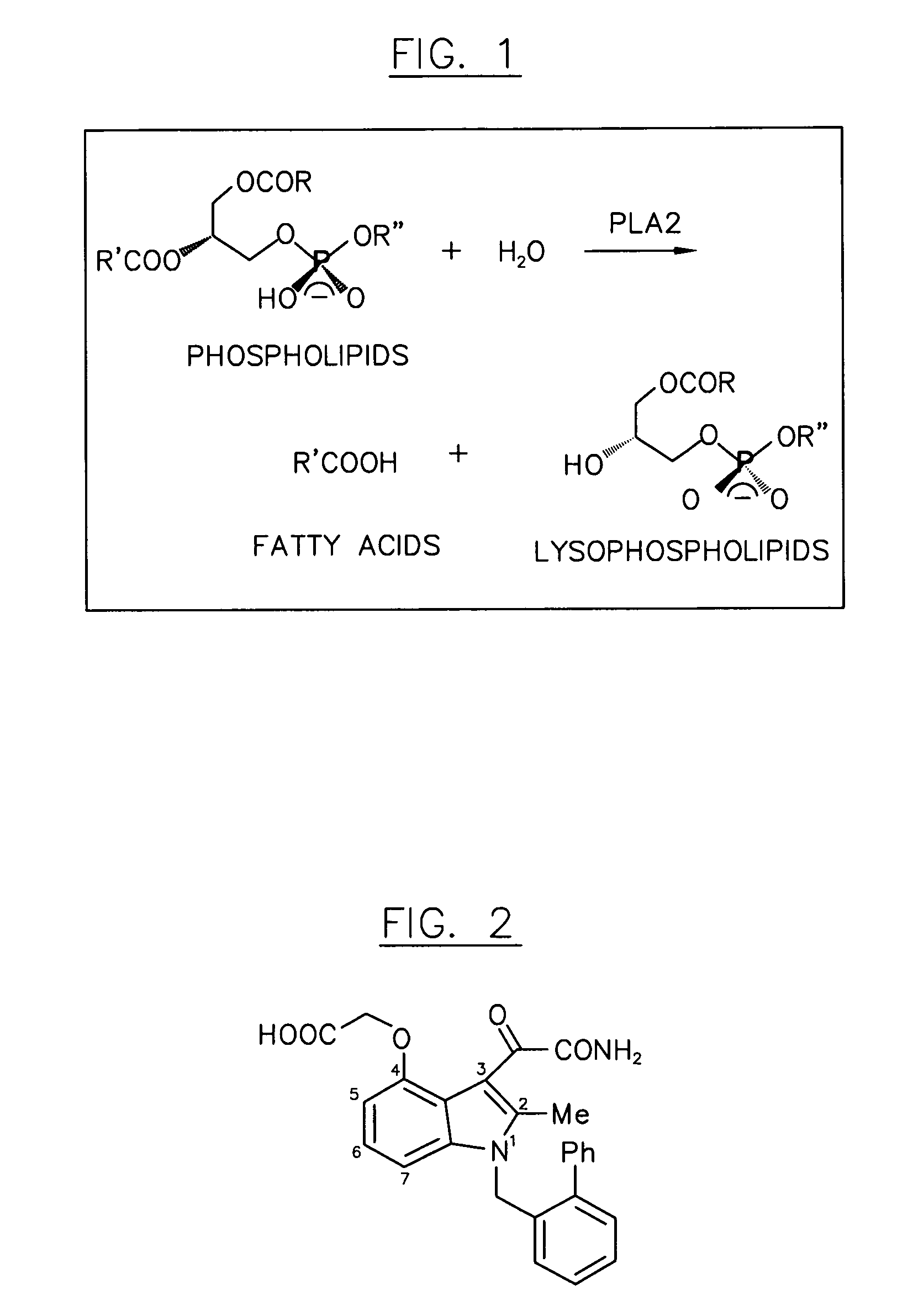

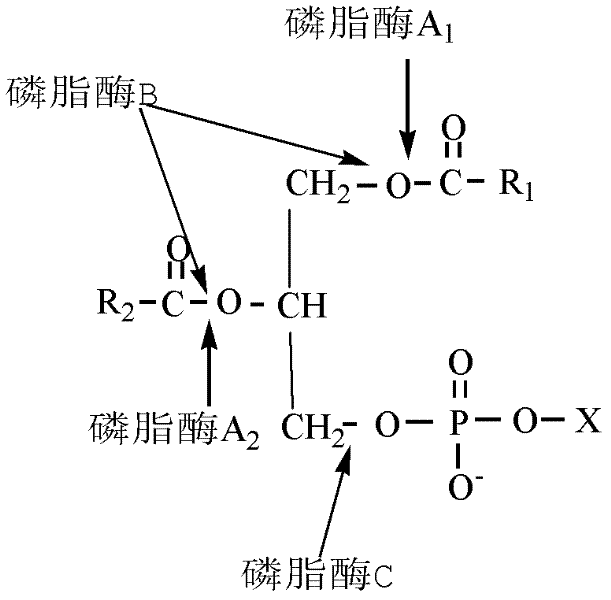

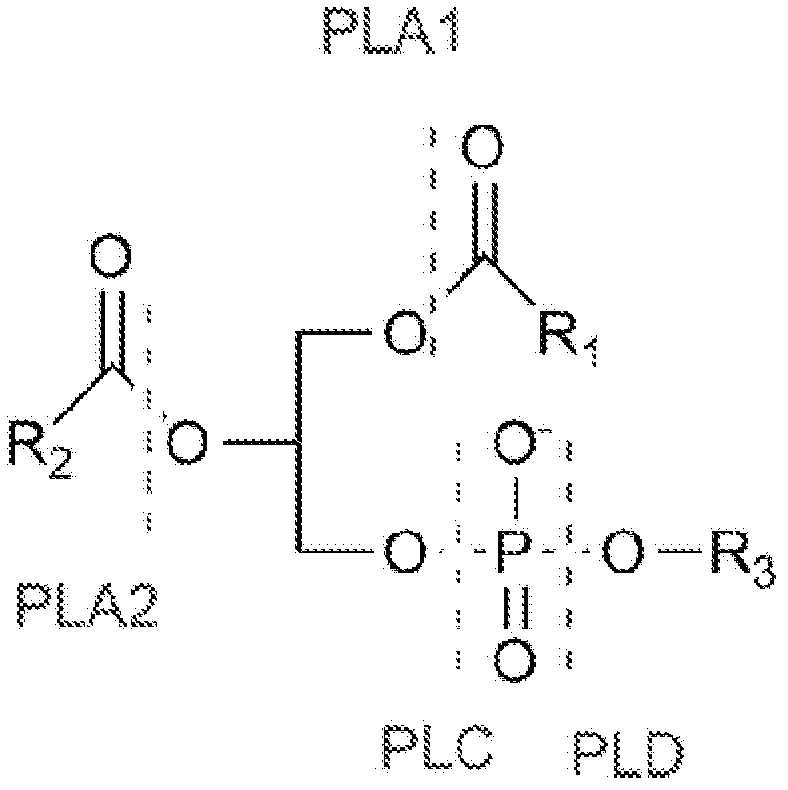

Phospholipase A1 encoded by the PLA1A gene is a phospholipase enzyme which removes the 1-acyl. Phospholipase A1 is an enzyme that resides in a class of enzymes called phospholipase that hydrolyze phospholipids into fatty acids. There are 4 classes, which are separated by the type of reaction they catalyze. In particular, phospholipase A1 (PLA1) specifically catalyzes the cleavage at the SN-1 position of phospholipids, forming a fatty acid and a lysophospholipid.

Process for the pre-treatment of vegetable oils for physical refining

ActiveUS20040005399A1Speed up the processFatty acids production/refiningTea extractionMicroorganismActivated carbon

The present invention relates to a simple and economically attractive process for the pretreatment of vegetable oils which involves (a) enzymatic degumming with commercially available phospholipase A1 from the sources like Aspergillus oryzae microorganism, (b) bleaching of the enzymatically degummed oil using bleaching earth and activated carbon, and (c) dewaxing (in case of rice bran oil) of degummed and bleached oil at lower temperature to obtain oil with less than 5 ppm of residual phosphorus which is amenable for physical refining.

Owner:COUNCIL OF SCI & IND RES

Method for degumming soybean oil by phospholipase catalysis

InactiveCN102634411AIncreased diglyceride contentShort degumming timeFatty-oils/fats refiningEdible oils/fatsVegetable oilOil production

The invention discloses a method for degumming soybean oil by phospholipase catalysis, which belongs to the field of vegetable oil degumming and includes the steps of preheating, adjusting pH, adding enzyme prior to mixing, allowing for enzymolysis, deactivating the enzyme and separating. The method is technically characterized by including: using phospholipase C as the phospholipase for catalysis, and preheating crude soybean oil prior to acid treatment; cooling oil-water mixture subjected to acid treatment to 37-60 DEG C, adding NaOH solution to adjust pH to 3-8, adding distilled water accounting for 1%-5% of the weight of the oil, adding the phospholipase C according to an oil proportion of 100-2000U / g, and mixing well; setting the mixing speed at 100-600r / min, and allowing for enzyme reaction for 0.5-2 hours; and deactivating the enzyme at high temperature for a reaction system, and performing high-speed centrifugal separation to complete degumming. The degumming time of the method is shortened by 1-2 times as compared with that of using phospholipase A1, phosphorus content is reduced, diglyceride content of the oil is increased slightly, and economic benefit is increased for oil production industries.

Owner:JIANGNAN UNIV

Process for the pre-treatment of vegetable oils for physical refining

ActiveUS7494676B2Speed up the processFatty acids production/refiningTea extractionMicroorganismActivated carbon

The present invention relates to a simple and economically attractive process for the pretreatment of vegetable oils which involves (a) enzymatic degumming with commercially available phospholipase A1 from the sources like Aspergillus oryzae microorganism, (b) bleaching of the enzymatically degummed oil using bleaching earth and activated carbon, and (c) dewaxing (in case of rice bran oil) of degummed and bleached oil at lower temperature to obtain oil with less than 5 ppm of residual phosphorus which is amenable for physical refining.

Owner:COUNCIL OF SCI & IND RES

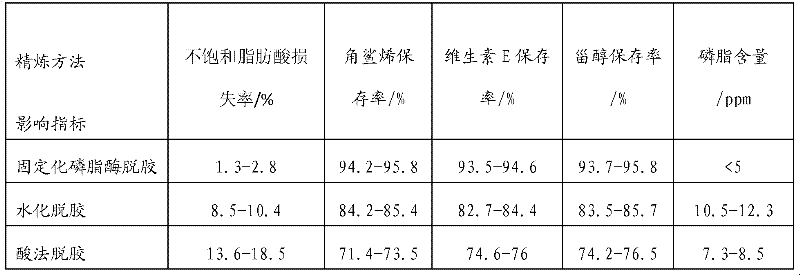

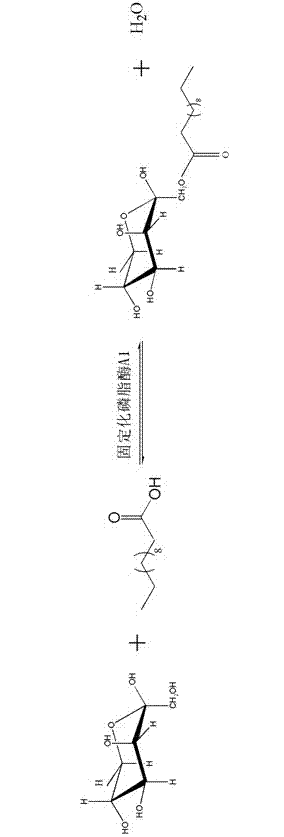

Method for refining vegetable seed crude oil using immobilized phospholipase A1

InactiveCN101485366AImprove heat resistanceReduce sensitivityEdible oils/fatsPhosphatidaseEconomic benefits

The invention provides a method for refining rape seed crude oil by immobilized phosphatidase A1, and relates to the method for refining the rape seed crude oil. The problems of inactivation of enzyme caused by an uneasily controlled enzyme reaction condition during production and high cost of phosphatidase in enzyme process degumming can be solved by selecting the immobilized phosphatidase A1 for degumming. The method for refining the rape seed crude oil by the immobilized phosphatidase A1 is realized by the following steps: 1, preparing a reaction solution; 2, preparing a mixed solution; 3, preparing granulated immobilized enzyme; 4, pretreating the rape seed crude oil; 5, adding the immobilized enzyme into the oil; and 6, stirring and centrifugating to realize the refined rape seed crude oil by the immobilized phosphatidase A1. The rape seed crude oil is subjected to the degumming treatment by the method to improve degumming efficiency. Compared with the prior method, the method improves the degumming efficiency by 5 to 30 percent and the economic benefit by 1 to 3 percent.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

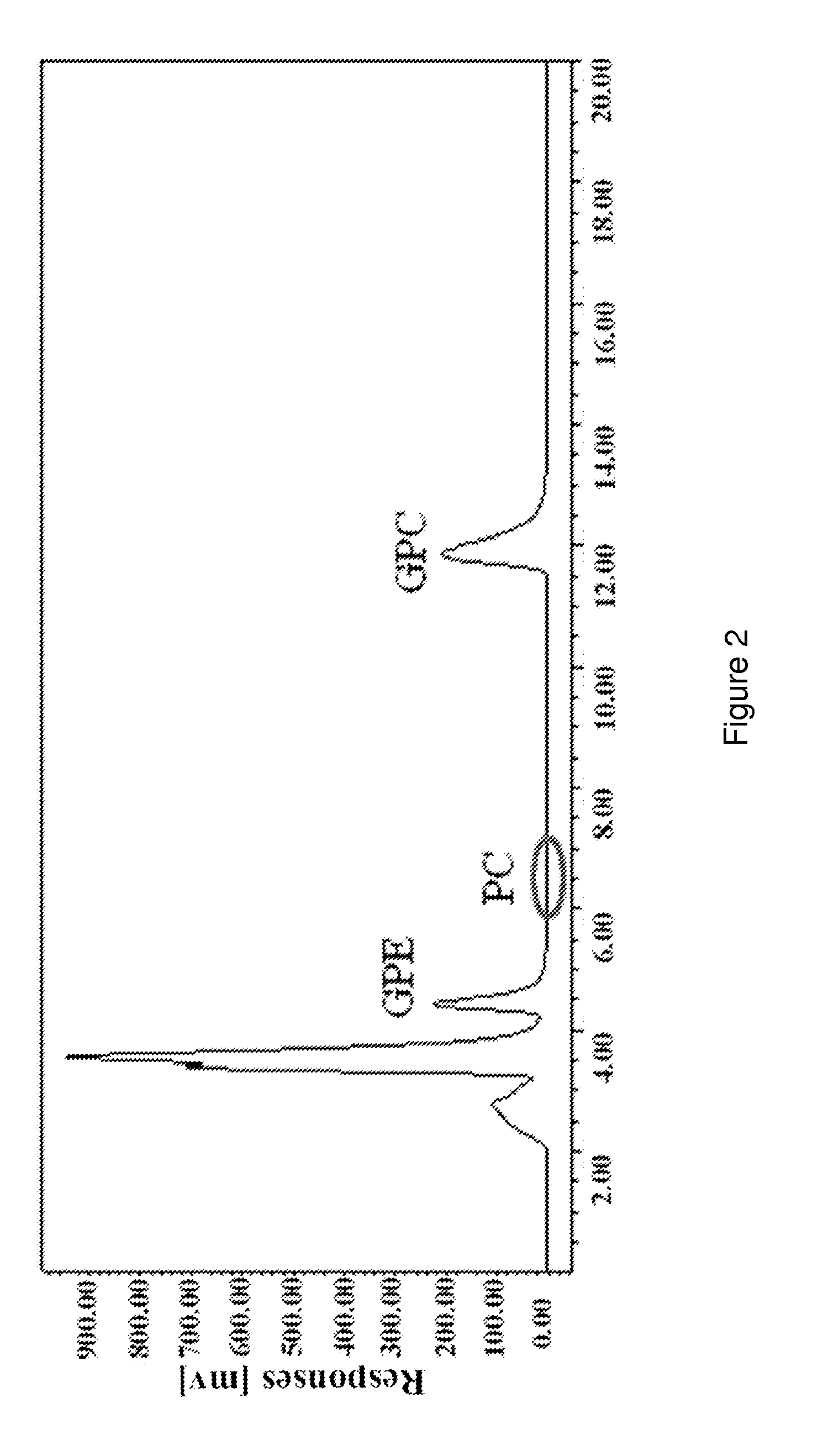

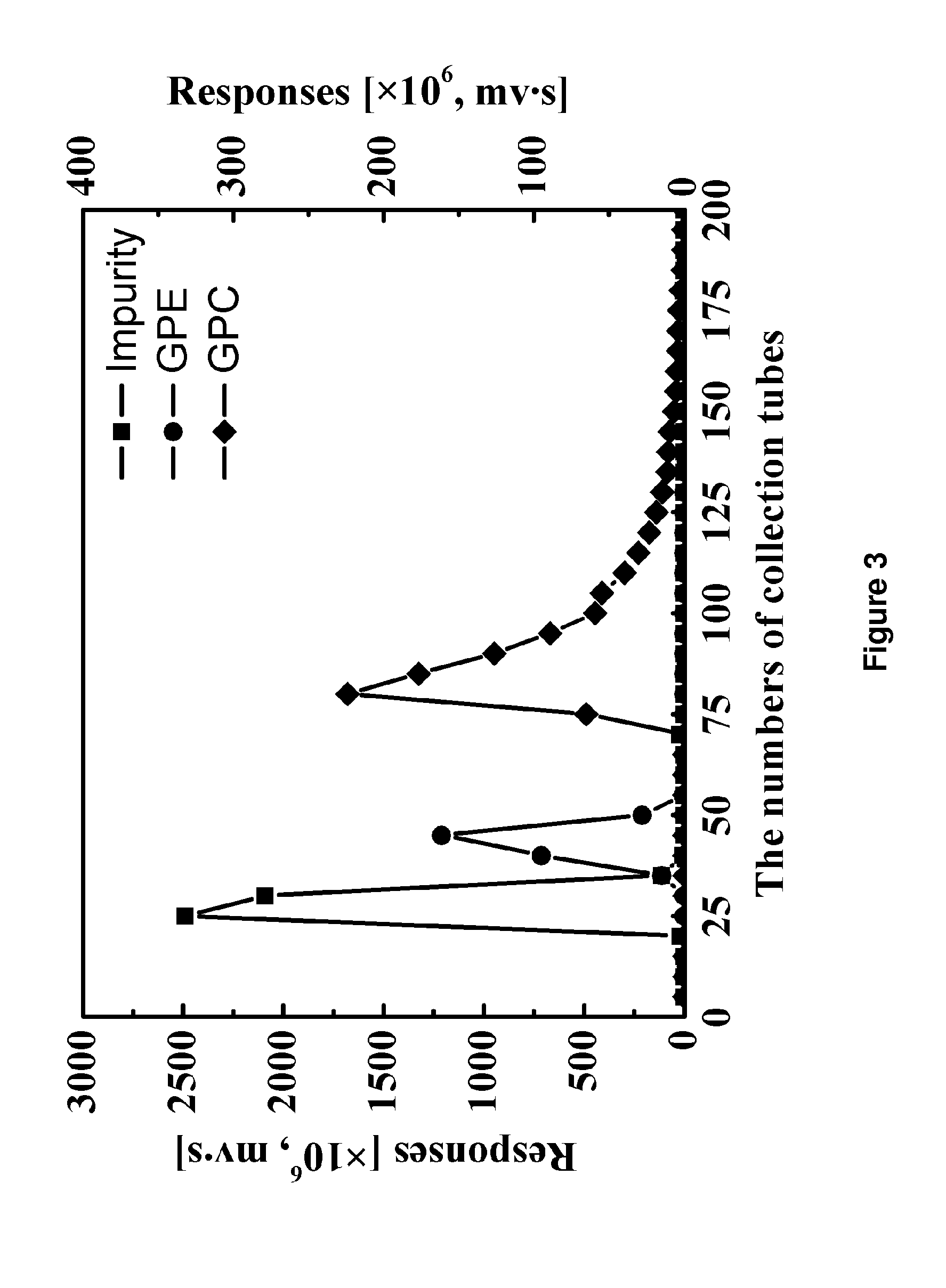

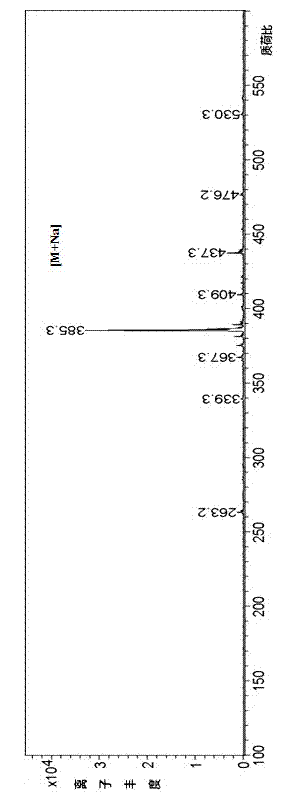

Method for Preparing High Purity L-alpha Glycerylphosphorylcholine

Disclosed is a method for preparing L-α-Glycerylphosphorylcholine with high yields and purity. The method uses phospholipase A1-based enzymatic hydrolysis, ion-exchange resin purification and silica gel column chromatography to prepare L-α-glycerylphosphorylcholin with purity up to 99.8% and a final yield up to 78.4%. The method disclosed is simple, cost-effective, environmentally friendly, and adaptable to industrial applications.

Owner:JIANGNAN UNIV

Improved vegetable oil enzymatic degumming method

ActiveCN102399627AShort reaction timeImprove degumming effectFatty-oils/fats refiningBiotechnologyVegetable oil

The invention discloses an improved vegetable oil enzymatic degumming method, which comprises the following steps of: (1) adopting phospholipase to carry out degumming reaction on the vegetable oil, wherein the phospholipase at least contains one of phospholipase A1, phospholipase A2 and phospholipase B; (2) raising the temperature of the degummed vegetable oil to 70-100 DEG C, and carrying out heat preservation for 15-90min; and (3) carrying out gum separation to obtain the degummed oil. By adopting the method disclosed by the invention, the enzymatic reaction in the enzymatic degumming can be shortened. The method disclosed by the invention has the advantages that the implementation is easy, and the degumming effect is good.

Owner:SOUTH CHINA UNIV OF TECH

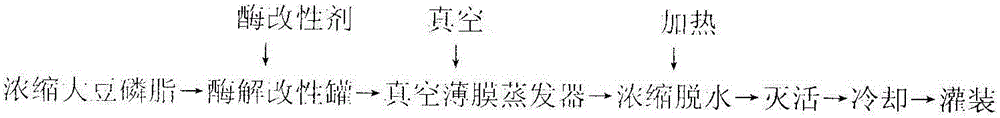

Preparation method suitable for industrialized continuous production of enzyme modified soybean phospholipids

The invention discloses a preparation method suitable for industrialized continuous production of enzyme modified concentrated phospholipids. The preparation method comprises the following steps: a, adding phospholipase A1, phospholipase A2, and a 1, 3-lipase aqueous solution into concentrated phospholipids for enzymatic modification reaction; b, pumping the concentrated soybean phospholipids after enzymatic modification into a fixed scraper film evaporator for dehydration by continuous evaporation and enzyme inactivation through a screw pump, so as to enable the moisture to be decreased to 1% or below; c, concentrating, dewatering, cooling the inactivated enzyme modified phospholipids with a cooler, and introducing the cooled enzyme modified phospholipids into a vacuum stirring tank for removing oxygen in the modified phospholipids, so as to obtain the enzyme modified soybean phospholipids with good storage stability. The preparation method is suitable for continuous industrial production, the processing technology is easy and convenient, the production efficiency is remarkably improved, and the produced enzyme modified soybean phospholipids are good in dispersity, hydrophilia and heat resistance in water, quite good in emulsion stability in a low pH value range and hyper-salt concentration, and widely applicable to the industries, such as, food, medicine, daily-use chemicals, pesticides, paint coatings, leather and textile, petrochemical industry and fodder.

Owner:李桂华 +1

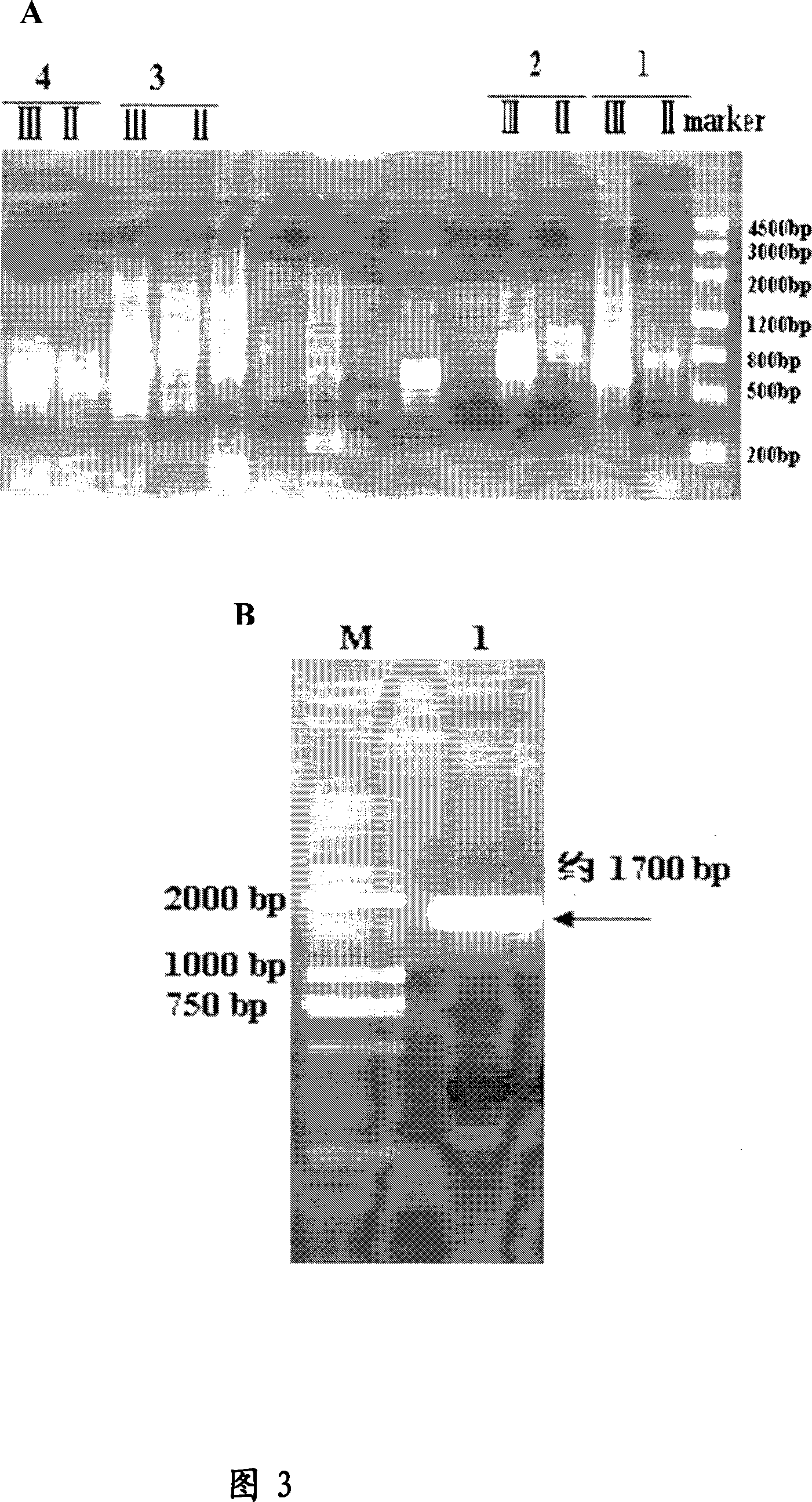

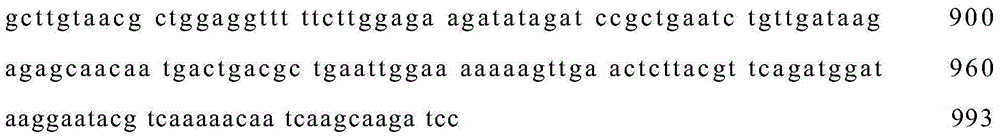

Low-temperature alkaline phosphatidase A1 and coding gene thereof

InactiveCN101070530ASimple production processHigh expressionFungiBacteriaBiotechnologySerratia fonticola

This invention open a cold tolerance of Serratia sand Habitat-chuen (Serratia fonticola) xjF1 CGMCC No.1971, through the strain characteristics, enzyme production conditions and the nature of enzyme research, proved a new phospholipase A1 gene consists of two open plA and plS reading frame, was certified plA gene coding phospholipase A1, plS gene coding phospholipase A1 auxiliary protein. This invention relates to the gene containing the recombinant plasmid and reorganization cell, the gene expression products phospholipase A1 in the show activity under low-temperature conditions, can be used in industries such as oil refining process can be simplified production process, lowering energy consumption, improve product quality , protecting the environment, reduce production costs, have important practical significance.

Owner:THE INST OF MICROBIOLOGY XINJIANG ACADEMY OF AGRI SCI

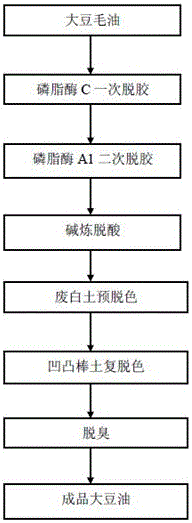

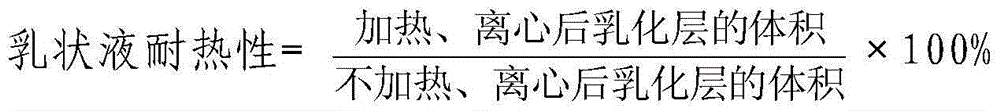

Processing method of soybean oil

InactiveCN105038977AReduce phosphorus contentRelieve pressureFatty-oils/fats refiningActivated carbonPhosphatidase

The invention discloses a processing method of soybean oil. The method comprises the following steps: 1, preparing crude soybean oil; 2, adding phosphatidase C, and carrying out primary degumming treatment to obtain primary degummed soybean oil; 3, adding phosphatidase A1, and carrying out secondary degumming treatment to obtain secondary degummed soybean oil; 4, carrying out alkali refining depickling treatment to obtain depickled soybean oil; 5, adding waste white clay to the depickled soybean oil, carrying out pre-decoloring treatment to obtain pre-decolored soybean oil, adding attapulgite and active carbon to the pre-decolored soybean oil, and carrying out re-decoloring treatment to obtain re-decolored soybean oil; and 6, carrying out deodorizing treatment on the re-decolored soybean oil to obtain finished soybean oil. The processing method of the soybean oil has the advantages of safety, environmental protection, simple process, convenient operation, low cost and high refining rate, and is suitable for soybean oil processing industrial production.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Method for refining raw oil by using magnetic immobilized phospholipase A1

InactiveCN102559378AResponsiveness to strong magnetic fieldsQuick and Easy EnrichmentFatty-oils/fats refiningPhospholipase ACitric acid

The invention provides a method for refining raw oil by using magnetic immobilized phospholipase A1, which relates to a method for refining raw oil by using immobilized phospholipase A1. The invention aims to solve the problems that the separation and the recovery of an immobilized enzyme are complicated, the activity recovering rate is low and a magnetic immobilized enzyme is not used for refining raw oil at present, which exist in a traditional method for preparing immobilized phospholipase A1. The method for preparing and refining the raw oil comprises the following steps of: (1) preparingthe magnetic immobilized phospholipase A1; (2) heating the raw oil and adding a citric acid solution; and (3) cooling, regulating the pH value, then adding the magnetic immobilized phospholipase A1, stirring and separating the magnetic immobilized phospholipase A1 so as to finish the preparation method of the magnetic immobilized phospholipase A1 and the method for refining the raw oil. The recovering rate of the magnetic immobilized phospholipase A1 prepared by the method for refining the raw oil by using the magnetic immobilized phospholipase A1 reaches more than 85 percent, so that the phosphorus content of the raw oil is lowered to 7-10mg / kg. The method for refining the raw oil by using the magnetic immobilized phospholipase A1 is applied to the field of degumming of grease.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Preparation method of degreased roe protein powder

ActiveCN104432106AGreat tasteEasy to eatProtein composition from fishFood preparationOrganic solventPhospholipase A2

The invention provides a preparation method of degreased roe protein powder. A degreased roe protein powder product is prepared by the following steps: carrying out mixed enzymolysis on phospholipase A1, phospholipase A2 and papain; degreasing by supercritical co2 extraction; and preparing. The method can be used for fully removing glyceride, free fatty acids, phospholipase and cholesteryl ester in roes under the condition of not using an organic solvent so as to obtain the degreased roe protein powder product which is good in taste, convenient to eat and high in additional value.

Owner:威海博宇食品有限公司

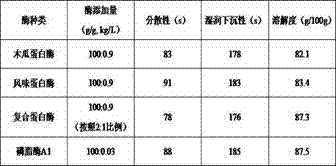

Preparation method of highly-emulsifiable egg yolk powder

InactiveCN106689880AIncreased emulsifying capacityNot easy to agglomerateFood preparationNeutral proteaseEnzymatic hydrolysis

The invention relates to a preparation method of highly-emulsifiable egg yolk powder. The preparation method comprises the following main steps: taking fresh eggs, breaking shells to take whole juice of the eggs, separating egg white liquid from egg yolk liquid, uniformly stirring the separated egg yolk liquid, filtering and removing impurities; adding neutral proteases and phosphatidases Al into the egg yolk liquid and performing enzymatic hydrolysis for 180 minutes at a temperature of 52-55 DEG C; adding maltodextrin powder into the egg yolk liquid after enzymatic hydrolysis to enable the mass percentage to reach 3 percent and uniformly stirring; pasteurizing, spraying and drying to obtain egg yolk powder; performing vacuum packaging to obtain a finished product. Compared with ordinary egg white powder, the egg yolk powder prepared by the preparation method has no difference exists in appearance and mouth feeling; the emulsifying capacity, the emulsifying stability and the emulsion heat resistance are significantly improved, so that the production demands of products with higher requirements for emulsification performances can be met; moreover, the preparation method also has the advantages of being difficult to cake, good in reconstituability, simple in process, low in cost and easy for industrial production.

Owner:泰州苏鹏蛋业生物科技有限公司

Method for preparing magnetic immobilized phospholipase A1 and method for refining crude oil by using magnetic immobilized phospholipase A1

InactiveCN102061293AResponsiveness to strong magnetic fieldsQuick and Easy EnrichmentFermentationOn/in inorganic carrierLow activityPhospholipase A

The invention relates to a method for preparing magnetic immobilized phospholipase A1 and a method for refining crude oil by using the magnetic immobilized phospholipase A1. The invention aims to solve the problems of complicated separation and recycling of immobilized enzyme and low activity recovery of the conventional method for preparing the immobilized phospholipase A1, and the problem that the magnetic immobilized enzyme is not used for refining the crude oil at present. The method for preparing and refining the crude oil comprises the following steps of: 1, preparing the magnetic immobilized phospholipase A1; 2, heating the crude oil, and adding citric acid solution; and 3, cooling, regulating the pH value, adding the magnetic immobilized phospholipase A1, stirring, and separating the magnetic immobilized phospholipase A1. The recovery rate of the prepared magnetic immobilized phospholipase A1 is over 85 percent, and the phosphorus content of the crude oil is reduced to 7-10mg / kg. The invention is applied to the field of oil degumming.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Method for refining camellia seed crude oil beneficial to individuals with hypertension, hyperglycemia, hyperlipidemia

ActiveCN102504946AImprove heat resistanceReduce sensitivityFatty-oils/fats refiningCamellia oleiferaSecondary hyperlipidemia

The invention relates to a method for refining camellia seed crude oil, in particular to a method for refining the camellia seed crude oil by using immobilized phospholipase A1. The technical scheme of refining the camellia seed crude oil by using the immobilized phospholipase A1provided by the invention is realized by the following steps of: a, immobilizing phospholipase; b, carrying out pre-treatment on the camellia seed crude oil; c, adding the immobilized phospholipase into the camellia seed crude oil; and d, agitating and then centrifuging, namely realizing that the camellia seed crude oil is refined by using the immobilized phospholipase. The method for refining the camellia seed crude oil provided by the invention has the beneficial effects that unsaturated fatty acid is lost for 1-3% and is reduced by 15-20% compared with the loss of the unsaturated fatty acid in chemically-refined camellia seed oil; the immobilized phospholipase A1 is degummed to reduce phosphorus content in the oil to be lower than 5 mg / kg; the heat resistance of the immobilized phospholipase A1 is improved; the immobilized phospholipase A1 can keep a higher activity in a wider pH value range and the sensitivity of the immobilized phospholipase A1 to a reaction environment is reduced, so that the operation conditions are easier to control and implement.

Owner:FUJIAN CHUNHUI BIOLOGICAL ENG

Method for degumming soybean crude oil by virtue of combined application of immobilized phospholipase A1 and immobilized phospholipase C

InactiveCN104560387AHigh activityImprove stabilityFatty-oils/fats refiningPhospholipases CPhospholipase A1

The invention provides a method for degumming soybean crude oil by virtue of combined application of immobilized phospholipase A1 and immobilized phospholipase C. The method comprises the following steps: developing an immobilized phospholipase A1-immobilized phospholipase C two-enzyme degumming technology according to respective characateristics of the phospholipase A1 and phospholipase C, namely, performing conventional enzymic method degumming by adopting a small amount of immobilized phospholipase A1, forming an emulsifying system favorable for the subsequent immobilized phospholipase C effects by utilizing lysophosphatide, and adding a proper amount of the immobilized phospholipase C so as to realize degumming. The lowest obtained degummed phosphorus content is 2.8mg / kg, and after the phospholipase C is continuously used in six batches, the relative activity of the immobilized enzyme is still maintained to be about 80 percent. Therefore, a combined degumming method is adopted, so that the refining rate can be improved, the production cost can be reduced, the degumming reaction time can be reduced by 2 hours, and the oil yield is improved by 1.3 times.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Recombinant escherichia coli for producing phospholipase D and application thereof

The invention discloses a recombinant escherichia coli for producing phospholipase D and an application thereof, which belongs to the technical field of bioengineering. A phospholipase D gene is obtained through clone in Streptomyces ambofaciens by means of molecular biology measures, constructed expression plasmid is guided into E. coli BL21(DE3), and phosphatase-containing engineering bacteria formed by highly copying and recombining an expression carrier are obtained through kanamycin resistant plate screening. The recombinant phospholipase D is used for converting phosphatidylcholine and serine to generate phosphatidylserine, and efficient production of vitamin C-2-phosphate is achieved. By carrying out reaction for 2 h at the temperature of 40 DEG C with the pH value of 4.5, the yield of phosphatidylserine can reach 15.8 g / L, the conversion rate is 63.9%, and the space time yield is 7.9 g / L / h.

Owner:JIANGNAN UNIV

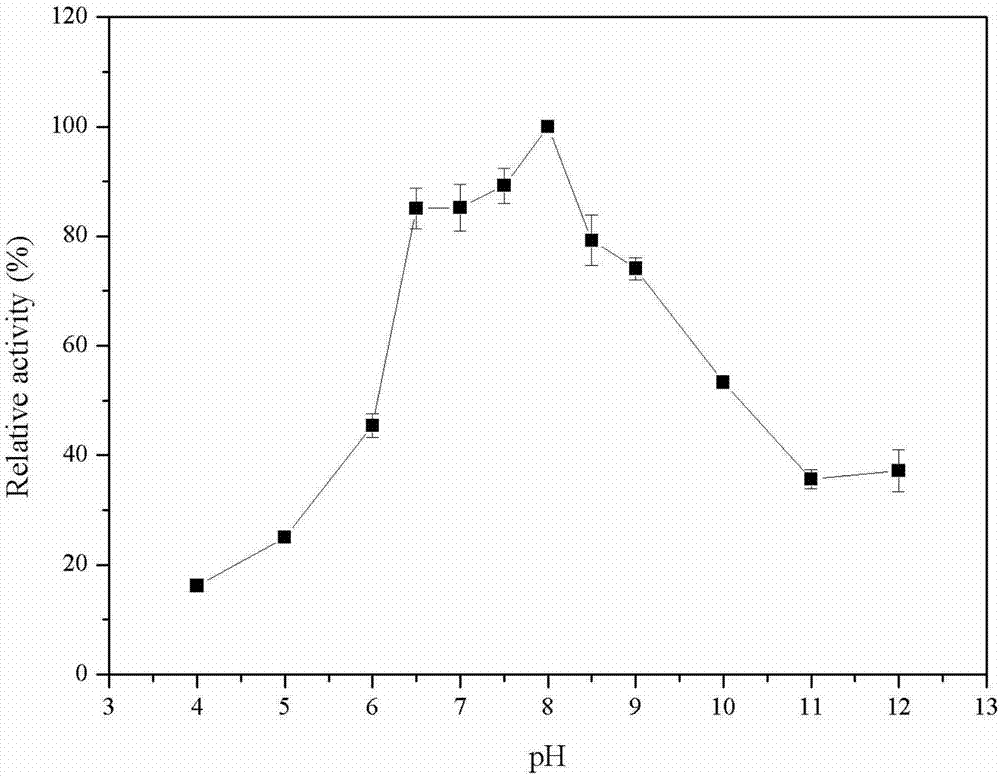

Method for entrapping and cross-linking phosphatidase A1 aggregates

InactiveCN102337256AGood chemical stabilityImprove mechanical propertiesOn/in organic carrierCross-linkCross-linked enzyme aggregate

The invention provides a method for immobilizing phosphatidase A1. The method is improved on the technical basis of cross-linked enzyme aggregates and comprises the steps of: preparing free phosphatidase A1 into cross-linked phosphatidase aggregates; and then entrapping the obtained cross-linked phosphatidase aggregates to obtain immobilized phosphatidase A1. The influences of concentration of a phosphatidase liquid, saturation degree of a precipitating agent, precipitation Ph value, precipitation time, concentration of a cross-linking agent, cross-linking time, concentration of sodium alginate, concentration of calcium ions and other different immobilizing conditions on the immobilizing efficiency and the catalytic effect of the phosphatidase are researched, and the enzymology nature of an immobilized phosphatidase membrane is discussed. The advantage of immobilizing the phosphatidase by adopting the method for entrapping and cross-linking aggregates is further explained through an SEM (Scanning Electron Microscope) image of the immobilized phosphatidase membrane. The phosphatidase is immobilized by utilizing the excellent chemical stability, mechanical property and other properties of the entrapped and cross-linked phosphatidase aggregates, the activity and the stability of the phosphatidase in a reaction system are improved, the activity and the selectivity of the phosphatidase are adjusted and controlled, so as to be favorable for the recovery of the phosphatidase and the maintenance of higher activity recovery rate of the phosphatidase; and the activity recovery rate of the finally obtained immobilized phosphatidase is 80.2 percent, and the relative activity of the phosphatidase after being repeatedly used for seven times is kept at 65 percent above.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

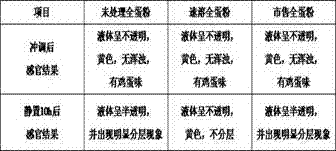

Instant whole egg powder free of bitter taste and fishy smell, and preparation method thereof

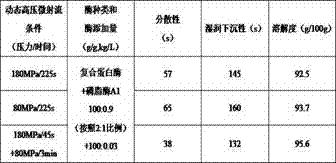

The invention relates to a non-bitter fishy smell, instant whole egg powder and a preparation method thereof. The method comprises: (a) adopting two-stage dynamic high-pressure micro-jet treatment; (b) sequentially adding compound protease and phospholipid to the whole egg liquid Enzyme A1; wherein the composite protease is papain and flavor protease, the dosage ratio of the two is 2:1, the amount of composite protease added in the whole egg liquid is whole egg liquid: composite protease=100:0.8-1.2, add The amount is calculated by mass ratio; phospholipase A1 is enzymatically hydrolyzed at room temperature, and the added amount in the whole egg liquid is whole egg liquid: phospholipase A1=100:0.01‑0.05, and the added amount is calculated by kg / L; (c) After spray drying, whole egg powder is fluidized bed granulated with a binder. The invention cooperates with dynamic high-pressure micro-jet homogenization, enzymatic hydrolysis and fluidized bed technology to obtain whole egg powder with good instant solubility, and no stratification is found within 10 hours after brewing.

Owner:南京中农食品科技有限公司

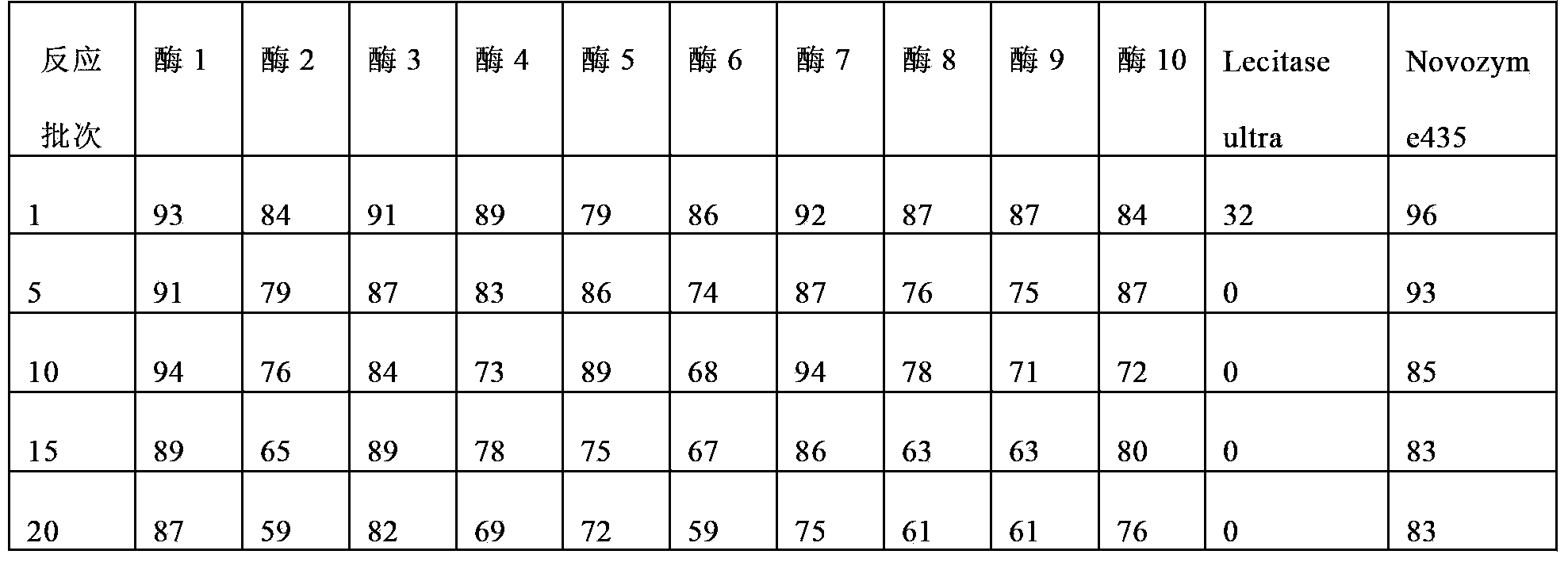

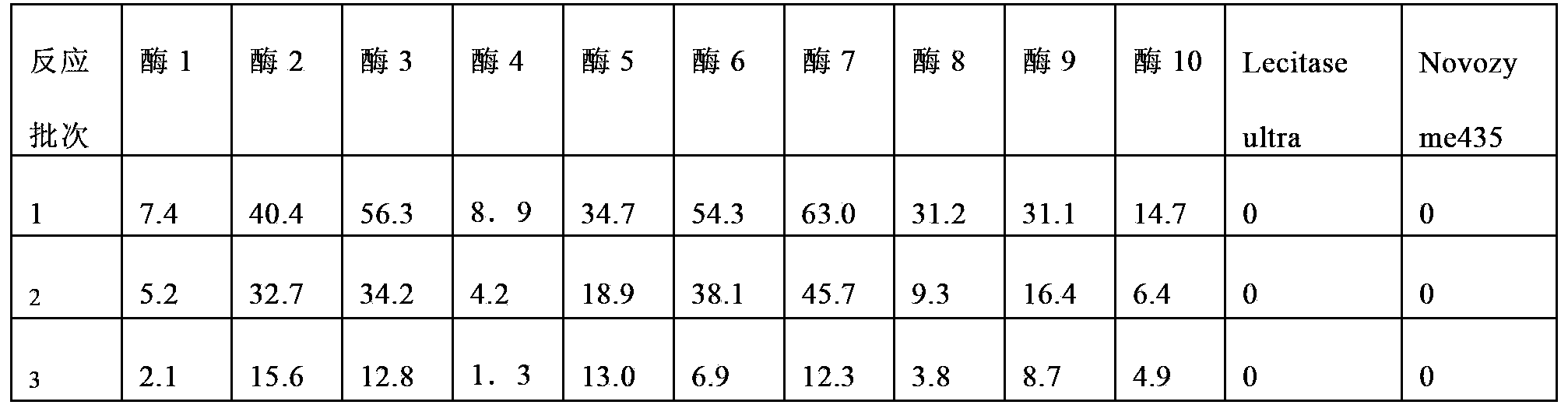

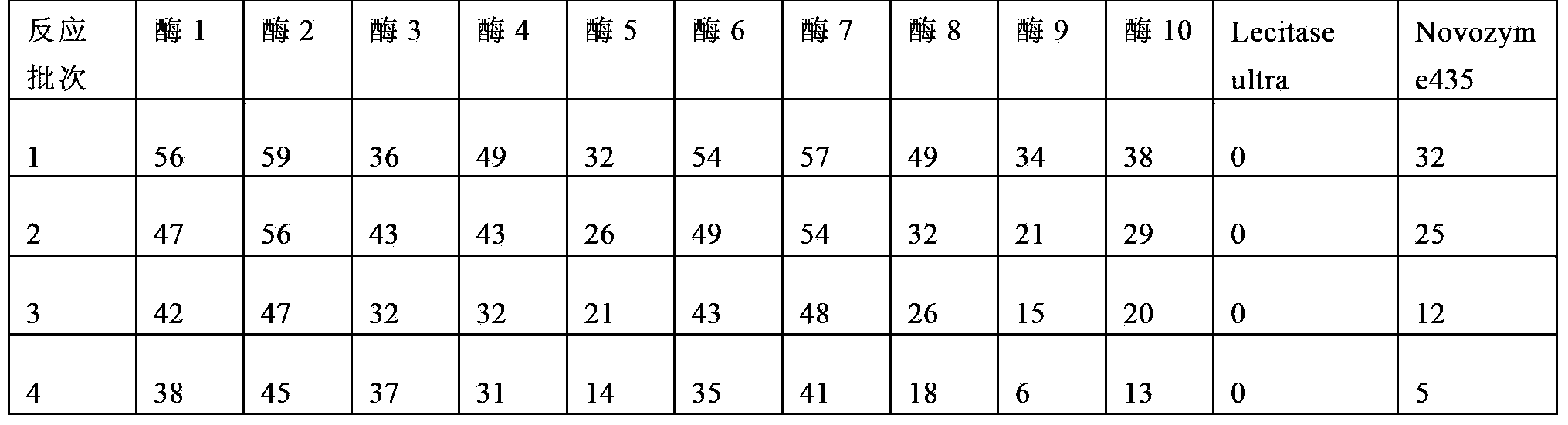

Phosphatidase A1 immobilization method

The invention relates to a phosphatidase A1 immobilization method. The method comprises the following steps: 1, allowing a carrier selected from macroporous adsorption resin or ion exchange resin to contact with phospholipase A1 in order to immobilize the phospholipase A1 on the carrier; and 2, drying the phospholipase A1 immobilized carrier obtained in step 1 in order to obtain immobilized phospholipase A1. The invention also provides immobilized phospholipase A1 prepared through the method, and an application of the immobilized phospholipase A1. The immobilized phospholipase A1 has the functions of esterification and acid hydrolysis, can be repeatedly used in the oil industry, and has the advantages of high reaction efficiency low cost and potential industrial application.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

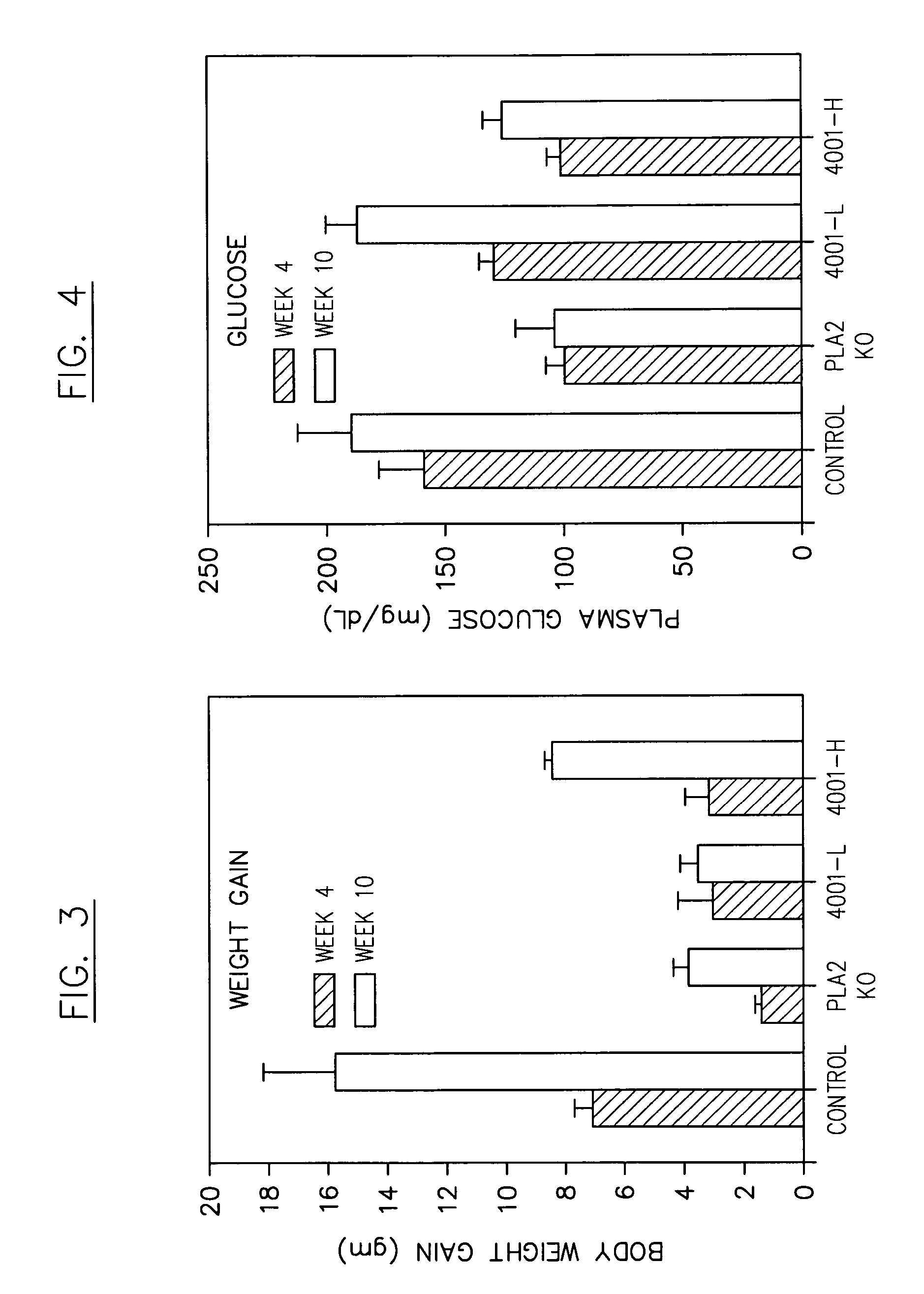

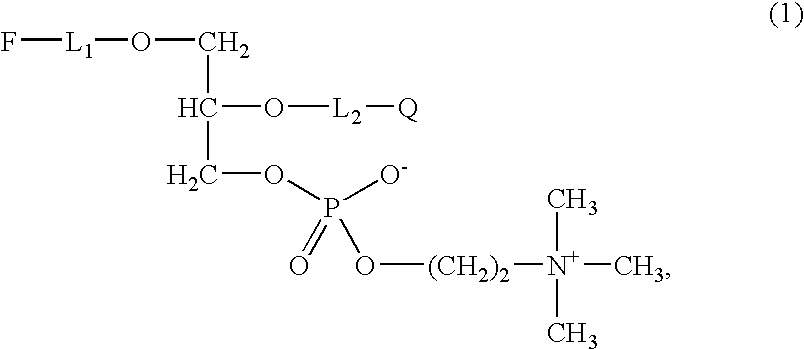

Compounds for determining the activity of phospholipase A.sub.2

InactiveUS7301043B2Simple wayActivity of the enzyme can be determined without burdensome process stepsMicrobiological testing/measurementBiological material analysisEtherPhospholipase A

Compounds for determining the activity of phospholipase A2, are described herein, and include embodiments having formula (1)whereinL1 is derived from an ether (R1—OR2)m, wherein R1 and R2 are independently selected and are derived from a hydrocarbon having 1 to 12 carbon atoms, with m being an integer from 1 to 4, or from a hydrocarbon R having 1 to 20 carbon atoms;F is unsubstituted or substituted pyrene as a flouraphore;Q is a quencher, andL2 is C(O)-L1 or C(O)-L1-NH, wherein L1 is as defined above. These compounds may be used to determine the activity of phospholipase A2, in particular PAF-AH.

Owner:SIRS LAB

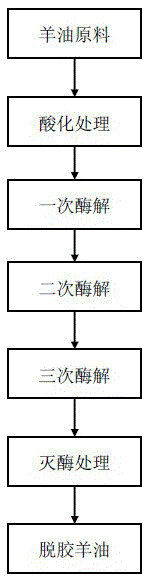

Mutton fat degumming method

ActiveCN105623847AEffectively catalyzes non-hydratable phospholipidsAvoid it happening againFatty-oils/fats refiningBiotechnologyAnimal science

The invention discloses a mutton fat degumming method which comprises the following steps that a citric acid solution is added to a mutton fat raw material, acidizing is conducted under assistance of ultrasonic waves, and acidized mutton fat is obtained; a certain quantity of distilled water is added to the acidized mutton fat, the pH and the temperature of the acidized mutton fat are adjusted, phospholipase A1 is added for conducting ultrasound-assisted enzymolysis, and the mutton fat obtained after preliminary enzymolysis is obtained; the pH and the temperature of the mutton fat obtained after preliminary enzymolysis are adjusted, phospholipase B is added for conducting ultrasound-assisted enzymolysis, and mutton fat obtained after secondary enzymolysis is obtained; the pH and the temperature of the mutton fat obtained after secondary enzymolysis are adjusted, phospholipase C is added for conducting ultrasound-assisted enzymolysis, and mutton fat obtained after third enzymolysis is obtained, enzyme deactivation processing is conducted on the mutton fat obtained after third enzymolysis, centrifugation is conducted to take fat samples on the upper layer, and mutton fat obtained after enzyme deactivation is conducted is obtained; the mutton fat obtained after enzyme deactivation is conducted is subjected to vacuum drying processing, and degummed mutton fat is obtained. The mutton fat degumming method is safe in process and convenient and fast to operate.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Vegetable oil degumming method

ActiveCN104629909AReduce the difficulty of separationRealize continuous separationFatty-oils/fats refiningVegetable oilOil phase

The invention discloses a vegetable oil degumming method. The method comprises the following steps: (1) simultaneously carrying out degumming reaction on vegetable oil with phospholipase and partial glyceride lipase, wherein the phospholipase at least contains one of phospholipase A1, phospholipase A2 and phospholipase B; (2) heating the degummed vegetable oil to 80-90 DEG C and carrying out heat preservation for 30-45 minutes; and (3) separating a reaction product and recovering an oil phase to obtain the degummed vegetable oil. The degumming treatment is carried out by phospholipase under the assistance of the partial glyceride lipase, so that a reaction product is easy to separate, and the degummed oil is high in yield, and has the advantages of continuous operation and good degumming effect.

Owner:SOUTH CHINA UNIV OF TECH

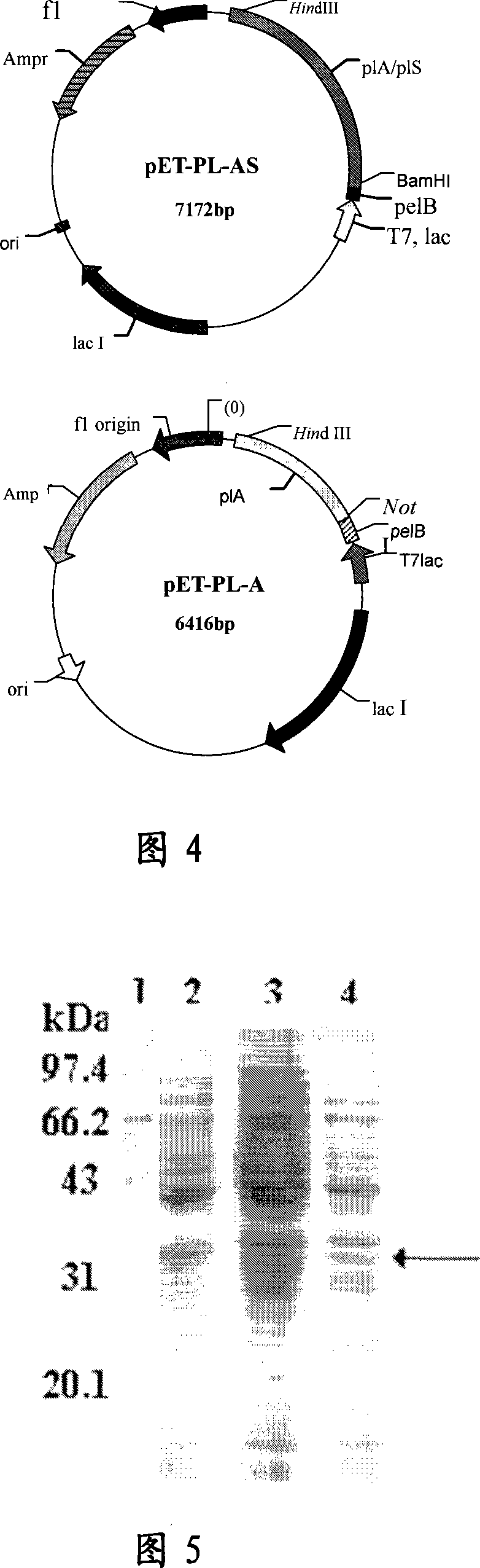

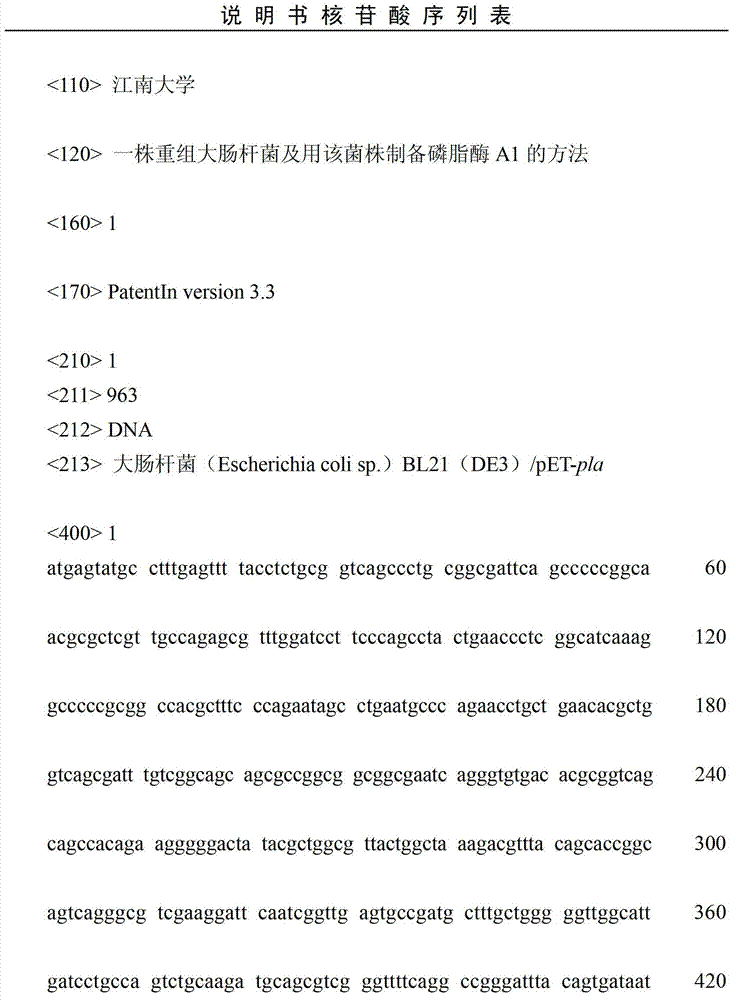

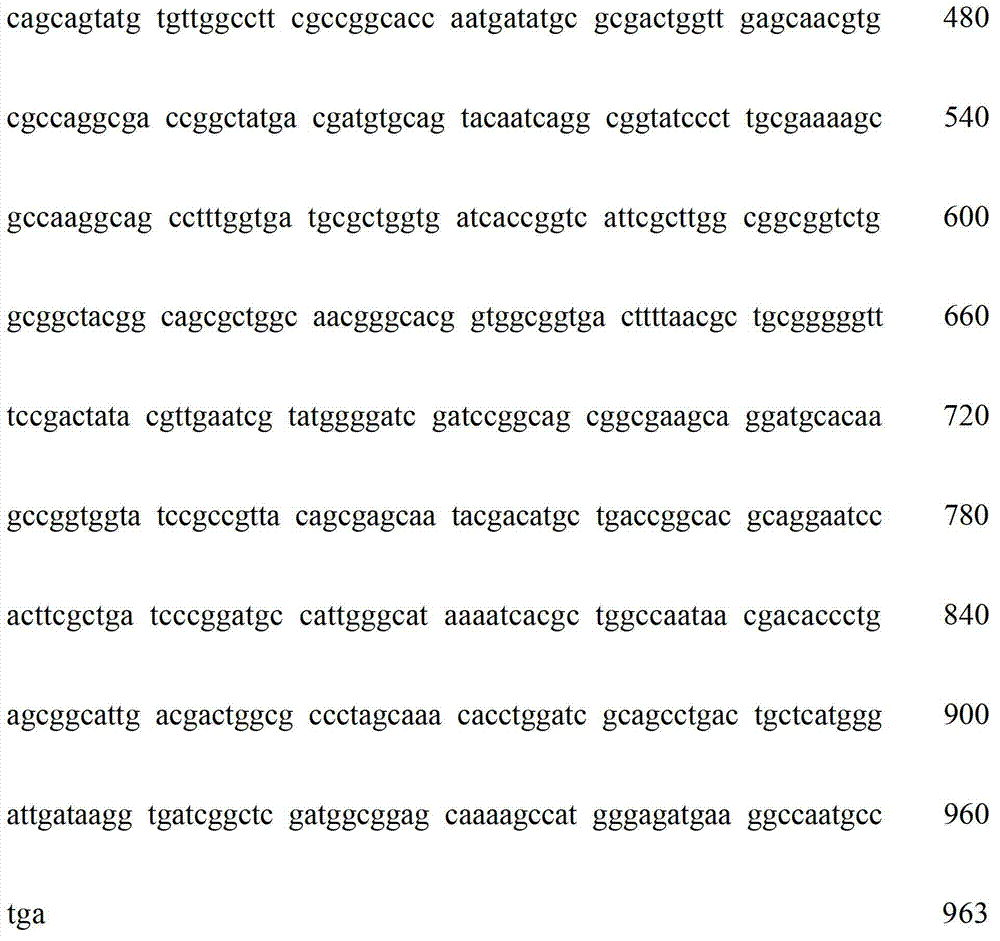

Recombinant Escherichia coli, and method for preparing phospholipase A1 through using recombinant Escherichia coli

ActiveCN103074290ALow sequence homologyLow costBacteriaHydrolasesSerratiaRecombinant escherichia coli

The invention provides a recombinant Escherichia coli, and a method for preparing phospholipase A1 through using the recombinant Escherichia coli. A gene-recombinant Escherichia coli BL21(DE3) / pET-pla CCTCC M 2012423 with the phospholipase A1 from liquefied Serratia liquefaciens CICC No.21538 is successfully constructed in the invention, and undergoes liquid fermentation to prepare hemolytic phospholipase A1, and the preparation method of the hemolytic phospholipase A1 comprises the steps of inclined plane culture, seed culture, autonomous induction culture (comprising permeable substance addition), and crude enzyme liquid extraction. The method for preparing the phospholipase A1 through the recombinant Escherichia coli has the advantages of high enzyme yield, high enzyme activity, simple production technology, short production period, low cost, easy technological amplification and the like, and can be widely applied to the grease refining field, the phosphatide modification field and the like.

Owner:JIANGNAN UNIV +1

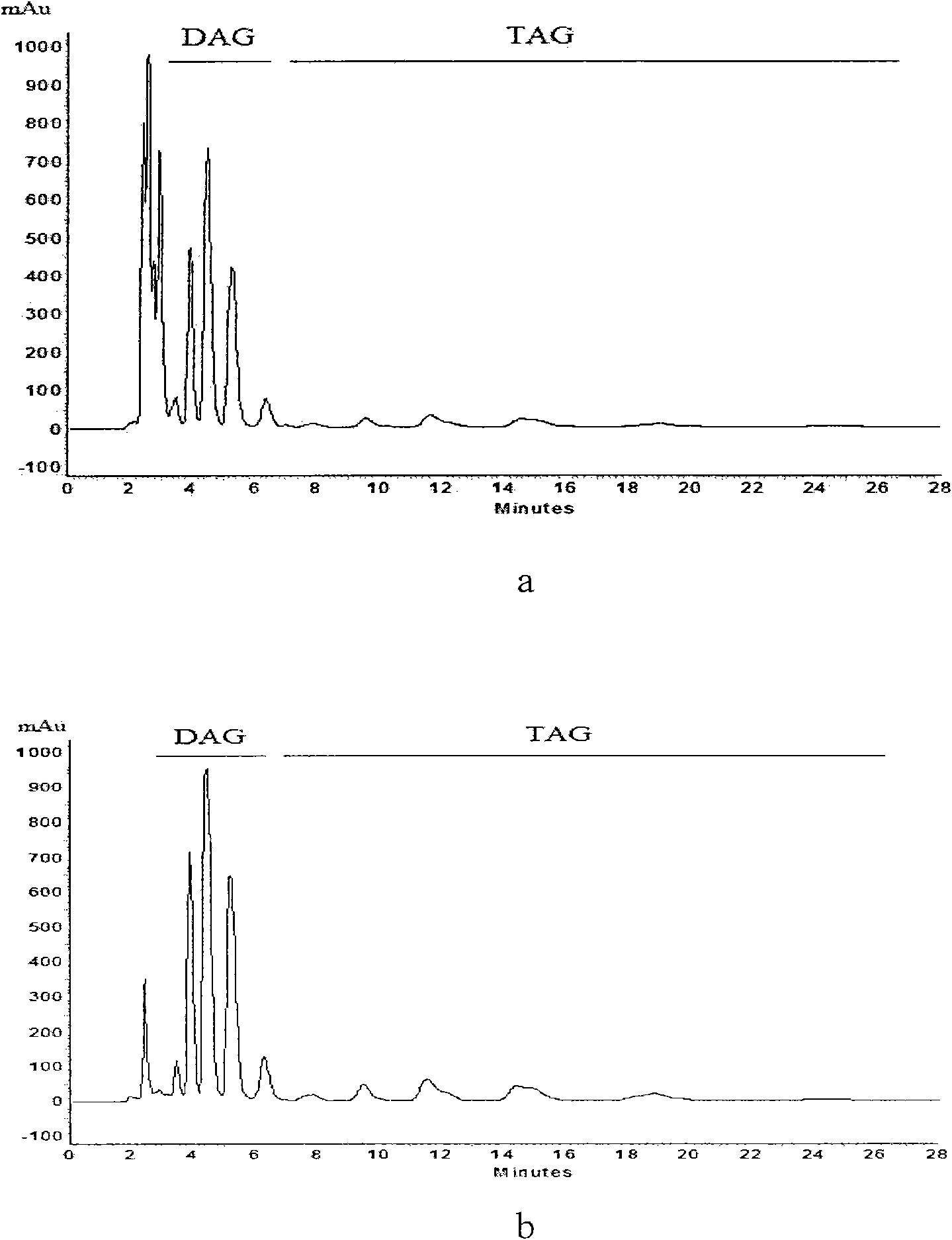

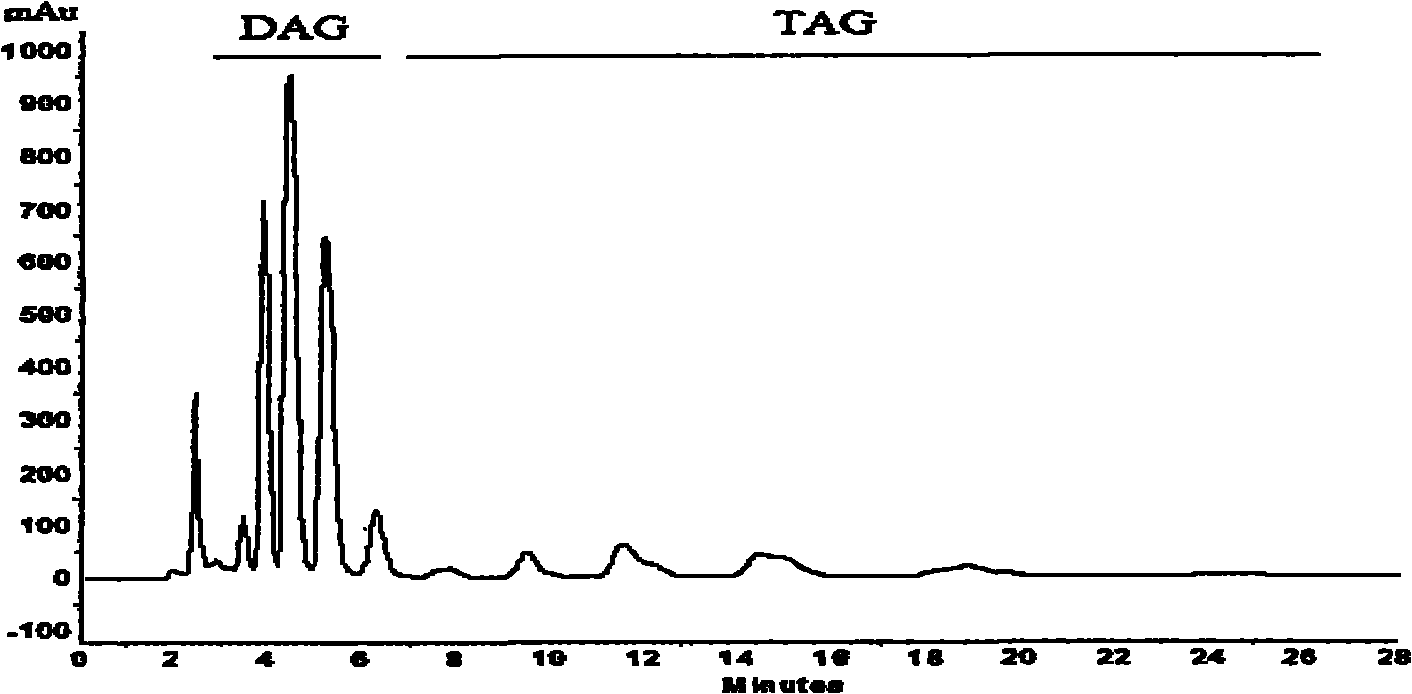

Method for preparing diglyceride from phosphatidase A1 through catalytic esterification

The invention discloses a method for preparing diglyceride from phosphatidase A1 (Lecitase Ultra) through catalytic esterification, which comprises the following steps: (1) obtaining substrates after mixing fatty acid and glycerin according to a mol ratio of 0.5 / 1 to 2.5 / 1; and sequentially adding phosphatidase A1 and de-ionized water into the substrates to obtain reactant, wherein the addition of the phosphatidase A1 meets the requirement of adding 50 to 120 U phosphatidase A1 into each gram of the substrates, and the addition of the de-ionized water accounts for 4.0 to 12.0 wt percent of the mass of the substrates; (2) controlling the temperature between 30 and 55 DEG C under the condition that the reactant is in the vacuum, stirring the materials for reaction for 4 to 16h to obtain reaction liquid; and carrying out centrifugation delamination on the reaction liquid to obtain coarse diglyceride at the upper layer; and (3) carrying out molecular distillation on the coarse diglyceride under the conditions of the temperature between 160 and 165 DEG C and the pressure between 0.3 and 1.0 Pa to remove unreacted fatty acid and obtain the diglyceride.

Owner:JINAN UNIVERSITY +1

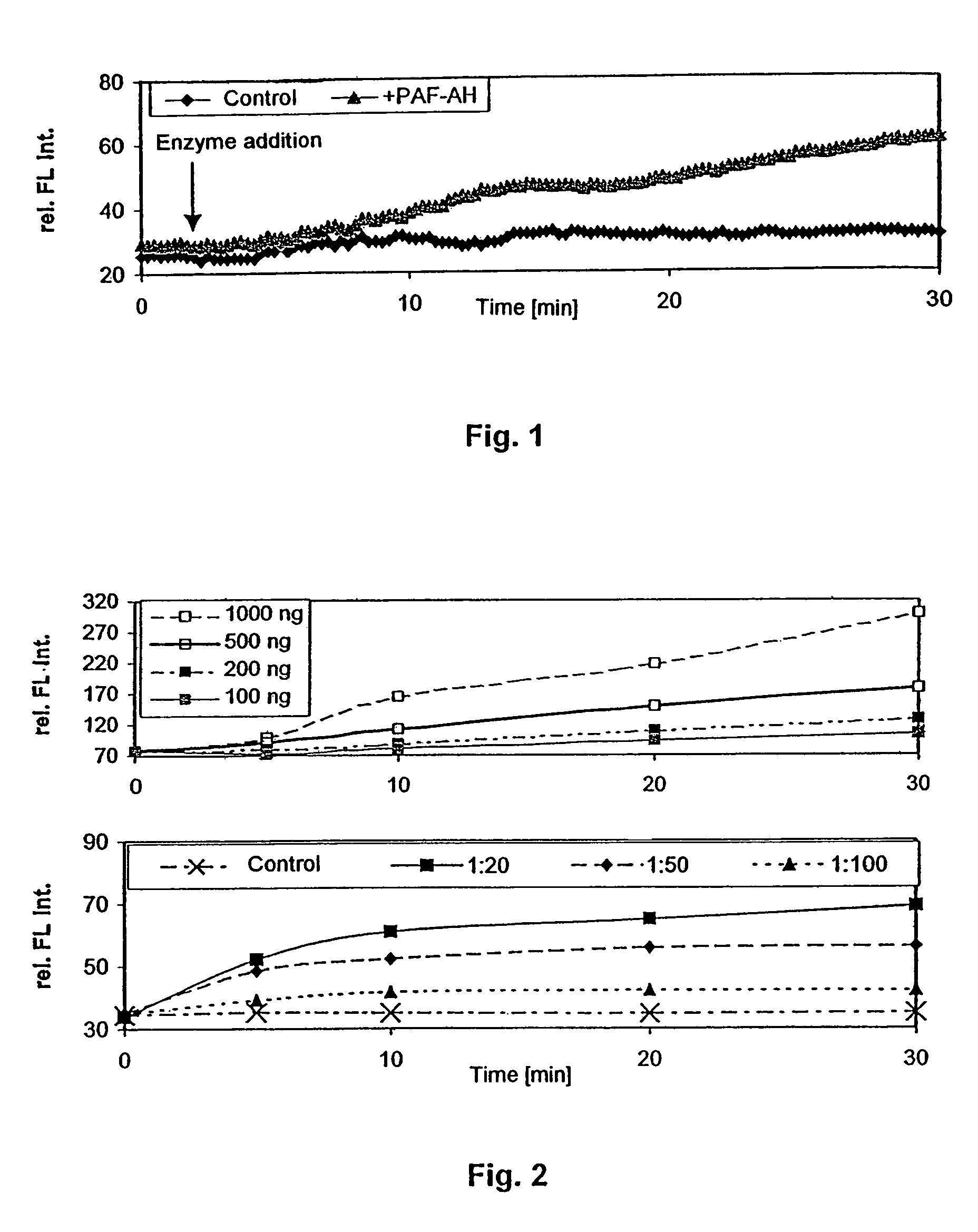

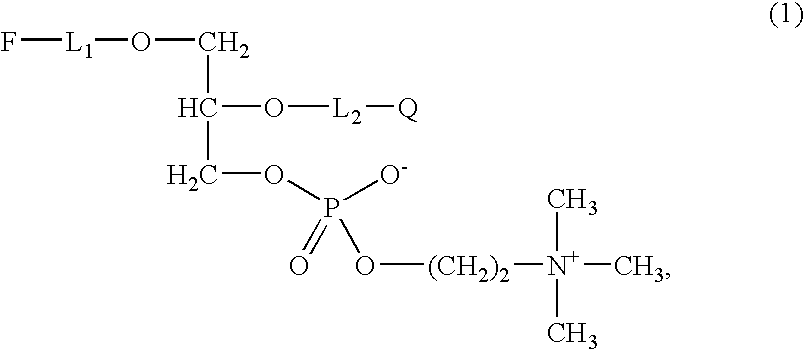

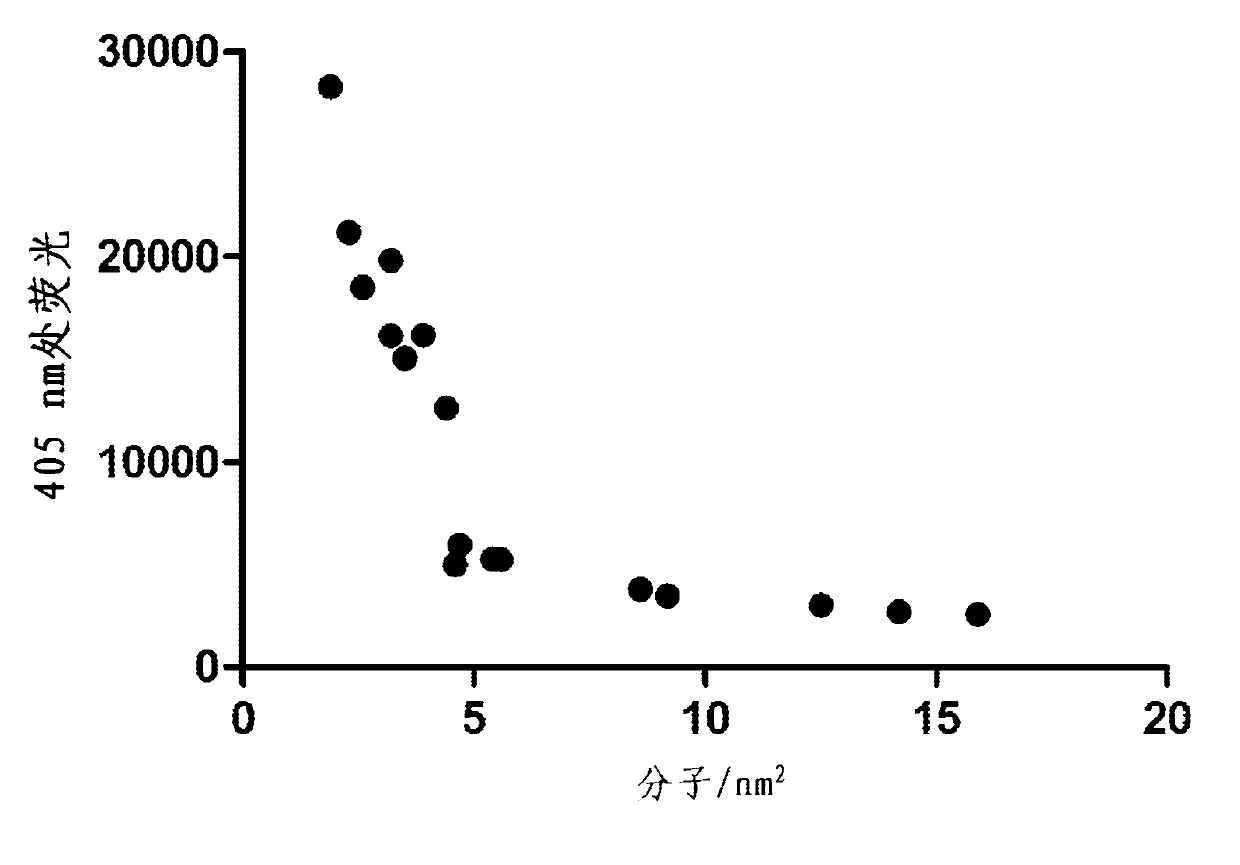

Enzymatic assay for the quantitative determination of phospholipase A1 or A2 activity in a sample

InactiveCN102388311ASensitivity advantageMicrobiological testing/measurementBiological material analysisQuantitative determinationFluorescence

The invention relates to a new method for measuring phospholipase A1 or A2 activity in a sample, using a solid phase coated with a fluorochrome-labelled phospholipase A1 or A2 substrate, wherein the molecular coverage is in the range from 8 to 30 fluorochrome-labelled phospholipase A1 or A2 substrate molecules / nm2, and kit for carrying out said method.

Owner:ATEROVAX

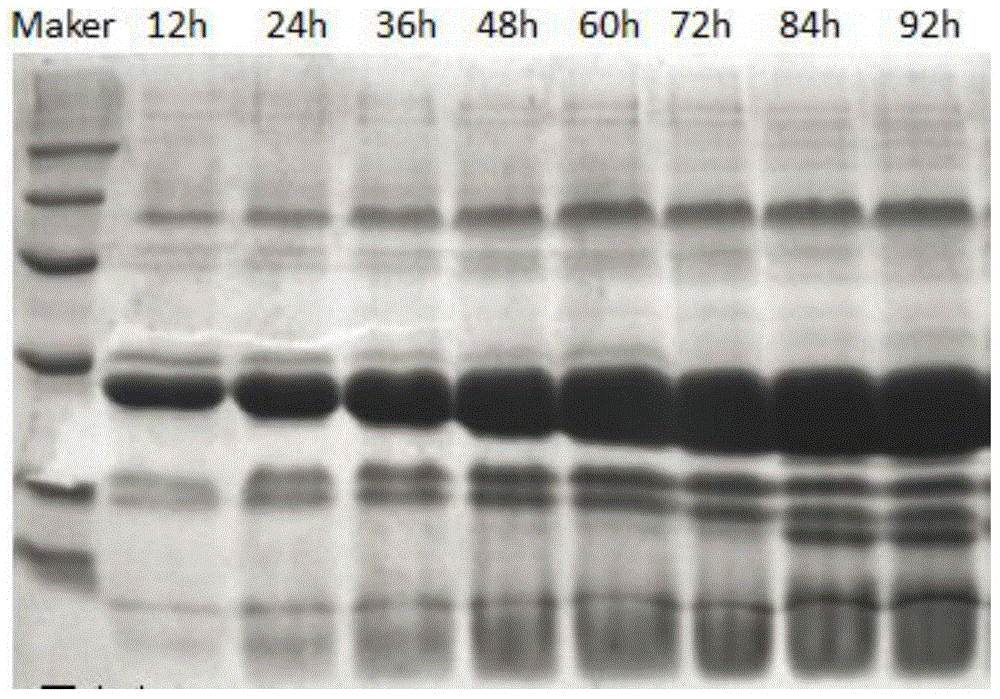

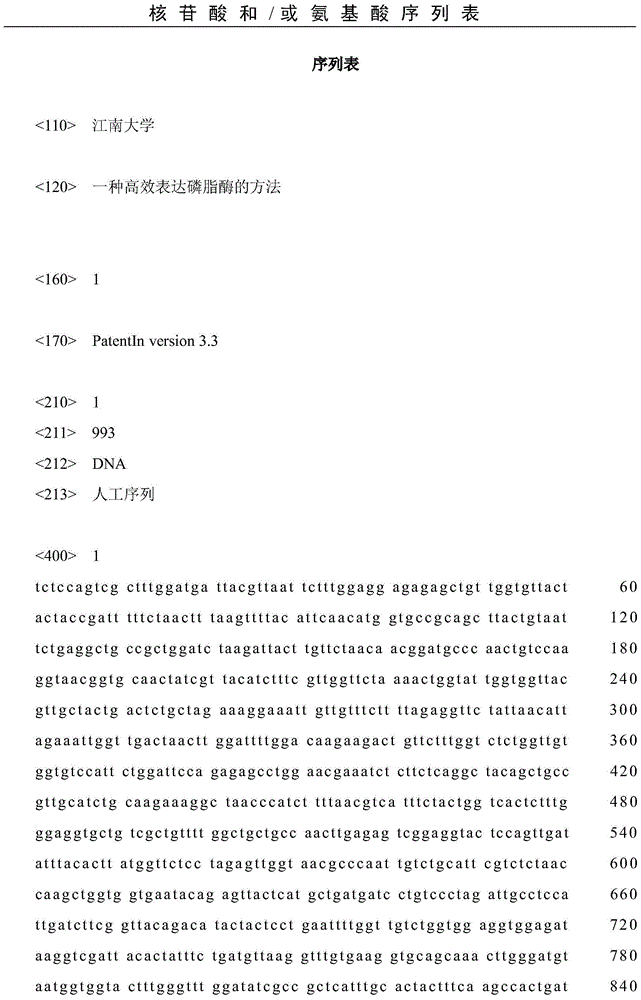

Method for efficiently expressing phospholipase

ActiveCN104450756AReduce phosphorus contentHydrolasesFatty-oils/fats refiningPichia pastorisBiotechnology

The invention discloses a method for efficiently expressing phospholipase, and belongs to the technical field of enzyme engineering. According to the method, a phospholipase A1 encoding gene as shown in the sequence SEQ ID NO.1 is subjected to recombinant expression by taking pichia pastoris as a host, and the enzyme activity is 6000U / ml after induction is performed for 120 hours in a tank of 3L. The phospholipase A1 encoding gene can be applied to industrial production of phospholipase. The phospholipase A1 can be used for degumming grain oil, and the content of phosphorus of the grain oil is increased.

Owner:JIANGNAN UNIV

Gene mining and application method of phospholipase D

InactiveCN107164397AEfficient expressionShort fermentation cycleHydrolasesFermentationEscherichia coliReaction temperature

The invention provides a phospholipase D acquired based on a gene mining method, as well as a gene coding sequence and application method thereof. A phospholipase D gene has a full length of 1,614bp, encodes 538 amino acids, uses plasmid pET28a (+) as an expression vector, and uses E. coli BL21 (DE3) as an expression host, to realize efficient expression of phospholipase D. The phospholipase D gene is simple and convenient in gene mining method; a recombinant strain constructed by the mined target gene can be fermented and induced to excrete the phospholipase D. For the phospholipase D, an optimum reaction temperature is 60 DEG C; an optimum reaction pH is 7.5; and Ca<2+> has good activating and promoting effects on enzyme activity of the phospholipase D; the phospholipase D can modify phospholipids, and can catalyze substrates phosphatidylcholine and L-serine to synthesize phosphatidylserine, thereby having good application prospects in food, medicine and healthcare industries.

Owner:JIANGNAN UNIV

Method for catalytic synthesis of fructose lauric acid monoester by using immobilized phospholipase A1

The invention discloses a method for catalytic synthesis of the fructose lauric acid monoester by using the immobilized phospholipase A1. According to the method, lauric acid and fructose are subjected to catalytic reaction through enzymes to synthesize the fructose lauric acid monoester. The preparation method includes the steps of immobilizing the phospholipase A1, preparing a dehydration organic solvent, and subjecting the immobilized phospholipase A1 to catalytic synthesis to produce the fructose lauric acid monoester. According to the method for catalytic synthesis of the fructose lauric acid monoester by using the immobilized phospholipase A1, the used phospholipase A1 is cheap in price and only 5% to 10% of the price of lipase, and the price of resin D-201 used for immobilizing the phospholipase is low. The immobilized phospholipase A1 has good catalytic effect, the conversion rate of the fructose lauric acid monoester is high, the product separation is simple, and the immobilized phospholipase A1 can be recycled. Accordingly, products prepared through the method are low in cost and have good application prospect in industry.

Owner:SOUTH CHINA UNIV OF TECH

Process for producing cheese

InactiveUS6875454B2Improve propertiesIncrease productionMilk preparationHydrolasesFat emulsionAdditive ingredient

The present invention relates to a process for producing cheese from enzyme-treated cheese milk, and the use of the resulting produced cheese as ingredient in food products. More particularly, the present invention relates to a process for producing cheese from cheese milk treated with a enzyme selected from the group of phospholipases, in particular phospholipase A1, A2 and B. Also, the present invention relates to a process for stabilizing the fat emulsion of a milk composition, e.g. cream, and the use of such stabilized milk composition, e.g. for the manufacturing of UHT-cream or cream liquor.

Owner:NOVOZYMES AS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com