Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Short degumming time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silk fabric degumming method and apparatus thereof

ActiveCN102605439AShort degumming timeImprove degumming efficiencyDe-gumming silkAlkaline proteasePolymer science

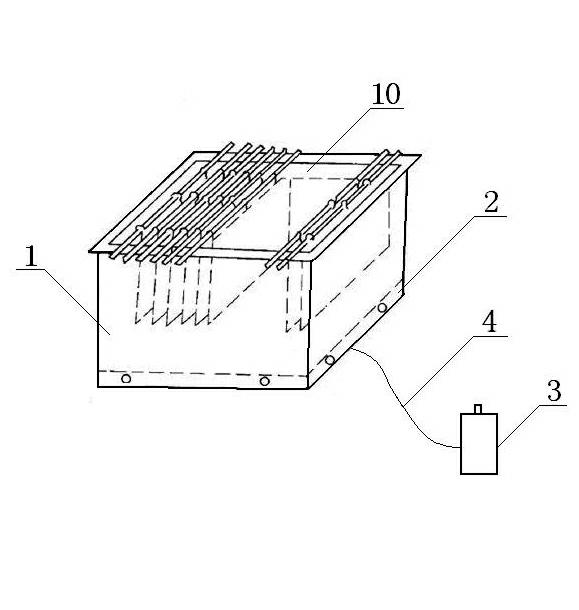

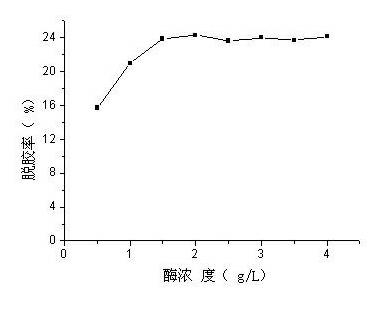

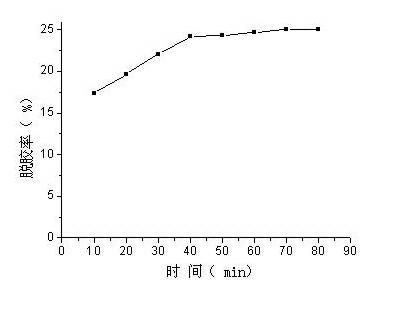

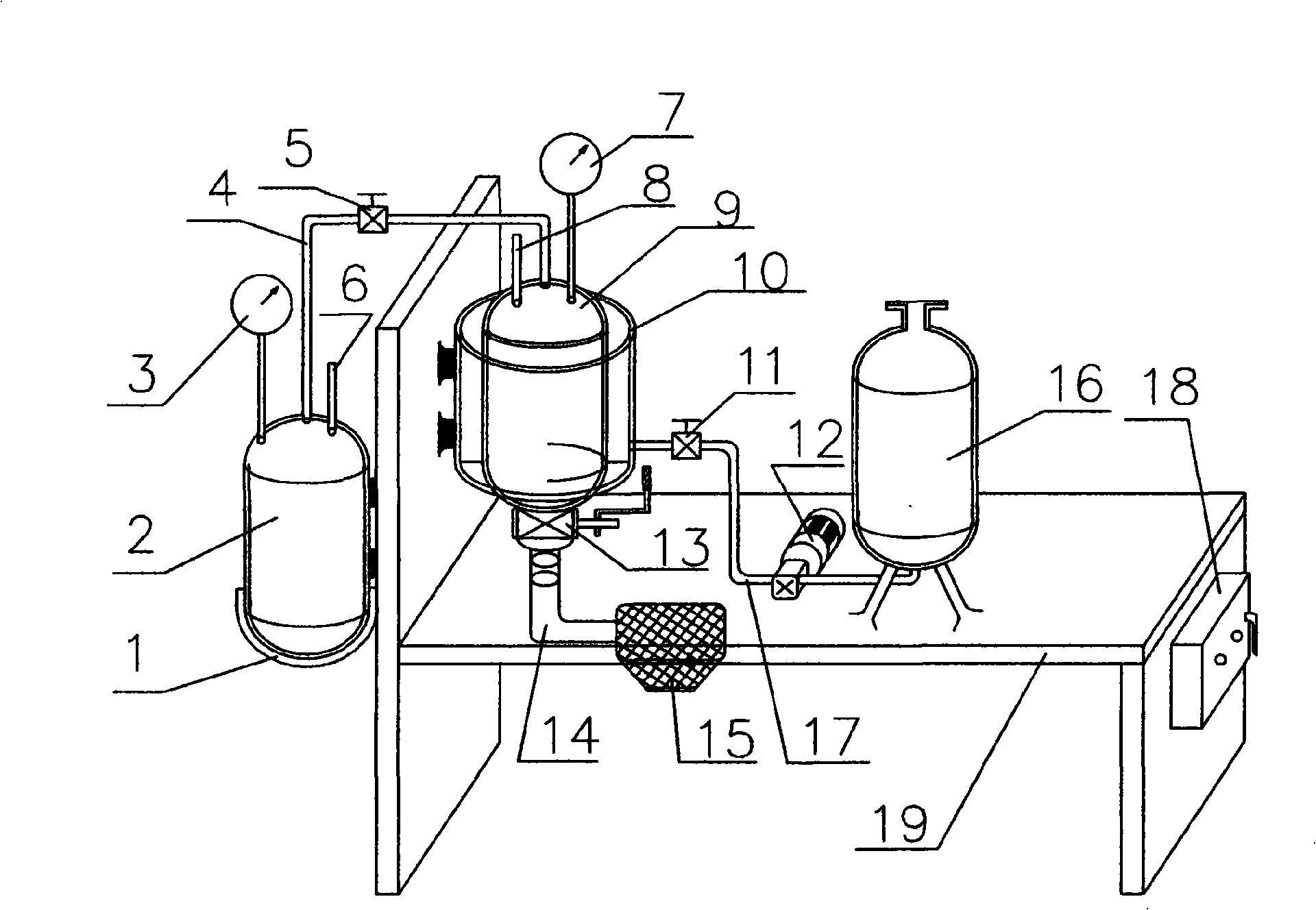

The invention discloses a silk fabric degumming method and a silk fabric degumming apparatus. The invention belongs to the technical field of silk degumming. The method is characterized in that the method comprises the steps that: water with a required volume is injected in a degumming tank according to the weight of silk fabric and a bath ratio of 1:40-50; a pH value of the water is regulated to 8.5-9.5; the water is heated to a temperature of 50-60 DEG C; 1.00-2.50g / L of alkali protease is added into the degumming tank; silk fabric is placed into the tank, and supersonic wave is started, wherein the supersonic wave frequency is 30-80KHz; the supersonic wave treatment is performed for 35-60min, and washing is carried out. According to the invention, factors influencing silk fabric degumming are analyzed, and optimal technical values of alkali protease concentration, degumming time, degumming temperature, pH value, and bath ratio are determined. Also, the degumming apparatus is improved, such that silk fabric degumming time is effectively reduced, and silk fabric degumming efficiency is greatly improved.

Owner:SHAOXING UNIVERSITY

Method for degumming soybean oil by phospholipase catalysis

InactiveCN102634411AIncreased diglyceride contentShort degumming timeFatty-oils/fats refiningEdible oils/fatsVegetable oilOil production

The invention discloses a method for degumming soybean oil by phospholipase catalysis, which belongs to the field of vegetable oil degumming and includes the steps of preheating, adjusting pH, adding enzyme prior to mixing, allowing for enzymolysis, deactivating the enzyme and separating. The method is technically characterized by including: using phospholipase C as the phospholipase for catalysis, and preheating crude soybean oil prior to acid treatment; cooling oil-water mixture subjected to acid treatment to 37-60 DEG C, adding NaOH solution to adjust pH to 3-8, adding distilled water accounting for 1%-5% of the weight of the oil, adding the phospholipase C according to an oil proportion of 100-2000U / g, and mixing well; setting the mixing speed at 100-600r / min, and allowing for enzyme reaction for 0.5-2 hours; and deactivating the enzyme at high temperature for a reaction system, and performing high-speed centrifugal separation to complete degumming. The degumming time of the method is shortened by 1-2 times as compared with that of using phospholipase A1, phosphorus content is reduced, diglyceride content of the oil is increased slightly, and economic benefit is increased for oil production industries.

Owner:JIANGNAN UNIV

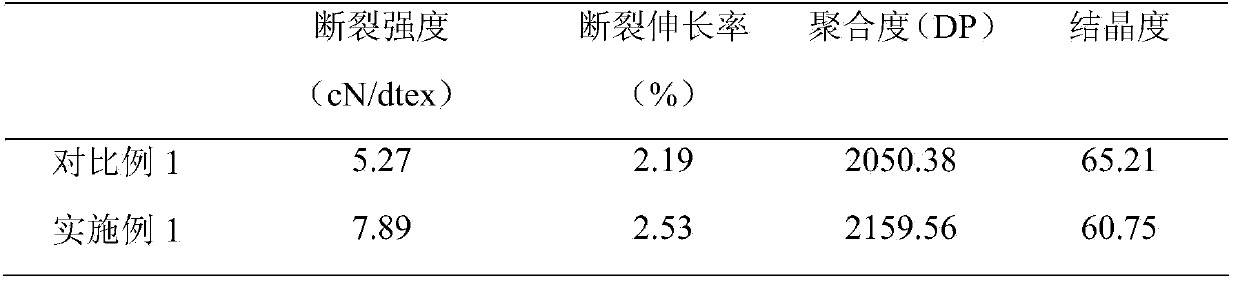

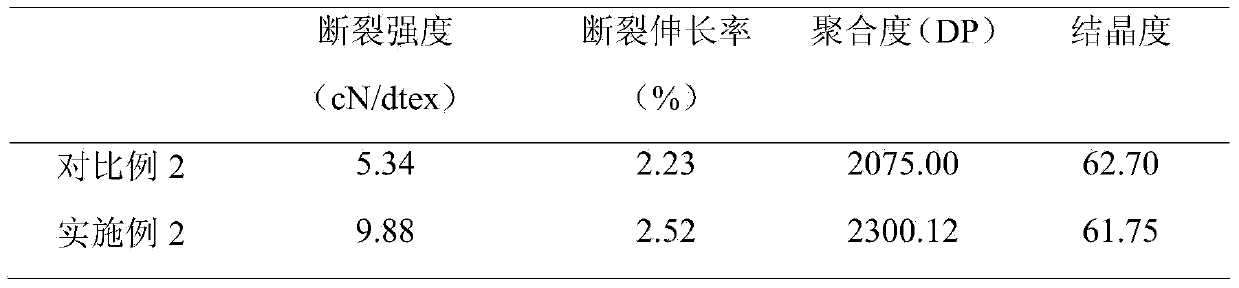

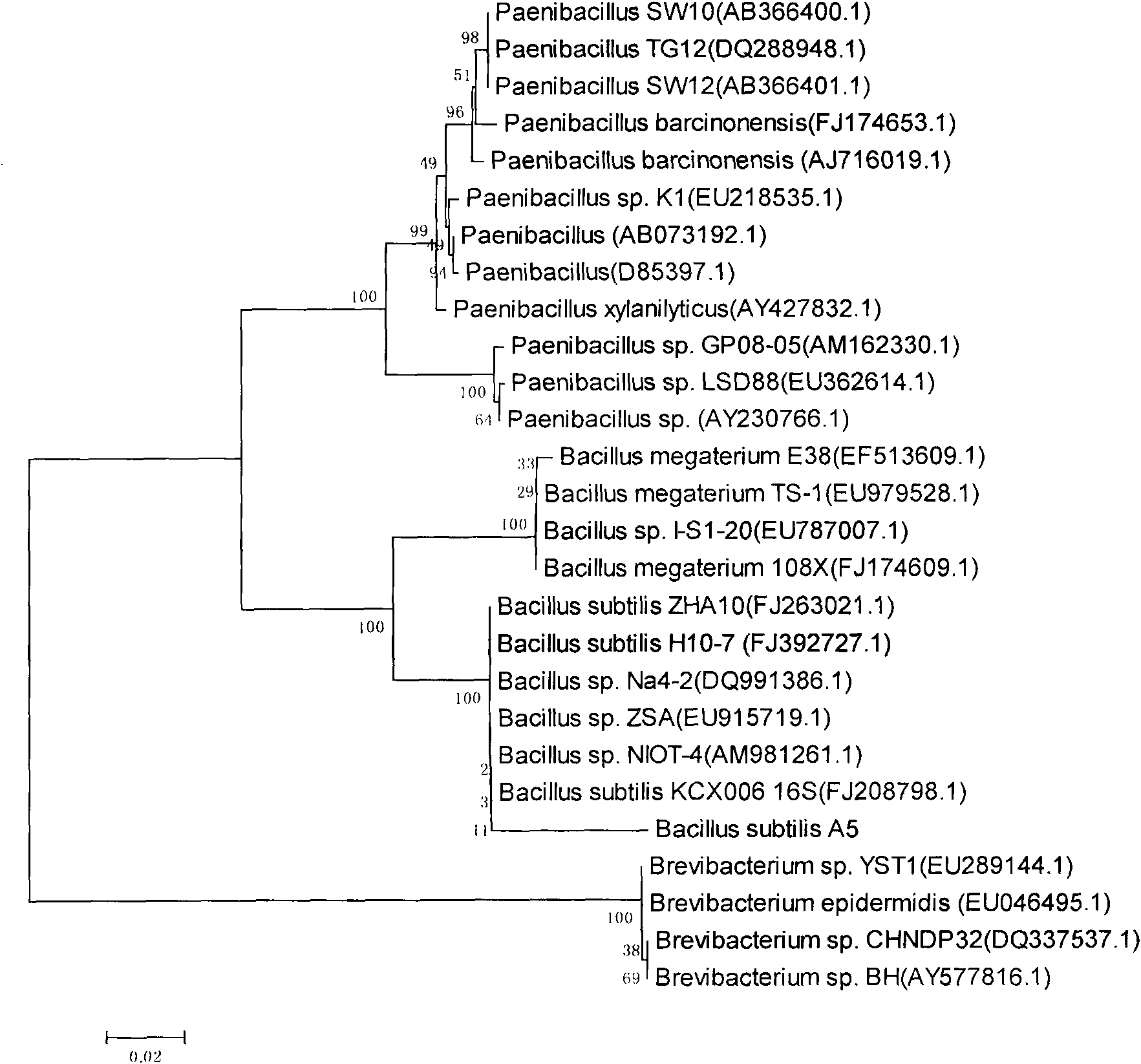

Method for enhancing property of ramie fiber through oxidative degumming

ActiveCN103993364AGood extensibilityHigh elongationFibre treatment to obtain bast fibreActive agentPhysical chemistry

The invention relates to a method for enhancing the property of a ramie fiber through oxidative degumming. The method comprises the following steps of mixing original ramie and a peroxide degumming solution according to mass ratio being 1 to 10, boiling for 40-60 minutes under the condition of 80-85 DEG C, wherein with respect to the weight percent of the original ramie, the peroxide degumming solution comprises the following components by weight percent: 1%-4% of sodium hydroxide, 3%-8% of peroxides, 0.5%-4% of quinones compounds, 1%-6% of a metal ion chelating agent, 2%-4% of a peroxide stabilizing agent, 2%-6% of a surface active agent and the balance being water; adding sodium hydroxide, boiling for 1-1.5 hours under the condition of 100 DEG C to obtain treated ramie; boiling the treated ramie and a reducing solution at 60-100 DEG C for 40-90 minutes, then applying oil, and drying. According to the method disclosed by the invention, needed degumming time is short and the efficiency is high and the bleaching and the degumming can be completed together; the prepared ramie fiber has good tensile property.

Owner:DONGHUA UNIV

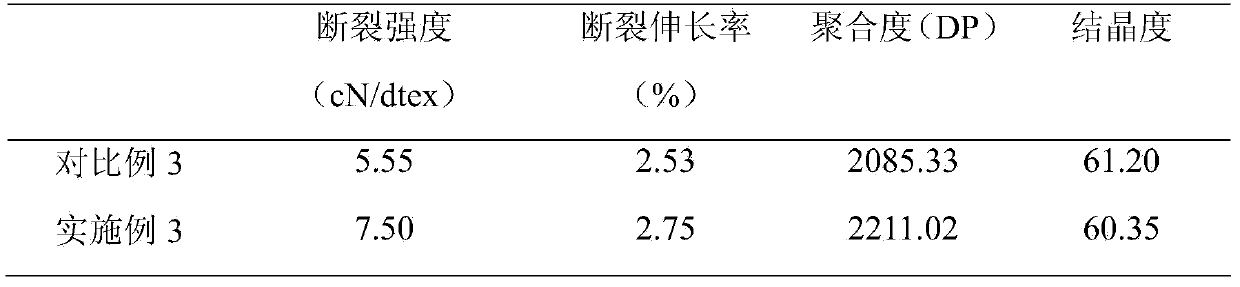

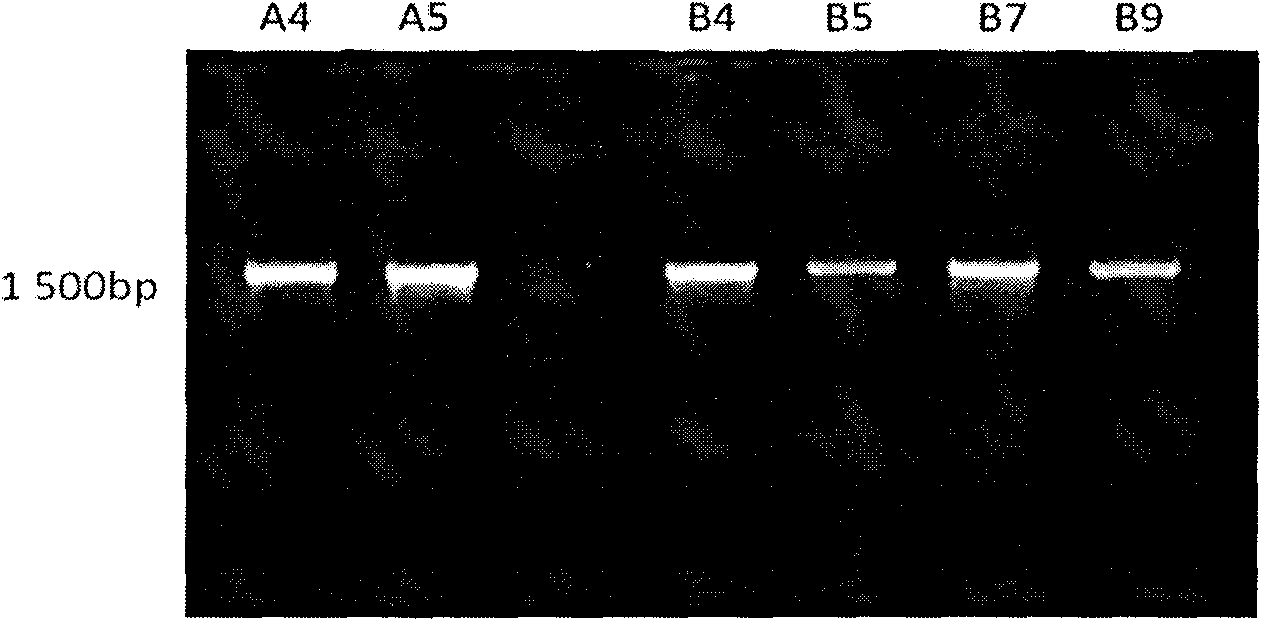

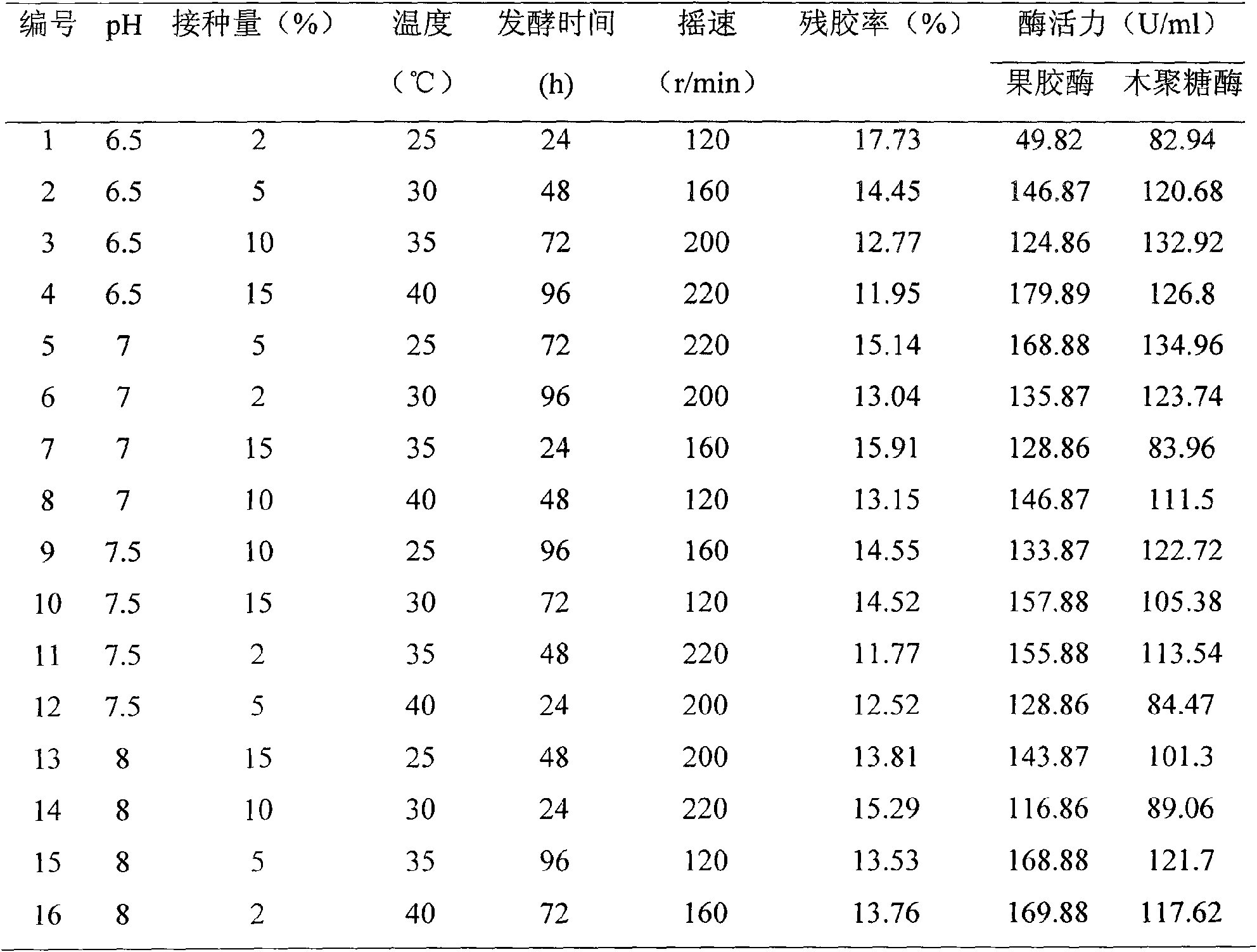

Bacillus subtillis strain containing ramie degumming activity, preparation and application thereof

InactiveCN101654660ANot easy to polluteNo pollution in the processBacteriaMicrobiological testing/measurementPectinaseBiotechnology

The invention relates to a bacillus subtillis strain containing ramie degumming activity, preparation and application thereof, which uses a system taking the strain as the core for ramie degumming. The strain of the system has high reproductive rate, high yield of pectase and xylanase, short production period, strong contamination resistance and favorable heat-resistant quality. The system and thecultivating process are safe to operate, have no toxicity and pollution no environment. Compared with the prior art, the invention has simple technology, is suitable for large-scale industrial production and the like. When the system is used for ramie degumming, degumming time is short, the dispersion coefficient of ramie fiber can reach 100%, degumming ratio can reach above 90%, and the qualityof refined dry ramie can reach the standard of chemical degumming.

Owner:DONGHUA UNIV

Degumming method of flax and enzyme preparation for using in degumming

ActiveCN102206874AHigh hemp strengthHigh hemp strength, high production rate of flax long fibersEnzymesVegetable materialChemistryPectinase

The invention provides a degumming method of flax, comprising the following steps: adjusting the PH value of water to 8.5-9.5, heating to 20-55 DEG C, adding the enzyme preparation composed of hemicellulase and alkaline pectinase with enzyme activity of 50-5000 U / ml in the water to obtain a mixed solution, adding flax in the heated mixed solution to ret and degum, and drying, cultivating and scotching the degummed flax to obtain linen fibers. The invention also provides an enzyme preparation for degumming of the flax, comprising hemicellulase and alkaline pectinase with enzyme activity of 50-5000 U / ml. According to the invention, by using the enzyme preparation for degumming, the degumming time is short, the intensity of the scotched flax is high, the yielding of linen fibers is high, the evenness is good, the operation is simple without the process of bacteria producing enzyme, and degumming waste can be reused or discharged to farmland so as to reduce the cost of industrialization of degumming.

Owner:SHANGHAI KDN BIOTECH +1

Epicoccum nigrum DB3 bacterial strain as well as preparation and application thereof

InactiveCN102329738AExtensive culture conditionsGood heat resistanceFungiMicroorganism based processesSea grassEpicoccum nigrum

The invention relates to an epicoccum nigrum DB3 bacterial strain as well as a preparation and an application thereof. The preparation method comprises the steps of: 1, placing rotten sea grass in an enrichment culture medium, standing and culturing at room temperature, then coating the enrichment culture medium in a separation culture medium, standing and culturing at a temperature of 30 DEG C for 1-4 days to obtain a wild type flax biological treatment bacterial strain; 2, inoculating the bacterial strain obtained from the step 1 into a flax lignin nutrition culture medium, culturing at a temperature of 28 DEG C for 72 hours; and 3, selecting the bacterial strain with the capacity of degrading the lignin from the flax lignin nutrition culture medium to obtain the epicoccum nigrum DB3 bacterial strain. The epicoccum nigrum DB3 bacterial strain can be applied to a process for preparing spinning flax, hemp, jute or red ramie fibers through peroxide degumming. The epicoccum nigrum DB3 bacterial strain has the characteristics of short growth period, low possibility of being polluted, low treatment cost, mild reaction conditions, strong pollution resistance capacity, good heat-resistant performance, no environment pollution and good quality of the treated fibers. The preparation method has a simple process and is suitable for large-scale industrial production.

Owner:DONGHUA UNIV

Alkaline pectinase preparation for cannabissalival degumming, and cannabissalival degumming method

InactiveCN103937771AReduce the probability of residual glueAvoid damageHydrolasesMicroorganism based processesPectinaseFiber

The invention relates to an alkaline pectinase preparation for cannabissalival degumming, wherein the components of the alkaline pectinase preparation comprise: an alkaline pectinase or an alkaline pectinase compound enzyme preparation, wherein the alkaline pectinase compound enzyme preparation is a mixture comprising an alkaline pectinase and one or a plurality of materials selected from pectinase, xylanase, mannanase, lipase and protease. According to the present invention, the alkaline pectinase preparation has characteristics of effective cannabissalival degumming and short degumming time, and the obtained fibers have characteristics of low gum residue, softness and less damage.

Owner:TIANJIN UNIV OF SCI & TECH

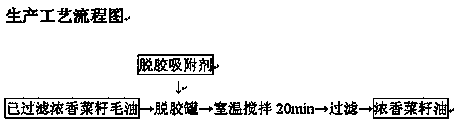

Simple degumming method of concentrated-fragrance colza oil

ActiveCN103215123AThe supporting facilities are simpleShort degumming timeOther chemical processesFatty-oils/fats refiningSlagPhospholipid

The invention relates to a simple degumming method of concentrated-fragrance colza oil. The degumming method comprises the following steps of: (1) pumping squeezed concentrated-fragrance colza crude oil with slag removed into a degumming tank, wherein the concentrated-fragrance colza crude oil does not need to be heated or cooled and just is operated at normal temperature; (2) adding a degumming absorption agent into the degumming tank; (3) stirring for 15-20min at room temperature; and (4) filtering and separating the absorption agent by using a plate frame filtering machine of which the filtering aperture is 5mu m, so as to obtain the refined concentrated-fragrance colza oil. The degumming absorption agent is prepared from montmorillonoid, silicate, modified bentonite and filter aids with different apertures which are mixed and stirred. According to the simple degumming method, the gum impurities such as phospholipids and protein in the concentrated-fragrance colza oil are absorbed by using the degumming absorption agent and then filtered and separated, thus degumming the concentrated-fragrance colza oil; and the conventional process that the concentrated-fragrance colza oil stands for a long time or is subjected to hydration degumming firstly and then dried and dehydrated is replaced, both the gum impurities can be simply and rapidly eliminated, and the concentrated fragrance of the oil is not lost, so that colza oil which is fragrant, pure in quality, nutritive and sanitary is obtained.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

High-gum-content raw hemp fiber degumming method

The invention discloses a high-gum-content raw hemp fiber degumming method. The method comprises a mechanical decortication and chemical immersion pre-degumming step, a steam explosion degumming step, a lignin oxidation degumming step and an ethanol boiling step. In the invention, based on the prior art, an independent lignin catalytic oxidation step is adopted, and chemical formula and technological conditions of a lignin catalytic oxidizer are improved to control the degradation degree of lignin, so that the lignin is partially degraded into non-water-soluble polyphenol substances, thus skillfully solving the problem that the lignin is sufficiently degraded into water-soluble monophenol and enters production wastewater. The polyphenol substances obtained after the degradation of the lignin are extracted through the subsequent ethanol boiling step, i.e. the polyphenol substances enter an ethanol solution and are subjected to simple distillation and purification to produce useful industrial byproducts. According to the invention, the method has the characteristics of favorable degumming effect, mild process, small fiber damage and the like; and the obtained fiber has high strength, favorable whiteness and high comprehensive quality.

Owner:QINGDAO UNIV

Ramie rapid degumming technique for producing high quality ramie top

InactiveCN101358380AReduced chance of acidic hydrolysisShort processVegetable materialCelluloseSodium acetate

The invention discloses a ramie quick degumming process in the production of high-quality sesame balls. The ramie quick degumming process comprises the following steps: ramie soaking: quick degumming dier boiling agent accounting for 1.0 weight percent to 1.5 weight percent of the ramie is used to soak the ramie for 1.0h to 1.5h at 50 DEG C to 60 DEG C; boiling at normal pressure: under the condition of normal pressure, 6g / l to 10g / l of NaOH aqueous solution is used to cook for 2h to 4h at 95 DEG C to 100 DEG C; the quick degumming dier boiling agent consists of gene improving alkaline pectase, stabilizer sodium acetate and magnesium chloride, penetrative emulsifier peregal O and trimeric sodium phosphate. The process shortens the technological process, and reduces the pickling procedure, so that the cellulose acidic hydrolysis probability is reduced and the degummed ramie forceful injury is small. The obtained degummed ramie has large break length and little hard thread doubling, is tender and applicable in spinning high grade cotton yarn.

Owner:湖南华升洞庭麻业有限公司

Fixing glue for cutting crystalline materials and preparation method thereof

InactiveCN102786904AImprove cutting efficiencyShort curing timeNon-macromolecular adhesive additivesEpoxynovolac adhesivesPolymer scienceNitrile rubber

The invention discloses a fixing glue for cutting crystalline materials and a preparation method of the fixing glue. The fixing glue comprises a component A and a component B, wherein the component A comprises the following components by mass percent: 30-60 percent of bisphenol-A epoxy resin, 2-10 percent of o-crosel novolac epoxy resin, 20-50 percent of calcareous filler, 5-20 percent of hydroxyl acrylonitrile-butadiene rubber, 0.1-5 percent of coupling agent, 0.1-1 percent of antifoaming agent and 0.01-3 percent of toner; and the component B comprises the following components by mass percent: 30-60 percent of poly mercaptan resin, 2-10 percent of polyamide resin, 0.5-5 percent of activating agent, 0.5-1 percent of degumming slow release agent, 20-50 percent of calcareous filler and 0.5-1 percent of antifoaming agent. The components A and B are uniformly mixed by the mass ratio of 1:(0.5-1) so as to prepare the fixing glue for cutting the crystalline materials. The fixing glue is short in curing and degumming time and greatly improves the cutting efficiency of the crystalline materials.

Owner:东莞市永固绝缘材料有限公司

Co-production even-molecular-weight-distribution fibroin-polypeptide and sericin-polypeptide powder and preparing method thereof

InactiveCN105385728AShorten the soaking timeShort degumming timeChemical industryPeptide preparation methodsFiltrationHigh pressure

The invention discloses a co-production even-molecular-weight-distribution fibroin-polypeptide and sericin-polypeptide powder and a preparing method thereof. The method includes the working procedures of cleaning, steam swelling, high-pressure degumming, secondary enzymolysis, ultra-filtration, membrane separation, concentration, drying and the like. The method has the advantages that molecular weight distribution is even, water and energy are saved, and co-production of fibroin polypeptide and sericin polypeptide is achieved; the defects of existing technologies are well overcome. The silk polypeptide powder comprises the fibroin polypeptide and the sericin polypeptide, and has the advantages of being high in purity and bioactivity, moderate in molecular weight, white, free of peculiar smells and the like. The powder can be used for preparing biological materials, medical materials, health food and the like, and the pure natural aim, the high activity aim, the excellent functionality aim, the rich nutrient aim and the like can be achieved.

Owner:湖州新天丝生物技术有限公司

Flash-explosion hemp degelatinizing technology with cryogenic processing and device

InactiveCN101255609AAvoid damageAchieve primary separationMechanical treatmentFibre treatment to obtain bast fibreEngineeringHigh pressure

The invention relates to a hemp degumming technology using a steam explosion with a low-temperature treatment and a device. The invention relatest to the hemp degumming technology, in particular to the steam explosion hemp degumming technology, comprising: firstly ramie is marinated for 15 hours in the temperature of 25 deg C; then the ramie which is already marinated by water is put into a groove which contains a solution of NaOH with a concentration of 18 percent to be processed alkali treatment; then the ramie is kept in high pressure; after being kept in high pressure the hemp fiber is processed a decompression steam explosion treatment with the low-temperature treatment. The hemp degumming technology of the invention has the advantages of that a low rate of incomplete glue, light fibre damage, no pollution, reducing cost of degumming, saving degumming time.

Owner:LANYAN GROUP

Pseudomonad DA10 bacterial strain and obtaining method and application thereof

InactiveCN102010837ANot easy to polluteNo pollution in the processBacteriaBiochemical fibre treatmentFiberPectinase

The invention relates to a pseudomonad DA10 bacterial strain and an obtaining method and application thereof. The bacterial strain has the capability of producing pectinase and hemicellulase and has the flax degumming activity. The bacterial strain and a culture system can be directly used for flax degumming, the bacterial strain has the advantages of short degumming period, low treatment cost, good fiber quality, mild degumming condition, strong anti-pollution capability, good heat resistance performance, no environment pollution and the like, the fiber dispersion rate reaches 100 percent, the degumming efficiency reaches 95 percent, and the bacterial strain can not be polluted. Compared with the prior art, the bacterial strain has the characteristic of simple process, is applied to large-scale industrial production and has potential theoretic and practical significance on the flax degumming of the pseudomonad bacterial strain under the alkaline condition.

Owner:DONGHUA UNIV

Method for high-temperature and high-pressure acid degumming of tussah silk

The invention discloses a method for high-temperature and high-pressure acid degumming of tussah silk. Firstly, acid, a penetrant and water are mixed, degumming liquid is obtained, silk is soaked with the degumming liquid, and degumming is carried out under the conditions that the pressure is 1.0-3.0 MPa and the temperature is 100-140 DEG C. The tussah silk is treated through the high-temperature and high-pressure acid degumming method, the hydrolysis speed of sericin and the breaking speed of protein peptide bonds are increased, degumming time is short, the degumming rate can reach 13%, the breaking strength of the silk obtained after degumming can be kept at about 620 N, the strength losses of the silk are small, and rapid degumming of the tussah silk is achieved.

Owner:EASTERN LIAONING UNIV

Penicillium purpurogenum DB1 strain and preparation and application thereof

InactiveCN102337220AImprove degumming effectNot easy to polluteFungiMicroorganism based processesBiotechnologyFiber

The invention relates to a penicillium purpurogenum DB1 strain and preparation and application thereof. A preparation method of the strain comprises the following steps of: (1) putting rotten seaweed into an enriched medium for stationary culture at room temperature, coating the enriched medium onto an isolation medium, and stationary culture for 1-4 days at 30 DEG C to obtain a wild flax biological treatment strain; (2) inoculating the strain obtained in the step (1) into a flax lignin enriched medium, and culturing at 28 DEG C for 72 hours; and (3) selecting a strain with lignin degrading capability from the flax lignin enriched medium to obtain the penicillium purpurogenum DB1 strain. The penicillium purpurogenum DB1 strain can be applied to preparation processes of flax, hemp, jute orred jute fiber for spinning by degumming with peroxides. The strain has the advantages of short growing period, difficultly polluted, low treatment cost, good fiber quality after treatment, mild reaction condition, high heat resistance and environmental friendliness; and the strain has a simple process and is suitable for mass industrial production.

Owner:DONGHUA UNIV

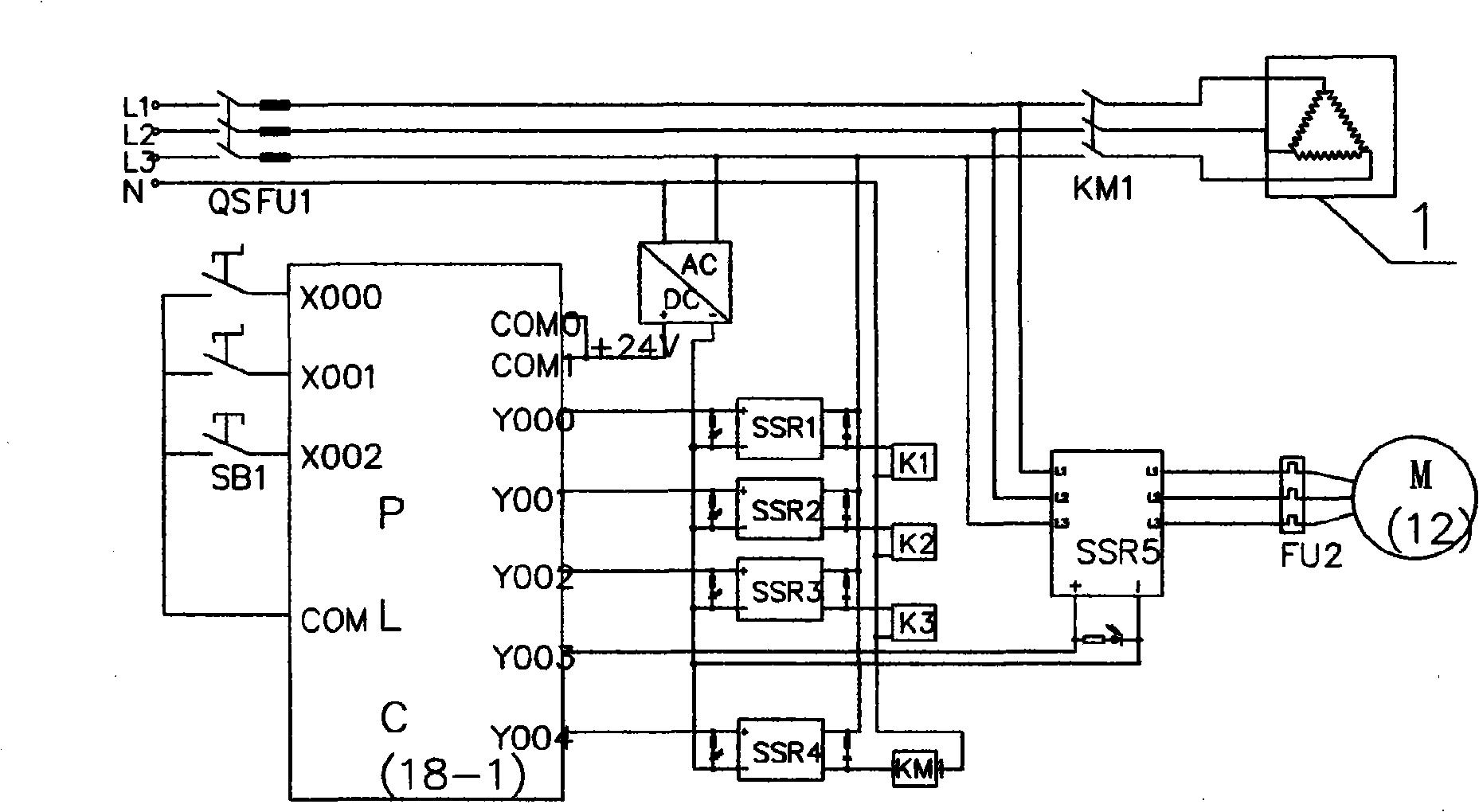

A glass plate hot water degumming device

InactiveCN102280528ABurn out preventionEasy to operateFinal product manufactureSemiconductor devicesEngineeringGlass sheet

The invention discloses a hot water degumming device for a glass plate. The device comprises a degumming tank and a controller for controlling the degumming tank. The degumming tank includes a bracket, a tooling basket installed inside the bracket and a cover plate for sealing the tooling basket , the heating part of the heating device is arranged inside the tooling basket. The invention has the advantages of convenient operation, short degumming time and good degumming effect, the degumming temperature can be adjusted according to the process conditions and glue conditions, heat preservation can save electricity, and heating parts can be prevented from burning out, which is safe and reliable.

Owner:太仓协鑫光伏科技有限公司

Method for preparing fibrilia by using alternaria tenuis DB3 strains

InactiveCN102409412AExtensive culture conditionsImprove heat resistanceFungiMicroorganism based processesFiberAlternaria

The invention relates to a method for preparing fibrilia by using epicoccum nigrum DB3 strains. The method comprises the following steps: (1) preserving the epicoccum nigrum DB3 strains in a potato dextrose agar medium for cultivation, and adding a freezing buffer solution; (2) inoculating bacteria the amount of which equals to the pick-up amount of an inoculating ring, obtained in the step (1) into the potato dextrose agar medium, and carrying out shaking culture; (3) inoculating the culture medium obtained in the step (2) into a flax lignin fermentation medium, and carrying out shaking culture to obtain a fermentation bacteria liquid; (4) mixing sterilized fiber raw material with the fermentation bacteria liquid obtain in the step (3), carrying out table shaking and removing fermentation liquid to obtain the fibrilia; and (5) mixing the fibrilia with degumming liquid, processing and then rinsing, oiling and drying to obtain the fibrilia. The method in the invention has simple technology, short degumming time and high degumming efficiency, thus being suitable for large-scale industrial production.

Owner:DONGHUA UNIV

Degumming technology for aqueous solution of methanesulfonic acid

InactiveCN102500569AOut of fullFully producedFinal product manufactureCleaning using liquidsAqueous solutionHeating temperature

The invention discloses a degumming technology for the aqueous solution of methanesulfonic acid. The technology comprises the following steps of: a, adding a certain amount of water into an acid soaking tank of a degumming machine, setting the heating temperature, and turning on a switch for heating; b, adding a certain amount of methanesulfonic acid with a prepared concentration into the acid soaking tank of the degumming machine; c, putting a silicon wafer after flushing and ultrasonic washing and a cutting substrate together into the acid soaking tank to soak for some time; and d, lifting the cutting substrate by a special tool, and taking down a few silicon wafers which do not drop. The technology adopts the aqueous solution of methanesulfonic acid in the acid soaking process, has the advantages of sufficient silicon wafer separation and low cost, can shorten the degumming time and does not produce gas with irritant odor.

Owner:KONCA SOLAR CELL

Enzyme preparation for bast fiber degumming, and hemp bast degumming technology thereof

ActiveCN107828757ARough culture conditionsFast growthHydrolasesMicroorganism based processesKenafXylanase

The invention discloses an enzyme preparation for hemp bast degumming. Xylanase and a CaCl2 assistant are added to a fermentation broth of Dickeya chrysanthemi, and above substances are mixed to obtain the enzyme preparation, wherein the preservation number of the is Dickeya chrysanthemi is CGMCC 14600, and the Dickeya chrysanthemi is named as Dickeya chrysanthemi DC. The invention also provides atechnology for degumming hemp bast by using the enzyme preparation. The technology sequentially comprises the following steps: preparing the enzyme preparation, preprocessing a hemp raw material, carrying out circulating immersion in the enzyme, performing inactivation, and washing hemp to finally obtain pure hemp fibers. The enzyme preparation has the advantages of rough culture conditions for the Dickeya chrysanthemi DC, high growth speed and high enzyme activity, and is suitable for to degumming of bast of ramie, kenaf, hemp, flax and kendir; and a circulating enzyme immersion process is adopted to cyclically use the enzyme preparation, so the use efficiency of the enzyme preparation is improved, the process flow is shortened, the production cost is reduced, pickling, high-pressure andhigh-concentration soda boiling and acid rinsing are not needed, conditions are mild, the treatment load of inorganic and organic pollutants is 70% less than that of chemical degumming, and the processing cost is reduced by about 20%.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

Bacillus subtillis strain containing ramie degumming activity, preparation and application thereof

InactiveCN101654660BNot easy to polluteNo pollution in the processBacteriaMicrobiological testing/measurementFiberBiotechnology

The invention relates to a bacillus subtillis strain containing ramie degumming activity, preparation and application thereof, which uses a system taking the strain as the core for ramie degumming. The strain of the system has high reproductive rate, high yield of pectase and xylanase, short production period, strong contamination resistance and favorable heat-resistant quality. The system and the cultivating process are safe to operate, have no toxicity and pollution no environment. Compared with the prior art, the invention has simple technology, is suitable for large-scale industrial production and the like. When the system is used for ramie degumming, degumming time is short, the dispersion coefficient of ramie fiber can reach 100%, degumming ratio can reach above 90%, and the qualityof refined dry ramie can reach the standard of chemical degumming.

Owner:DONGHUA UNIV

Deep-eutectic solvent and microorganism combined degumming method for flax roving

ActiveCN113373527AShort degumming timePromote degradationBacteriological rettingBiotechnologyMicroorganism

The invention relates to a deep-eutectic solvent and microorganism combined degumming method for flax roving, and belongs to the technical field of biology. The deep-eutectic solvent and microorganism combined degumming method comprises the steps that the flax roving is added into an aqueous solution of a deep-eutectic solvent, heated and then taken out; the aqueous solution of the deep-eutectic solvent enables fibers in the flax roving to be dispersed, and hydrogen bonds between hemicelluloses and pectin molecules in the flax roving are damaged, so that removal of colloids in the flax roving is promoted; and the taken-out flax roving is washed to remove the residual aqueous solution of the deep-eutectic solvent on the surface, and then degumming microorganisms are inoculated for microbial degumming. According to the deep-eutectic solvent and microorganism combined degumming method for the flax roving, the aqueous solution of the deep-eutectic solvent is used for pretreating the flax roving, the aqueous solution of the deep-eutectic solvent can effectively disperse roving fibers and remove part of the colloid, and subsequent biological degumming is facilitated. The process does not need acid-base pretreatment, is environment-friendly and good in degumming effect, and has a good application prospect in flax roving degumming.

Owner:HUAZHONG UNIV OF SCI & TECH

Degumming liquid

The invention relates to a degumming solution and belongs to a chemical treatment solution, which is used for removing a fastening glue film adhering to the surface of mechanical parts. The invention provides a degumming solution that has a short degumming duration and has no corrosion to the mechanical parts. The invention consists of halogenated hydrocarbon, acetone, paraffin, white oil, a high molecular polymer and the latent solvent for the high molecular polymer. The degumming solution is characterized in that the weight percentage for the components is as follows: halogenated hydrocarbon 30 to 50 percent, white oil 4 to 10 percent, acetone 40 to 60 percent, high molecular polymer 0.05 to 0.1 percent, paraffin 0.5 to 2 percent and the rest is the latent solvent for the high molecular polymer.

Owner:SHENYANG POLYTECHNIC UNIV

Processing technology for rapeseed oil

InactiveCN109536277AMeets moderate refining requirementsReduce degumming water consumptionFatty-oils/fats refiningEdible oils/fatsWater useOil processing

The invention discloses a processing technology for rapeseed oil. As ultrasonic waves can be adopted to assist a phospholipase C degumming process to perform degumming processing on rapeseed crude oil, the water using amount of degumming can be greatly reduced, and the generated wastewater amount can be greatly reduced as well, so that the processing technology is green and environmentally friendly; and the degumming time can be shortened to 60 min, and the processing technology can accord with the moderate refining of oils and fats. The processing technology is safe, environmentally friendly,simple, convenient in operation, low in cost, high in refining rate and suitable for the industrial production of rapeseed oil processing.

Owner:余握中

Simple degumming method of concentrated-fragrance colza oil

ActiveCN103215123BThe supporting facilities are simpleShort degumming timeOther chemical processesFatty-oils/fats refiningSlagPhospholipid

The invention relates to a simple degumming method of concentrated-fragrance colza oil. The degumming method comprises the following steps of: (1) pumping squeezed concentrated-fragrance colza crude oil with slag removed into a degumming tank, wherein the concentrated-fragrance colza crude oil does not need to be heated or cooled and just is operated at normal temperature; (2) adding a degumming absorption agent into the degumming tank; (3) stirring for 15-20min at room temperature; and (4) filtering and separating the absorption agent by using a plate frame filtering machine of which the filtering aperture is 5mu m, so as to obtain the refined concentrated-fragrance colza oil. The degumming absorption agent is prepared from montmorillonoid, silicate, modified bentonite and filter aids with different apertures which are mixed and stirred. According to the simple degumming method, the gum impurities such as phospholipids and protein in the concentrated-fragrance colza oil are absorbed by using the degumming absorption agent and then filtered and separated, thus degumming the concentrated-fragrance colza oil; and the conventional process that the concentrated-fragrance colza oil stands for a long time or is subjected to hydration degumming firstly and then dried and dehydrated is replaced, both the gum impurities can be simply and rapidly eliminated, and the concentrated fragrance of the oil is not lost, so that colza oil which is fragrant, pure in quality, nutritive and sanitary is obtained.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Water-based adhesive removal agent for plastic film for package printing

InactiveCN105886130ALow volatilityShort degumming timeCationic surface-active compoundsOrganic detergent compounding agentsSolventChemistry

A water-based adhesive removal agent for a plastic film for package printing is prepared from components in percentage by weight as follows: 17%-40% of a main solvent, 17%-40% of a cosolvent, 0.05%-5% of a surfactant, 0.5%-5% of an antifoaming agent and 20%-60% of water. With use of a swelling action of effective ingredients in the adhesive removal agent on a composite adhesive, a composite adhesive layer on the surface of the film is swelled rapidly to fall off. Under the action of the antifoaming agent, the adhesive removal agent cannot produce a large amount of foam when reused in a cleaning machine. The adhesive removal agent has the characteristics that a preparation method is simple, the adhesive removal agent is stable and not prone to delamination or volatilization, the adhesive is removed rapidly, damage to a film substrate is not produced, heating is not needed when the adhesive removal agent is used at the room temperature, the adhesive removal agent can be reused in the cleaning machine, a large amount of foam cannot be produced and the like.

Owner:GUANGDONG ZHUANGLI COLOR PRINTING

Processing method of silk

InactiveCN107653496AHigh degumming rateShort degumming timeDe-gumming silkAlkaline proteaseHydrolysis

The invention belongs to the technical field of silk processing, and particularly relates to a processing method of silk. The method comprises the following steps of (1) silk drying; (2) degumming: adding 1.0 to 2.0 mol / L of urea solution into a degumming groove; performing heating to 50 to 60 DEG C; starting ultrasonic waves; soaking the silk dried in the step (1) into water in the degumming groove; adding alkaline protease into the urea solution according to the proportion of 0.6 / 100 mL to 1.2g / 100 mL to be subjected to hydrolysis for 1h to 2h; then, adding lipase according to the proportionof 0.3 / 100 mL to 0.6g / 100 mL to be subjected to hydrolysis for 1h to 2h; preparing coarse degumming silk; (3) water washing; (4) washing: adding a functional detergent for washing for 50 to 60min; then, preparing the degumming silk after cleaning by clean water. The method has the advantages that the silk degumming efficiency is high; the degumming time is short; the color quality of raw silk isbetter; no pollution exists; green and environment-friendly effects are achieved.

Owner:河池市宜州区壮之都丝绸家纺有限公司

Industrialized production method of pectase

InactiveCN101659946BStrength damage is smallIncrease enzyme activityMicroorganism based processesEnzymesPectinaseBacillus cereus

The invention discloses an industrialized production method of pectase with high enzyme activity, which comprises the following steps: bacterial strain selecting and breeding, strain culturing, flask-shaking and fermenting as well as enzyme solution preparation. The industrialized production method is characterized in that the pectase, namely, bacillus cereus is obtained by the separation and thescreening of natural-collecting bacterial samples and strain mutagenesis under the cellular level, the laboratory number is MAPLE21, the conversation number is CCTCC NO: M209147, and the pectase has the following biological properties: bacilliform thallus, even dyeing, G<+>, facultative aerobe, spores forming without exposing out of the thallus, leveler two ends of the thallus and chain-like arrangement of a majority of spores. The invention has the advantages of high enzyme activity, low cost, short fermentation period, and the like; when the invention is used for bast fiber degumming, the degumming time (2-4h) is short and stable, the defective gum ratio is below 1.5 percent, the destruction to fiber strength is small, the fiber dispersion ratio is 100 percent, the finished product ratio is above 65 percent, and the generation amount of degumming waste water is reduced by more than 80 percent.

Owner:沅江浣溪沙酶技术有限公司 +1

Method for preparing garlic bolt leaf fibers

ActiveCN105908263AHigh degumming rateShort degumming timeVegetable materialMechanical fibre separationFiberMicrowave

The invention provides a method for preparing garlic bolt leaf fibers. The method comprises the steps of compound acid pretreatment, low-temperature plasma treatment, microwave radiation and complex enzyme alternate treatment, water washing, soap washing, dewatering, shaking to be loose, oil feeding and drying. According to the method for preparing the garlic bolt leaf fibers, fiber degumming time can be shortened, attachments on the surfaces of the garlic bolt leaf fibers can be reduced, spinnability can be improved, and the garlic bolt leaf fibers prepared through the method for preparing the garlic bolt leaf fibers have high strength and elongation at break and large length.

Owner:南通隆特家纺有限公司

Eupenicillium javanicum DB4 strain as well as preparation and application thereof

InactiveCN102329737AShorten the growth cycleReduce processing costsFungiMicroorganism based processesEupenicilliumCulture mediums

The invention relates to a Eupenicillium javanicum DB4 strain as well as preparation and application thereof. The preparation method comprises the following steps of: (1) placing rotten seaweed in an enrichment culture medium, standing and culturing at room temperature, coating the enrichment culture medium on a separation culture medium, and standing and culturing at the temperature of 30 DEG C for 1-4 days to obtain wild flax bio-treated strain; (2) inoculating the strain obtained in the step (1) to a flax lignin nutrient culture medium and culturing at the temperature of 28 DEG C for 72 hours; and (3) selecting the strain with lignin degrading capability from the flax lignin nutrient culture medium. The obtained strain can be applied to the processes for preparing flax, hemp, jute or red ramie fibers for textile by peroxide degumming. The strain has the advantages of short growth period, low pollution probability, low treatment cost, mild reaction conditions, strong pollution resistance, good heat resistance, no environmental pollution, and good fiber quality after treatment; and the process is simple and is suitable for large-scale industrial production.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com