Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Reduce the probability of residual glue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkaline pectinase preparation for cannabissalival degumming, and cannabissalival degumming method

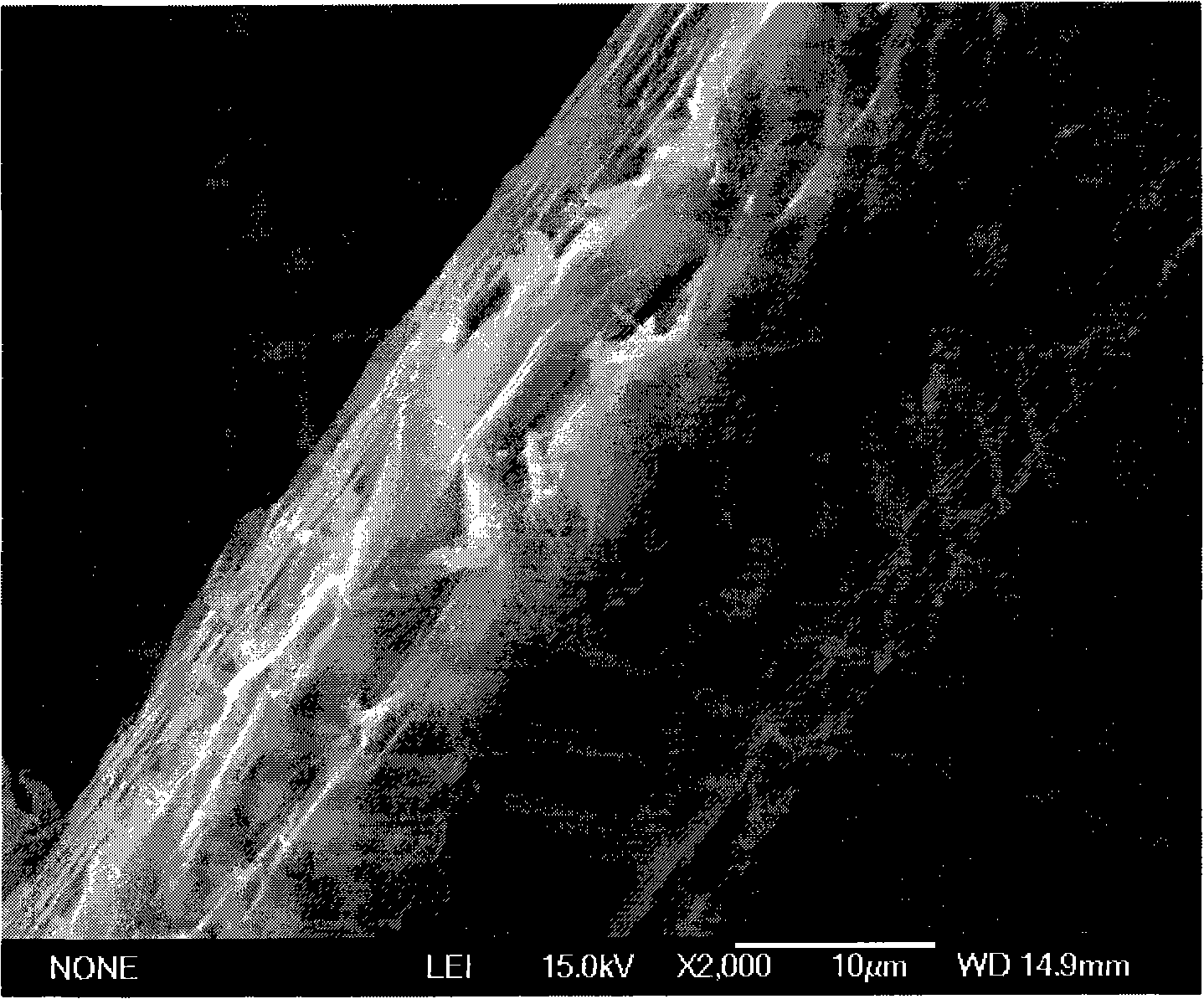

InactiveCN103937771AReduce the probability of residual glueAvoid damageHydrolasesMicroorganism based processesPectinaseFiber

The invention relates to an alkaline pectinase preparation for cannabissalival degumming, wherein the components of the alkaline pectinase preparation comprise: an alkaline pectinase or an alkaline pectinase compound enzyme preparation, wherein the alkaline pectinase compound enzyme preparation is a mixture comprising an alkaline pectinase and one or a plurality of materials selected from pectinase, xylanase, mannanase, lipase and protease. According to the present invention, the alkaline pectinase preparation has characteristics of effective cannabissalival degumming and short degumming time, and the obtained fibers have characteristics of low gum residue, softness and less damage.

Owner:TIANJIN UNIV OF SCI & TECH

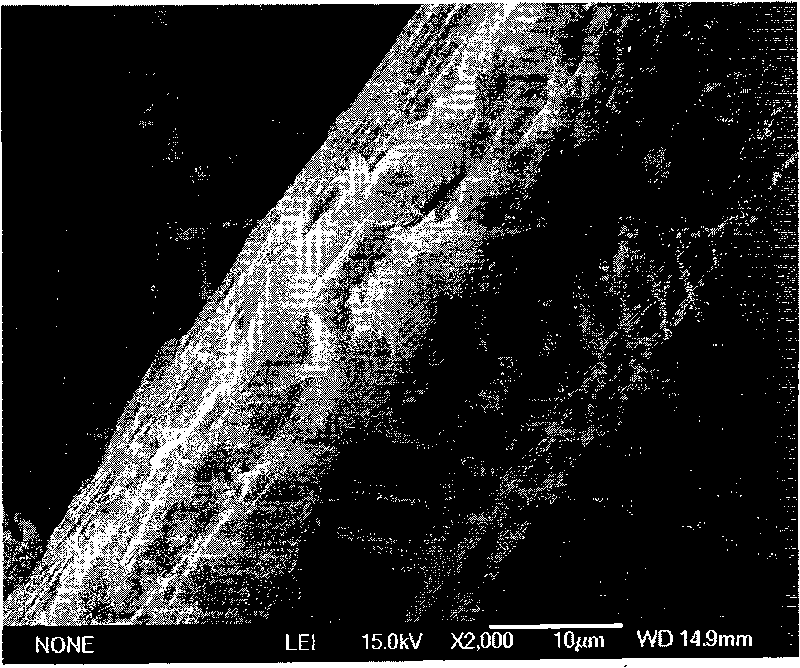

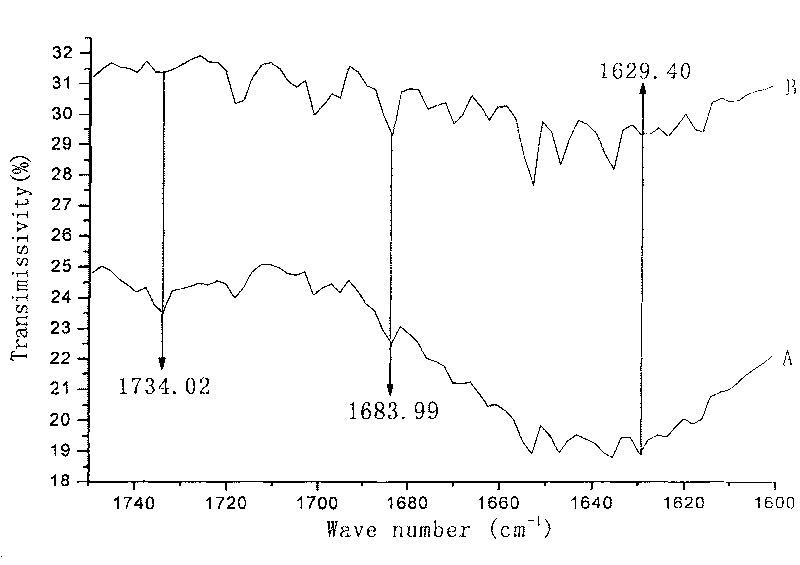

Natural plant fibre extraction by alkali oxidation

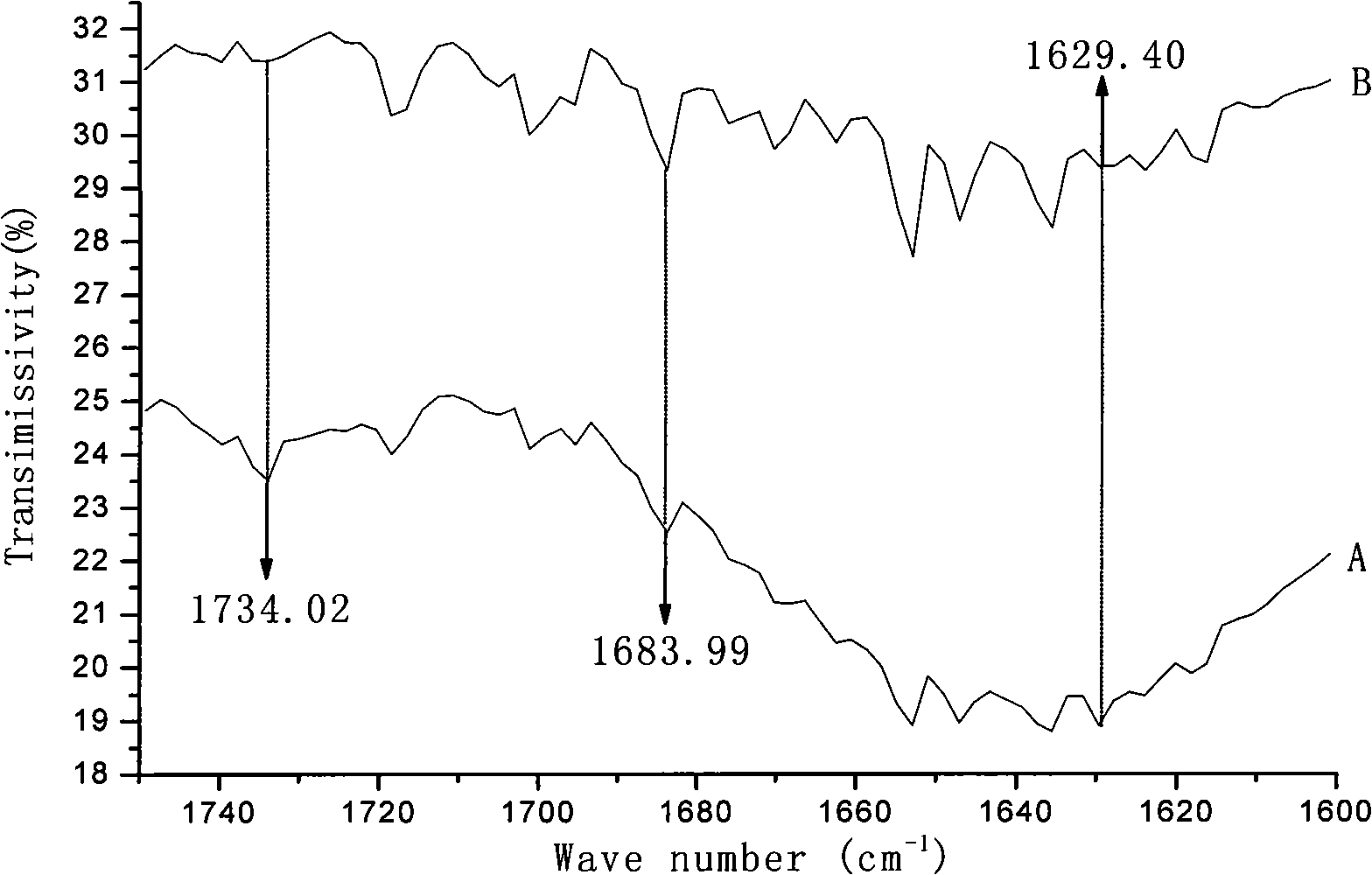

InactiveCN1818157AReduce the probability of residual glueLow lignin contentFibre treatment to obtain bast fibreChemistryNatural fiber

The invention provided an alkaline extracting method of the natural plant fiber. The process is: the material->acid etch->washing->alkaline with oxygen->strike the fiber->washing by the water->washing by the acid->washing by the water->dehydration->shake the fiber->oil feed->dehydration->air dry or oven dry. The fiber can be protected by adding the assistant Mg<2+>, the stability of the H2O2 in the alkali and the chemical assistant, also the nucleophilic reaction of the H2O2 to lignine can reach the best efficient. It can be used for extracting the plant fiber of the spinning, weaving and the dressing.

Owner:QINGDAO UNIV

Frozen-irradiated auxiliary degumming process for china-hemp fibers

InactiveCN101275289AConvenient lengthImprove finenessFibre treatment to obtain bast fibreQuenchingHemp fiber

The invention discloses a hemp fiber freezing radiation auxiliary de-gumming technique, comprising the following steps of undergoing UV radiation, quenching, and heating treatment after hot bath, acid pre-etching, and pre-chlorination, and then undergoing base oxygen-mechanical associative de-gumming treatment, finally adding a softener for secondary scouring. The hemp fiber surface de-gumming effect treated by the technique is prior to ordinary base oxygen method and mechanical de-gumming, and the former meets the requirement of product of national first grade; the lignin content meets requirement of finishing technique after spinning, which obtains good whiteness and flexibility, and controls breaking strength and tensile stretch of fiber in requirement of spinnability, with improved length and fineness of fiber is improved, greatly improved serviceability, and less pollutant effluents discharged, so that the invention is environment-friendly.

Owner:TAIYUAN UNIV OF TECH

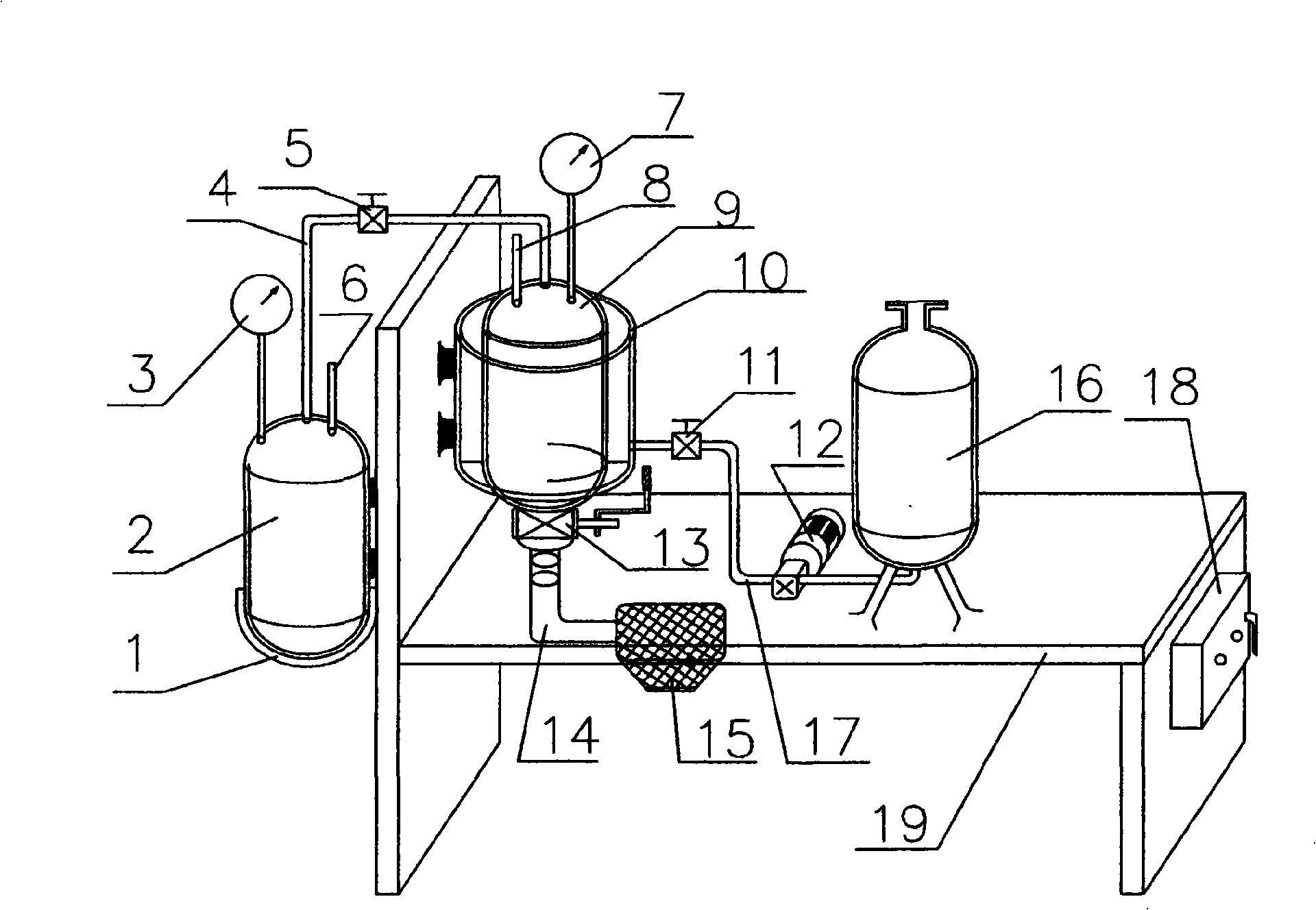

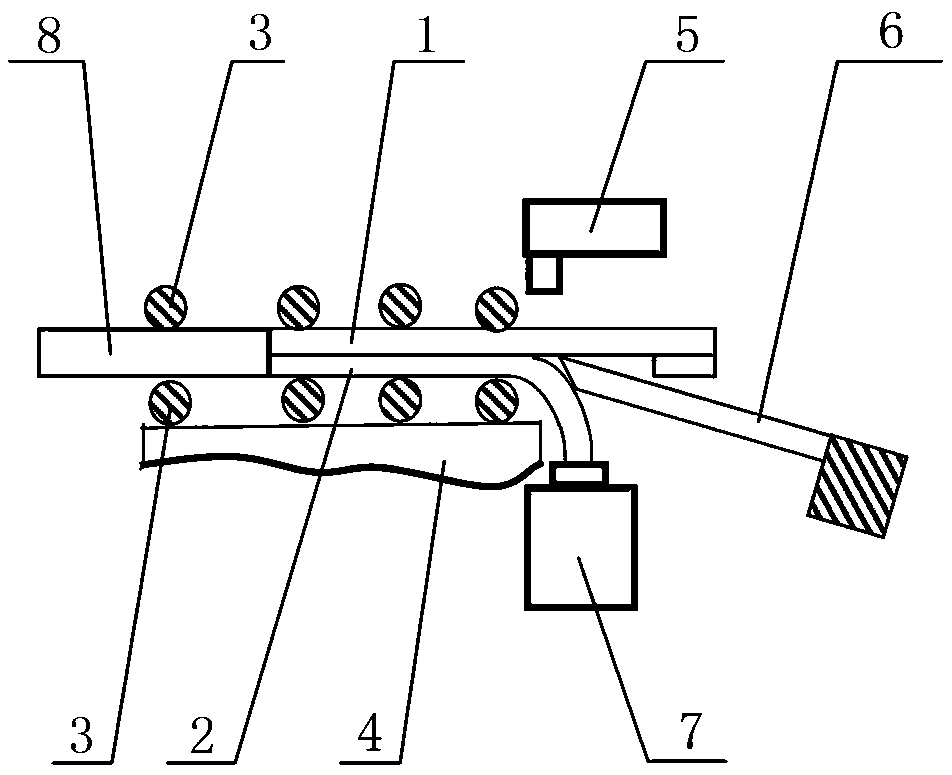

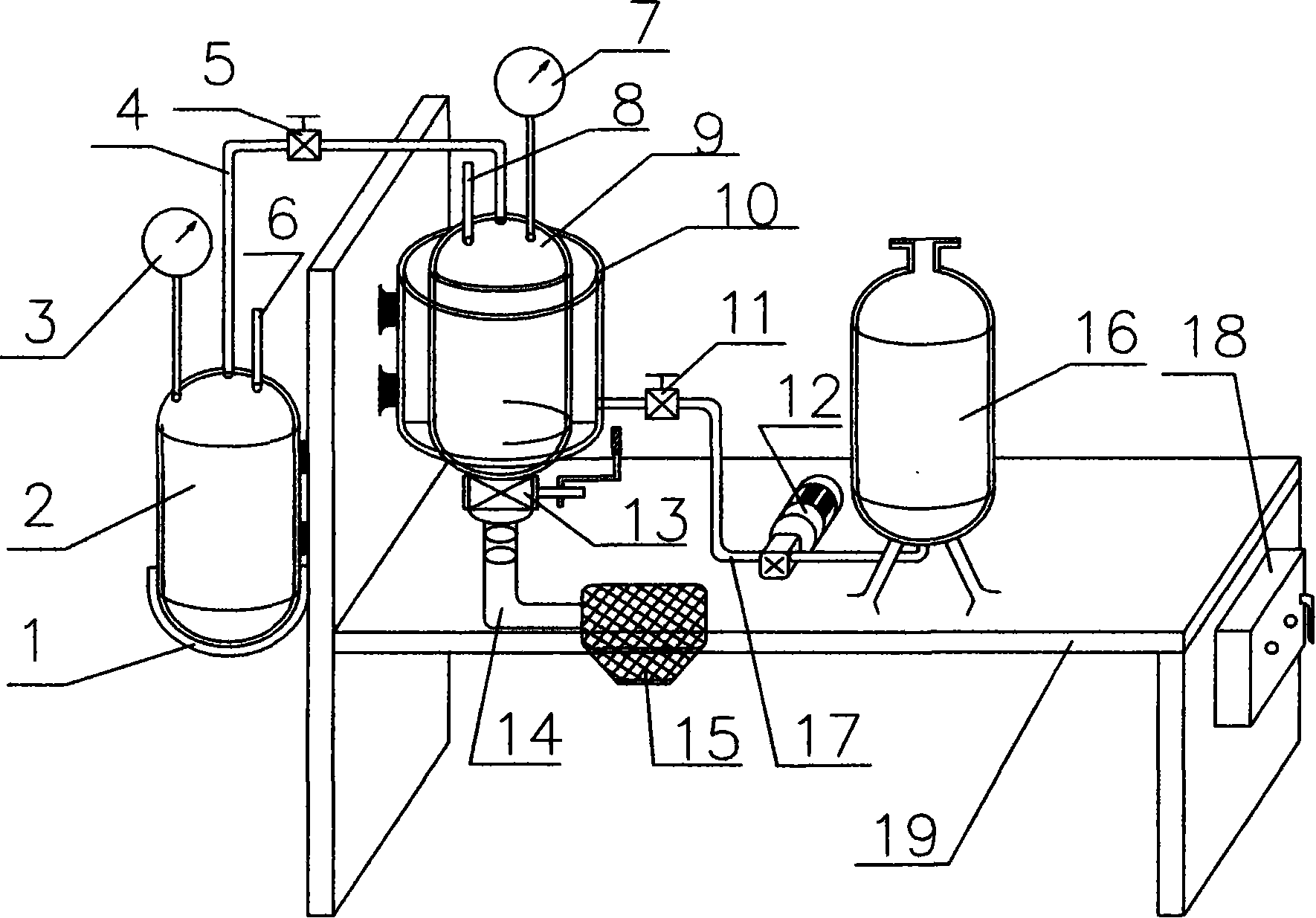

Flash-explosion hemp degelatinizing technology with cryogenic processing and device

InactiveCN101255609AAvoid damageAchieve primary separationMechanical treatmentFibre treatment to obtain bast fibreEngineeringHigh pressure

The invention relates to a hemp degumming technology using a steam explosion with a low-temperature treatment and a device. The invention relatest to the hemp degumming technology, in particular to the steam explosion hemp degumming technology, comprising: firstly ramie is marinated for 15 hours in the temperature of 25 deg C; then the ramie which is already marinated by water is put into a groove which contains a solution of NaOH with a concentration of 18 percent to be processed alkali treatment; then the ramie is kept in high pressure; after being kept in high pressure the hemp fiber is processed a decompression steam explosion treatment with the low-temperature treatment. The hemp degumming technology of the invention has the advantages of that a low rate of incomplete glue, light fibre damage, no pollution, reducing cost of degumming, saving degumming time.

Owner:LANYAN GROUP

Deoiling and degumming treatment method for waste bave

InactiveCN103572382ALow boiling pointEasy to recycleAnimal materialDe-gumming silkResidual oilNational standard

The invention relates to a deoiling and degumming treatment method for waste bave. The method comprises the following steps of: A, deoiling and degumming treatment, namely, adding a leaching solution which is a isopropyl alcohol aqueous solution containing sodium carbonate or sodium silicate at a certain concentration to the waste bave, and reacting for 40 to 120 minutes under 70 to 100 DEG C, wherein the concentration of sodium carbonate or sodium silicate in the leaching solution is 3 to 6g / L, and the volume concentration of isopropyl alcohol is 20 to 70%, and the ratio of the mass of the waste bave to the volume of the leaching solution is 1g: 30 to 60mL; B, washing with water, namely, taking out the waste bave after the reaction is finished, and washing with water; C, drying, namely, drying the waste bave washed with water, wherein the waste bave is long silk waste or silk floss. The method has a good deoiling and degumming effect, is short in treatment time and low in temperature; after the deoiling and degumming, both the residual oil ratio and residual glum ratio of the long silk waste easily reach the national standard in which the residual glum ratio of refined waste silk is 3 to 7%, and the residual oil ratio is not more than 0.55%; moreover, the whiteness of the long silk waste is obviously improved; the residual oil ratio of the silk floss is far less than 1.5% of that as specified by the national standard, and the residual glum ratio is relatively small.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Microbiological degumming method for smartweed fibre

InactiveCN101012574AReduce consumptionReduce pollutionMicroorganismsVegetable materialMicroorganismCarding

The invention discloses a microbial degumming method of nettle fiber. In the method, the nettle is infiltrated firstly; then bacteria degumming cultivated and filtered in the collected of white wine cellar fermented grains is inoculated to the infiltrated nettle so as to carry out degumming; and then the degumming fiber is deposed by washing in water, oiling and drying in turn; and finally it is deposed by opening, carding and packaging. Because microbial degumming is used in the invention, not only the consumption of chemical medicine such as strong acid, strong alkali and so on is decreased, the manufacturing cost is decreased; the pollution to environment and the corrosion to equipments are lessened; but also the process is shortened, the labor strength is lessened, the efficiency is improved and the output is increased. In addition, the fiber is separated more completely, the residual gum rate of fiber is lower, the proportion between doubling and stripe is decreased, and the quality and the success rate of nettle fiber are improved greatly.

Owner:SICHUAN UNIV

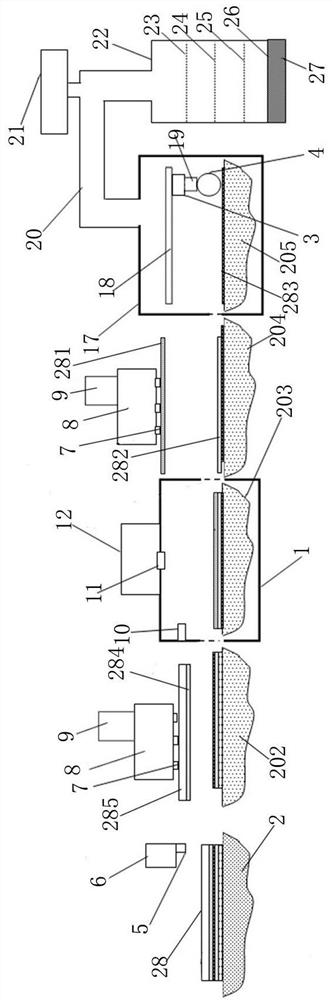

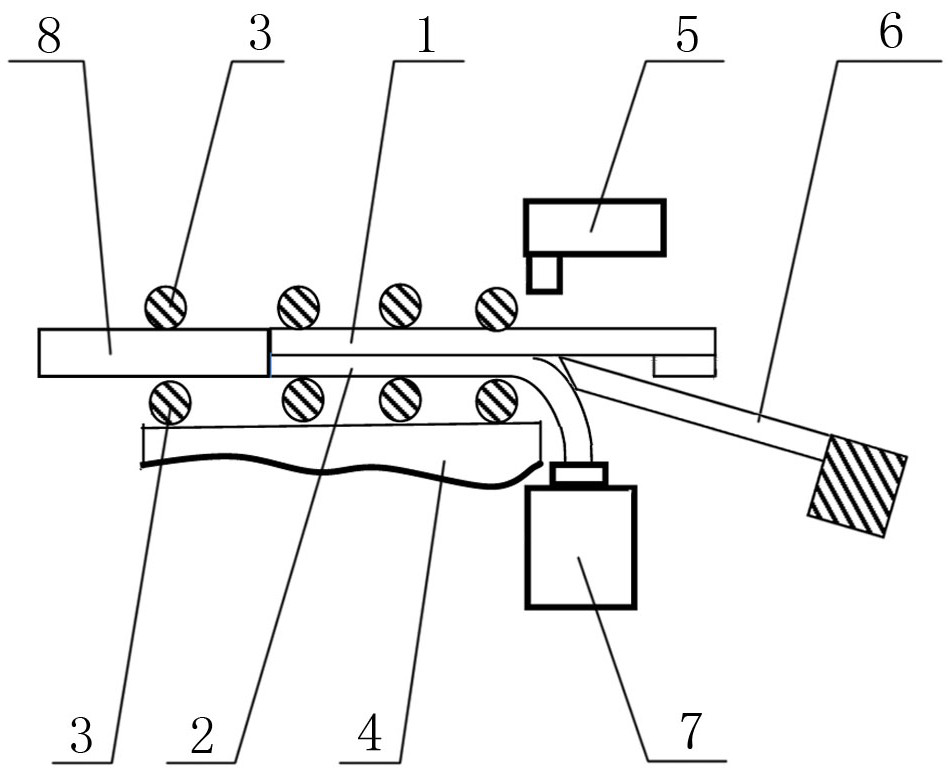

Equipment and method for disassembling solar cell module

ActiveCN112058871ARealize environmental protectionRealize sorting and recyclingWaste processingSolid waste disposalPhysicsSilicon chip

The invention provides equipment and a method for disassembling a solar cell module. The equipment for disassembling the solar cell module comprises a laser scanning device, a first collecting and conveying device, a hot knife device, a low-temperature processing device, a second collecting and conveying device, a rolling device and a separating device. According to the equipment and the method for disassembling the solar cell module provided by the invention, glass and an upper cover ethyl vinyl acetate (EVA) film adhered to the glass are disassembled from the solar cell module through the laser scanning device, and the glass and the upper cover EVA film adhered to the glass are separated through the hot knife device, so that the complete glass is obtained. Then through a low-temperatureenvironment manufactured by a low-temperature processing device under normal pressure, a complete backboard, a complete laid EVA film and a cell of the solar cell module are obtained. According to theequipment and the method for disassembling the solar cell module provided by the invention, the cells are crushed through the rolling device so as to obtain silicon wafer particles, metal welding strips and metal busbar, and different materials are separated and sorted through the separating device, so that the environment-friendly disassembling and the classified recycling of waste solar cell modules are achieved.

Owner:HEBEI UNIVERSITY

Method for extracting coconut fiber

ActiveCN109162132AReduce hydroxylRealize the second degreasingCellulose treatment using microorganisms/enzymesRaw material divisionChlorine dioxideThermal water

The invention discloses a method for extracting coconut fiber. The method comprises the following steps: crushing coconut shell; adding deionized water and lipase into a cylinder, conducting uniform mixing, heating the mixture to 45 DEG C, and soaking the coconut shell into a cylinder for 2-3 h after soaking; adding sodium hydroxide solution in a cooking tank, putting the filtered coconut shell into the cooking tank, heating and pressurizing the mixture, cooking the mixture for 1-1.5 h, taking out the cooked coconut shell, and rinsing off the cooked coconut shell with water for 10-15 min; dissecting the rinsed coconut shell in the step (3) into crude fiber by a filament forming machine, and then rinsing the fiber with water for 10-15 minutes; mixing the deionized water with chlorine dioxide and sodium carbonate uniformly, and then the rinsed crude fiber in the step (4); conducting soaking for 30 to 40 minutes, taking out the fiber, and rinsing the fiber with hot water for 15 to 20 minutes; and dehydrating the dried fiber in the step (5), and then loosening the fiber with a carding machine to obtain the coconut fiber. The coconut shell fiber extracted by the method for extracting the coconut fiber of the invention has uniformity, less impurities, low residual fat ratio, and guaranteed quality.

Owner:安徽九天印务有限公司

Emulsion pressure-sensitive adhesive for polarizer protective film, and polarizer protective film thereof

InactiveCN111187584AWith antistatic functionPrevent precipitationEster polymer adhesivesPressure sensitive film/foil adhesivesPolyesterSulfonate

The invention discloses an emulsion pressure-sensitive adhesive for a polarizer protective film, and the polarizer protective film thereof. The pressure-sensitive adhesive is prepared from the following raw materials in parts by weight: 100 to 200 parts of deionized water, 0.5 to 1.5 parts of a sulfonate reactive emulsifier, 1 to 4 parts of a double bond-containing quaternary ammonium salt monomer, 15 to 40 parts of a soft monomer, 5 to 10 parts of a hard monomer, 2 to 5 parts of a functional monomer and 1 to 4 parts of closed water-based isocyanate. According to the invention, the pressure-sensitive adhesive disclosed by the invention can be directly coated on the surface of a polyester film, an antistatic agent does not need to be added, the resistance of an adhesive layer is below 109 ohms, and the pressure-sensitive adhesive has an antistatic property; and when the polarizer protective film adhesive layer is attached to the surface of a polarizer, after high-temperature and high-temperature and high-humidity tests are carried out for 500 hours, the protective film and the polarizer are tightly attached, bubbles and bulges do not exist, and the defects of residual adhesive, shadows and the like do not exist when the protective film is torn off.

Owner:HEFEI LUCKY SCI & TECH IND

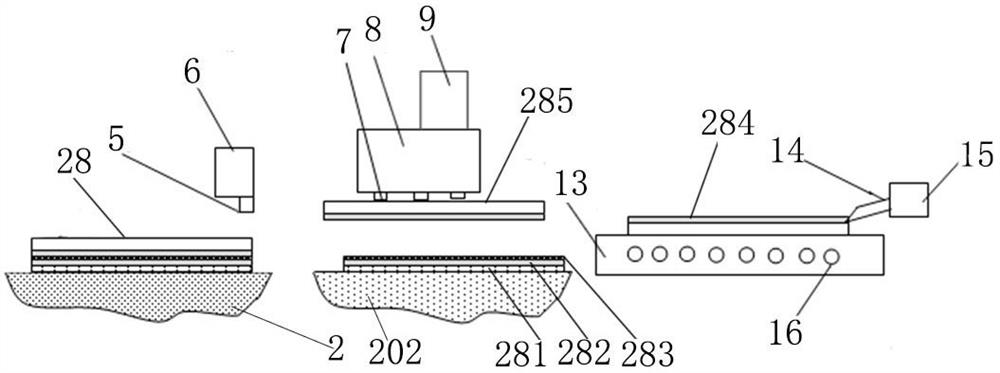

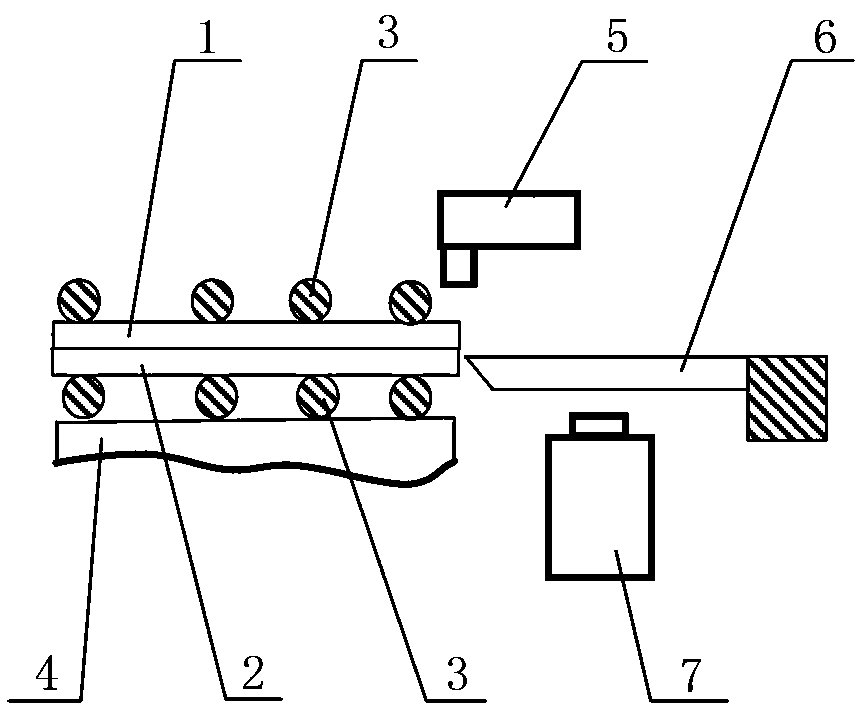

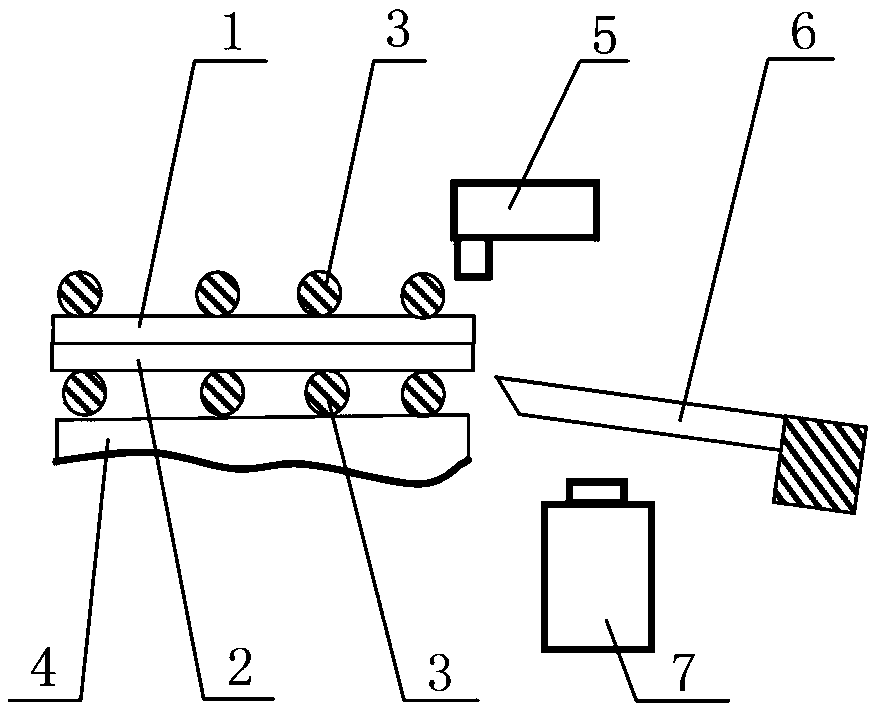

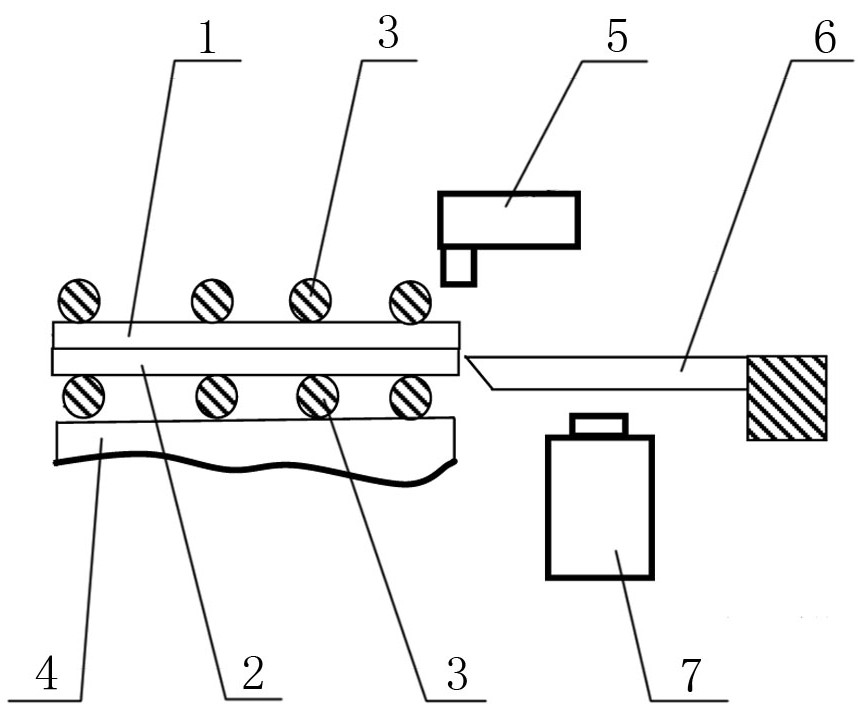

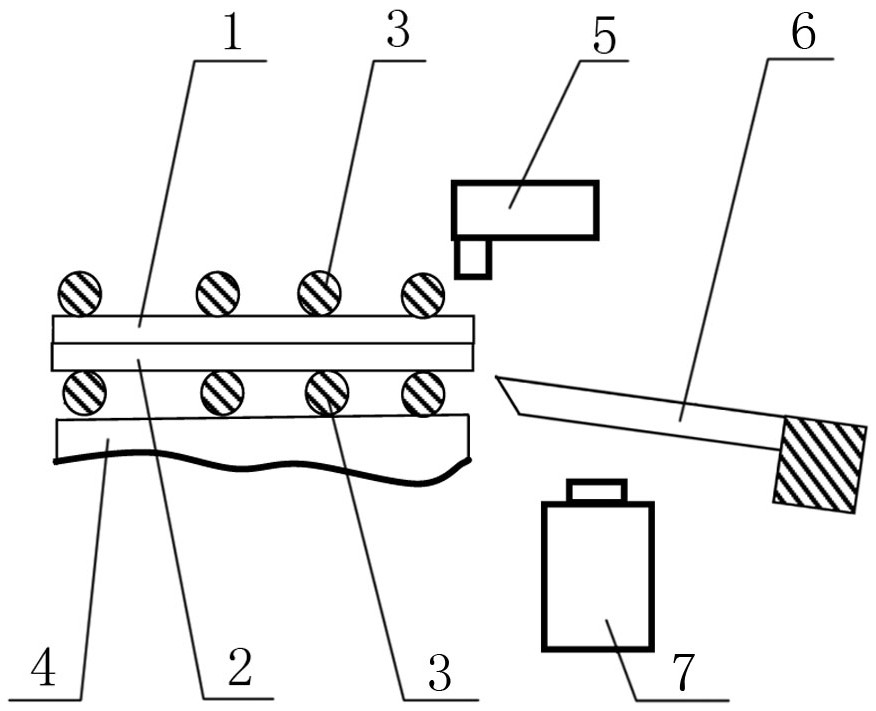

Method for separating solar cell module glass

ActiveCN111525000AIntegrity guaranteedAvoid removing uncleanWaste processingFinal product manufactureLaser scanningEngineering

The invention provides a method for separating solar cell module glass. The method comprises the following steps that firstly, a scraper blade is preheated, and then a solar cell module is driven by atransmission mechanism to move forwards by a set distance; a blade of the scraper is cut into the solar cell module from the lower part of the solar cell module in an obliquely upward manner, and theblade of the scraper contacts with the lower surface of the glass; and then the solar cell module continues to move, and the adhesive film adhered to the glass and the lower-layer module bonded withthe adhesive film are scraped off together by the blade of the scraper. Before scraping, the solar cell module can be scanned by the laser scanning mechanism so as to reduce the adhesive force of theadhesive film on the lower surface of the glass. According to the invention, efficient separation of complete glass in a solar cell module, especially a crystalline silicon module, can be realized, and the residual glue rate of the glass surface is very low.

Owner:HEBEI UNIVERSITY

Ramie biological degumming method

ActiveCN105525360AReduce energy consumptionReduce pollutionVegetable materialChemistryLight pollution

The invention relates to a ramie biological degumming method. The method comprises carrying out activation on Bacillus sp. HG-28 as a strain, carrying out enlarge cultivation, carrying out dilution to obtain a degumming bacterial liquid F for ramie biological degumming, immersing raw ramie in the degumming bacterial liquid F and carrying out biological degumming. The ramie biological degumming method has small energy consumption, light pollution, short biological degumming time, process operation easiness, high degumming efficiency, short bacterial culture time and a low cost. The refined dry ramie has high quality, a low residual gum rate and high breaking strength, has appearance and all indexes superior to first-order refined dry ramie national standards GB / T 20793-2006 and has a wide large scale production prospect.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Processing technology of fibrilia for seedling base cloth

InactiveCN108754620AReduce intensityImprove mechanical propertiesCarding machinesMechanical fibre separationCardingEngineering

The invention discloses a processing technology of fibrilia for seedling base cloth, andthe processing technology flow is as follows: after mechanically and repeatedly rolling of the raw hemp, the fine fibrilia is obtained by facilitating pre-soaking, boiling, softening, dewatering and drying and mechanical post-treatment. The processing method realizes good degumming effect by using three flow steps of mechanical pretreatment, pre-leaching and boiling off, in particular to the degumming treatment of the fibrilia by using an acid-base coordination compound enzyme, the residual gum rate is low,the process flow is simple, and the fine fibers are favorably obtained. By using the softening and mechanical post-processing, the fine fibrilia is further obtained through slow carding, the strengthof the fibrilia is reduced, and the fiber is uniformly distributed, so that the prepared seedling base cloth has stable quality, and the mechanical property can well meet the requirement of seedlingraising and seedling cultivation.

Owner:JIANGXI JINGZHU IND

Frozen-irradiated auxiliary degumming process for china-hemp fibers

InactiveCN101275289BHigh whitenessGood flexibilityFibre treatment to obtain bast fibreBreaking strengthOxygen

Owner:TAIYUAN UNIV OF TECH

A kind of extraction method of eucalyptus bark fiber

ActiveCN109162136BLow boiling pointReduce the residual fat ratePulping with inorganic basesCellulose treatment using microorganisms/enzymesPectinaseCrude fibre

The invention discloses an extraction method of eucalyptus bark fibers. The extraction method comprises the following steps: cutting eucalyptus barks; adding deionized water, pectinase and lipase intoa cylinder, heating the mixture to 45 DEG C, putting the crushed eucalyptus barks in the cylinder to be soaked and filtered, and then drying the eucalyptus barks with steam at a high temperature; blending boron trifluoride into a 26% alcohol solution, brushing the surfaces of dried eucalyptus thin barks with the solution, and brushing the eucalyptus barks; adding a potassium carbonate solution into a cooking pot, putting the brushed eucalyptus thin barks to be heated and pressurized, and washing the barks with water; putting the washed eucalyptus thin barks in an opener to be opened; mixing deionized water, chlorine dioxide and sodium carbonate uniformly, then adding the washed coarse fibers, soaking the mixture and washing the mixture; dehydrating and drying the washed coarse fibers andloosening the fibers by a carding machine to obtain the eucalyptus bark fibers. The eucalyptus bark fibers extracted by the extraction method are uniform in fiber and few in impurity and the quality of the eucalyptus bark fibers is ensured.

Owner:安徽九天印务有限公司

Extraction method of eucalyptus bark fibers

ActiveCN109162136ALow boiling pointReduce the residual fat ratePulping with inorganic basesCellulose treatment using microorganisms/enzymesFiberPectinase

The invention discloses an extraction method of eucalyptus bark fibers. The extraction method comprises the following steps: cutting eucalyptus barks; adding deionized water, pectinase and lipase intoa cylinder, heating the mixture to 45 DEG C, putting the crushed eucalyptus barks in the cylinder to be soaked and filtered, and then drying the eucalyptus barks with steam at a high temperature; blending boron trifluoride into a 26% alcohol solution, brushing the surfaces of dried eucalyptus thin barks with the solution, and brushing the eucalyptus barks; adding a potassium carbonate solution into a cooking pot, putting the brushed eucalyptus thin barks to be heated and pressurized, and washing the barks with water; putting the washed eucalyptus thin barks in an opener to be opened; mixing deionized water, chlorine dioxide and sodium carbonate uniformly, then adding the washed coarse fibers, soaking the mixture and washing the mixture; dehydrating and drying the washed coarse fibers andloosening the fibers by a carding machine to obtain the eucalyptus bark fibers. The eucalyptus bark fibers extracted by the extraction method are uniform in fiber and few in impurity and the quality of the eucalyptus bark fibers is ensured.

Natural plant fibre extraction by alkali oxidation

InactiveCN100430533CReduce the probability of residual glueLow lignin contentFibre treatment to obtain bast fibrePlant fibreOxygen

The invention provided an alkaline extracting method of the natural plant fiber. The process is: the material->acid etch->washing->alkaline with oxygen->strike the fiber->washing by the water->washing by the acid->washing by the water->dehydration->shake the fiber->oil feed->dehydration->air dry or oven dry. The fiber can be protected by adding the assistant Mg<2+>, the stability of the H2O2 in the alkali and the chemical assistant, also the nucleophilic reaction of the H2O2 to lignine can reach the best efficient. It can be used for extracting the plant fiber of the spinning, weaving and the dressing.

Owner:QINGDAO UNIV

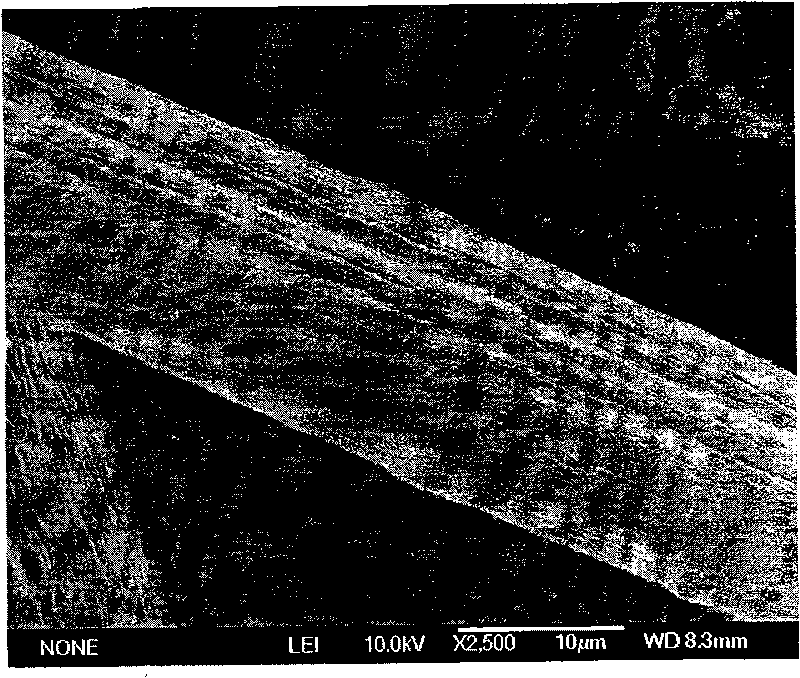

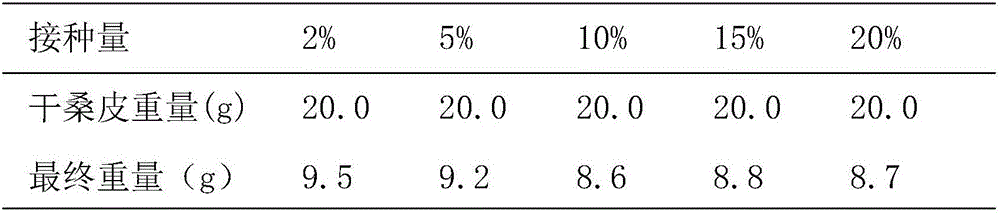

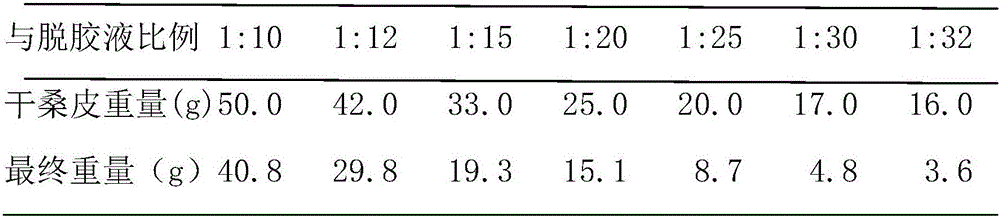

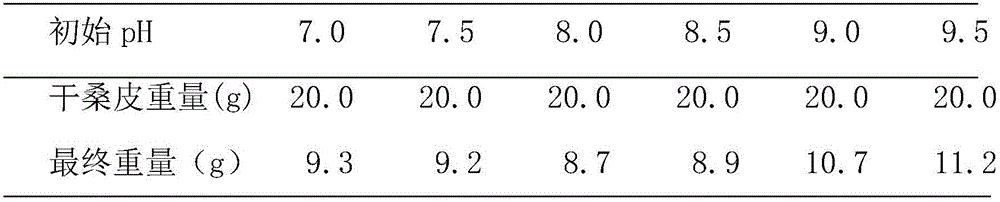

Degumming process for mulberry fibre by bacilli compound bacteria

InactiveCN101285212BEfficient removalReduce the probability of residual glueBacteriaMicroorganism based processesFiberSludge

The invention provides a method for degumming mulberry fiber with bacteria complex flora. The method uses mulberry as a culture medium for a carbon source to filter the bacteria complex flora with good degumming effect to the mulberry from sludge of a methane tank, substrate sludge of a pool, wood, banana land and other samples, has dried mulberry directly immersed into degumming liquid, and inoculates the cultured degumming complex bacterial flora into the degumming liquid for degumming, so that loose mulberry fiber can be obtained via water rinsing and drying. The method has the advantages of mild process condition and simple operation, need not use strong acid or strong alkali, has the manufacturing cost greatly reduced compared with a chemical degumming method, has lower environmentalpollution, less cull in the prepared mulberry fiber and white and loose fiber.

Owner:GUANGXI UNIV

Processing technology of bamboo fibers for seedling culture base fabric

InactiveCN108728911AUniform distribution of poresReduce intensityMechanical fibre separationFibre treatment to obtain bast fibreCardingPre treatment

The invention relates to a processing technology of bamboo fibers for a seedling culture base fabric. A flow of the processing technology comprises the following steps: after mechanically and repeatedly rolling bamboo wood; carrying out pre-impregnation, scouring, softening, dehydration and drying, and mechanical post-treatment to obtain fine bamboo fibers. According to the processing technology provided by the invention, a good degumming effect is realized by utilizing three flow steps including mechanical pre-treatment, the pre-impregnation and the scouring; especially, scouring liquid prepared by matching acid and alkali with a complex enzyme is used for carrying out degumming treatment on the bamboo fibers; the residual gum rate is relatively low and a technological flow is simple; relatively fine fibers are easy to obtain. Softening and mechanical post-treatment are utilized; furthermore, the fine bamboo fibers are obtained through slow-speed carding, the strength of the bamboo fibers is reduced and the fibers are uniformly distributed, so that the prepared seedling culture base fabric has stable quality and the mechanical properties can meet the utilization requirements of seedling culture and rice seedlings culture very well.

Owner:江西创迪科技有限公司

Natural freezing and mechanical combined degumming method for fibrilia

InactiveCN111676520ALow costImprove efficiencyMechanical fibre separationFibre treatment to obtain bast fibrePulp and paper industryEnvironmental engineering

The invention provides a natural freezing and mechanical combined degumming method for fibrilia. The method comprises the following steps of: low-temperature treatment: exposing hemp stalks and placing the hemp stalks under the natural condition of -10 to -30 DEG C in winter in northeast for 30-90 days; peeling treatment: placing the fibrilia subjected to low-temperature treatment into a peeling machine for treatment; mechanical beating: removing colloid of fibrilia bundles and separating fibers by using a softening machine through a feeding area, a mechanical kneading area, a beating impurityremoval area, a discharging area and an impurity removal device; and post-treatment process: cleaning the fibers with an alkali solution, then washing the fibers with distilled water for a pluralityof times until the fibers are close to neutral, and drying the fibers for later use to complete degumming. The degumming method provided by the invention adopts natural freezing and mechanical combined degumming, and compared with other process methods, the method has the advantages that the treatment cost is reduced on the whole, the emission of pollutants is reduced, the damage to the fibrilia is reduced, the performance of the fibrilia is improved, and the method is a fibrilia degumming process with low cost, high efficiency and environmental protection.

Owner:JILIN UNIV

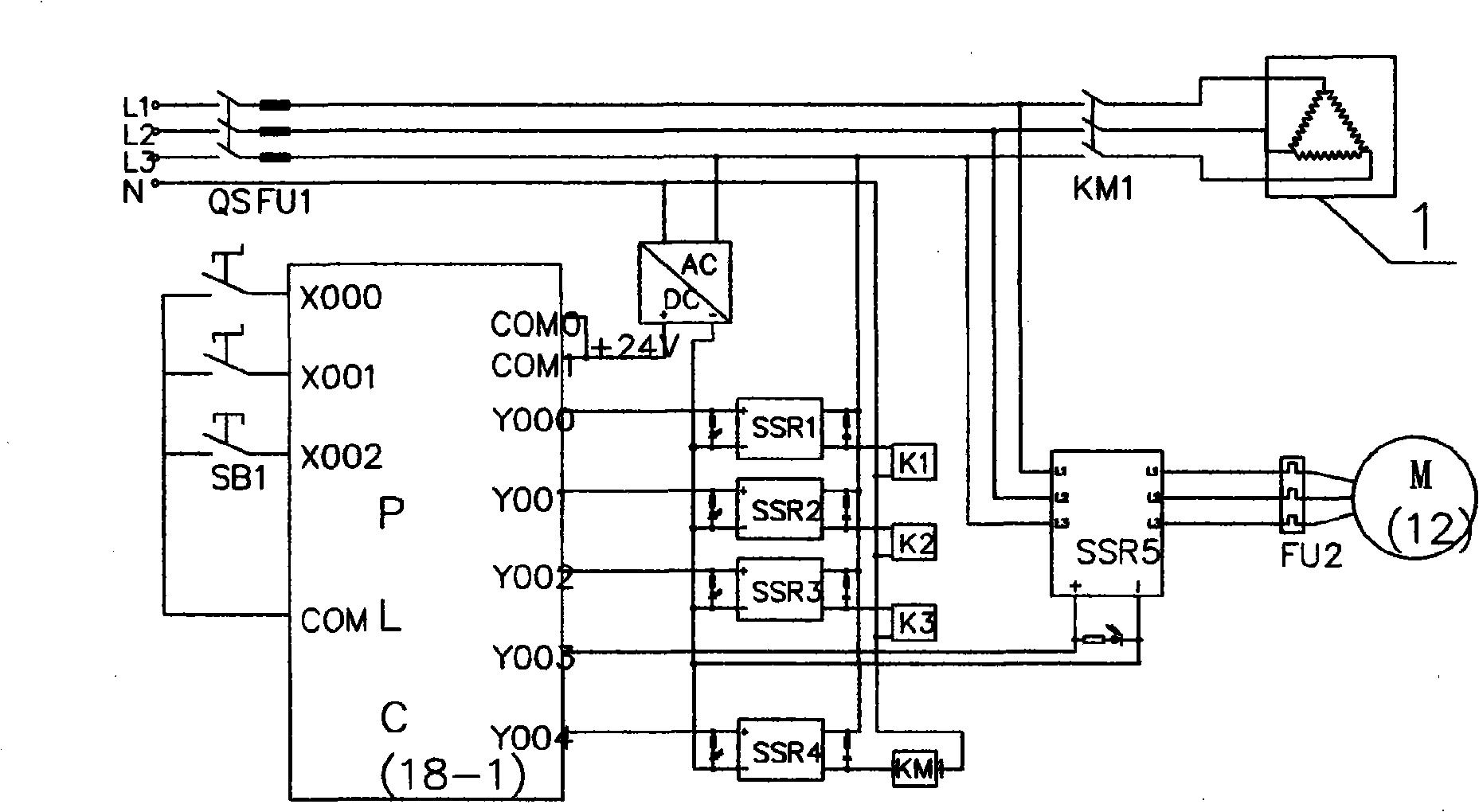

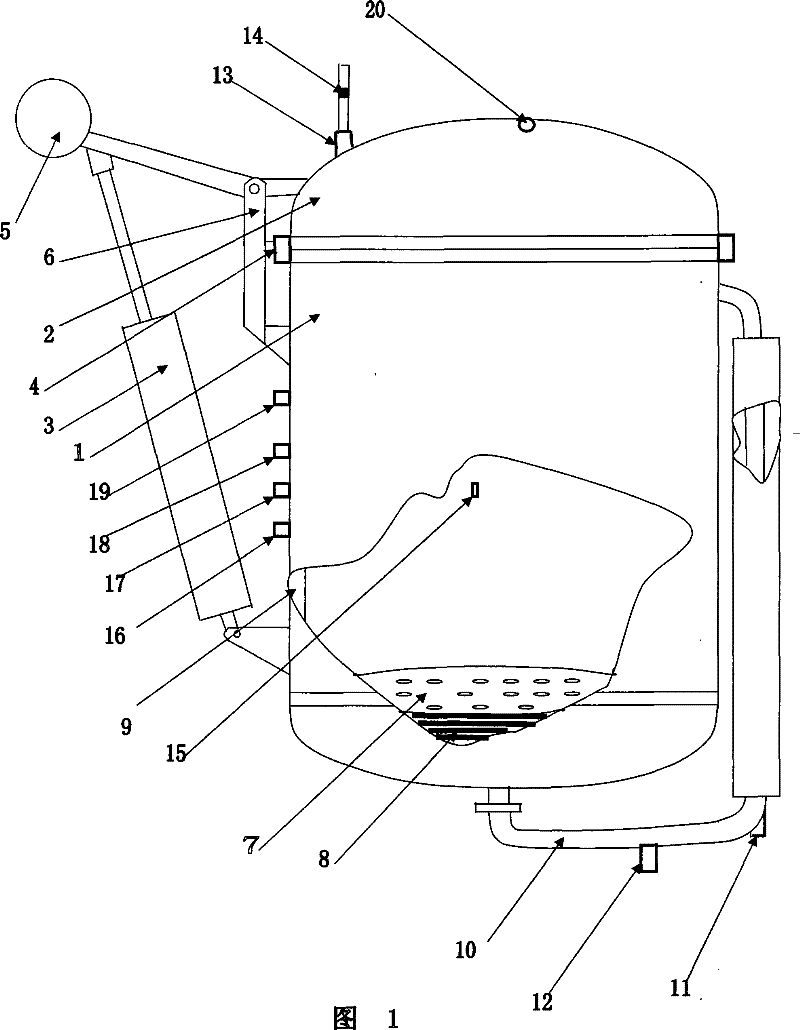

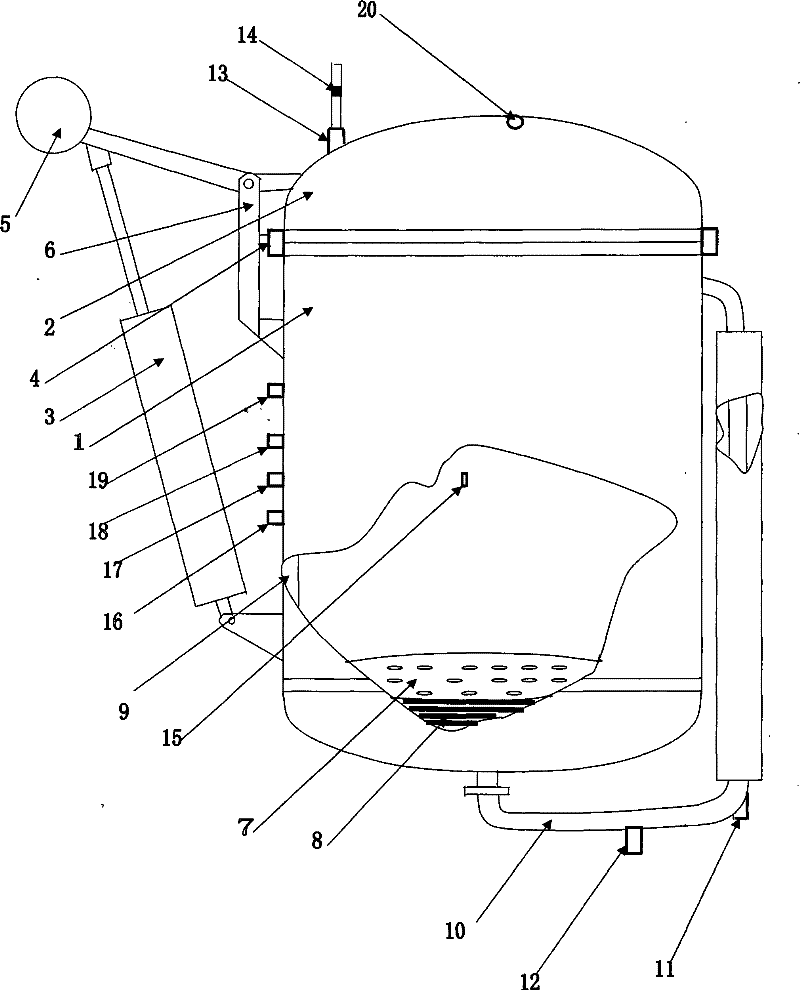

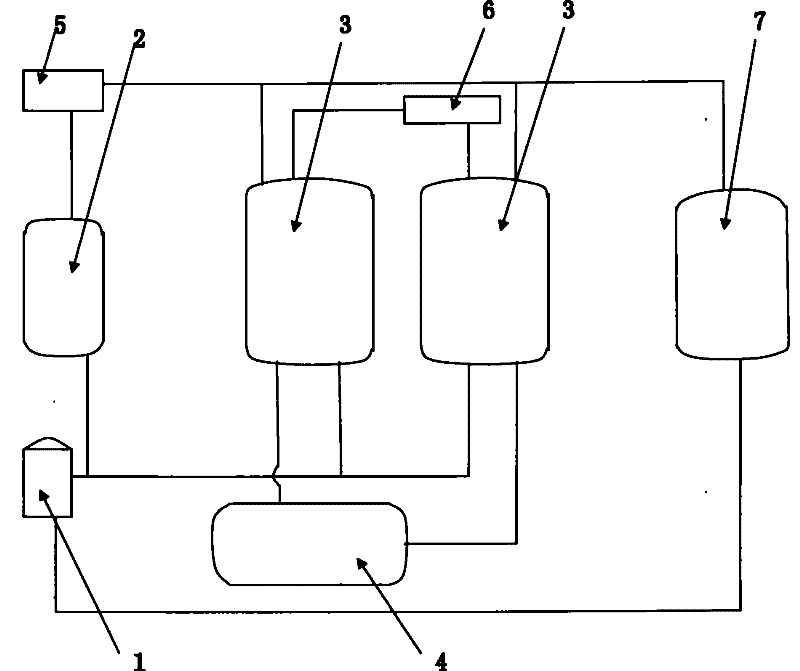

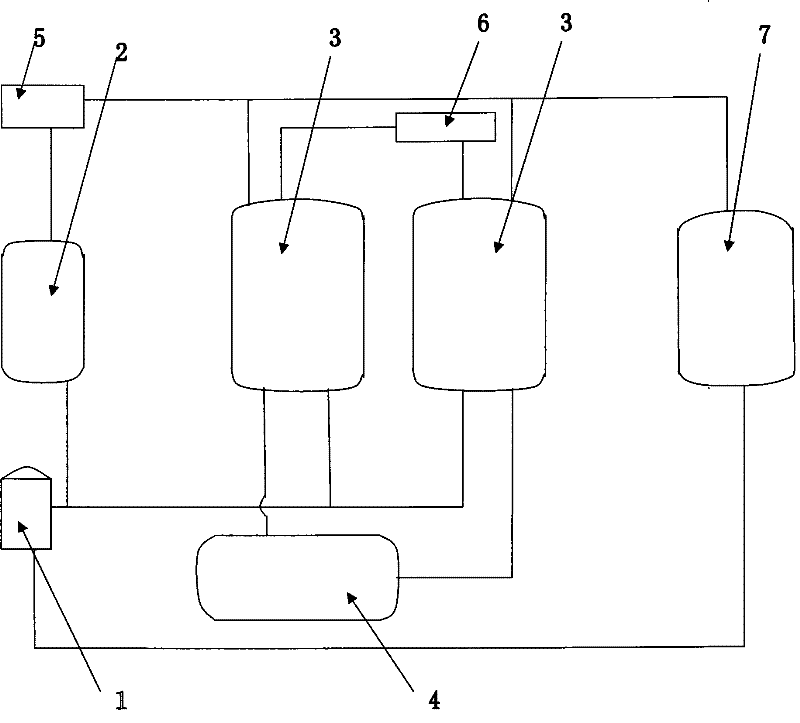

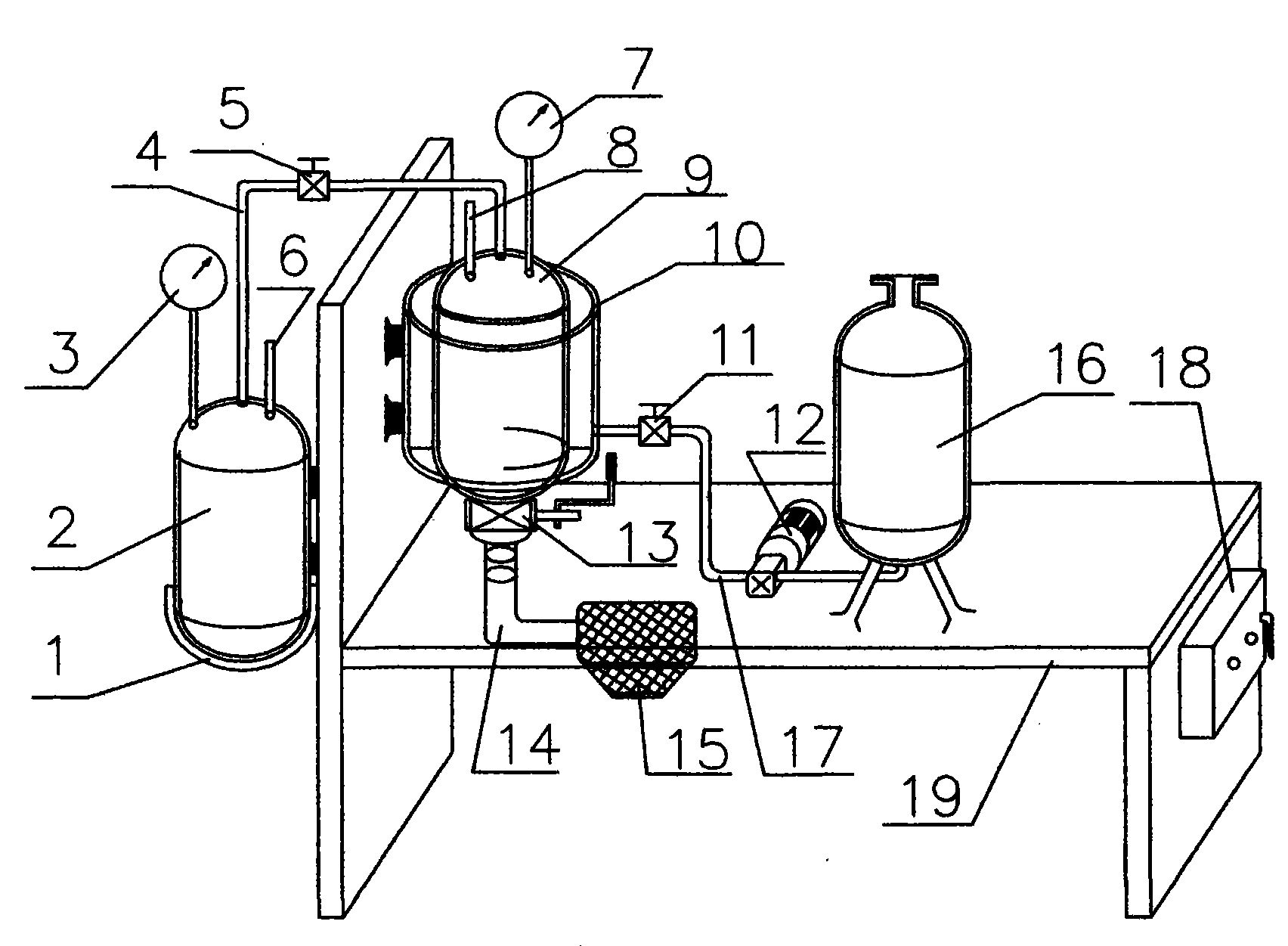

Biological degumming tank

ActiveCN101560697BReduce consumptionAlkali light corrosionBacteriological rettingBiochemical engineeringPollution

The invention provides a biological degumming tank which is characterized in that a tank body is internally provided with a temperature-regulating device, the outer side wall of the tank body is provided with a jacket regulating the temperature of a space in the tank body, the tank body is externally provided with a circulating pipe used for circulating solution in the tank body, the circulating pipe is internally provided with an air nozzle, and the top of a tank cover is provided with an air outlet. The invention lays the foundation for the industrialization and the scale of bast-fibre biological degumming, lowers the production cost, improves the quality and the yield of bast-fibre, and greatly lightens the pollution to the environment.

Owner:JIANGXI ENDAMA CENTURY TECH

A kind of flax degumming liquid and preparation method thereof

The invention discloses a flax degumming liquid and a preparation method thereof, and relates to a plant fiber degumming liquid and a preparation method thereof, which solve the problems that in a current flax retting degumming method, added microorganisms contaminate a flax retting liquid and the environment, and an added pure enzyme preparation is greatly increased in cost and liable to inactivate. The flax degumming liquid is prepared by fermenting in a konjaku flour fluid nutrient medium for inoculating bacillus licheniformis HDYM-03, and centrifuging to get liquid supernatant. The flax degumming liquid is prepared by the following steps: inoculating the bacillus licheniformis HDYM-03 into the konjaku flour fluid nutrient medium to culture; and then, centrifuging to get the liquid supernatant, thereby obtaining the flax degumming liquid. The flax degumming liquid is short in degumming time, complete in degumming, low in residual gum content, high in cellulose yield and high in strength. The preparation method for the flax degumming liquid is simple and low in cost.

Owner:HEILONGJIANG UNIV

Method for extracting mulberry bark fibers

InactiveCN107523885AGuaranteed qualityImprove production rateVegetable materialMechanical fibre separationFiberSocial benefits

The invention discloses a method for extracting mulberry bark fibers. The synthetic technology uses a biological method as the primary method and a chemical method as the auxiliary method. Through surface skin removing, refining, bleaching, cleaning, softening, drying, carding and other processing technologies, the mulberry bark fibers are extracted and can be applied to the development of mulberry-bark series textile products and mulberry-bark pure or blended products which are high in additional value and good in market prospect, a large quantity of waste mulberry bark and stem resources turn into raw materials which can be used for industrial production and into consumer goods high in additional value. The method has the advantages of being clean in production, high in technological content and good in economic benefit, social benefit and ecological benefit.

Owner:温美群

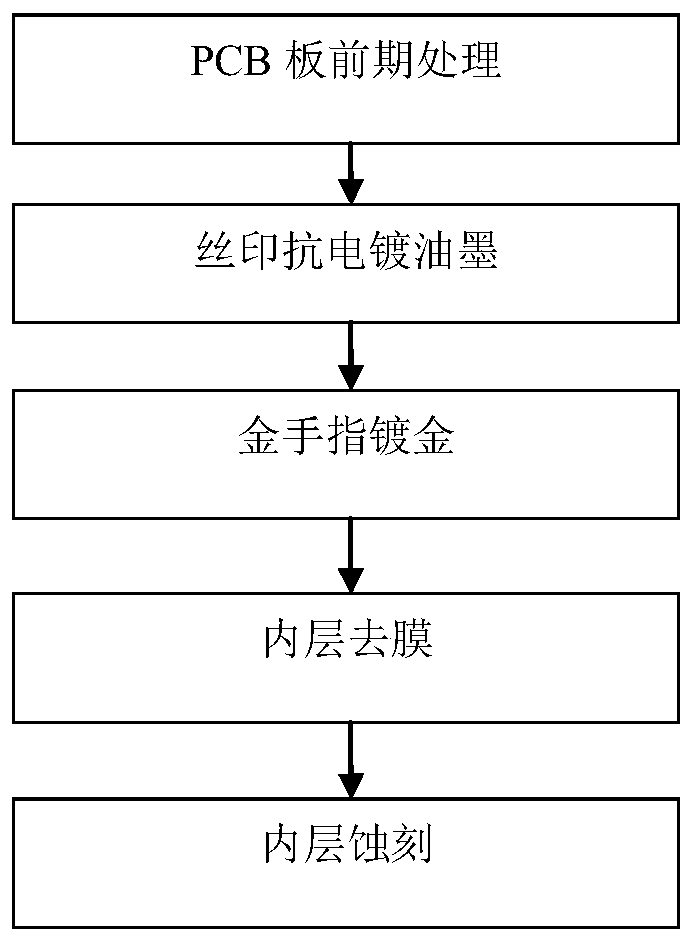

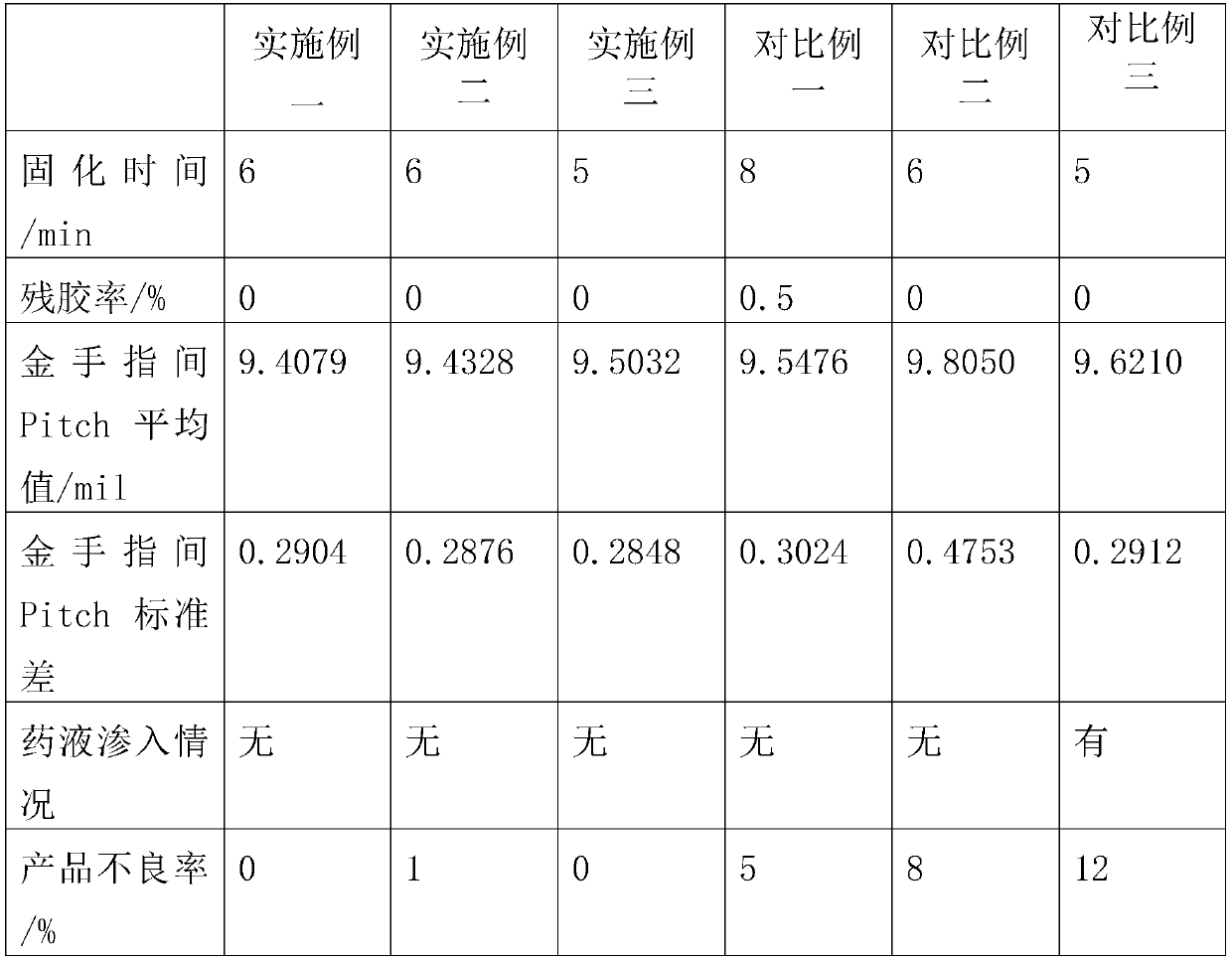

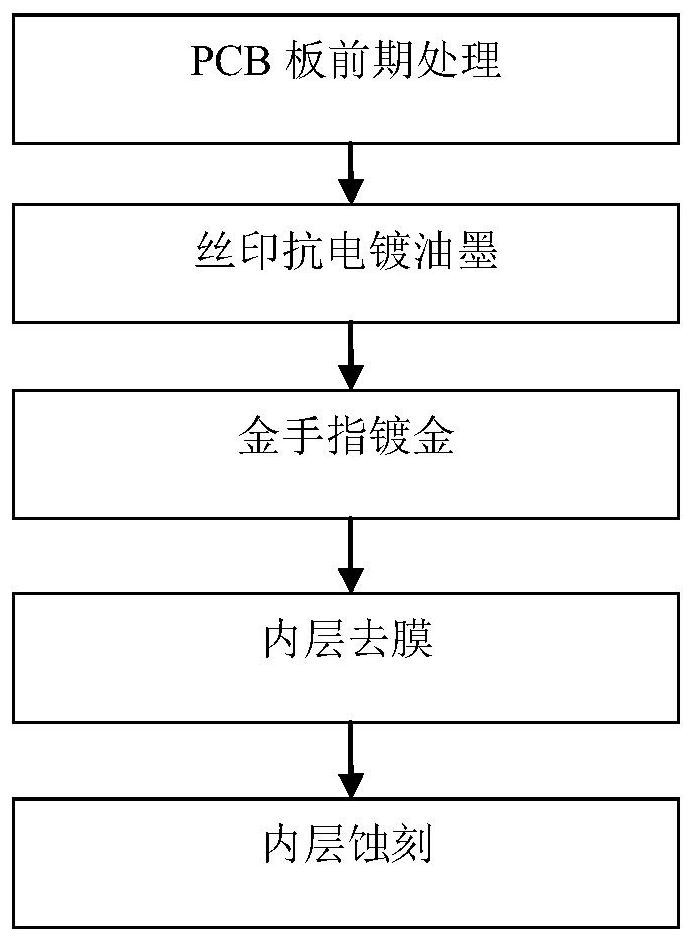

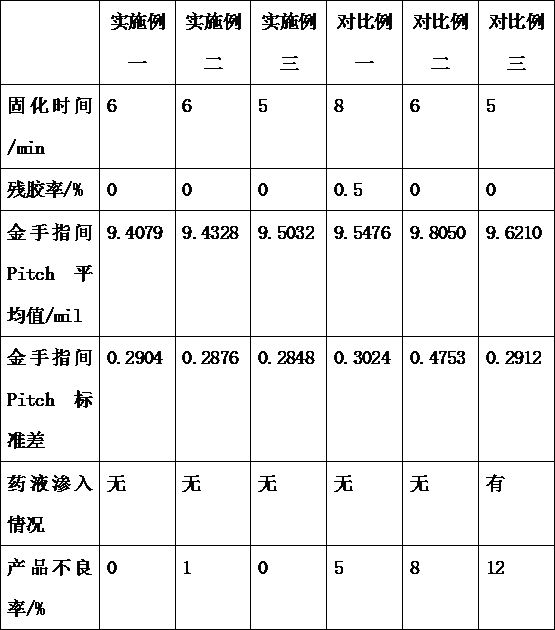

Method for manufacturing hot insertion application gold fingers

ActiveCN109905979AGood pitch flatness between gold fingersShort curing timeConductive material chemical/electrolytical removalConductive pattern reinforcementSolder maskElectroplating

The invention discloses a method for manufacturing hot insertion application gold fingers, comprising the following steps: 1) pre-processing of a PCB board, providing a solder mask layer on the PCB board and performing sand blasting treatment; 2) screen printing of anti-plating ink; 3) gold plating of gold fingers; 4) film removal of the inner layer, fading a wet film formed by the anti-plating ink; and 5) etching of the inner layer. After the wet film formed by the anti-plating ink in the invention is exposed and developed, the Pitch average value between the obtained gold fingers is closer to the design requirement, the standard deviation is smaller from the statistical point of view, that is, the Pitch flatness between the gold fingers is better; in addition, the blue glue in the invention is used, so that the curing time is shorter, and the residual glue rate is lower, the blue glue is filled at an electrogilding gold pinch point after gold plating of the gold fingers is completed,it is ensured that the standing time from etching of the inner layer to film removal of the inner layer is enough, such that the electroplating chemical can be prevented from infiltrating from the pinch point, thereby further reducing the defect rate of the product.

Owner:CHANGSHU MUTUAL TEK CO LTD

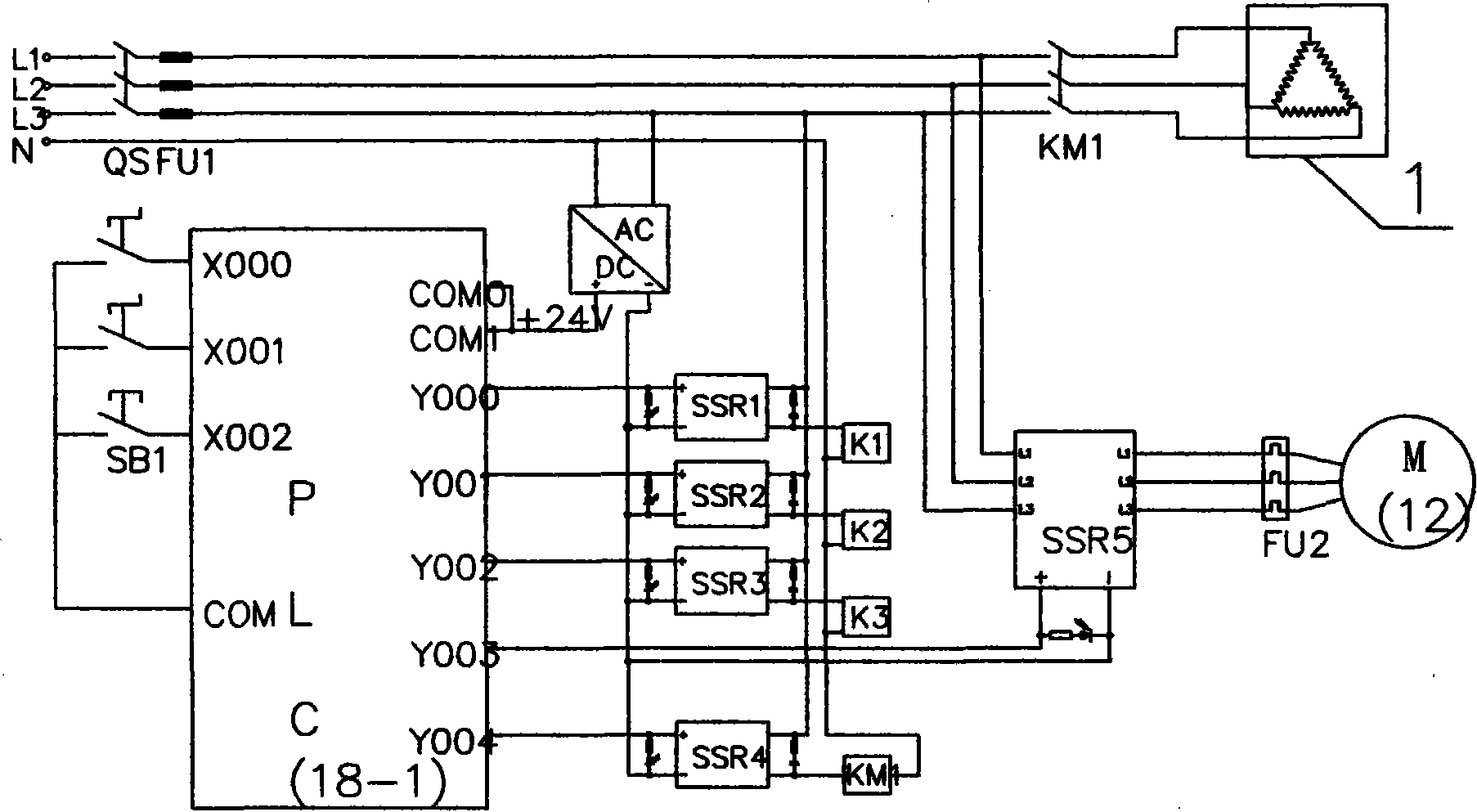

Bast-fibre biological degumming device

ActiveCN101560698BThe degumming process is smoothReduce consumptionBacteriological rettingElectricityBiochemical engineering

Owner:JIANGXI ENDAMA CENTURY TECH

A kind of extraction method of coir fiber

ActiveCN109162132BReduce hydroxylRealize the second degreasingCellulose treatment using microorganisms/enzymesRaw material divisionCrude fibreBiology

The invention discloses a method for extracting coconut fiber. The method comprises the following steps: crushing coconut shell; adding deionized water and lipase into a cylinder, conducting uniform mixing, heating the mixture to 45 DEG C, and soaking the coconut shell into a cylinder for 2-3 h after soaking; adding sodium hydroxide solution in a cooking tank, putting the filtered coconut shell into the cooking tank, heating and pressurizing the mixture, cooking the mixture for 1-1.5 h, taking out the cooked coconut shell, and rinsing off the cooked coconut shell with water for 10-15 min; dissecting the rinsed coconut shell in the step (3) into crude fiber by a filament forming machine, and then rinsing the fiber with water for 10-15 minutes; mixing the deionized water with chlorine dioxide and sodium carbonate uniformly, and then the rinsed crude fiber in the step (4); conducting soaking for 30 to 40 minutes, taking out the fiber, and rinsing the fiber with hot water for 15 to 20 minutes; and dehydrating the dried fiber in the step (5), and then loosening the fiber with a carding machine to obtain the coconut fiber. The coconut shell fiber extracted by the method for extracting the coconut fiber of the invention has uniformity, less impurities, low residual fat ratio, and guaranteed quality.

Owner:安徽九天印务有限公司

Device for separating solar cell module glass

ActiveCN111618913BIntegrity guaranteedGuaranteed efficiencyWaste processingSolid waste disposalLaser scanningEngineering

The invention provides a device for separating glass of a solar battery module. Its structure includes transmission mechanism, scraping mechanism, laser scanning mechanism, control mechanism and clamping mechanism, etc. The invention scans the solar cell components through the laser scanning mechanism, which can firstly reduce the adhesive force between the adhesive film and the glass, and then scrapes the adhesive film by using the heated scraper blade in the scraping mechanism, and the scraper blade cuts into the gap between the glass and the lower component in an oblique upward manner. This way of entering the knife is more convenient, and it can avoid the problem of broken glass or unclean removal of the adhesive film on the glass caused by the small gap between the adhesive film and the glass, which ensures the integrity of the glass and the The residual glue rate on the surface. While scraping, use the clamping mechanism to tear the lower component, which is more conducive to the separation of the glass. The invention can realize high-efficiency separation of complete glass in the solar battery module, especially in the crystalline silicon module, and the residual glue rate on the glass surface is very low.

Owner:HEBEI UNIVERSITY

Method for making hot plug application gold finger

ActiveCN109905979BImprove flatnessShort curing timeConductive material chemical/electrolytical removalConductive pattern reinforcementEtchingMechanical engineering

The invention discloses a method for making a gold finger for hot insertion, which comprises the following steps: 1) pre-treatment of a PCB board, setting a solder resist layer and sandblasting on the PCB board; 2) silk screen printing anti-plating ink; 3) gold finger Gold plating; 4) removing the inner layer, removing the wet film formed by the anti-plating ink; 5) etching the inner layer. After the anti-plating ink in the present invention is used to form a wet film and then exposed and developed, the average value of the Pitch between the gold fingers obtained is closer to the design requirements, and the standard deviation is smaller from a statistical point of view, that is, the pitch between the gold fingers is better; In addition, the blue glue in the present invention is used, the curing time is shorter, the residual glue rate is lower, and the blue glue is subsidized at the pinch point of the electroplating gold after the gold finger gold plating is completed, and it is ensured that the inner layer is etched until the inner layer removes the film. Sufficient setting time can prevent the electroplating liquid from penetrating from the pinch point, thereby further reducing the defective rate of products.

Owner:CHANGSHU MUTUAL TEK CO LTD

Microbiological degumming method for mulberry fibre

InactiveCN100529201CReduce consumptionReduce pollutionMicroorganismsVegetable materialFiberMicroorganism

The microbial degumming method of the mulberry fiber disclosed by the invention, the method is to carry out infiltration treatment on the mulberry bark first, and then use the degumming bacteria screened and cultivated from the collected mulberry bark to inoculate the infiltrated mulberry bark for degumming, Then, the degummed fibers are sequentially washed, softened, dehydrated and dried, and finally opened, carded and packaged. Because the present invention uses microbial degumming, it not only reduces the consumption of chemicals such as strong acid and strong alkali, reduces production costs, reduces environmental pollution, and equipment corrosion, but also shortens the process flow, reduces labor intensity, and improves The efficiency is improved, the output is increased, and the fiber is separated more completely, the residual glue rate of the fiber is lower, and the ratio of doubling and stalks is reduced, which greatly improves the quality and production rate of mulberry fiber.

Owner:SICHUAN UNIV +1

Microbiological degumming method for smartweed fibre

InactiveCN100535202CReduce consumptionReduce pollutionMicroorganismsVegetable materialMicroorganismFiber

The method for microbial degumming of nettle fiber disclosed by the invention comprises the steps of soaking nettles first, and then inoculating the soaked nettles with degumming bacteria screened and cultivated from collected distiller's grains Degumming is carried out, and then the degummed fibers are washed, oiled, dehydrated and dried in sequence, and finally opened, carded and packaged. Since the present invention adopts microbial degumming, it can not only reduce the consumption of chemicals such as strong acids and alkalis used in conventional chemical methods, reduce production costs, reduce environmental pollution and equipment corrosion, but also shorten the process flow and reduce labor intensity. , improve efficiency, increase output, and also make the fiber separation more complete, the fiber residual glue rate is lower, and the ratio of parallel silk and stems is reduced, which greatly improves the quality and production rate of nettle fiber.

Owner:SICHUAN UNIV

Flash-explosion hemp degelatinizing technology with cryogenic processing and device

InactiveCN101255609BAvoid damageAchieve primary separationMechanical treatmentFibre treatment to obtain bast fibreEngineeringHigh pressure

The invention relates to a hemp degumming technology using a steam explosion with a low-temperature treatment and a device. The invention relatest to the hemp degumming technology, in particular to the steam explosion hemp degumming technology, comprising: firstly ramie is marinated for 15 hours in the temperature of 25 deg C; then the ramie which is already marinated by water is put into a groove which contains a solution of NaOH with a concentration of 18 percent to be processed alkali treatment; then the ramie is kept in high pressure; after being kept in high pressure the hemp fiber is processed a decompression steam explosion treatment with the low-temperature treatment. The hemp degumming technology of the invention has the advantages of that a low rate of incomplete glue, light fibre damage, no pollution, reducing cost of degumming, saving degumming time.

Owner:LANYAN GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com