Flash-explosion hemp degelatinizing technology with cryogenic processing and device

A low-temperature treatment and flash explosion technology, applied in mechanical treatment, fiber treatment, chemical method to produce bast fibers, etc., can solve the problems of fiber damage, high glue residue rate, labor and time-consuming, etc., and achieve slight fiber damage and glue residue. The effect of low rate and no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

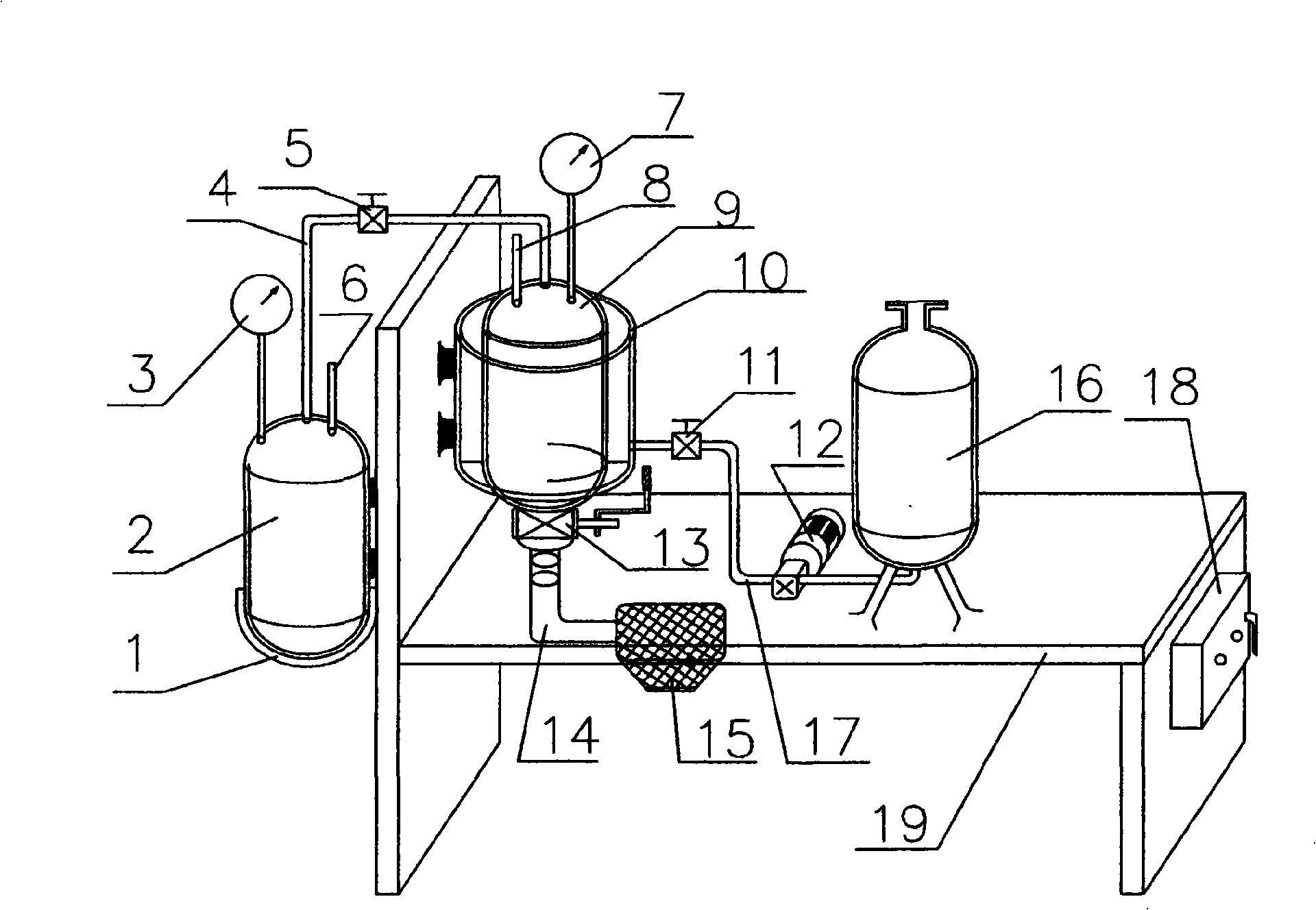

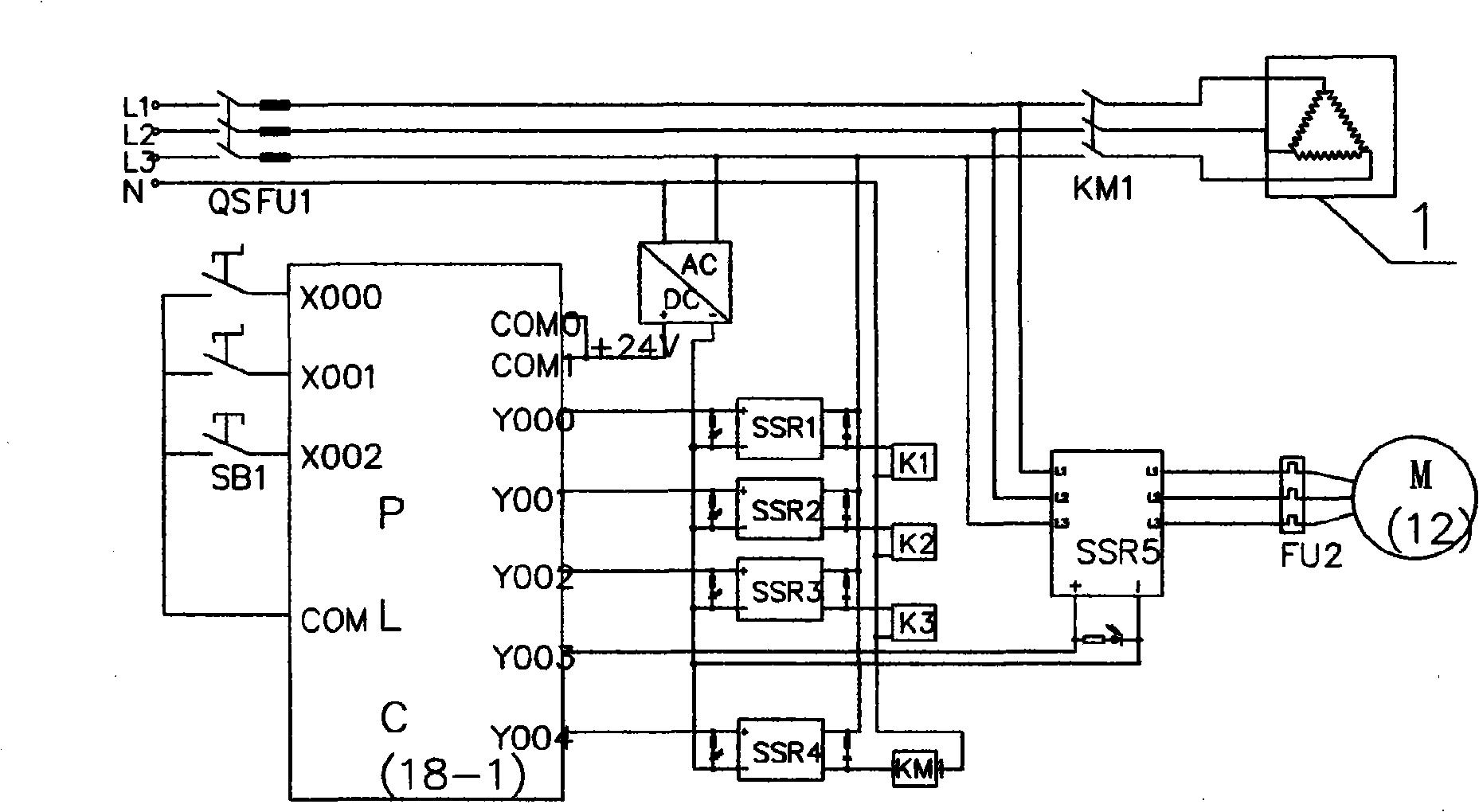

[0009] A flash-explosion hemp degumming technology accompanied by low-temperature treatment, characterized in that the ramie is first soaked at 25°C for 15 hours, and then the ramie fiber soaked in water is put into a tank with a concentration of 18% NaOH solution Alkali treatment is carried out in the medium, followed by high-pressure maintenance for ramie, and decompression flash explosion treatment with low-temperature treatment for hemp fibers after high-pressure maintenance.

[0010] The first step: carry out the water treatment process, immerse 30kg of hemp fibers in a tank filled with water, let the water cover the fibers, and soak for 15 hours at a temperature of 25°C. Then remove the fibers from the sink and use a centrifuge to remove excess water.

[0011] Step 2: Alkali treatment is carried out to the fibers soaked in water, and the hemp fibers are put into a tank with a concentration of 18% NaOH solution, so that the NaOH solution is not over the hemp fibers. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com