Bast-fibre biological degumming device

A biological degumming and hemp technology, applied in the direction of bacterial retting, can solve the problems of inapplicability of chemical degumming tanks, damage to fiber quality, and inability to recover acid and alkali, and achieves the increase of fiber length distribution, production cost reduction, and strength improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

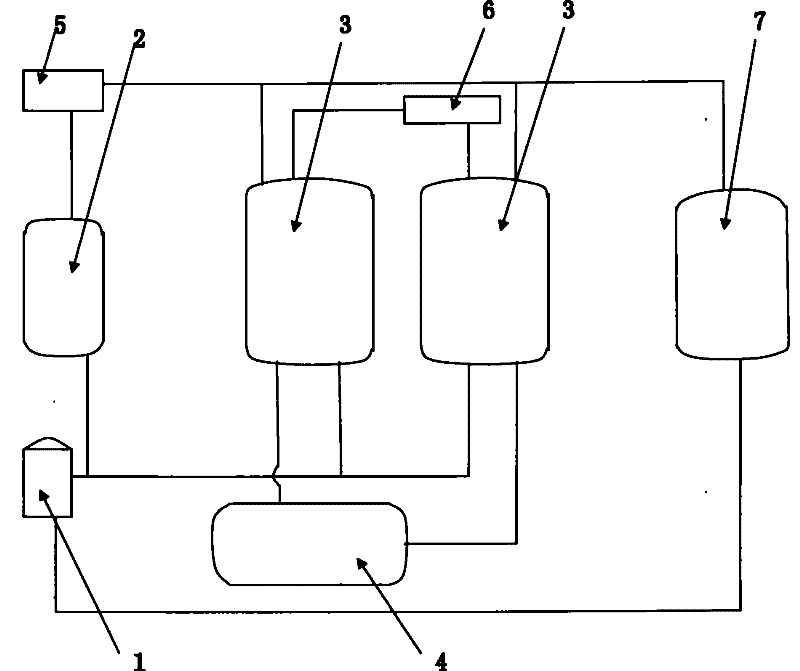

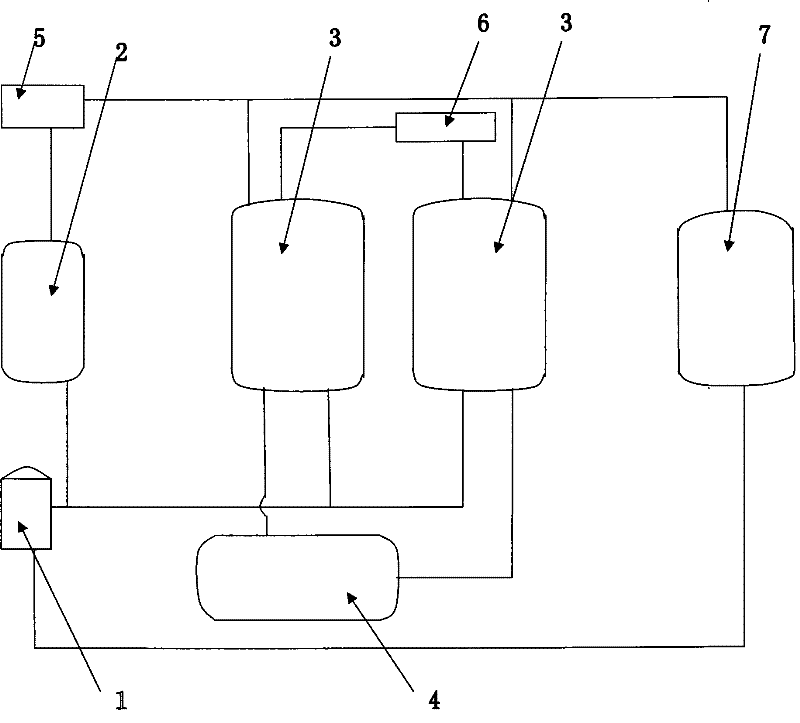

[0018] See attached figure 1 , the structure and production process of this device are:

[0019] One, the steam in the steam generator 1 is introduced into the seed tank 2 (the quantity of the seed tank 2 is determined according to the production scale, which is more than one.), the seed tank 2 is subjected to high-temperature sterilization, and after sterilization, it is lowered to a suitable temperature. Place the basophilic bacillus in it, adjust the dissolved oxygen, temperature and other parameters, and prepare it into a bacterial liquid whose solubility and other parameters meet the requirements. During the fermentation process, when the temperature in the seed tank 2 is higher than the set value, the system automatically opens the cold water solenoid valve to cool down; when the temperature in the tank is lower than the set value, the system automatically turns on the hot water circulation pump. The operation modes of the stirring motor in the seed tank include manual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com