Method for manufacturing hot insertion application gold fingers

A manufacturing method and technology for gold fingers, which are applied in chemical/electrolytic methods to remove conductive materials, reinforce conductive patterns, and form electrical connection of printed components, etc. Liquid infiltration and other problems, to achieve the effect of sufficient dwell time, short curing time and low residual glue rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

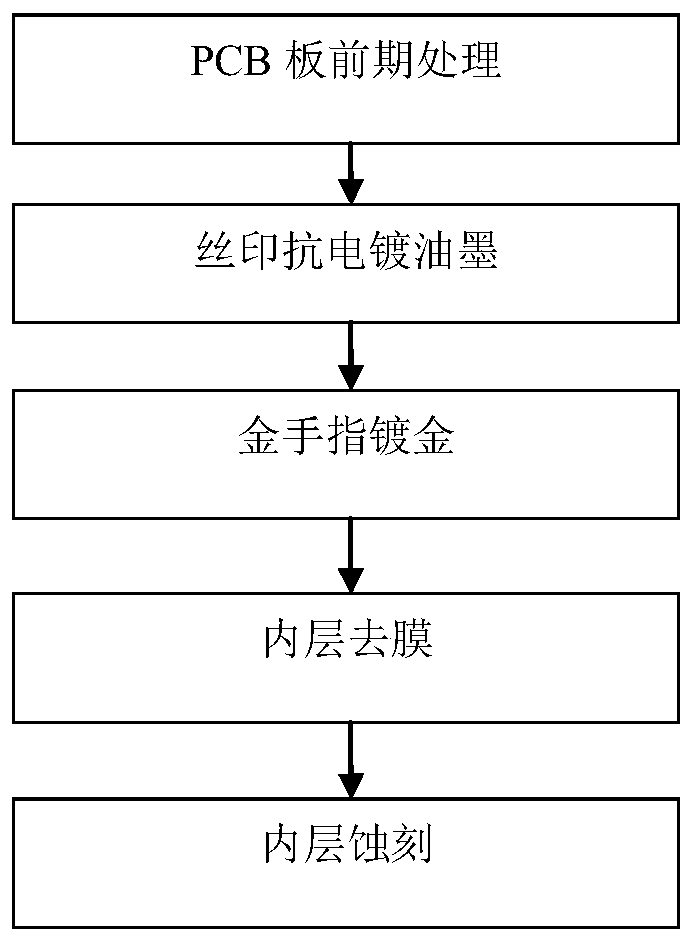

[0040] like figure 1 As shown, a method for making a gold finger for hot insertion in the present invention includes the following steps:

[0041] 1) Pre-treatment of the PCB board, setting a solder mask and sandblasting treatment on the PCB board;

[0042] 2) Silk-screen anti-plating ink, silk-screen anti-plating ink on the gold finger area and after exposure and development, cover the gold finger guide line part in the circuit board;

[0043] 3) The gold finger is gold-plated, the whole board is pasted with blue glue and the window is opened in the gold finger area for gold-plated treatment;

[0044] 4) the inner layer removes the film, and removes the wet film formed by the anti-plating ink;

[0045] 5) Inner layer etching, etch to remove the gold finger wires.

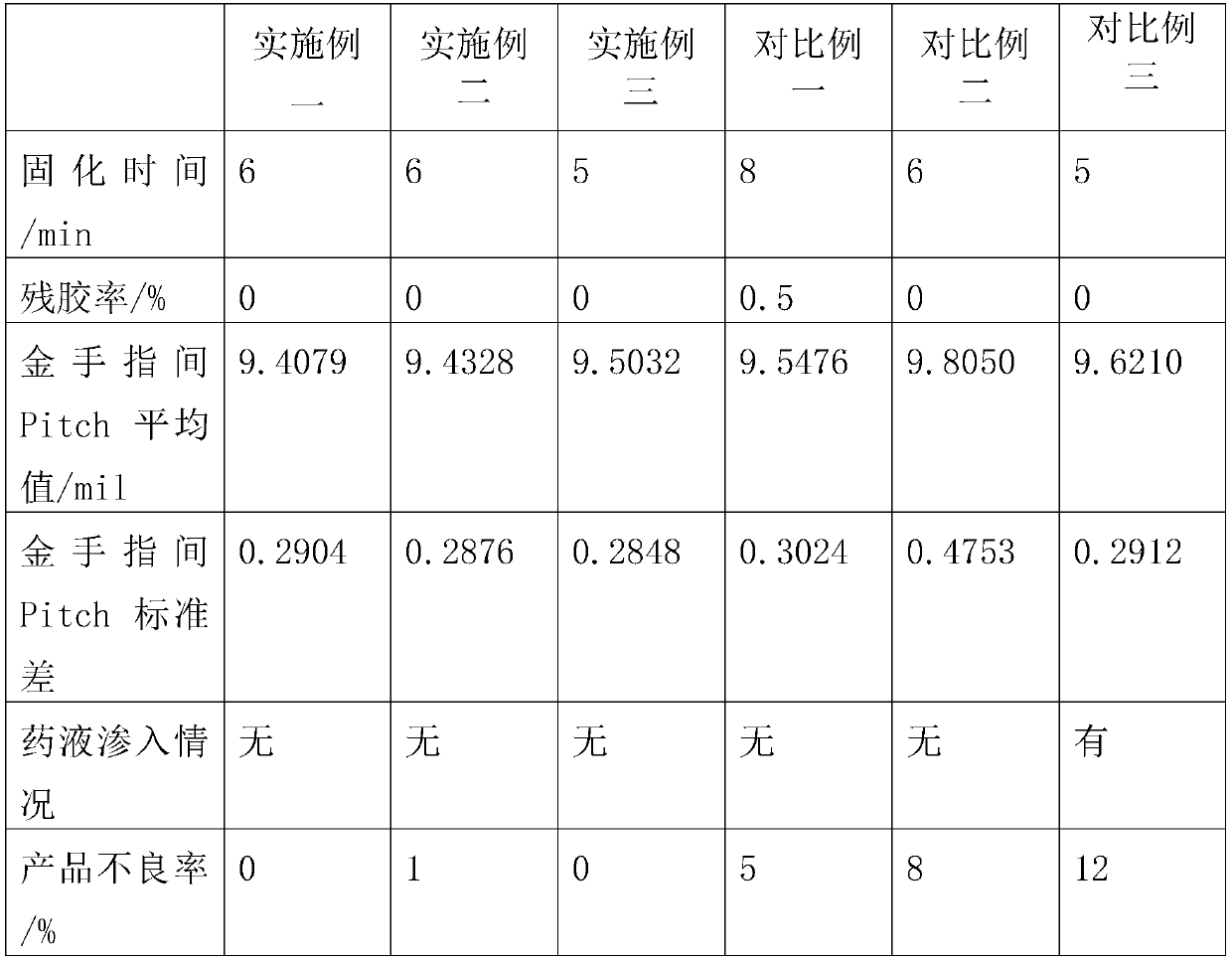

[0046] Wherein, the blue glue includes the following components by weight: 35 parts of vinyl acetate resin, 16 parts of alkyd resin, 20 parts of epoxy resin, 9 parts of acrylate monomer, 2.5 parts of light curin...

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 is that the blue glue includes the following components by weight: 40 parts of vinyl acetate resin, 14 parts of alkyd resin, 18 parts of epoxy resin, 9 parts of acrylate monomer, and 2.8 parts of curing agent, 1.5 parts of thixotropic agent, 4.5 parts of pigment, 0.4 part of cellulose acetate butyrate, 8 parts of nano calcium sulfate whiskers, 2 parts of butyl benzyl phthalate; the rest are the same as in Example 1.

Embodiment 3

[0051] The difference between this embodiment and Embodiment 1 is that the blue glue includes the following components by weight: 38 parts of vinyl acetate resin, 15 parts of alkyd resin, 19 parts of epoxy resin, 10 parts of acrylate monomer, light 2.7 parts of curing agent, 1.4 parts of thixotropic agent, 4.0 parts of pigment, 0.45 parts of cellulose acetate butyrate, 9 parts of nano-calcium sulfate whiskers, 1.5 parts of butyl benzyl phthalate, and the light curing agent is isopropyl Thioxanthone; All the other are identical with embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com