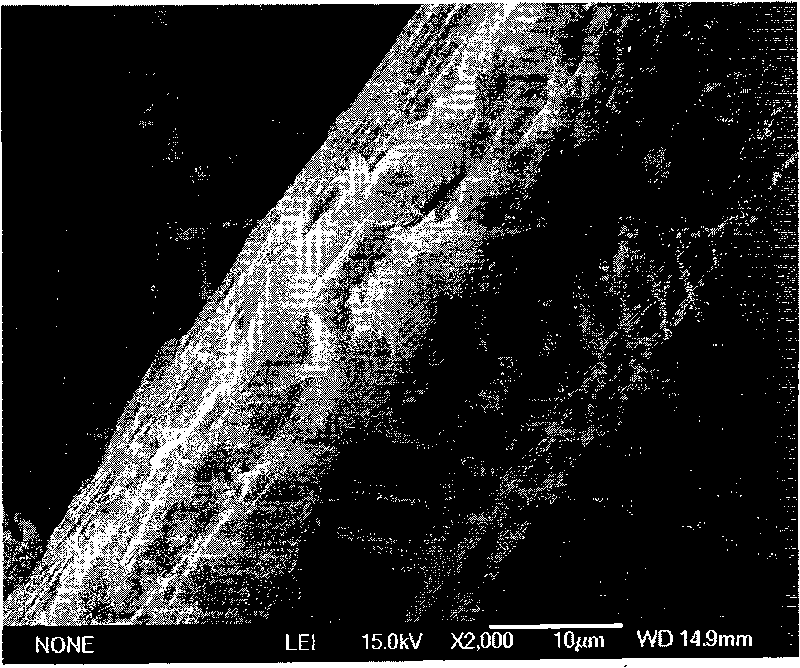

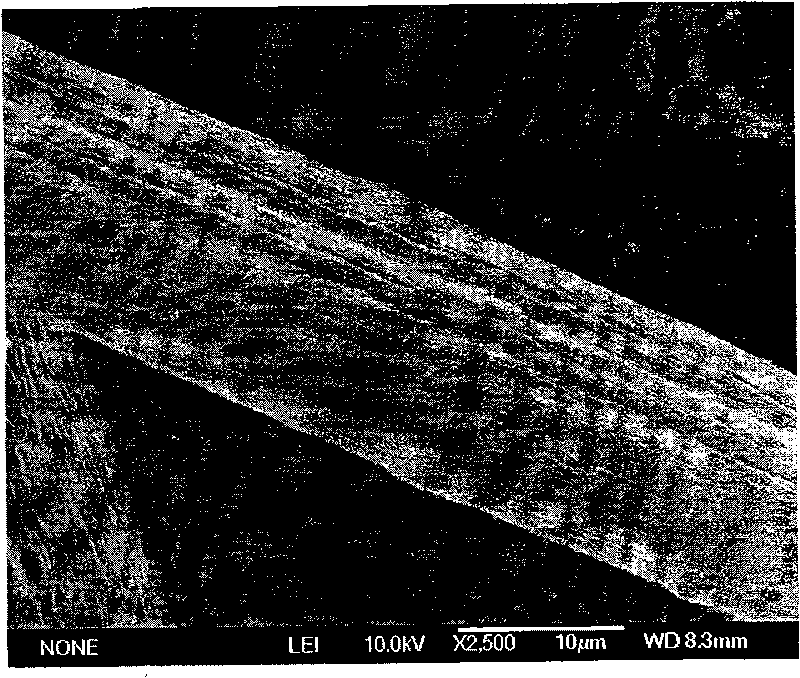

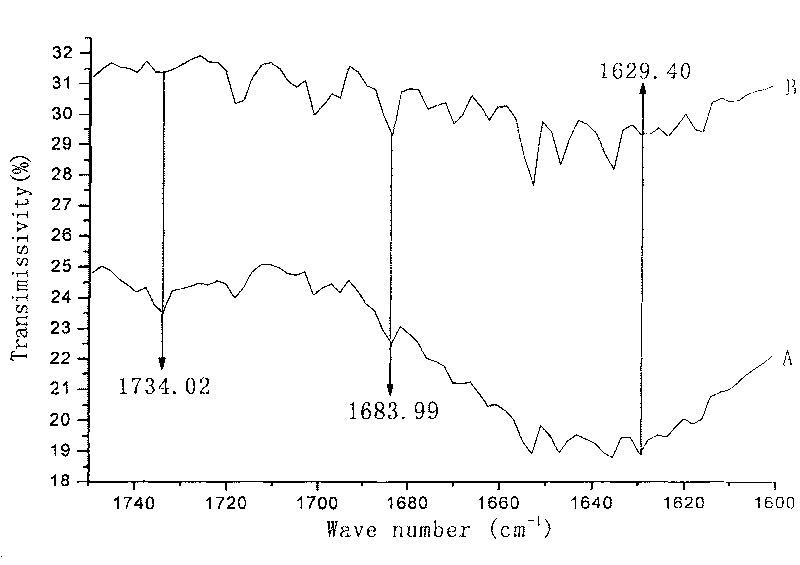

Frozen-irradiated auxiliary degumming process for china-hemp fibers

A hemp fiber and fiber technology, which is applied in the field of hemp fiber freezing and radiation-assisted degumming technology, can solve the problems of high residual glue rate, low whiteness and softness, unsatisfactory lignin removal effect, etc., and achieve improved wearing performance, The effect of length and fineness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0039] The detailed process step of hemp fiber freezing radiation assisted degumming process of the present invention is as follows:

[0040] 1. Hot water bath treatment

[0041] At 80°C, completely soak the fiber with deionized water (the concentration of the fiber in the solution is 25g / L) for 100min, and use a stirrer to stir clockwise / counterclockwise every 10min to make it soak evenly. Wash several times with water until the pH value of the soaking solution is 7.

[0042] 2. Pre-soaking treatment

[0043] At 60°C, use dilute sulfuric acid with a concentration of 9.8g / L to completely soak Gansu hemp raw hemp (the concentration of fiber in the solution is 25g / L) for 100min, and alternately stir clockwise / counterclockwise every 10min to make it soak evenly. Wash several times with water until the pH value of the soaking solution is 7.

[0044] 3. Pre-chlorination treatment

[0045] At room temperature, adjust the pH value to 4, use sodium hypochlorite with an available c...

Embodiment approach 2

[0058] According to the process method of embodiment 1, the difference of embodiment 2 is:

[0059] 1. During UV radiation, the concentration of hydrogen peroxide is 10g / L, the concentration of sodium hydroxide is 10g / L, the concentration of magnesium sulfate is 3g / L, the wavelength of ultraviolet radiation is 280nm, and the radiation time is 30min.

[0060] 2. During alkaline oxygen scouring, the scouring time is 150min, the scouring temperature is 100°C, the stirrer speed is 150r / min, and the stirring method is alternating clockwise / counterclockwise every 30min.

[0061] 3. During the second scouring, add 20g / L nano softener MS-2 for hemp.

Embodiment approach 3

[0063] According to the process method of embodiment 1, the difference of embodiment 3 is:

[0064] 1. During UV radiation, the concentration of hydrogen peroxide is 14g / L, the concentration of sodium hydroxide is 14g / L, the concentration of magnesium sulfate is 4g / L, the wavelength of ultraviolet radiation is 350nm, and the radiation time is 50min.

[0065] 2. During alkaline oxygen scouring, the scouring time is 200min, the scouring temperature is 120°C, the speed of the agitator is 200r / min, and the stirring method is alternating clockwise / counterclockwise every 20min.

[0066] 3. When scouring for the second time, add 40g / L strong soft flake soft T20 for textile use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com