Instant whole egg powder free of bitter taste and fishy smell, and preparation method thereof

A technology of whole egg powder and bitter taste, which is applied in the field of egg powder processing, can solve the problems of poor solubility, slow reconstitution, insufficient dissolution, etc., and achieves the effects of improving solubility and improving instant solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

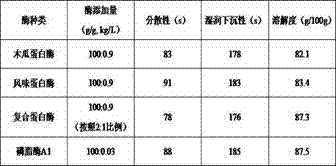

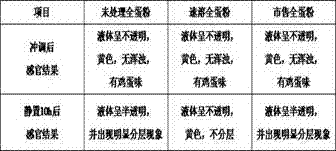

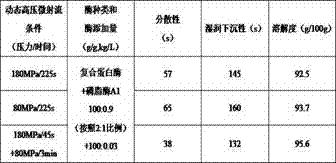

Embodiment 1

[0034]Select 10kg of fresh eggs produced within 3 days of the same chicken breed and the same batch in a chicken farm, disinfect and clean, dry the surface moisture of the eggshell, break the shell and take out the contents, stir the egg liquid at room temperature for 30min, and the stirring speed of the stirring paddle is 200r / min, then filter, pasteurize at 62°C for 30min; then carry out two-stage dynamic high-pressure micro-jet treatment, the homogeneous pressure of the first stage is 180MPa, the processing time is 45s, the homogeneous pressure of the second stage is 80MPa, and the treatment The time is 3 minutes; then enzymatic hydrolysis is divided into two stages: the first stage, at 50°C, use compound protease for 20 minutes; the second stage, after the protease is hydrolyzed, stop heating, directly put in phospholipase A1, and enzymatically hydrolyze for 3 hours at room temperature . Described composite protease is papain and flavor protease, and the consumption ratio...

Embodiment 2

[0037] Select 10kg of fresh eggs produced within 3 days of the same chicken breed and the same batch in a chicken farm, disinfect and clean, dry the surface moisture of the eggshell, break the shell and take out the contents, stir the egg liquid at room temperature for 30min, and the stirring speed of the stirring paddle is 200r / min, then filter, pasteurize at 63°C for 30min; then carry out two-stage dynamic high-pressure micro-jet treatment, the homogeneous pressure of the first stage is 200MPa, the processing time is 30s, the homogeneous pressure of the second stage is 120MPa, and the treatment The time is 2 minutes; then enzymatic hydrolysis is divided into two stages: the first stage, at 48°C, use compound protease to hydrolyze for 25 minutes; the second stage, after the protease is hydrolyzed, stop heating, directly put in phospholipase A1, and enzymatically hydrolyze for 4 hours at room temperature . Described composite protease is papain and flavor protease, and the co...

Embodiment 3

[0040] Select 10kg of fresh eggs produced within 3 days of the same chicken breed and the same batch in a chicken farm, disinfect and clean, dry the surface moisture of the eggshell, break the shell and take out the contents, stir the egg liquid at room temperature for 30min, and the stirring speed of the stirring paddle is 200r / min, then filter, pasteurize at 65°C for 30min; then carry out two-stage dynamic high-pressure micro-jet treatment, the homogeneous pressure of the first stage is 150MPa, the processing time is 60s, the homogeneous pressure of the second stage is 100MPa, and the treatment The time is 5 minutes; then enzymatic hydrolysis is divided into two stages: the first stage, at 45°C, use compound protease to hydrolyze for 30 minutes; the second stage, after protease hydrolysis, stop heating, directly put in phospholipase A1, and enzymatically hydrolyze for 5 hours at room temperature . Described composite protease is papain and flavor protease, and the consumpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com