Improved vegetable oil enzymatic degumming method

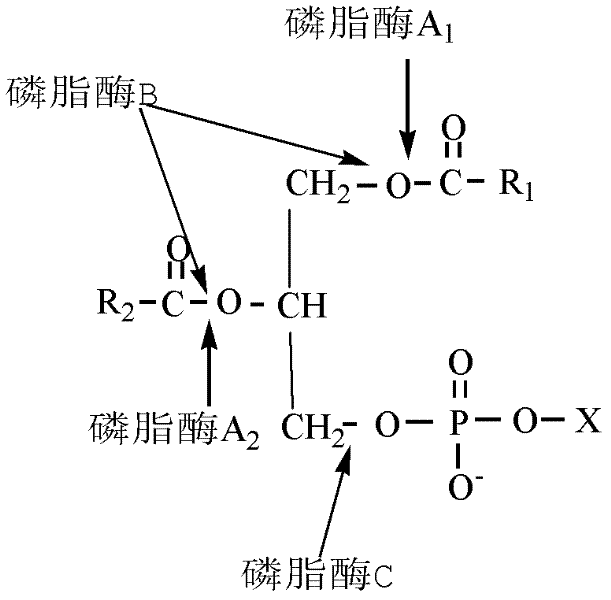

A degumming method and vegetable oil technology, applied in the field of vegetable oil degumming, can solve the problems of prolonged production cycle, increased equipment investment, long enzyme reaction time, etc., and achieve the effect of reducing volume and improving degumming effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 250g crude soybean oil in a 500ml Erlenmeyer flask, the phosphorus content of crude soybean oil is 128.5mg / kg, heat to 80°C in a water bath, then add 0.30ml 45% citric acid solution, mix homogeneously, put back to Incubate in a water bath at 80°C for 20 minutes of acid reaction, shaking from time to time during the reaction. Cool the sample after the acid reaction to 55°C, then add 1.60ml of 4% NaOH solution and 5mL of distilled water, stir and mix evenly, then add lightly homogenize for 10 seconds, then add about 5ml of water, homogenize for 10 seconds and mix well, then add 0.75 mL of 10-fold diluted Lecitase Ultra (a product of Novozymes, with phospholipase A1 activity) phospholipase, homogeneously mixed.

[0031] Place the triangular flask in a water bath at 50°C, and carry out the enzyme reaction under 300-500rpm mechanical stirring for 6 hours. After the reaction, heat the water bath to 80°C, then centrifuge at 4000 rpm for 5 minutes, and take the upper oil ...

Embodiment 2

[0033] The difference between this embodiment and embodiment 1 is:

[0034]Place the triangular flask in a water bath at 50°C, and carry out the enzyme reaction under mechanical stirring at 300-500rpm for 1.5 hours. After the reaction, heat the water bath to 80°C, then centrifuge at 4000 rpm for 5 minutes, and take the upper oil phase to analyze the phosphorus content. , the results are shown in Table 1.

Embodiment 3

[0036] The difference between this embodiment and embodiment 1 is:

[0037] Place the triangular flask in a water bath at 50°C, and carry out the enzyme reaction for 1.5 hours under mechanical stirring at 300-500 rpm. After the reaction, heat the water bath to 70°C and maintain it for 90 minutes, then centrifuge at 4000 rpm for 5 minutes, and take the upper oil phase for analysis. Phosphorus content, the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com