Recombinant Escherichia coli, and method for preparing phospholipase A1 through using recombinant Escherichia coli

A technology for recombining Escherichia coli and phospholipase, which is applied in the fields of genetic engineering and microbial fermentation, can solve the problems of difficult large-scale production, limited extraction, high price, etc., and achieves the effects of short production cycle, easy process amplification and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

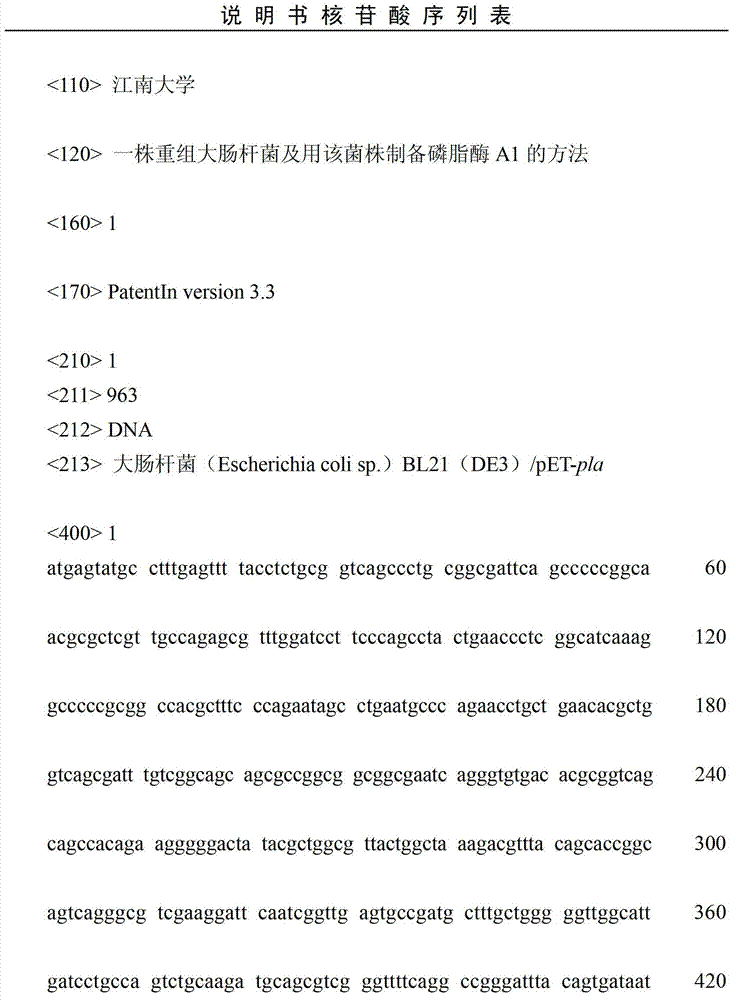

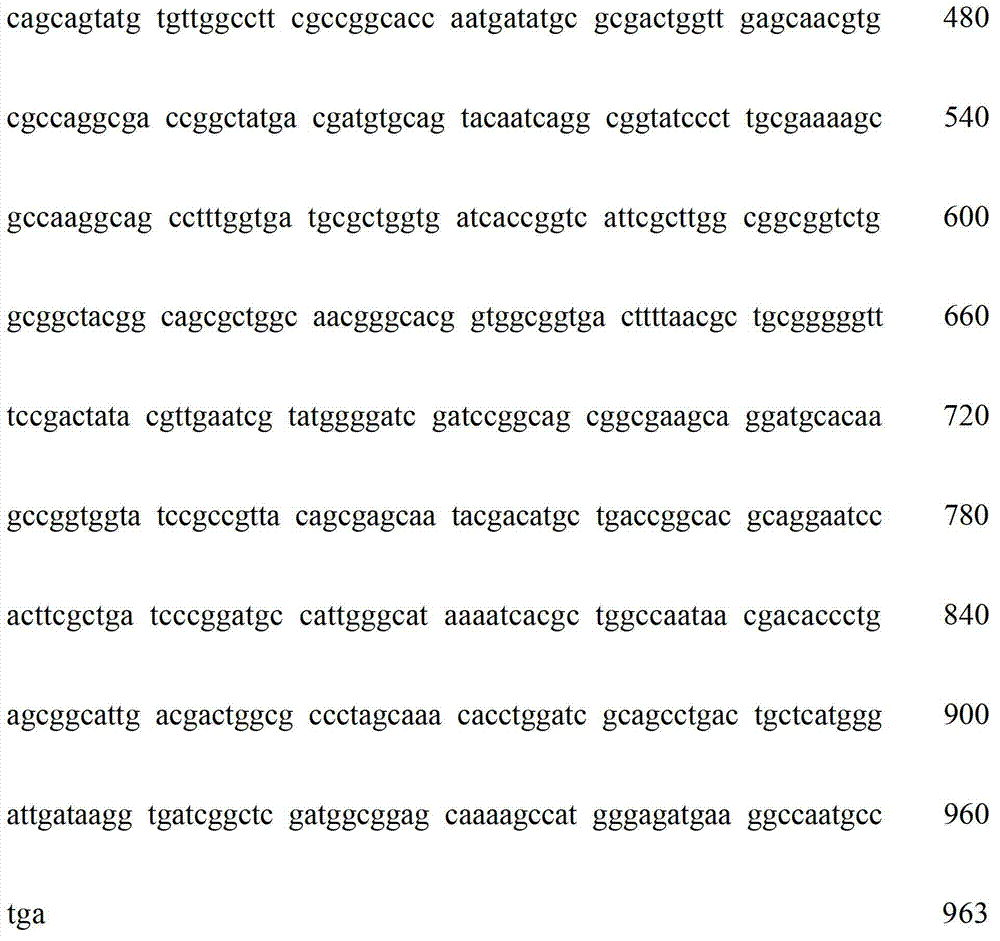

[0029] Example 1 Phospholipase A 1 gene cloning

[0030] Design primers according to the gene sequence of NCBI GenBank: X66505.1, where the upstream primer is: 5′-CG GAATTC AGTATGTCTTTGAGTTTTACCTCTGC-3' (the underline indicates the EcoR Ⅰ restriction site), the downstream primer is: 5'-CC AAGCTT CGTTACTGCTGTCCGTATTGC-3' (the underline indicates the HindⅢ restriction site).

[0031] Phospholipase A was cloned by using the PCR method (primers as above) using Serratia liquefaction genomic DNA with the preservation number CICC No. 21538 as a template 1 The gene pla was connected with the vector pMD18T-simple to obtain the cloning vector pMD-pla. The cloning vector was transformed into Escherichia coli competent cell E.coli JM109, and positive clones were selected and verified by sequencing. Its base sequence is shown in SEQ ID NO: 1 showed that the results showed that phospholipase A 1 Gene cloning was successful. Sequence analysis showed that the gene sequence was identical...

Embodiment 2

[0032] The construction of embodiment 2 recombinant vector pET-pla

[0033] The recombinant vector pMD-pla and the expression vector pET-28a (+) were double digested with EcoR Ⅰ and Hind Ⅲ. The enzyme digestion reaction system was 50 μL: vector 20 μL, enzyme reaction buffer 5 μL, EcoR Ⅰ 2.5 μL, Hind Ⅲ 2.5 μL, supplemented Double-distilled deionized water to 50 μL, reacted at 37°C for 2 hours. Recover the digested target gene and carrier DNA, and connect them with T4 DNA ligase, ligation reaction system 10 μL: target gene 2 μL, carrier DNA 1 μL, 10×T4 ligase buffer 1 μL, T4 DNA ligase 1 μL, double distilled deionized water 5 μL , reacted at 16°C for 12 hours.

[0034] Transform the ligation product into Escherichia coli competent cells E.coli JM109, the transformation method is as follows:

[0035] (1) Take 100 μL of E.coli JM109 and place it in a sterile 1.5ml EP tube;

[0036] (2) Add the above ligation product and mix gently;

[0037] (3) Put the above EP tube in a metal...

Embodiment 3

[0042] Example 3 Construction of recombinant Escherichia coli BL21(DE3) / pET-pla CCTCC M 2012423

[0043] Transform the constructed recombinant vector pET-pla into Escherichia coli BL21 (DE3), the transformation method is as follows:

[0044] (1) Take 100 μL of E.coli BL21 (DE3) and place it in a sterile 1.5ml EP tube;

[0045] (2) Add the above recombinant plasmid pET-pla and mix gently;

[0046] (3) Put the above EP tube in a metal bath at 42°C, accurately time it for 90 seconds, and do not shake the EP tube;

[0047] (4) Transfer the EP tube to an ice bath and cool for 5-10 minutes;

[0048] (5) Add 800 μL of sterile SOC medium to each tube, and place in a 37°C incubator to recover for 1 hour;

[0049] (6) Centrifuge at 8000r / min for 2min, suck off 800μL of supernatant medium, gently blow and suck the remaining medium and cells with a pipette gun, and transfer to LB solid containing final concentration of 50μg / ml kanamycin Plate, spread evenly and incubate in a 37°C incu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com