Production process for producing chitin and efficiently removing pigments

A production process and technology for chitin, which is applied in the field of production technology for producing chitin with high efficiency for depigmentation, can solve the problems of prolonging the production cycle of chitin and slow depigmentation, so as to shorten the decolorization time, reduce the production cycle and improve the production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

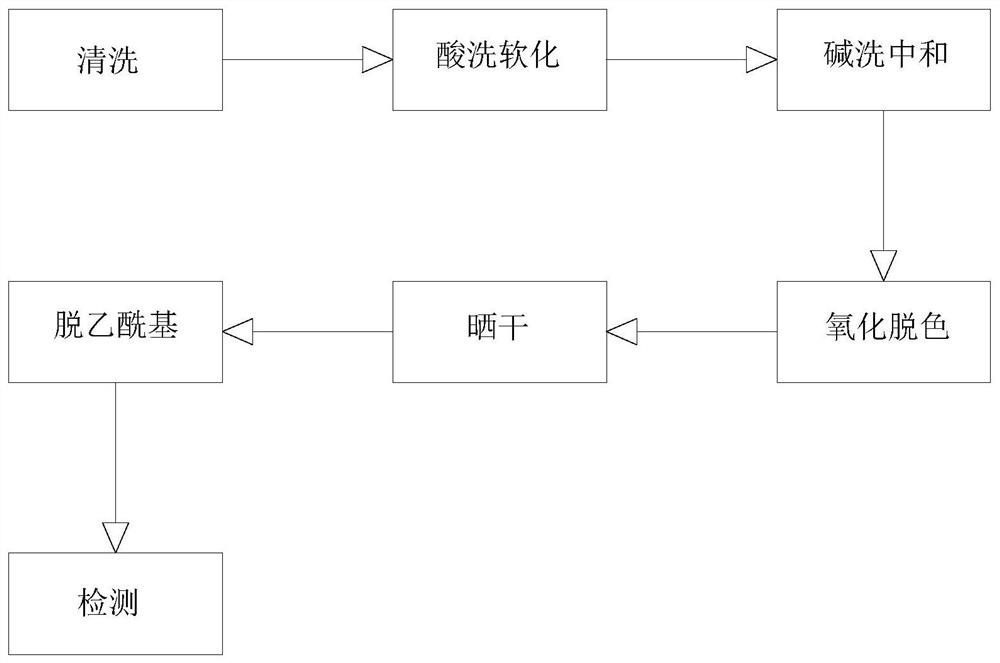

[0024] A kind of production technology of producing chitin efficient depigmentation, described production technology comprises the steps:

[0025] (1) Cleaning, prepare an appropriate amount of shrimp shells or crab shells, soak the shrimp shells or crab shells in clean water, and then use a brush to scrub. After scrubbing, pour off the water and repeat the above steps.

[0026] (2) Pickling and softening. The shrimp shells or crab shells treated in step (1) are soaked in dilute hydrochloric acid according to a certain ratio, and soaked for a certain period of time until no bubbles are generated.

[0027] (3) Alkaline washing and neutralization, putting the shrimp shells or crab shells treated in step (2) into a pot, and putting an appropriate amount of sodium hydroxide solution into the pot, and then boiling.

[0028] (4) Oxidative decolorization, transfer the processed shrimp shells or crab shells in step (3) to the bucket, then put water and potassium permanganate decoloriz...

Embodiment 2

[0041] A kind of production technology of producing chitin efficient depigmentation, described production technology comprises the steps:

[0042] (1) Cleaning, prepare an appropriate amount of shrimp shells or crab shells, soak the shrimp shells or crab shells in clean water, and then use a brush to scrub. After scrubbing, pour off the water and repeat the above steps.

[0043] (2) Pickling and softening. The shrimp shells or crab shells treated in step (1) are soaked in dilute hydrochloric acid according to a certain ratio, and soaked for a certain period of time until no bubbles are generated.

[0044] (3) Alkaline washing and neutralization, putting the shrimp shells or crab shells treated in step (2) into a pot, and putting an appropriate amount of sodium hydroxide solution into the pot, and then boiling.

[0045] (4) Oxidative decolorization, transfer the processed shrimp shells or crab shells in step (3) to the bucket, then put water and potassium permanganate decoloriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com