A kind of method for the preparation of Yunzhi glycopeptide

A technology of Yunzhi glycopeptide and mycelium, applied in the biological field, can solve the problems of low yield of Yunzhi glycopeptide, hinder product development, low economic benefits, etc., and achieve the improvement of production technology and industrialization level, easy separation, The effect of high decolorization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

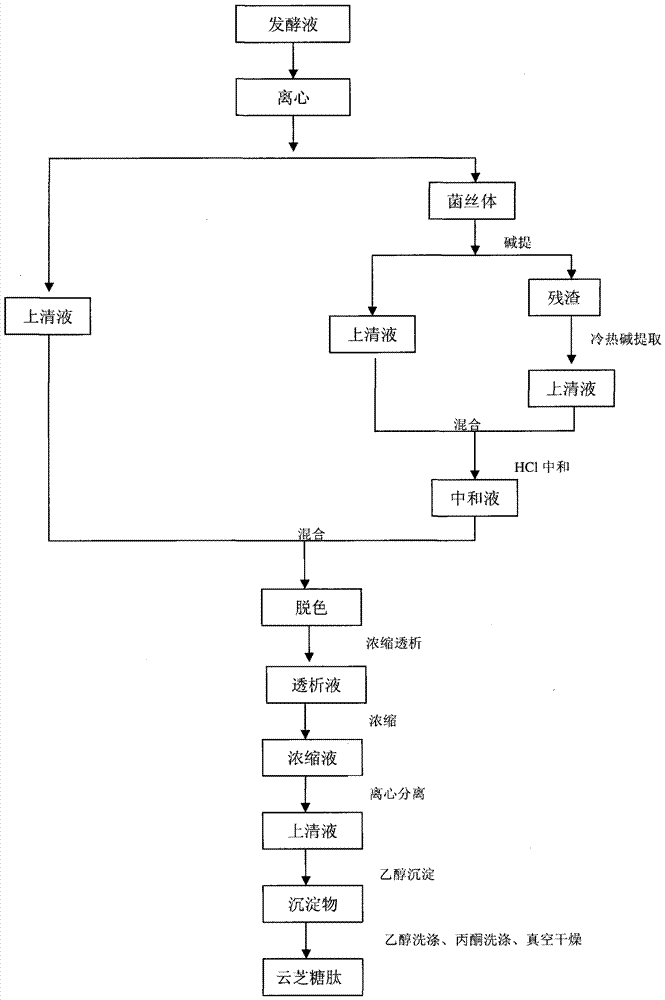

Image

Examples

Embodiment 1

[0022] After the microbial fermentation is completed, 50L of the fermented liquid is separated by centrifugation, and the supernatant is reserved for later use; the mycelium is dried, ground, and accurately weighed, and 0.3mol / L NaOH lye is added at a ratio of 1:10, and extracted twice at 90°C , once for 2 hours, combine the extracts for subsequent use; collect the mycelia residues of alkali extraction, dry them, grind them finely, weigh them accurately, add 0.5mol / L NaOH lye in a ratio of 1:10, and extract twice at normal temperature. One time for 2 hours, the extracts are combined for later use, the residue after alkali extraction is added with 0.3mol / L NaOH lye in a ratio of 1:10, extracted twice at 90°C, one time for 2 hours, mycelium extract and mycelium residue extract Combined, concentrated under reduced pressure to about 1 / 5 of the original volume, after adding HCl to neutralize, the obtained neutralized extract was combined with the supernatant obtained after fermentat...

Embodiment 2

[0024] After the microbial fermentation is completed, 50L of the fermented liquid is separated by centrifugation, and the supernatant is reserved for later use; the mycelium is dried, ground, and accurately weighed, and 0.5mol / L of NaHCO is added at a ratio of 1:11 3 Alkaline solution, extract twice at 92°C, once for 2 hours, combine the extracts for later use; collect the mycelia residue of alkali extraction and dry, grind finely, accurately weigh, add 0.5mol / L NaOH alkali in a ratio of 1:11 solution, extracted twice at room temperature, once for 2 hours, the extracts were combined for later use, the residue after alkali extraction was added with 0.5mol / L NaOH lye at a ratio of 1:10, extracted twice at 92°C, once for 2 hours, mycelium was extracted combined with the mycelium residue extract, concentrated under reduced pressure to about 1 / 5 of the original volume, neutralized by adding HCl, and combined with the supernatant obtained after fermentation and centrifugation, and co...

Embodiment 3

[0026] After the microbial fermentation is completed, 50L of the fermentation liquid is separated by centrifugation, and the supernatant is reserved for use; the mycelium is dried, ground, and accurately weighed, and 0.6mol / L of NaHCO is added at a ratio of 1:10 3 Alkaline solution, extract 3 times at 90°C, 2 hours each time, combine the extracts for later use; collect the mycelia residue of alkali extraction for drying, grind finely, accurately weigh, add 0.8mol / L NaHCO at a ratio of 1:10 3 Alkaline solution, extract twice at room temperature, once for 2 hours, combine the extracts for later use, add 0.6mol / L NaHCO to the residue after alkali extraction at a ratio of 1:10 3 Alkaline solution, extract twice at 92°C, once for 2 hours, combine mycelium extract with mycelium residue extract, concentrate under reduced pressure to about 1 / 5 of the original volume, add HCl for neutralization, and obtain a neutralized extract Combine with the supernatant obtained after fermentation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com