Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

140results about How to "Reduce orientation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

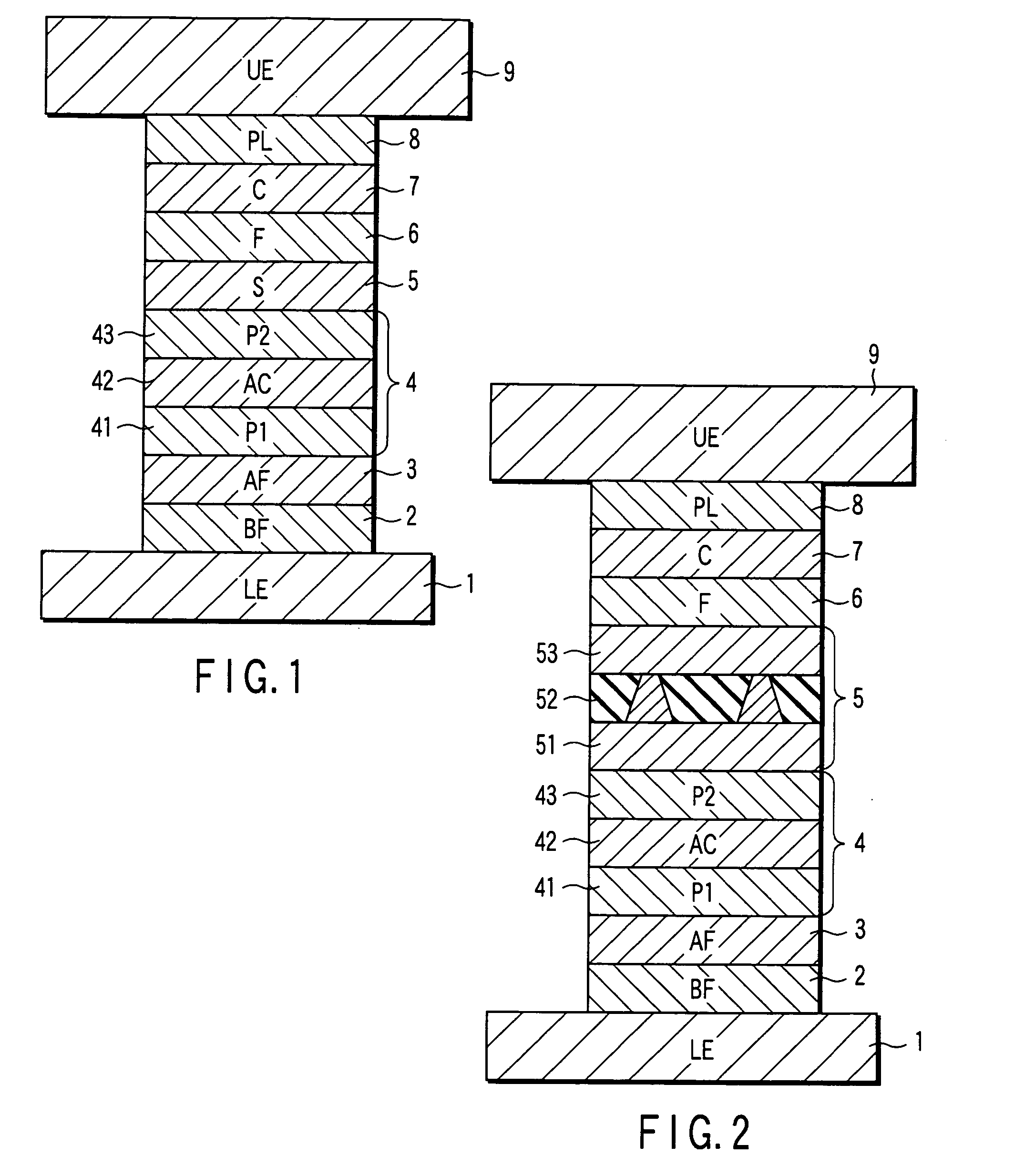

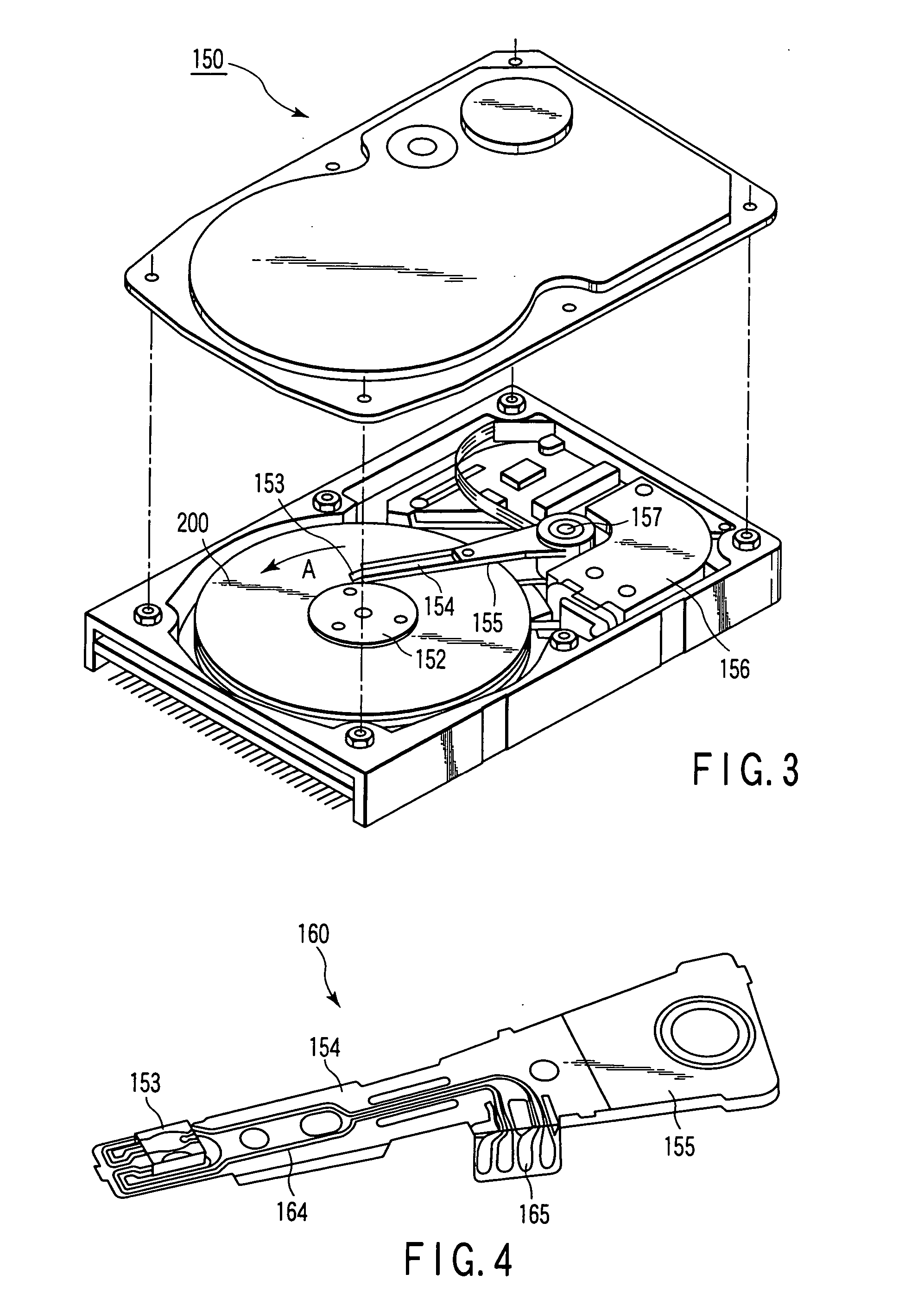

Magnetoresistive element, magnetic head, and magnetic recording and reproducing apparatus

ActiveUS20050201020A1Improve lattice stabilityPromote productionNanomagnetismMagnetic measurementsCrystal structureMagnetic reluctance

A magnetoresistive element has a magnetization pinned layer, a nonmagnetic spacer layer including a stack of a nonmagnetic metal layer, a resistance increasing layer and another nonmagnetic metal layer, a magnetization free layer having an fcc crystal structure, a cap layer having an fcc, an hcp, or a bcc crystal structure and having an interatomic distance between nearest neighbors greater than that of the magnetization free layer, and a pair of electrodes configured to provide a sense current in a direction substantially perpendicular to planes of the magnetization pinned layer, the nonmagnetic spacer layer, and the magnetization free layer.

Owner:KK TOSHIBA

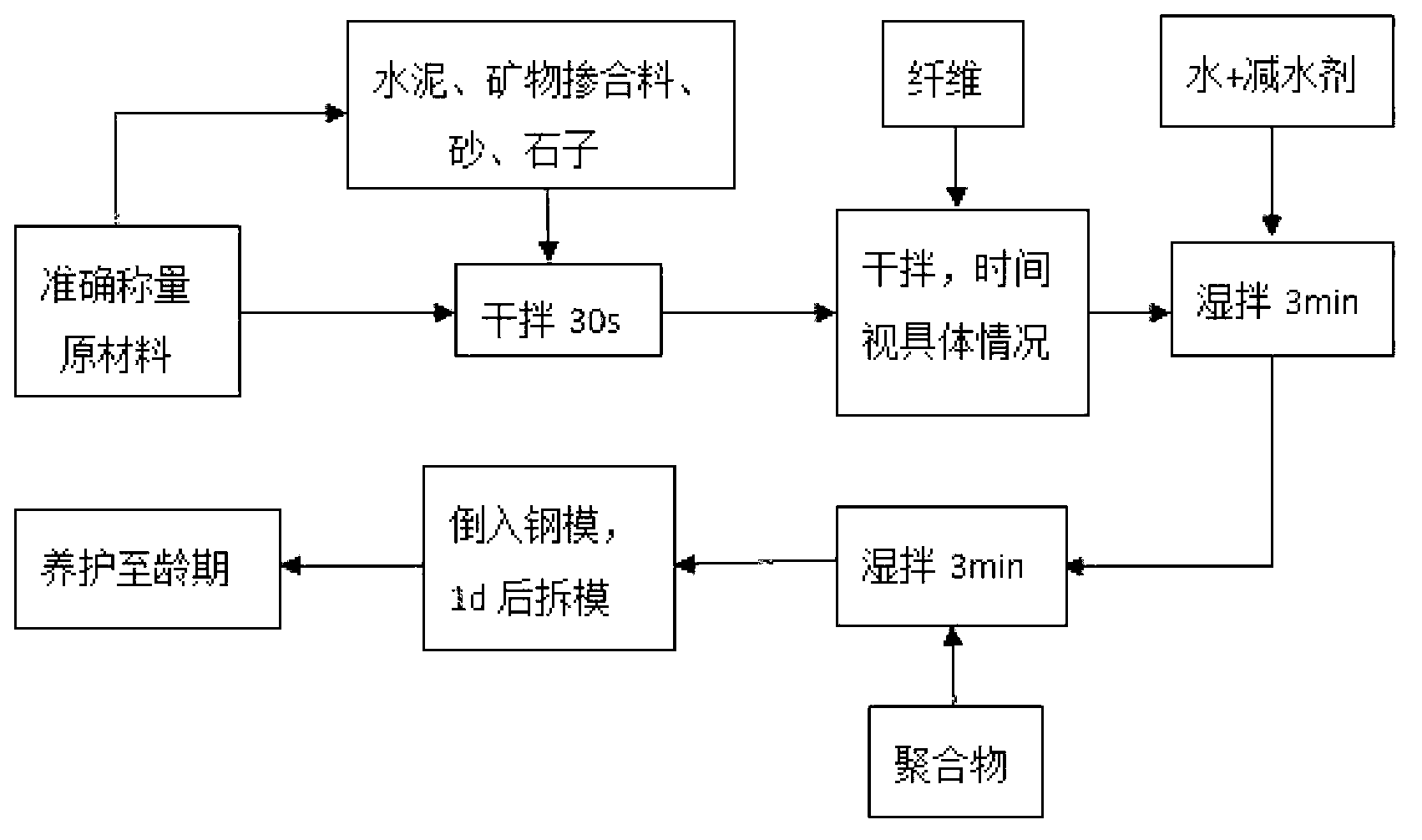

Fibre-polymer compound toughened concrete and preparation method for same

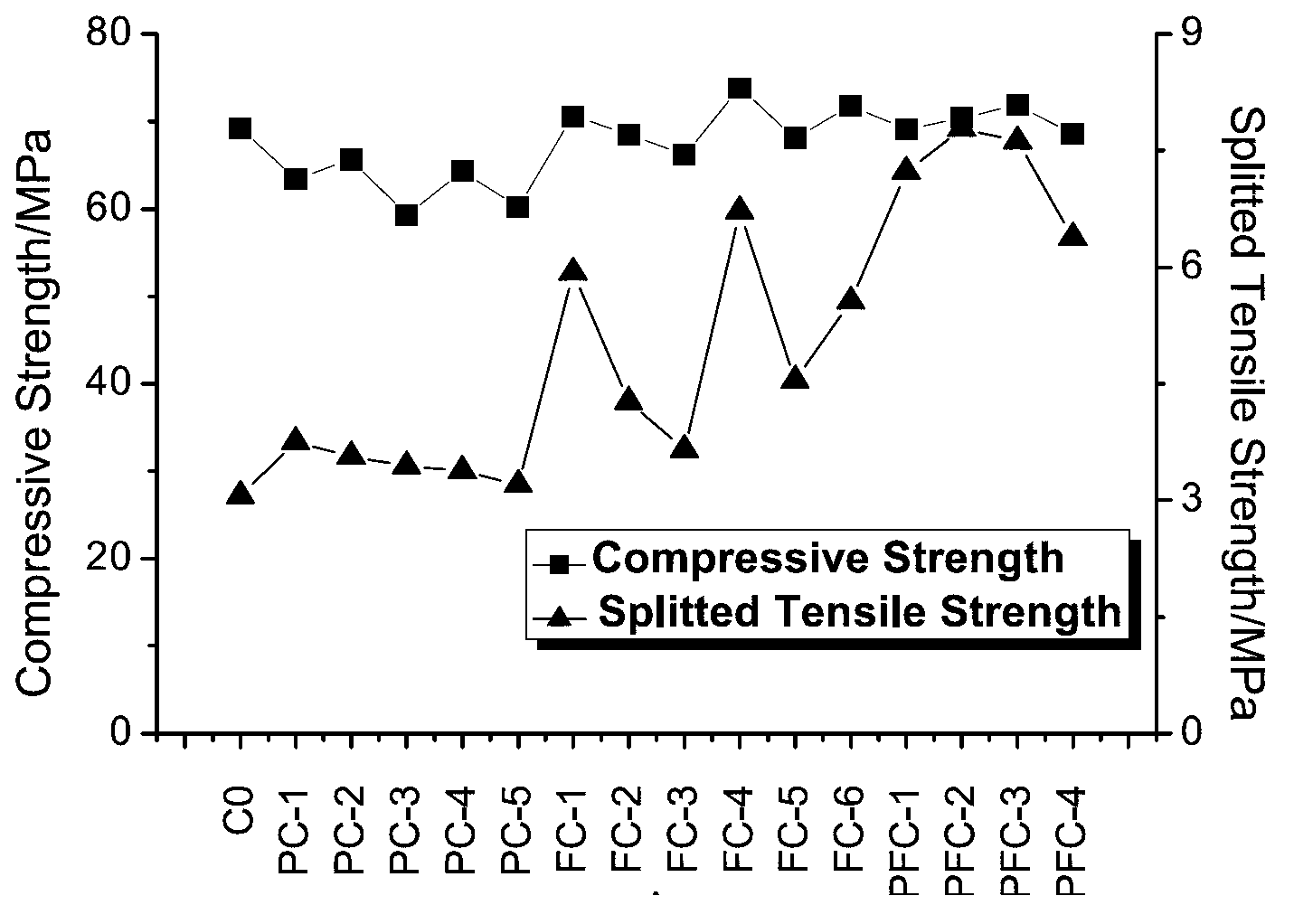

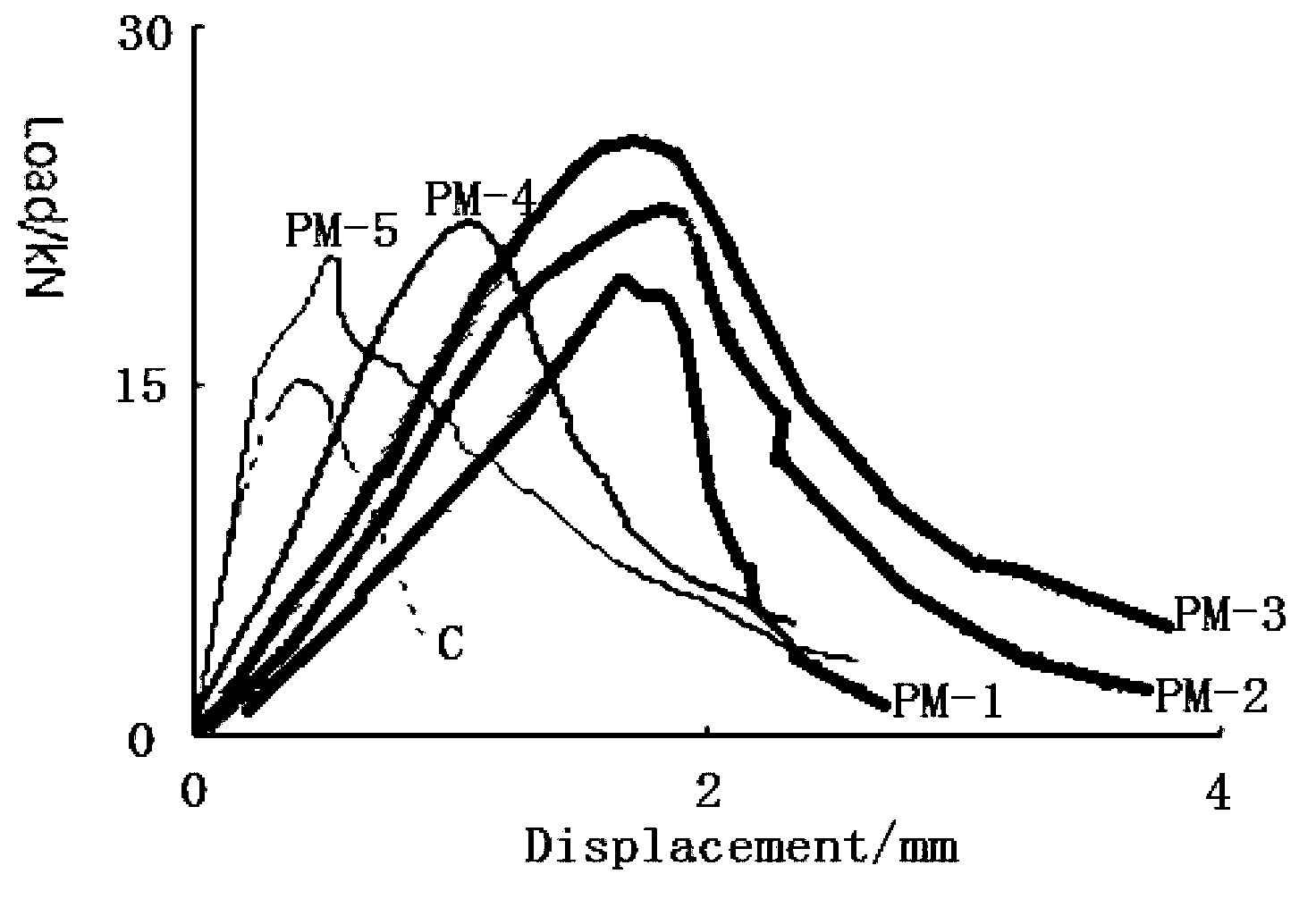

The invention discloses a fibre-polymer compound toughened concrete and a preparation method for the same. The basic raw materials of the concrete are coarse aggregate, fine aggregate, portland cement, fly ash and a polycarboxylic water reducer; moreover, fibres and a polymer are added, the fibres are any one of end-hook type steel fibres, superfine type steel fibres, modified polyester fibres, polyvinyl alcohol fibres, basalt fibres and cellulose fibres, and are doped in a ratio that the volume doped amount in per 1 m<3> concrete is 0.08%; and the polymer is any one of ethylene-vinyl acetate copolymer, ethyl acrylate, styrene-acrylate copolymer, vinyl acetate-acrylate copolymer and organosilicone acrylate, and the doped amount of each polymer is 10% based on the mass of the portland cement and the fly ash. The preparation method comprises the following steps of: pouring stone, sand, a gelling material, fibres, and water dissolved with a water reducer, and then stirring according to a blending mode of pouring dry materials at first and then pouring wet materials; and pouring the polymer, and stirring and forming.

Owner:SOUTHEAST UNIV

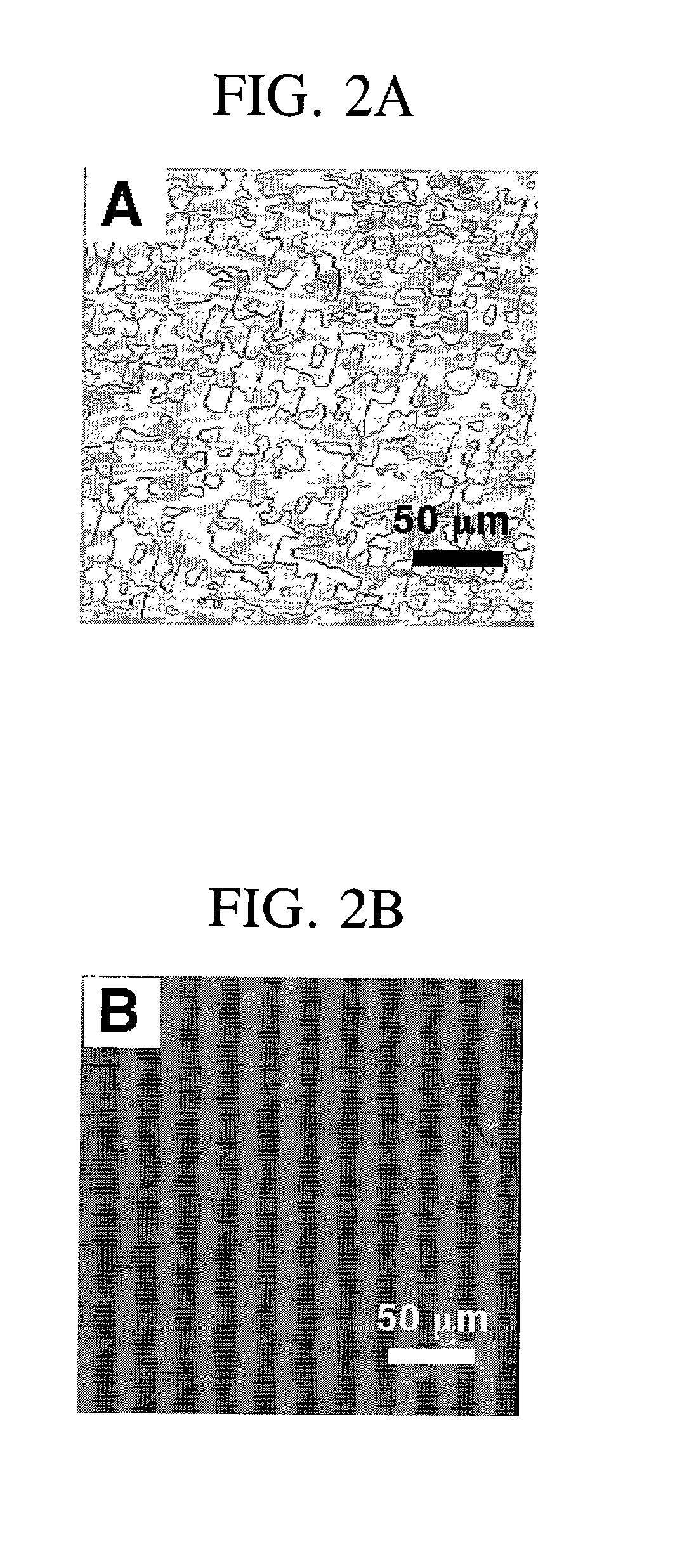

Detecting compounds with liquid crystals

ActiveUS7135143B2Improve orientationReduce orientationBioreactor/fermenter combinationsMaterial nanotechnologyLiquid crystalMetal

A device for detecting a compound in a sample includes a substrate and a self-assembled monolayer. The substrate includes a support with a metallized top surface, and the self-assembled monolayer includes an alkanethiol attached to the metallized top surface of the substrate and having a functional group that reversibly or irreversibly interacts with the compound. A liquid crystal is disposed on the self-assembled monolayer opposite the side of the self-assembled monolayer attached to the metallized top surface of the substrate. The liquid crystal includes a moiety that interacts with the functional group of the alkanethiol. When the compound is present in a sample that that contacts the self-assembled monolayer, the orientation of the liquid crystal is altered.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

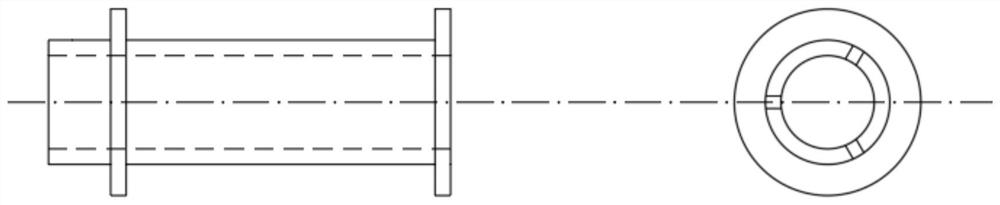

Manufacturing method for superlow shrinkage type PET industrial yarn

ActiveCN102797056AGuaranteed positionControl and reduce dwell timeArtificial thread manufacturing machinesMelt spinning methodsFiberYarn

The invention relates to a manufacturing method for superlow shrinkage type PET industrial yarn, which is characterized in that the superlow shrinkage type PET industrial yarn is manufactured through selecting and controlling cooling conditions, and the technological process is as follows: hyperviscous melting to polyester raw materials, metering, spanning, cooling, oil supplying, stretching, hot shaping, and reeled forming. For lowing the irregularity and shrinkage percentage of fiber, a slow cooling device is arranged in the production of industrial yarn, a precooling device adopted is a hollow stepped ring-shaped belt comprising an upper part and a lower part, through holes with the diameters of 5 to 7 mm are uniformly distributed in the upper part of the ring-shaped belt, through holes with the diameters of 3 to 4 mm are uniformly distributed in the lower part, and the hole arrangement densities are the same. The natural target of the PET industrial yarn is as follows: the fracture strength is equal or greater than 7.0 cN / dtex, the breaking elongation is 20.0 plus or minus 1.5 percent, and the dry heat shrinkage percentage under the test conditions of 170 DEGC, 0.05cN / dtex reaches 1.9 plus or minus 0.25 percent.

Owner:JIANGSU HENGLI CHEM FIBER

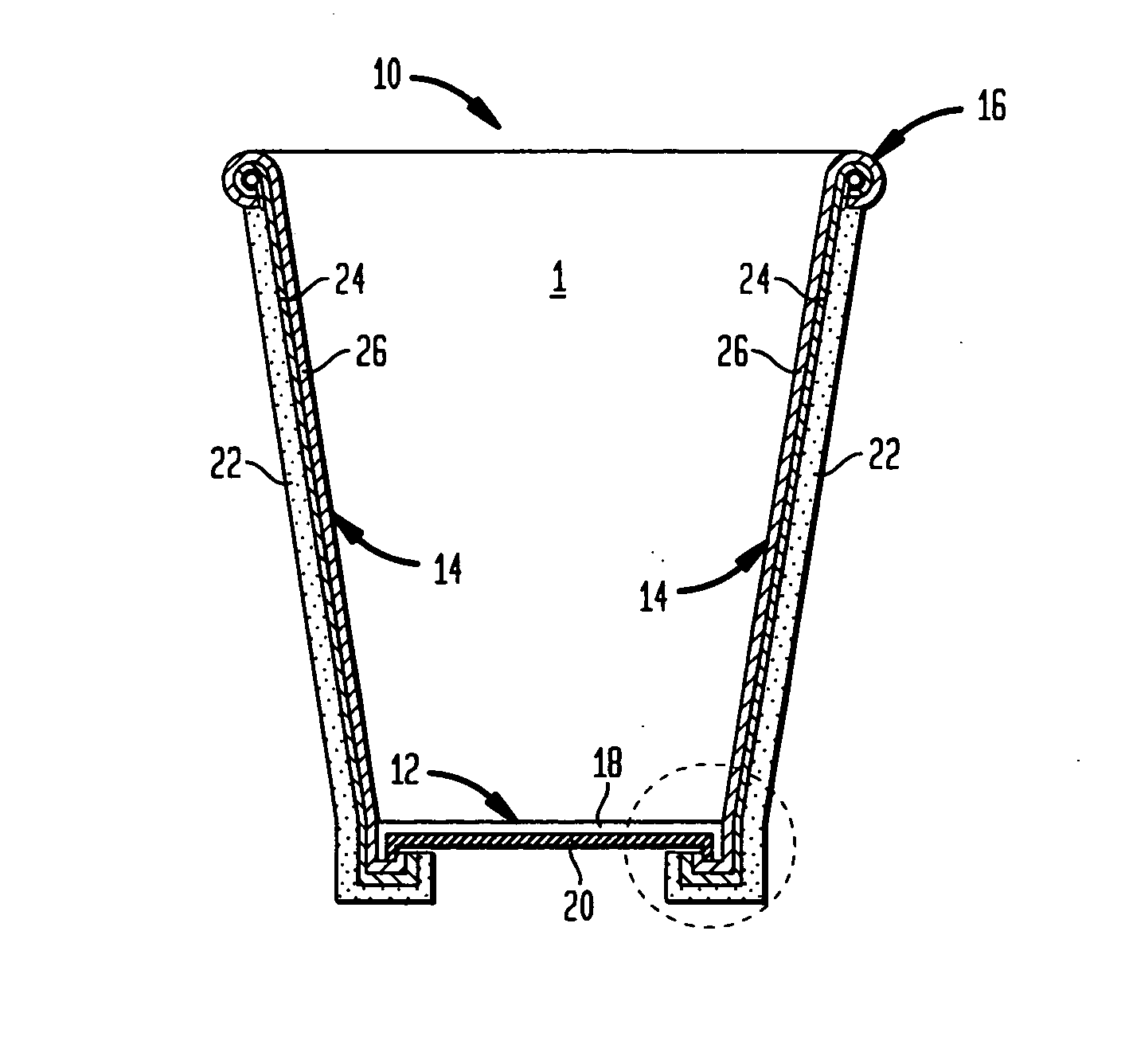

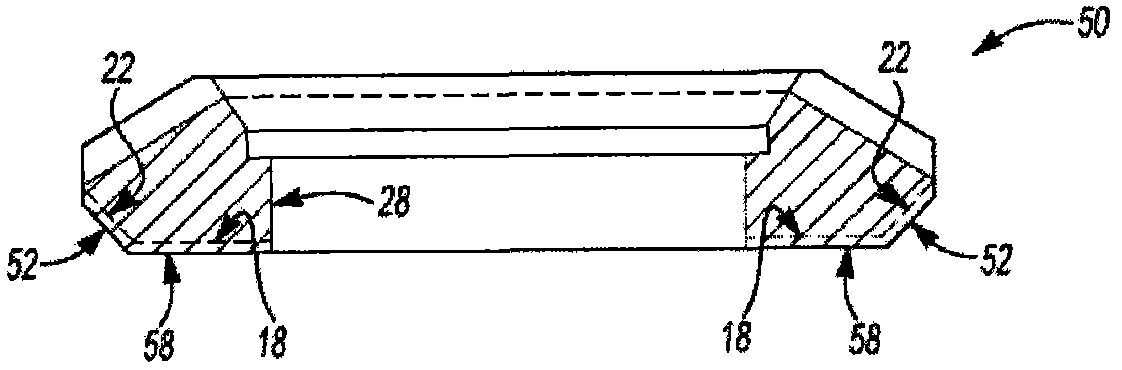

Foam-paperboard laminates, articles incorporating same and methods of making the same

InactiveUS20060286325A1Increase speedReduce orientationDomestic containersThin material handlingPolymer sciencePaperboard

The present invention relates to foam-paperboard laminates (foam-paperboard laminates) prepared using an in situ foaming process. The foam-paperboard laminates of the present invention are formed by extruding LDPE polymer onto a moisture containing paperboard to provide a LDPE-coated paperboard material. Upon heating of the LDPE-coated paperboard, the moisture in the paperboard causes steam to act as a blowing agent for the LDPE and a LDPE foam is obtained. The foam is adhered to the paperboard by way of physical adhesion of the polymer to the paperboard. The foam-paperboard laminates of the present invention exhibit insulating and cushioning properties. The foam-paperboard laminates are suitable for use, for example, in insulating beverage cups, food service containers, packaging material, and in other products where laminates can be useful.

Owner:DIXIE CONSUMER PROD

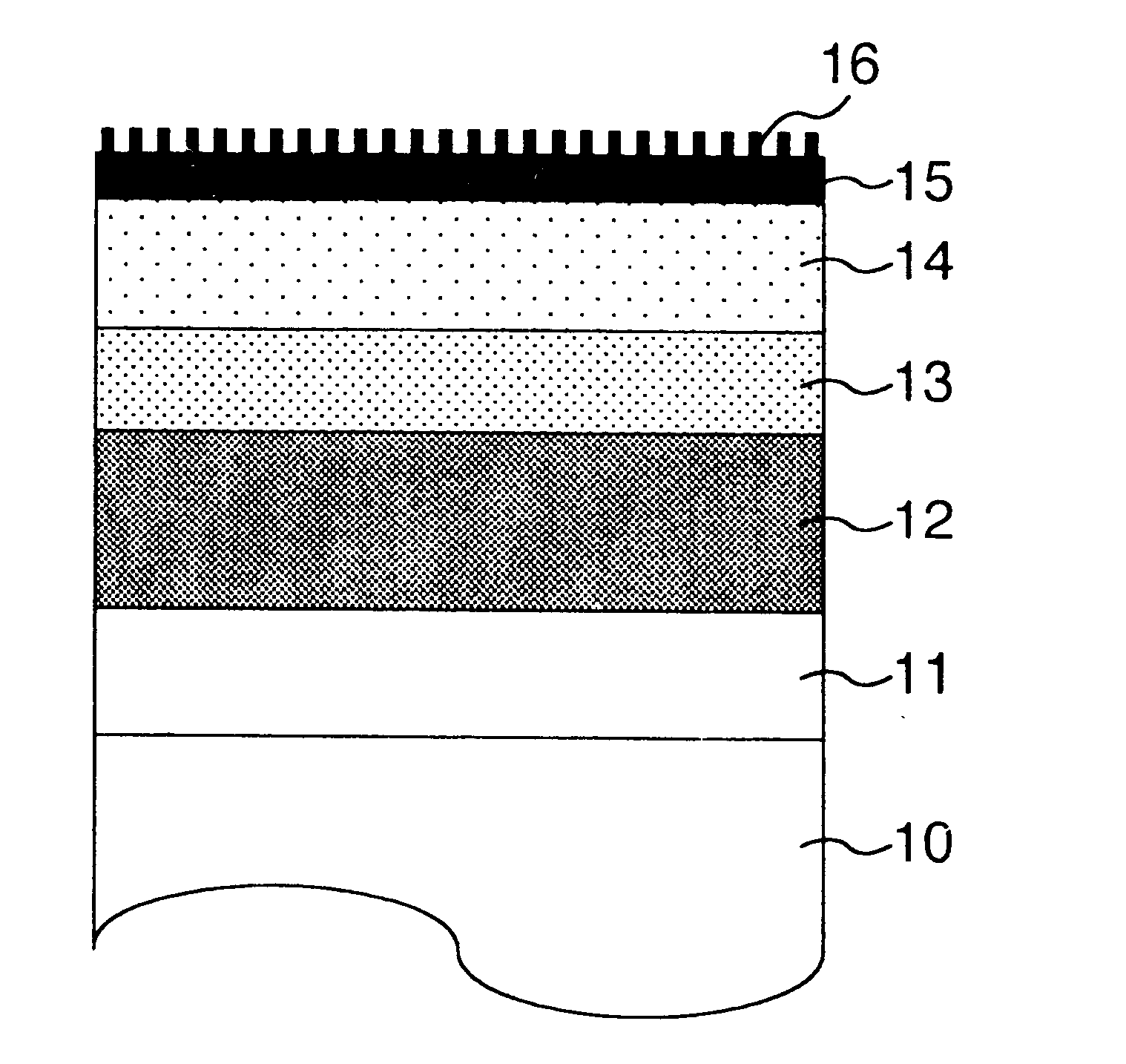

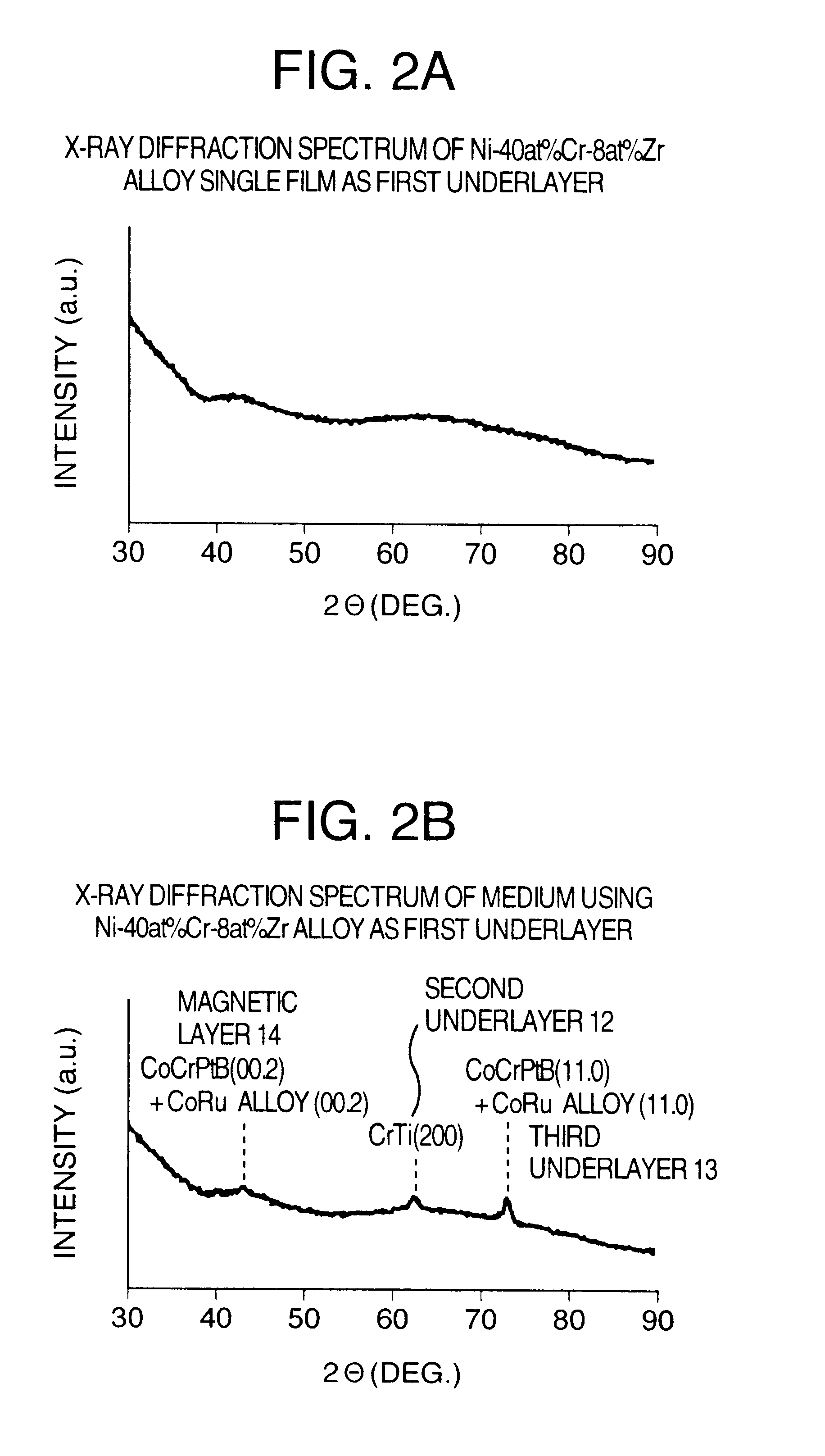

Magnetic recording medium and magnetic recording apparatus

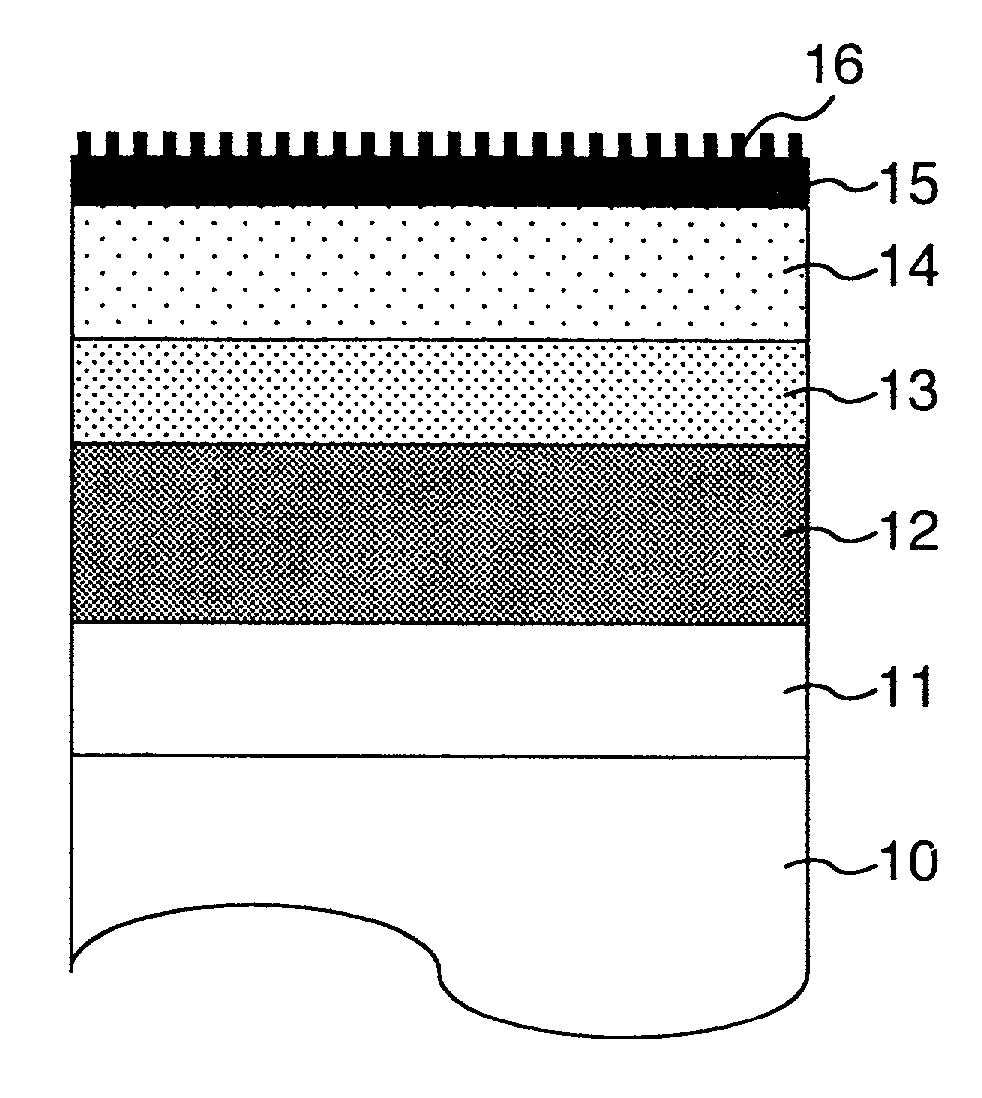

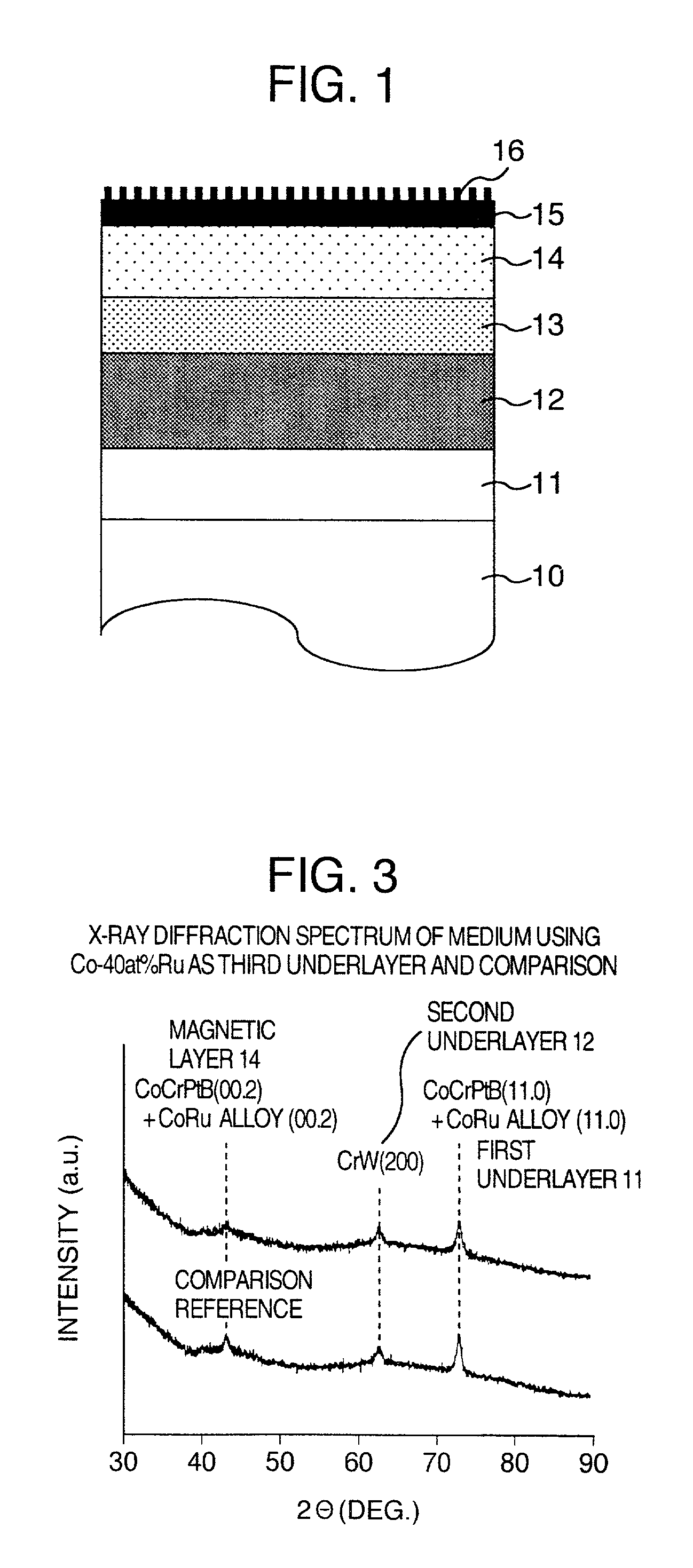

InactiveUS20020064691A1Improve lattice matchingEnhance coercivityBase layers for recording layersRecord information storageCrystal structureOptoelectronics

The longitudinal magnetic recording medium includes a non-magnetic substrate, a first underlayer having at least one of an amorphous structure and a fine crystal structure formed on the non-magnetic substrate, a second underlayer having a body-centered cubic structure formed on the first underlayer, a third underlayer having a hexagonal closed packed structure formed on the second underlayer, and a magnetic layer having the hexagonal closed packed structure formed on the third underlayer, wherein the third underlayer is composed of an alloy containing Co and Ru.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD

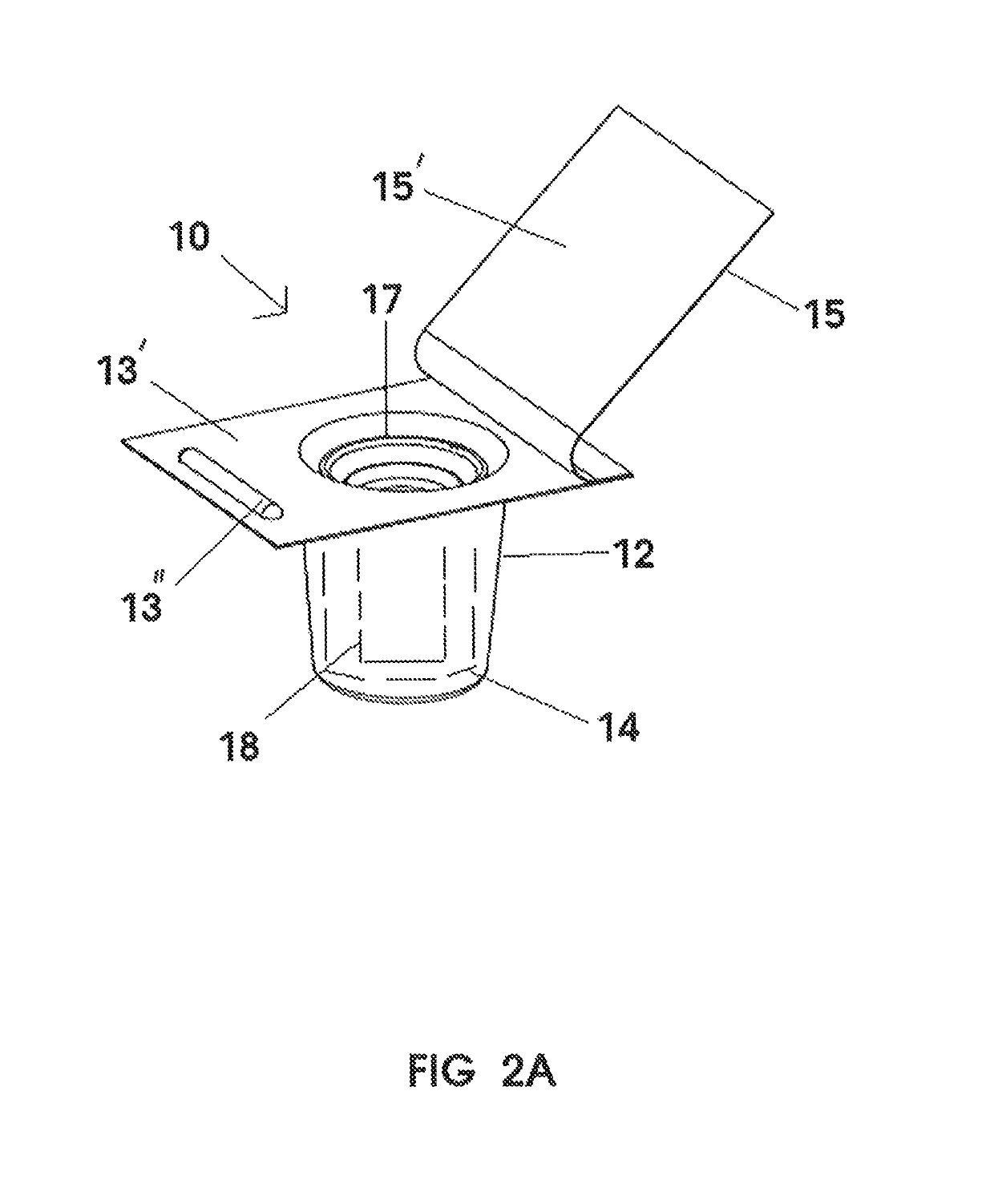

Tracking system and method for medical devices

ActiveUS10307548B1Facilitate “ peeling-back ”Facilitate receipt and passageMedical devicesIntravenous devicesEngineeringMedical device

A tracking system for medical devices which may include a closure and a container and a method for implementation the tracking system. Packaging removably retains the closure therein and a label is connected to the closure in an at least initially reduced orientation within the packaging. The packaging is structured for receipt of at least a portion of the container to establish an attached relation to the closure, whereupon the attached closure and container are concurrently removed from the packaging. The label is disposed in an expanded orientation and connected to both the closure and the container and includes a coded identifier having at least first and second coded segments. The coded identifier, including the first and second coded segments, include coded indicia may be machine readable and structured to define an identifying, matching relation of the closure and the container.

Owner:HUNT TIMOTHY BRANDON +1

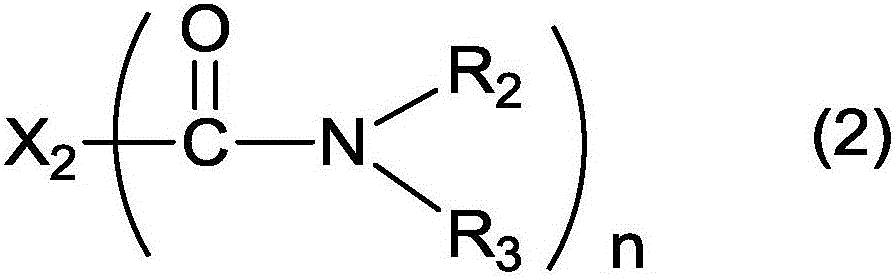

Liquid crystal aligning agent, and liquid crystal display element using same

ActiveCN105723276AGood adhesionIndicates uneven resolutionCoatingsNon-linear opticsSealantStructural unit

Provided is a liquid crystal aligning agent that can increase adhesiveness between a sealing agent and a liquid crystal alignment film, and can suppress display anomalies that may occur under high temperature and high humidity conditions in liquid crystal display elements near the frame. The liquid crystal alignment agent contains a component (A), a component (B), and an organic solvent. Component (A): at least one polymer selected from the group consisting of a polyimide precursor having a structural unit represented by formula (1), and an imidized polymer of said polyimide precursor. Component (B): a compound having a hydroxyalkylamide group. (X1 independently represents a tetravalent organic group; Y1 represents a divalent organic group; R1 represents a hydrogen atom or a C1-5 alkyl group; and A1 and A2 independently represent a hydrogen atom, a C1-10 alkyl group, a C2-10 alkenyl group, or a C2-10 alkynyl group, and said groups may have a substituent.)

Owner:NISSAN CHEM IND LTD

Magnetic recording medium and magnetic recording apparatus

InactiveUS6623874B2Improve lattice matchingEnhance coercivityBase layers for recording layersRecord information storageCrystal structureOptoelectronics

The longitudinal magnetic recording medium includes a non-magnetic substrate, a first underlayer having at least one of an amorphous structure and a fine crystal structure formed on the non-magnetic substrate, a second underlayer having a body-centered cubic structure formed on the first underlayer, a third underlayer having a hexagonal closed packed structure formed on the second underlayer, and a magnetic layer having the hexagonal closed packed structure formed on the third underlayer, wherein the third underlayer is composed of an alloy containing Co and Ru.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD

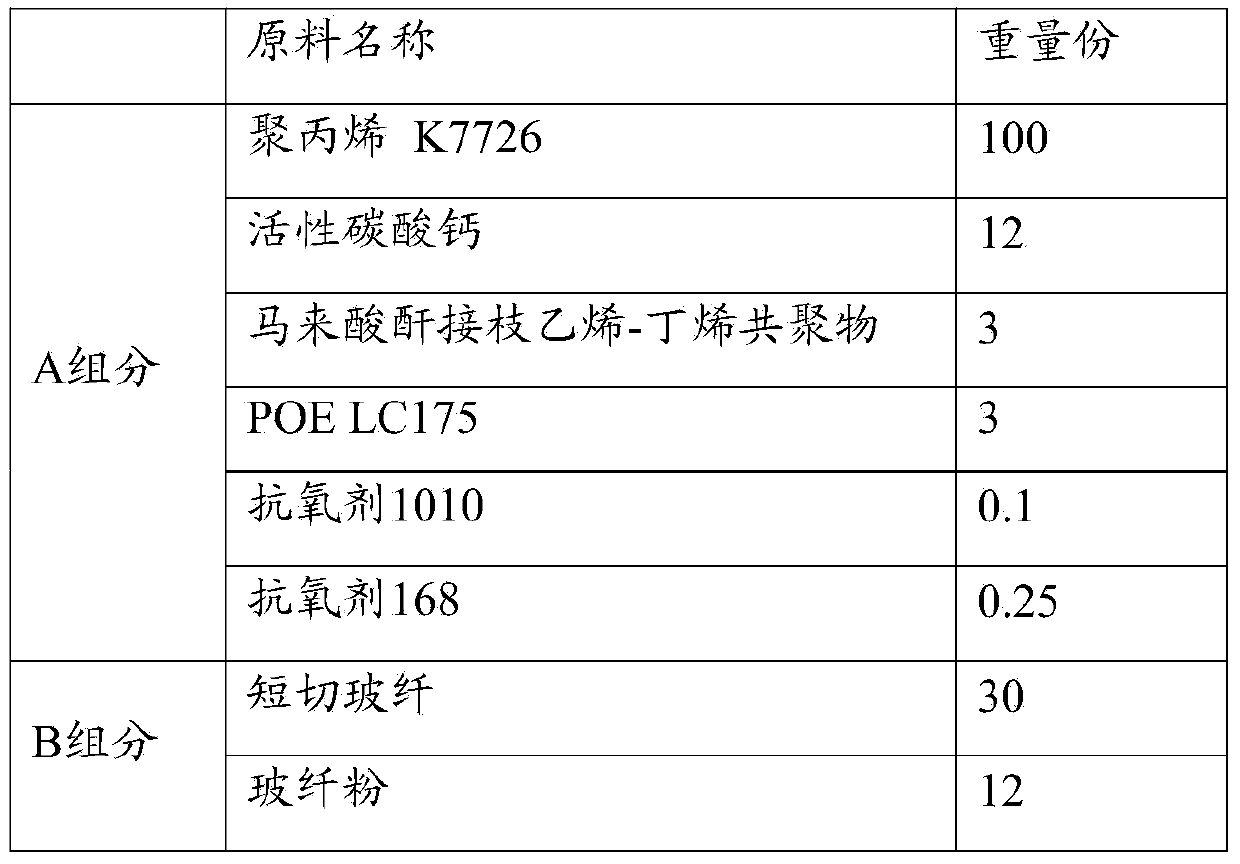

High-rigidity low-warpage glass fiber reinforced polypropylene material

The invention discloses a high-rigidity low-warpage glass fiber reinforced polypropylene material comprising the raw materials in parts by weight: polypropylene, short-cut glass fiber, a glass fiber powder, an inorganic filling material, a compatibilizer, a flexibilizer and an antioxidant. The related high-rigidity low-warpage glass fiber reinforced polypropylene material is compared with a reinforced polypropylene material prepared by a traditional technology, in the material injection molding process, the glass fiber orientation is significantly reduced, and the post-contraction of a product is also reduced significantly in the use process; and in the reinforced polypropylene material prepared by the traditional technology, warping and deformation phenomena generated during injection molding of large long-flow pieces are obviously improved, and the product has the characteristics of high rigidity, high heat resistance, low warpage and the like.

Owner:SICHUAN GLARY ASIA PLASTIC TECH

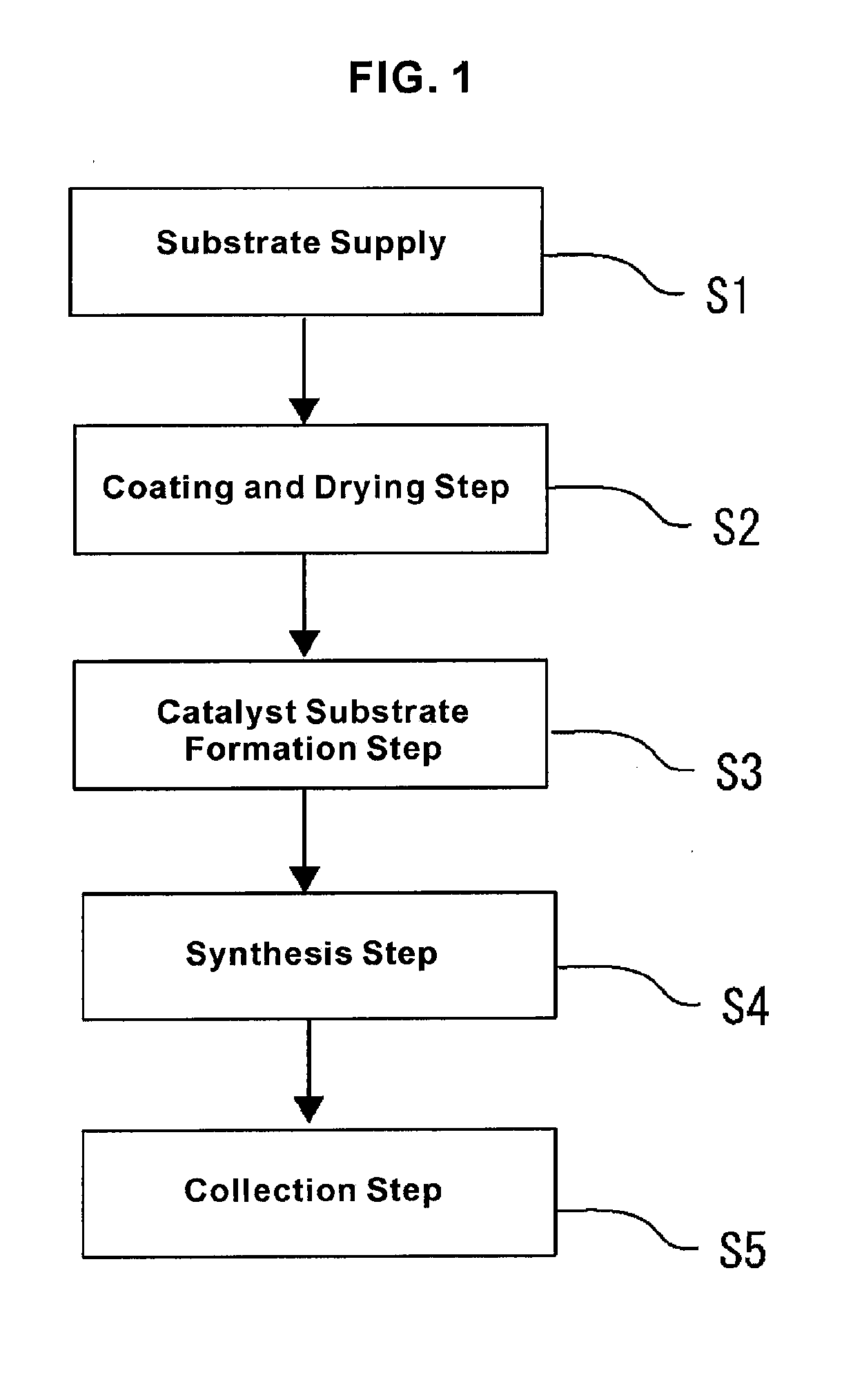

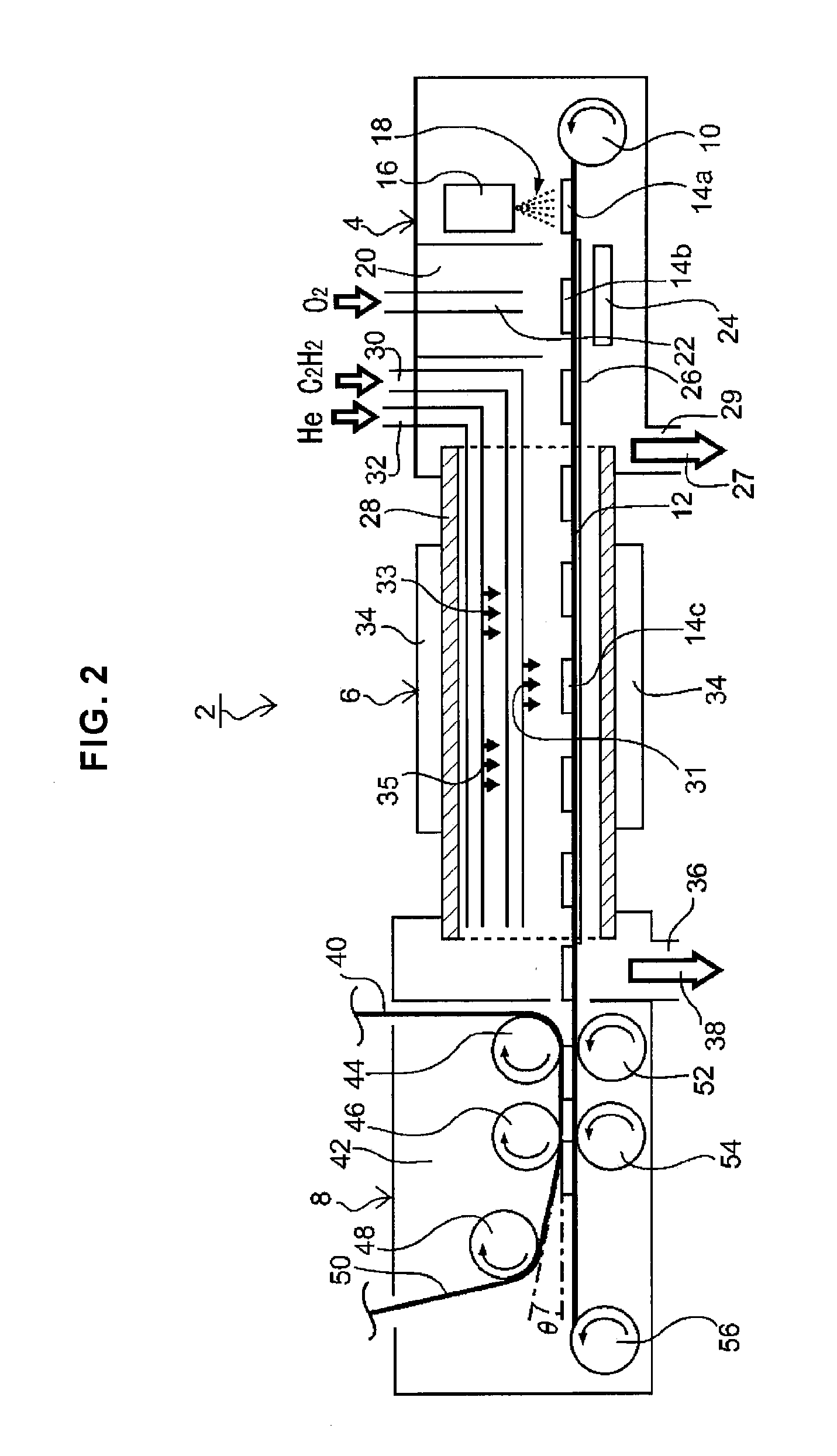

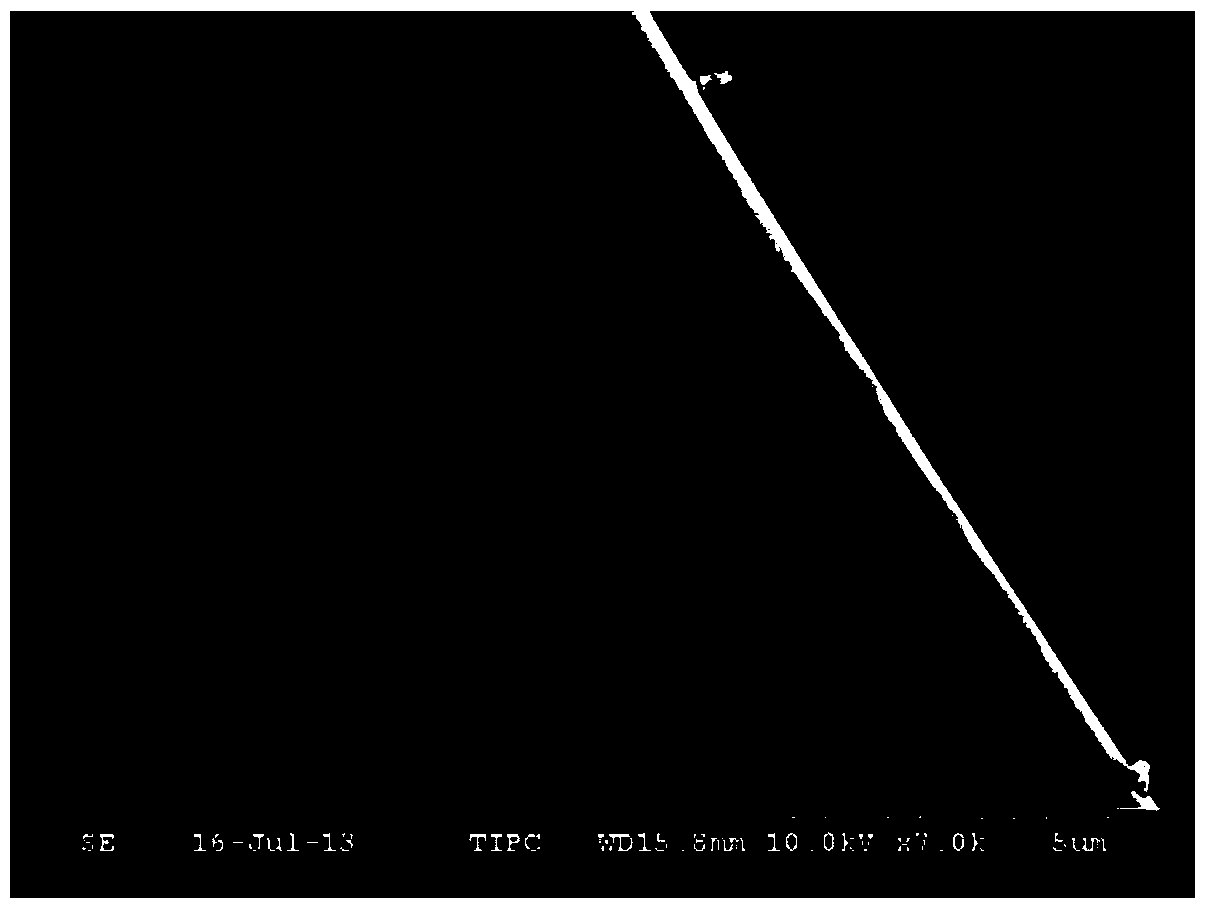

Method of Continuously Synthesizing Oriented Carbon Nanotubes and Apparatus for Continuously Synthesizing Same

InactiveUS20110318256A1Stable synthesis concentration regionInhibited DiffusionMaterial nanotechnologyFibre chemical featuresCarbon nanotubeProduct gas

A method and apparatus for continuously synthesizing oriented carbon nanotubes, with which oriented carbon nanotubes can be stably synthesized in large quantities, is presented.The method and apparatus for continuously synthesizing oriented carbon nanotubes comprise: a coating and drying step in which a catalyst liquid is applied and dried to form a catalyst layer on a substrate surface; a catalyst substrate formation step in which the catalyst layer is heated to form a catalyst substrate having a catalyst particle layer on the substrate surface; a synthesis step in which a raw material gas heated to a temperature equal to or higher than a synthesis temperature for the oriented carbon nanotubes is brought into contact with the surface of the catalyst substrate to synthesize oriented carbon nanotubes; and a collection step in which the oriented carbon nanotubes are collected. In the synthesis step, a carrier gas having a temperature equal to or higher than the synthesis temperature is supplied to the periphery of the raw material gas which is in contact with the surface of the catalytic substrate, or to its front and rear stages. Thus, oriented carbon nanotubes are continuously or intermittently synthesized.

Owner:NIPPON SANSO CORP +1

Fuel cell separator and a method for manufacturing the same

InactiveUS20050277009A1Lower resistanceLow costFinal product manufactureElectrode carriers/collectorsFuel cellsShear viscosity

A first resin is prepared which has a content of electrically conductive particles adjusted in the range from 60 wt % to 90 wt %, and a melt shear viscosity adjusted in the range from 1×103 Pa.sec to 1×107 Pa.sec. A second resin is prepared which has a content of electrically conductive particles that is adjusted in the range from 50 wt % to less than 90 wt % and that is less than that of the first resin. The second resin has a melt shear viscosity adjusted in the range from 1×102 Pa.sec to less than 1×105 Pa.sec. A resin block prepared from the first resin is placed in a mold, and the second resin is injection molded into the mold while heating the mold to the melting temperature of the first resin or above.

Owner:MITSUBISHI ELECTRIC CORP

Pneumatic tire

InactiveUS20130206302A1Enhancement in tire durability performanceImprove workabilityPneumatic tyre reinforcementsYarnEngineeringMechanical engineering

Owner:YOKOHAMA RUBBER CO LTD

Preparation method for chopped fiber reinforced thermoplastic composite materials

InactiveCN104262653AHigh bonding strengthThe law is novelFibre typesPolymer scienceThermoplastic composites

The invention discloses a preparation method for chopped fiber reinforced thermoplastic composite materials. The method comprises the following steps: compounding a phenolic aldehyde ethyl alcohol coating solution of which the concentration is 0.05-0.2g / ml; cleaning and treating the chopped fibers with acetone and drying the cleaned and treated chopped fibers to obtain dried chopped fibers; adding the phenolic aldehyde ethyl alcohol coating solution to the dried chopped fibers, compacting the dried chopped fibers, so that the compacted chopped fibers are completely soaked in the phenolic aldehyde ethyl alcohol coating solution, and soaking the compacted chopped fibers with discontinuous stir; drying the soaked chopped fibers at a room temperature to obtain the dried chopped fibers which are coated with phenolic resin; precuring the dried chopped fibers, and cooling and quickly stirring the precured and dried chopped fibers, so that chopped fiber bundles coated with the phenolic resin on the surface present a decentralized single bundle form; mixing the chopped fibers which present the decentralized single bundle form and a thermoplastic polymer, and then melting and extruding pelleting to obtain the chopped fiber reinforced thermoplastic composite materials. The method has the advantages that the equipment used is simple, the operation is convenient, the energy consumption is low, and the expense is low; the bonding strength of fibers and thermoplastic plastic interface is high, and the coating effect of the phenolic resin to the fibers is good.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Low-oriented extrusion grade polypropylene material and preparation method thereof

The invention discloses a low-oriented extrusion grade polypropylene material. The polypropylene material comprises the following components in parts by weight: 60-90 parts of polypropylene resin, 2-3 parts of polytetrafluoroethylene, 1-5 parts of toughening agent, 0-10 parts of heat-resistant modifier, 7-28 parts of packing, 0.1-1 part of lubricant and 0.1-1 part of antioxidant, wherein the polypropylene resin is a copolymer of polypropylene and polyethylene, and the weight ratio of polypropylene to polyethylene in the polypropylene copolymer is 95 to 5-99 to 1. According to the low-oriented extrusion grade polypropylene material and a preparation method thereof, polytetrafluoroethylene is added in the formula, so that the melt strength of the polypropylene material can be improved, then the orientation of the polypropylene material is reduced, the vertical unnotched impact of polypropylene is improved on the basis of little change of flow-directional unnotched impact, and the mechanical properties and uniformity of the material are improved. The preparation method is simple, easy to operate and low in relative cost.

Owner:SUZHOU EXCELLENCE ENG PLASTICS

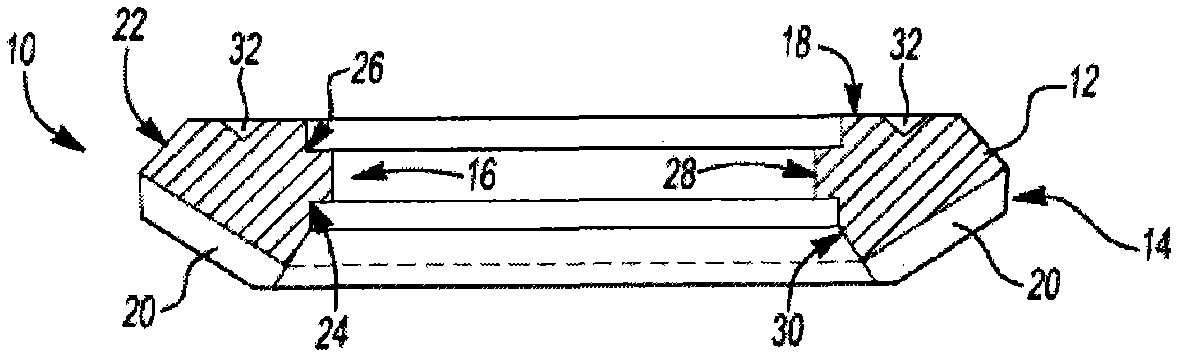

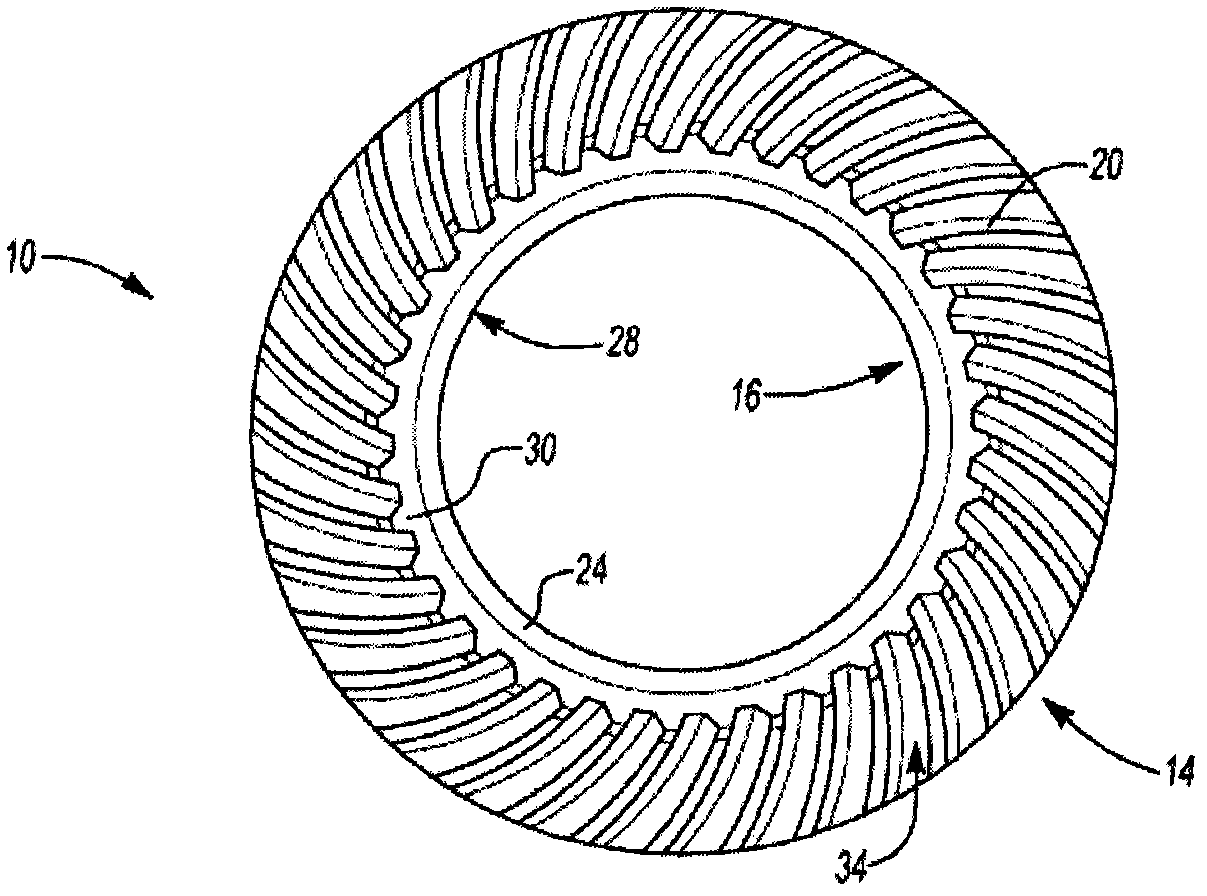

Bevel and hypoid gear and method of manufacture

InactiveCN102101171AExtend your lifeReduced forming process stepsPortable liftingGearing elementsRoll formingEngineering

Bevel and hypoid gears are used in power transmissions including automotive applications. Provided is a net shaped bevel or hypoid gear having a generally annular gear body including a plurality of radially outwardly extending gear teeth formed from a generally annular blank made of powdered metal. Also provided is a method for manufacturing a net shaped bevel or hypoid gear including the steps of providing and optionally heat treating a generally ring-shaped or annular blank made of metal powder, then incrementally deforming the blank by orbitally forming or roll forming to produce a net shaped gear member with a plurality of outwardly extending gear teeth, which may be of a bevel or hypoid type.

Owner:GM GLOBAL TECH OPERATIONS LLC

Electric arc additive manufacture device using magnetic field and ultrasonic vibration and method

InactiveCN111843107AGood molding effectImprove tissue performanceAdditive manufacturing apparatusWelding accessoriesCrystal orientationEngineering

The invention belongs to the field of additive manufacturing, and particularly relates to an electric arc additive manufacture device using a magnetic field and ultrasonic vibration and a method. Thedevice comprises an additive welding gun, a magnetic control coil, a magnetic control power supply, an ultrasonic vibration generating device and an ultrasonic vibration power supply. The magnetic control power supply controls a magnetic control coil coaxially arranged on the additive welding gun in a sleeving mode to generate the longitudinal alternating magnetic field so as to control the electric arc form, the molten drop transition behavior and the molten pool flowing behavior; and meanwhile, the ultrasonic vibration power supply controls the ultrasonic vibration generating device fixed atthe bottom of a substrate to generate ultrasonic vibration, so that the substrate and the whole additive part are subjected to ultrasonic vibration, and a molten pool is under the condition of ultrasonic vibration in the whole forming and solidifying process. According to the device and the method, the forming precision and quality of weld joints can be effectively controlled, the forming effectis obviously improved, crystal grains are effectively refined, the crystal orientation is reduced, the porosity is reduced, residual stress is fully released and the structure property of the additivepart is greatly improved.

Owner:NANJING UNIV OF SCI & TECH

Built-in suspended rail beam and built-in suspended air-rail traffic system

InactiveCN107215341ASimple structureSelf-directedMonorailsElevated railway with suspended vehicleEffective solutionEngineering

The invention discloses a built-in suspended track beam and a built-in suspended air-rail transportation system, and relates to the field of rail transportation. The inside of the track beam is used for the running wheels on both sides of the suspended monorail vehicle, and it includes a running track. The running track includes a top plate, two side plates and two walking plates for the running wheels to slide, and the two side plates are arranged opposite to each other. , the two ends of the top plate are respectively fixedly connected with one end of the two side plates, the other ends of the two side plates are respectively fixedly connected with one end of the corresponding running board, and there is a space between the free ends of the two running boards for suspending the carriage The gap through which the suspension frame passes; the top surfaces of the two walking boards form a walking part, the top surface of the walking part is an inclined plane, and the traveling wheels run on the inclined plane. The invention has simple structure, self-guiding and self-stabilizing functions, effectively solves the problem of lateral movement of the car body due to the influence of external force, improves stability and safety, reduces cost, reduces noise and protects the environment.

Owner:ZHONGJIAN AIR TRAIN BEIJING TECH CO LTD

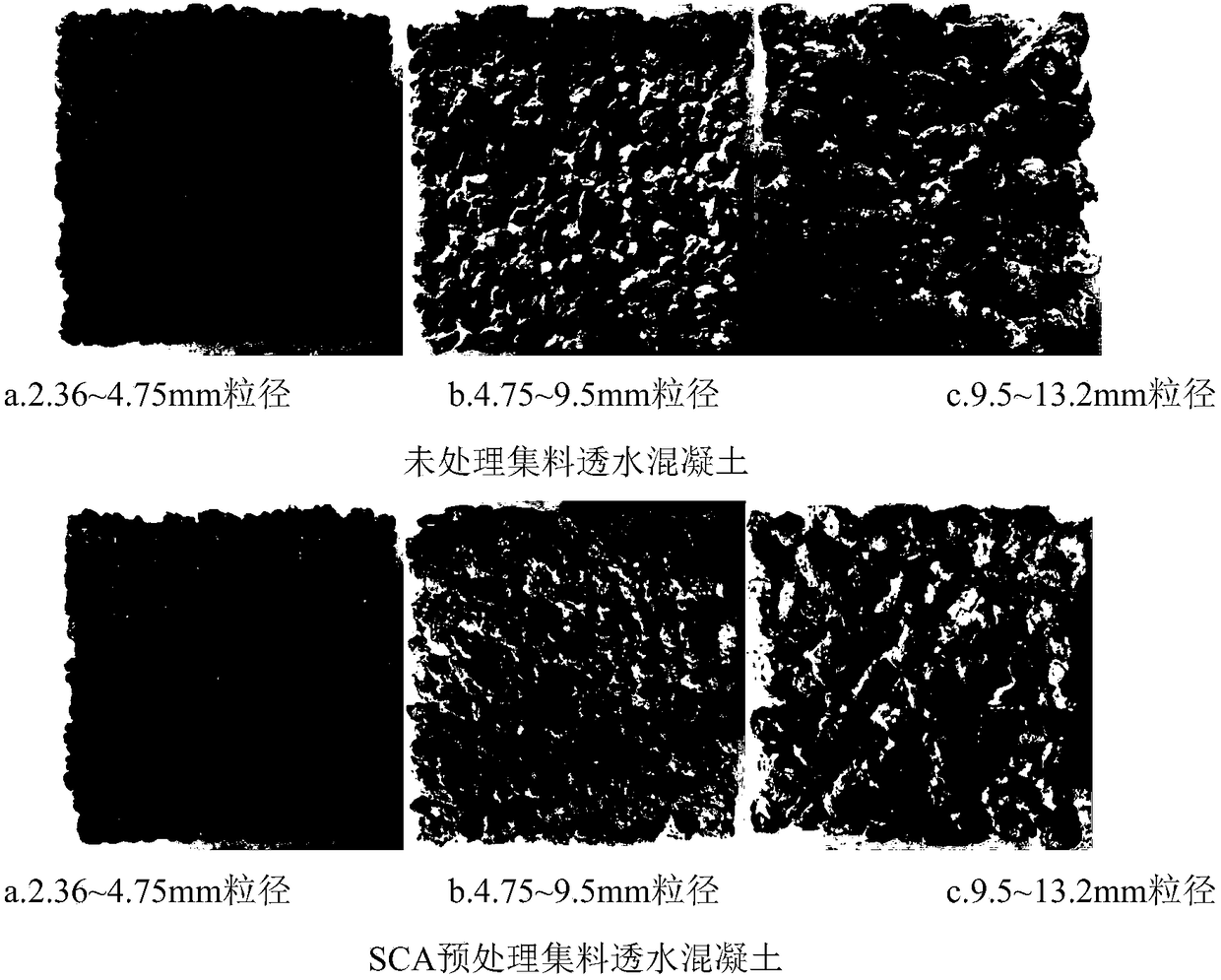

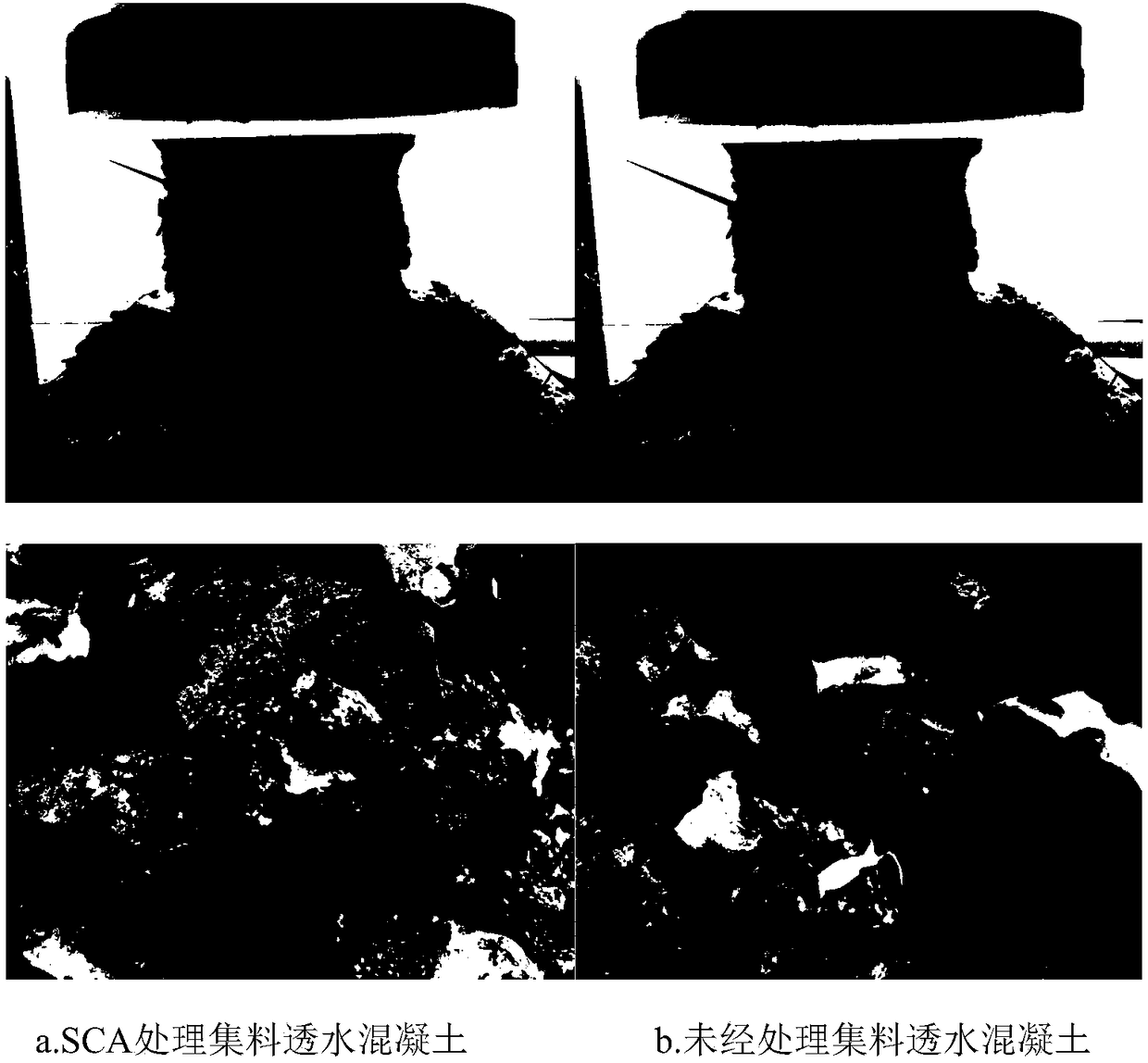

Silane coupling agent modified diabase permeable concrete

ActiveCN108358547AImprove mechanical propertiesGood modification effectCeramicwarePorosityPermeability coefficient

The invention provides a preparation method of silane coupling agent modified diabase permeable concrete. The method comprises the following steps: silane coupling agent modified diabase as aggregateis uniformly mixed with cement and a water reducing agent, molding and demolding are performed, and the silane coupling agent modified diabase permeable concrete is obtained. Mechanical properties ofpermeable concrete are obviously improved by SCA modified diabase aggregate, and permeability is decreased to a certain extent. The smaller the particle size of aggregate is, the higher the increase amplitude of strength of the SCA modified aggregate permeable concrete specimen is, and the better the modification effect is; the larger the particle size is, the higher the porosity of the SCA modified aggregate specimen is and the higher the permeability coefficient is. According to comprehensive consideration of requirements of maximum practical economy and ecological benefit of engineering, anSCA solution with concentration of 1% is more appropriate for pretreatment.

Owner:广西建设职业技术学院

Efficient environmental-friendly filter element and filter material thereof

ActiveCN104190170ASimple structureLight in massDispersed particle filtrationCircular discStructural engineering

The invention discloses an efficient environmental-friendly filter element which comprises an upper end cover, a lower end cover and a filter material arranged between the upper end cover and the lower end cover, wherein the upper end cover is a round end cover, the lower end cover is a disc-shaped end cover, a conical cylinder is arranged in the disc center of the lower end cover, the outer side of the conical cylinder is fixedly connected with a cylindrical skeleton made of a metal mesh, the upper end of the cylindrical skeleton is fixedly connected with an inner hole of a circular ring of the upper end cover, the filter material is arranged on the outer side of the cylindrical skeleton, and the metal mesh which is connected fixedly with the outer edges of the upper end cover and the lower end cover is arranged on the outer side of the filter material. The filter element is simple in structure, the filter element is supported through the arrangement of the annular skeleton, the quality of the filter element is greatly reduced, meanwhile, the conical cylinder is arranged on the lower end cover, so that the air is guided, the resistance of the filter element to the air is reduced, and the air permeability of the filter element is improved.

Owner:江苏欧瑞特新材料有限公司

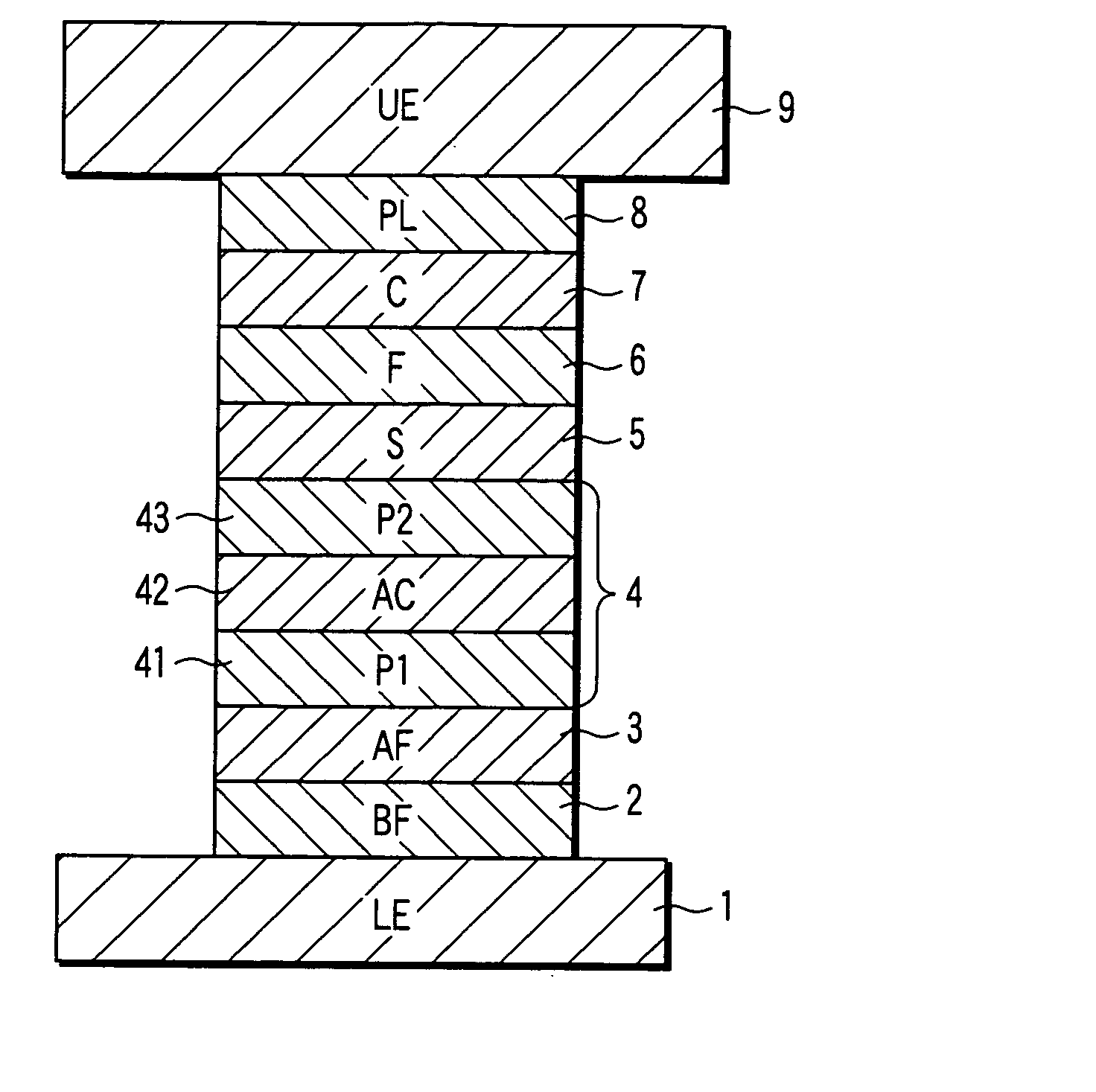

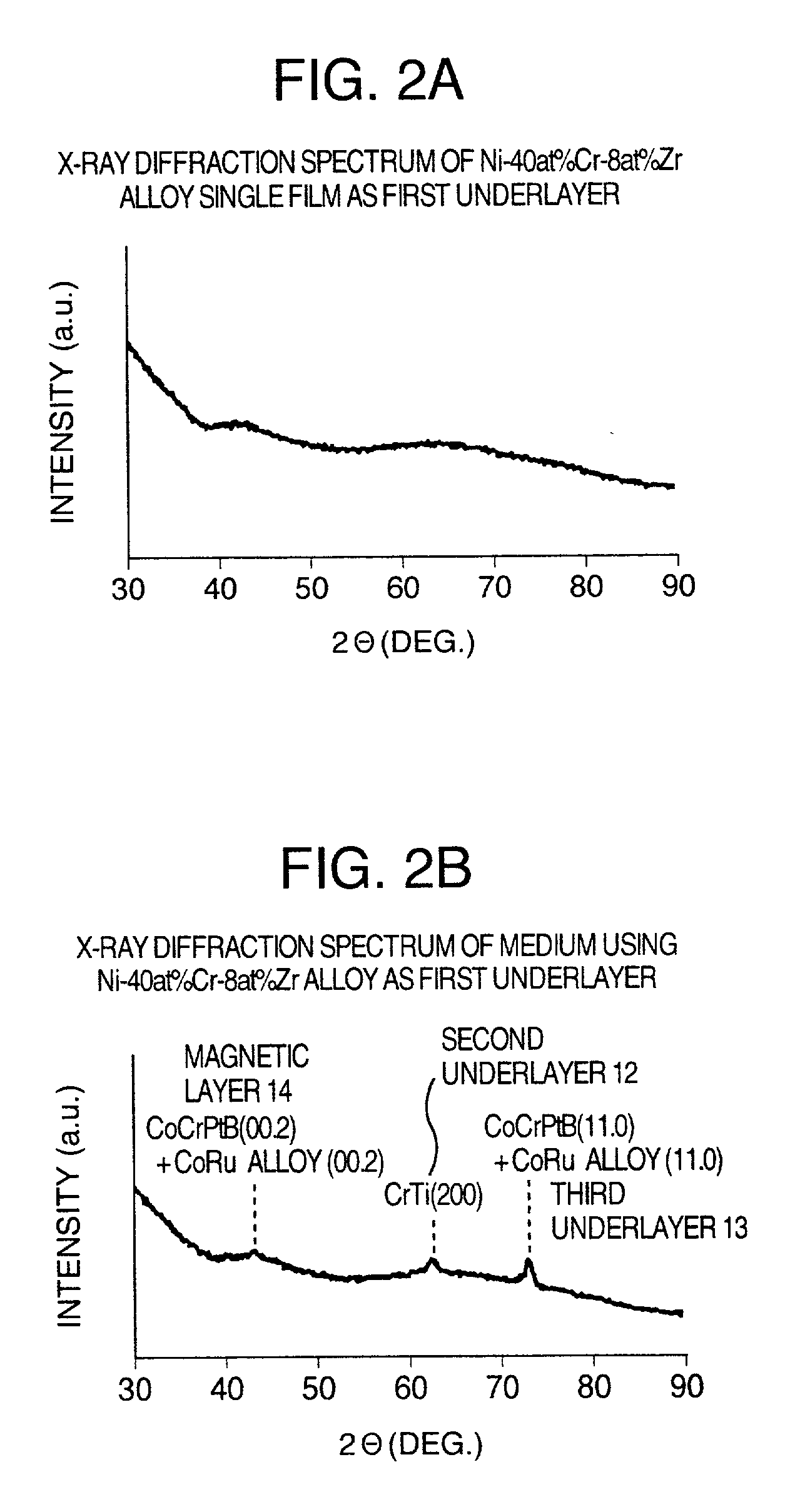

Perpendicular magnetic recording medium and magnetic storage apparatus

InactiveUS7604879B2Reduce orientation and alignment distributionPromote stratificationRecord information storageDisk carriersMagnetic storageMagnetization

A perpendicular magnetic recording medium is provided with a substrate, a soft magnetic back layer provided on a surface of the substrate, an orientation controlling underlayer provided on the soft magnetic back layer, and a recording layer provided above the orientation controlling underlayer and having axes of easy magnetization approximately perpendicular to the surface of the substrate. The recording layer is made of a ferromagnetic material having an hcp crystal structure. The orientation controlling underlayer is made of a nonmagnetic material having an fcc crystal structure and having NiCr or NiCu as a main component.

Owner:SHOWA DENKO KK

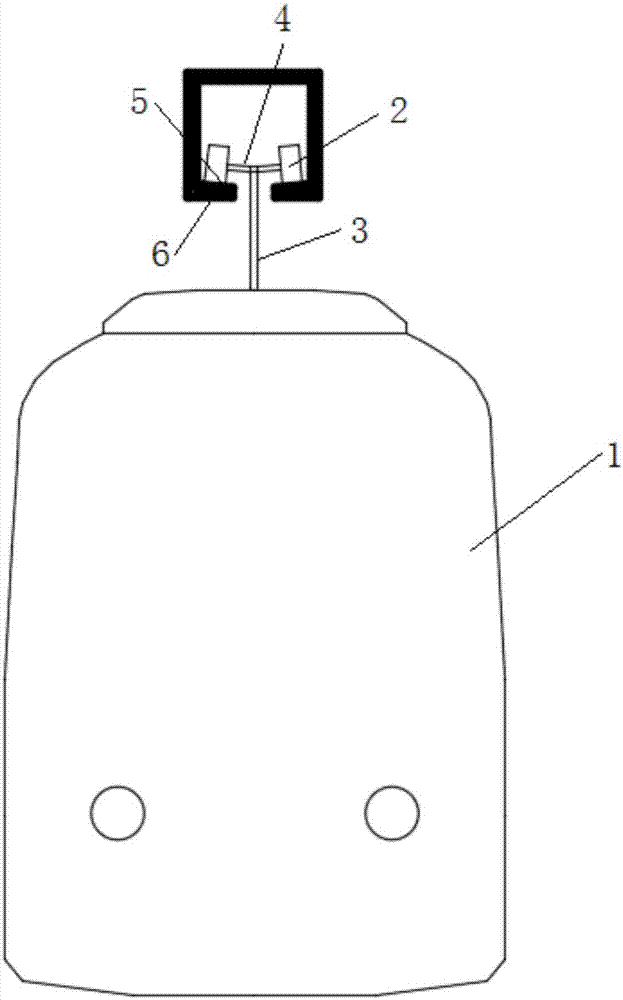

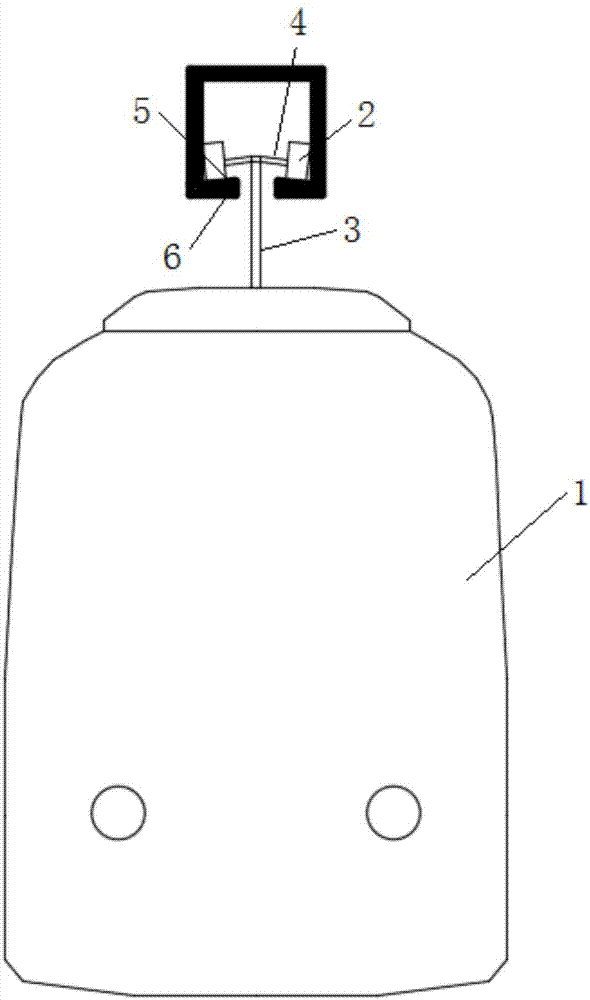

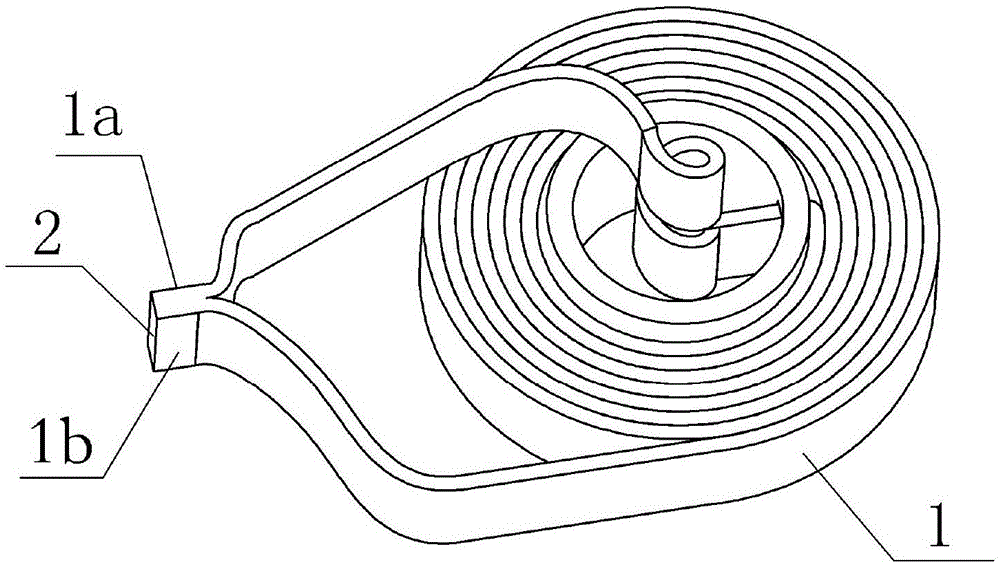

Manufacturing method of superconducting magnet for high-temperature superconducting maglev train

ActiveCN106340381AIncrease the critical current densityGood suspensionSuperconducting magnets/coilsMagnetic core manufactureForce linesHigh-temperature superconductivity

The invention discloses a manufacturing method of a superconducting magnet for a high-temperature superconducting maglev train. The manufacturing method comprises the steps of A. coating the surface of a high-temperature superconducting strip (1) with a curing agent; winding the high-temperature superconducting strip (1) from inside to outside during coating to form a hollow circular ring shape or solid round cake, and enabling the inner end (1a) of the strip (1) to be exposed; B. connecting the inner end (1a) of the high-temperature superconducting strip (1) and the outer end (1b) of the high-temperature superconducting strip (1) to form a superconducting joint (2), and forming a closed blocky superconducting ring or superconducting cake. The superconducting magnet manufactured by the method is high in critical current density, and magnetic force lines concentrated in an area above a magnetic track can enter the superconducting magnet in a dense and concentrated way so as to be subjected to concentrated pinning, so that the superconducting magnet can produce strong suspension force and guide force.

Owner:SOUTHWEST JIAOTONG UNIV

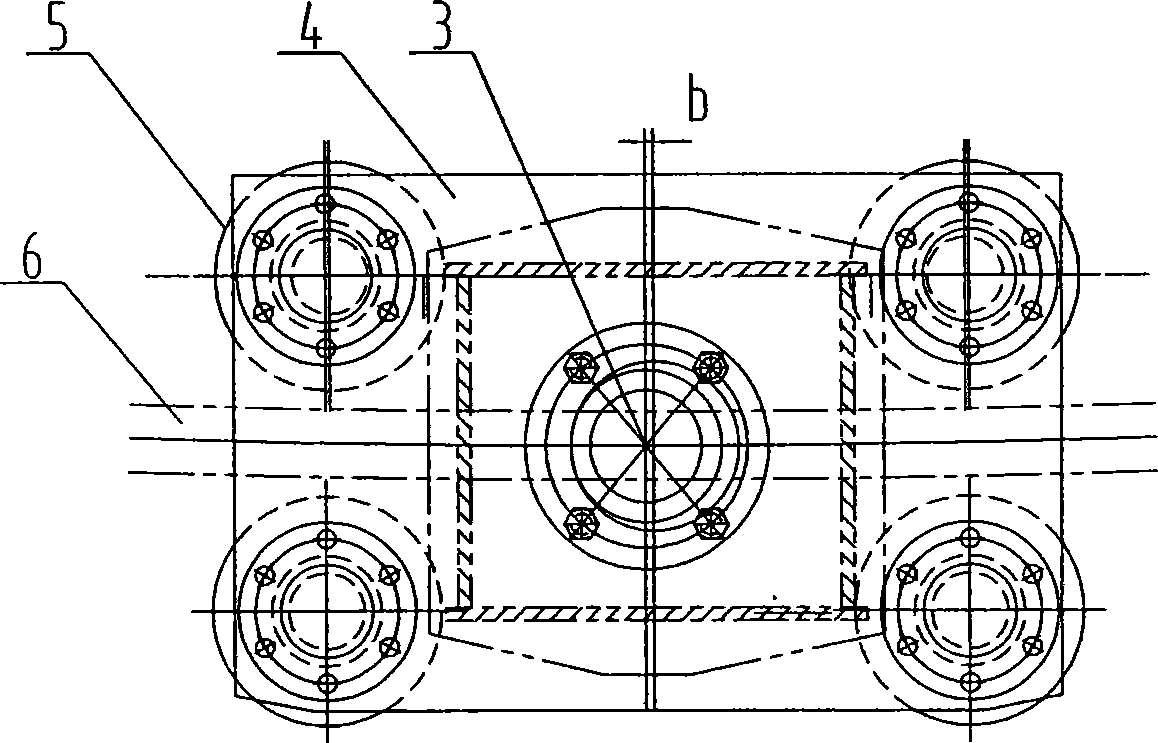

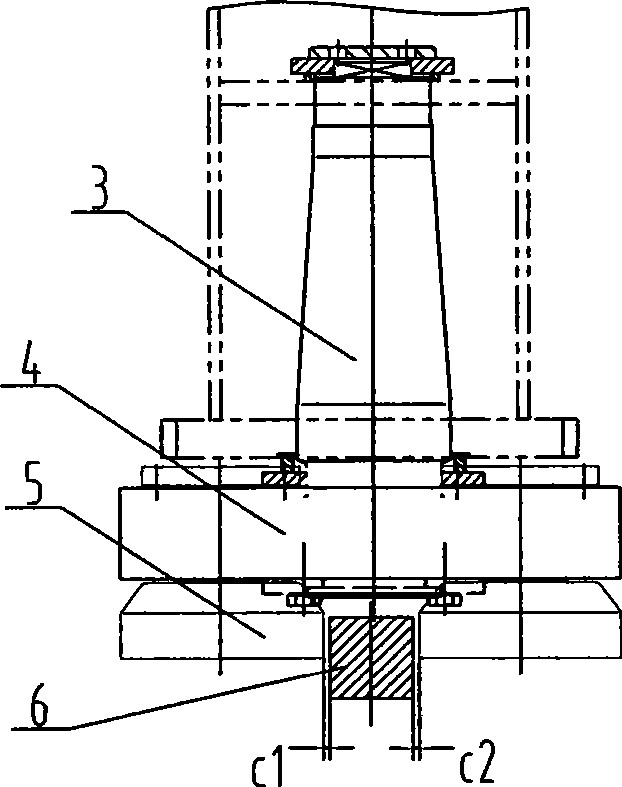

Guiding device for rotating mechanism of ring crane

InactiveCN101362573AHigh coincidenceHigh lifting point positioning accuracyTravelling gearMechanical engineeringOrbit

A guiding device of a rotating mechanism of a ring crane relates to an auxiliary device of cranes. The guiding device of the prior art is composed of four groups of inside guide wheel devices arranged on the four angles of a crane; the adjustment of the clearance between a horizontal roller and an orbit thereof is not easily controlled, which causes the problems that the horizontal guide wheels of the ring crane has fast wear and short service life, and the crane has poor centering property and low positioning accuracy of hoisting points, etc. The guiding device has two groups of the guide wheel devices which are respectively arranged on two ends of an end beam of the crane, and the mounting frame for each group of the guide wheel device is connected with the end beam of the crane; an idler axle is fixed with the mounting frame; four horizontal rollers are fixed on the mounting frame by bearings and horizontal roller shafts, wherein, two horizontal rollers are arranged at the insides of the orbit, and the other two horizontal rollers are arranged at the outsides of the orbit; and the idler axle and the horizontal roller shafts are eccentric structures. The guiding device solves the problems existing in the prior art and ensures that the crane are in optimum running state.

Owner:TAIYUAN HEAVY IND

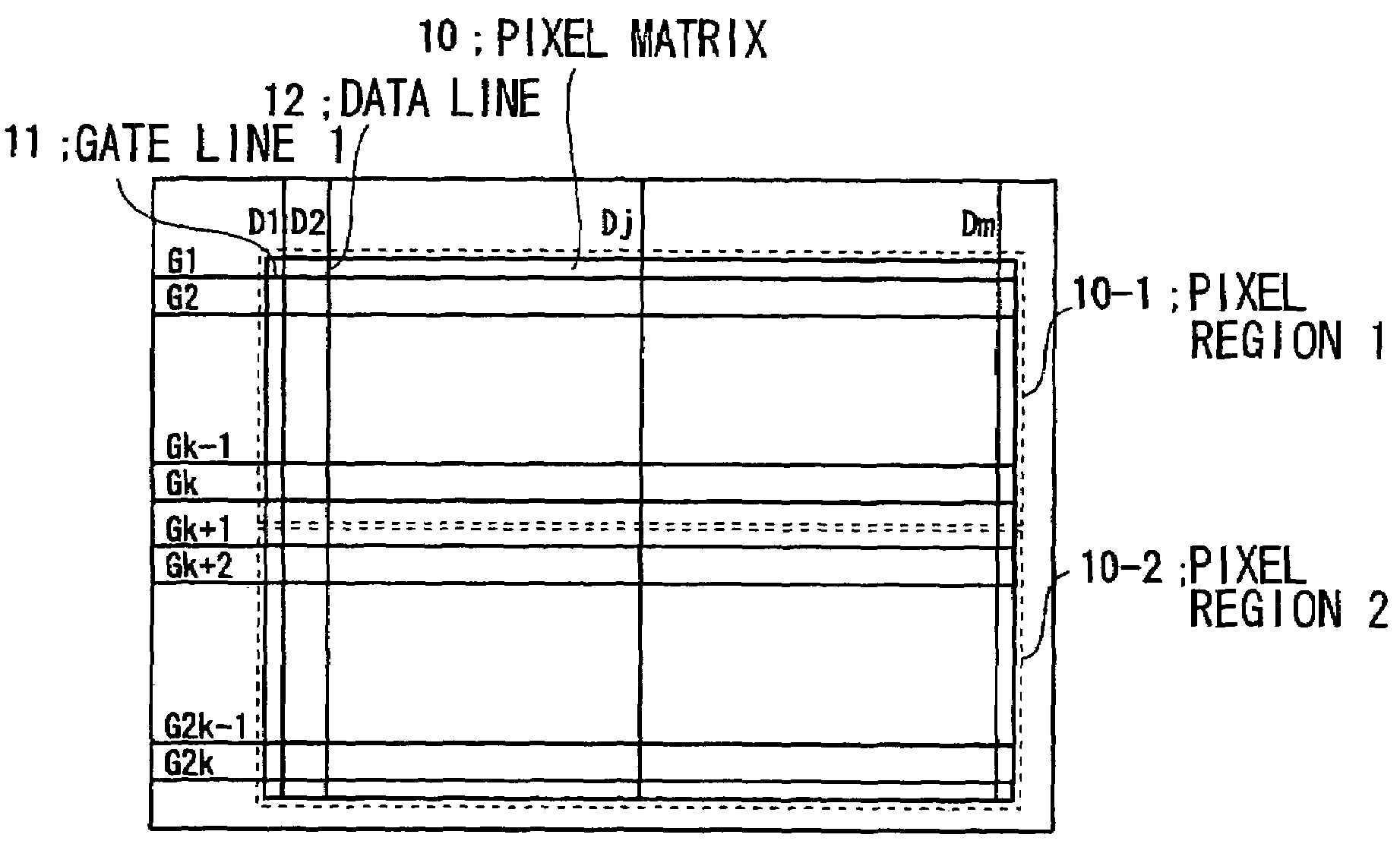

Method for driving a liquid crystal display device

ActiveUS7525527B2Increase opening ratioReduce brightness unevennessStatic indicating devicesIdentification meansPattern recognitionLiquid-crystal display

In a liquid crystal display device, a pixel matrix is divided into a plurality of pixel regions in unit of pixel column. The pixel matrix is driven so that video signals having the same polarity are written into every divided pixel regions and video signals having different polarities are written into adjacent pixel regions during a vertical period during which signals of one screen are written and the polarity of the video signals is alternately changed every vertical period.

Owner:HANNSTAR DISPLAY CORPORATION

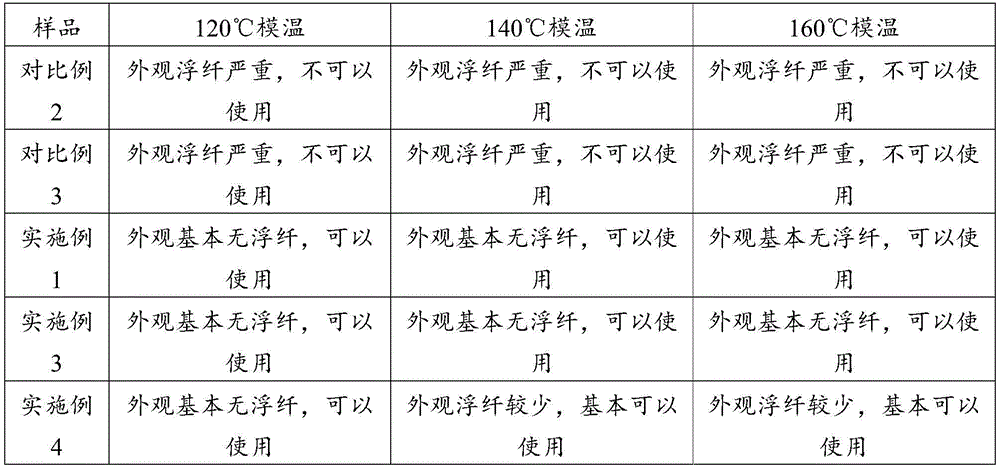

Glass fiber reinforced polypropylene material used for thin-wall injection molding and preparation method of glass fiber reinforced polypropylene material

The invention relates to a glass fiber reinforced polypropylene material used for thin-wall injection molding. The glass fiber reinforced polypropylene material comprises the following components (inpercentages by mass): 41-47% of polypropylene resin, 4.5-8% of an amorphous polyolefin, 18-22% of modified glass fibers, 12.5-16.2% of a polyolefin elastomer, 7.7-11% of ternary copolymer polypropylene, 4-6% of styrene-butadiene transparent impact-resistant resin, 0.1-0.5% of a main antioxidant, and 0.3-0.8% of an auxiliary antioxidant, wherein the cross section of the glass fibers is elliptical.At the same time, the invention also relates to a method of preparing the material. The surface of a component prepared from the material provided by the invention has no floating fibers, low warpage,no gas mark and no tiger skin stripes, and the component has good mechanical properties; at the same time, the elliptical cross section of the glass fibers reduces orientation of the glass fibers andreduces anisotropy of the glass fibers, so that the problem of warpage deformation of the glass fiber reinforced polypropylene material is improved, and the mechanical properties of the material areimproved; and the glass fibers have better compatibility with the polypropylene material after being modified by hydrofluoric acid, the glass fibers and the polypropylene material are more tightly combined, so that the mechanical properties of the prepared finished product are improved.

Owner:SUZHOU RUNJIA ENGINEER PLASTIC

Carbon fiber reinforced resin composite material, use thereof and preparation method of rubber frame of electronic equipment enclosure and/or module

The invention discloses a carbon fiber reinforced resin composite material, use thereof and a preparation method of a rubber frame of an electronic equipment enclosure and / or a module, and relates to the technical field of carbon fiber reinforced resin composite materials. A product injection-molded by the carbon fiber reinforced resin composite material can not only meet the requirements of high rigidity and high dimensional stability, but also obtain high-light spraying-free effects. The carbon fiber reinforced resin composite material is prepared from the following components: 15-25wt% of carbon fibers, 50-70wt% of PC+ABS alloy, 10-20wt% of a smoothing agent, 2-4wt% of a flexibilizer and 0.3-0.5wt% of an antioxidant, wherein the melt index of the PC+ABS alloy is greater than and equal to 40. The carbon fiber reinforced resin composite material disclosed by the invention is applicable to the injection molding of thin-wall products.

Owner:HISENSE VISUAL TECH CO LTD

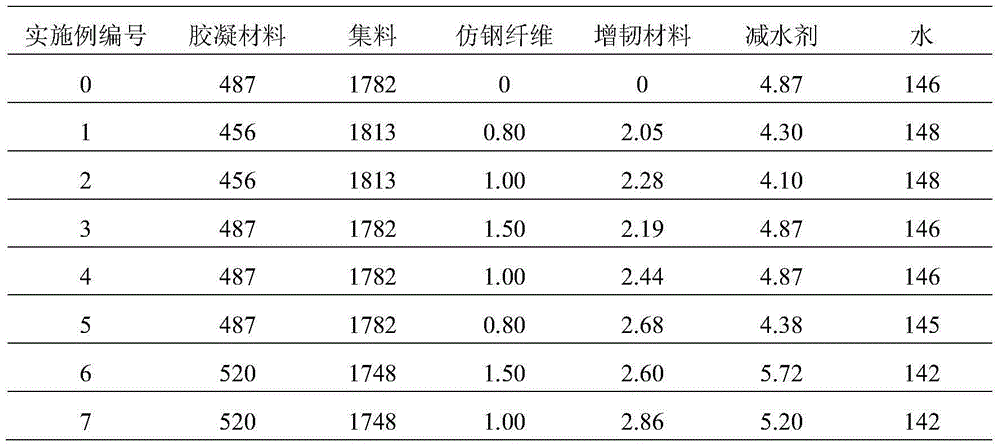

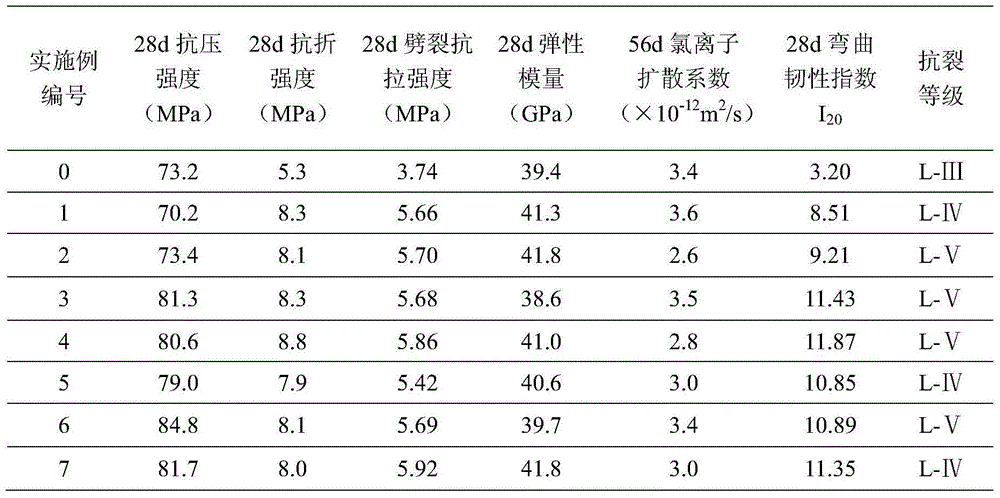

Long-service-life concrete for steel-concrete composite beam hogging moment area and preparation method long-service-life concrete

The invention discloses long-service-life concrete for a steel-concrete composite beam hogging moment area and a preparation method of the long-service-life concrete, and relates to the field of long-service-life concrete preparation. The long-service-life concrete comprises, in parts by mass, 456-520 parts of a cementing material, 1748-1813 parts of aggregates, 0.80-1.50 parts of imitation steel fibres, 2.05-2.86 parts of a toughening material, 4.10-5.72 parts of a water reducer and 142-148 parts of water; the 28-d compressive strength of the long-service-life concrete is not less than 69.0MPa, the 28-d breaking strength of the long-service-life concrete is not less than 7.0MPa, the 28-d splitting tensile strength of the long-service-life concrete is not less than 5.0MPa, the 28-d elasticity modulus of the long-service-life concrete is not less than 36.0GPa, the 56-d chloride ion diffusion coefficient of the long-service-life concrete is less than 4.0*10<-12>m<2> / s, the cracking resistance rank of the long-service-life concrete achieves L-IV rank, and the 28-d bend ductility index I20 of the long-service-life concrete is not less than 8. The flexural strength, bend ductility and crack resistance of the long-service-life concrete are high, the fragility of the concrete is changed, and the concrete is good in structure durability, long in service life, low in cost, and convenient to massively use.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

Preparation method for graphene oxide treated hybrid chopped fiber reinforced polyether sulfone composite material

The invention belongs to the technical field of fiber reinforced thermoplastic composite materials, and particularly relates to a preparation method for a graphene oxide treated hybrid chopped fiber reinforced polyether sulfone composite material. The preparation method specifically comprises the following steps: blending, washing and drying fiberglass and carbon fibers; preparing an aqueous solution of graphene oxide at a certain concentration; adding the aqueous solution of graphene oxide into the hybrid fibers; drying the hybrid fibers treated with graphene oxide in a drying oven to remove water; mixing the treated hybrid short fibers and polyether sulfone particles, and performing melting, extrusion and granulation to prepare the hybrid chopped fiber reinforced polyether sulfone composite material. According to the method, the bonding strength of an interface of the fibers of the prepared composite material and polyether sulfone resin is strong, equipment adopted for a preparation process is simple, convenient to operate and low in energy consumption and cost, and the composite material has excellent mechanical performance and strength designability.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

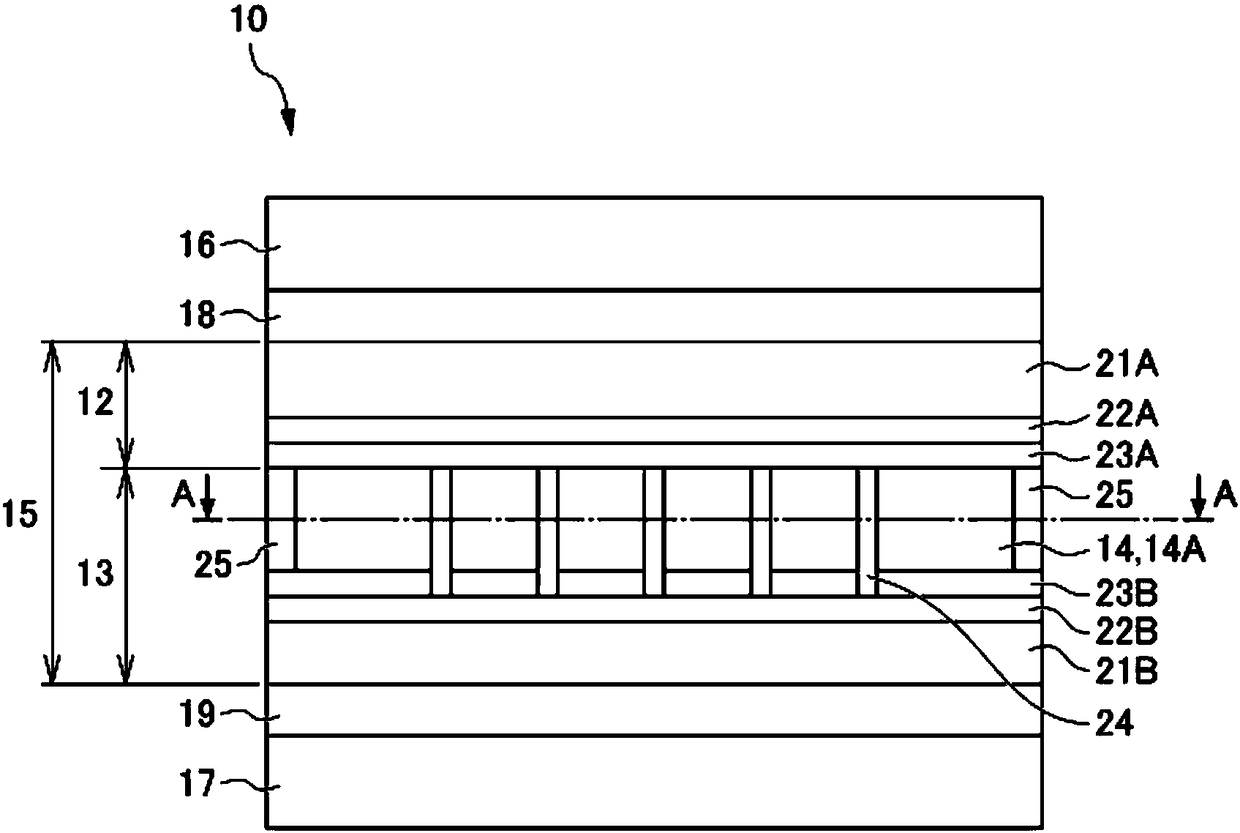

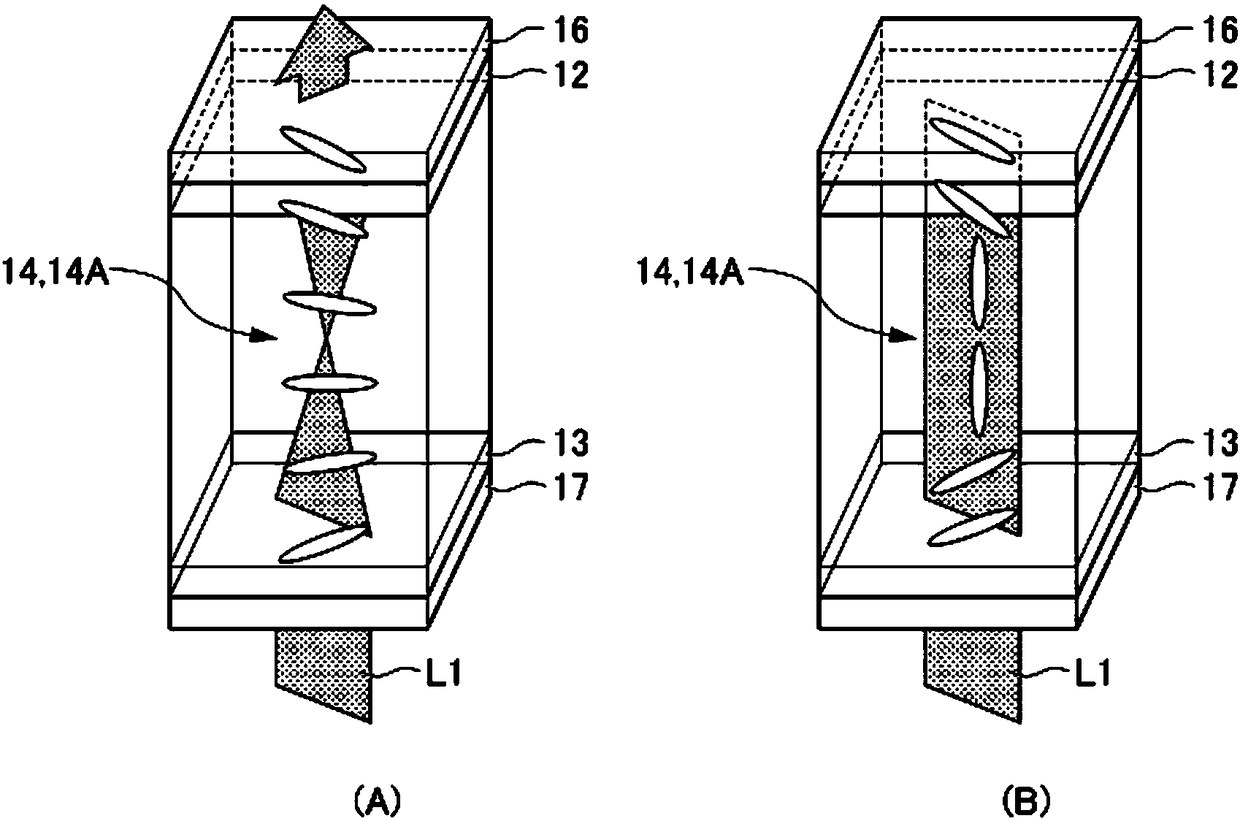

Light control film and laminated glass

PendingCN108463768AReduce orientationPrevent deterioration of appearance qualityWindowsAntiglare equipmentTransmittanceEngineering

The purpose of the present invention is to, for example, even when a light control film is used as an intermediate material of laminated glass, enable effective avoidance of a reduction in external appearance quality, and sufficiently stable driving, and prevent diffracted light from being discerned by effectively avoiding a reduction in transmittance and a deterioration in liquid crystal alignment. A light control film (1) is provided with: a first laminate (13) in which an alignment layer (23B) is provided; a second laminate (12) in which an alignment layer (23A) is provided; a liquid crystal layer (14) which is sandwiched between the first laminate (13) and the second laminate (12) and contains liquid crystal molecules; a spacer (24) which is disposed in the liquid crystal layer (14) tohold the thickness of the liquid crystal layer (14); and electrodes (22B, 22A) provided in the first laminate (13) and / or the second laminate (12), and controls transmitted light by controlling the alignment of the liquid crystal molecules by driving by the electrodes (22B, 22A), wherein the proportion of an area occupied by the spacer (2) per unit area when the light control film (1) is viewed from the front in a light controllable-region of the liquid crystal layer is 0.1-10% inclusive.

Owner:DAI NIPPON PRINTING CO LTD

Production method of super-strength chinlon 66 fiber

ActiveCN108441974AImprove spinnabilityUniform and stable viscosityMonocomponent copolyamides artificial filamentMelt spinning methodsFiberMaterials science

The invention discloses a production method for super-strength chinlon 66 fiber. The production method comprises the main steps of nylon 66 saline solution, concentration polymerization, spinning, cooling, oiling, drafting forming and winding. The production method is simple in technology and easy to implement, batched and continuous production of the super-strength chinlon 66 fiber can be achieved, the production efficiency is high, the yield is large, the performance of product batch pieces is uniform and stable, the breaking strength of the obtained super-strength chinlon 66 fiber reaches 10.0-10.4 g / d, the elongation at break reaches 16-22%, the elongation rate under the constant load reaches 10.5-13.5%, the dry hot shrinkage rate is 4.7-7.7%, the strength retention is larger than 90%,and the method has the advantages of being high in strength, low in unit weight, good in fatigue resistance, impact resistance, friction resistance and heat resistance and the like.

Owner:SHEN MA INDUSTRY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com