Preparation method for chopped fiber reinforced thermoplastic composite materials

A technology for reinforcing thermoplastics and chopped fibers, which is applied in fiber types, fiber treatment, textiles and papermaking, etc. It can solve the problems of poor surface activity, poor interface performance, and difficulty in infiltration, and achieve reduced orientation, improved inertness, and increased viscosity. The effect of the ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

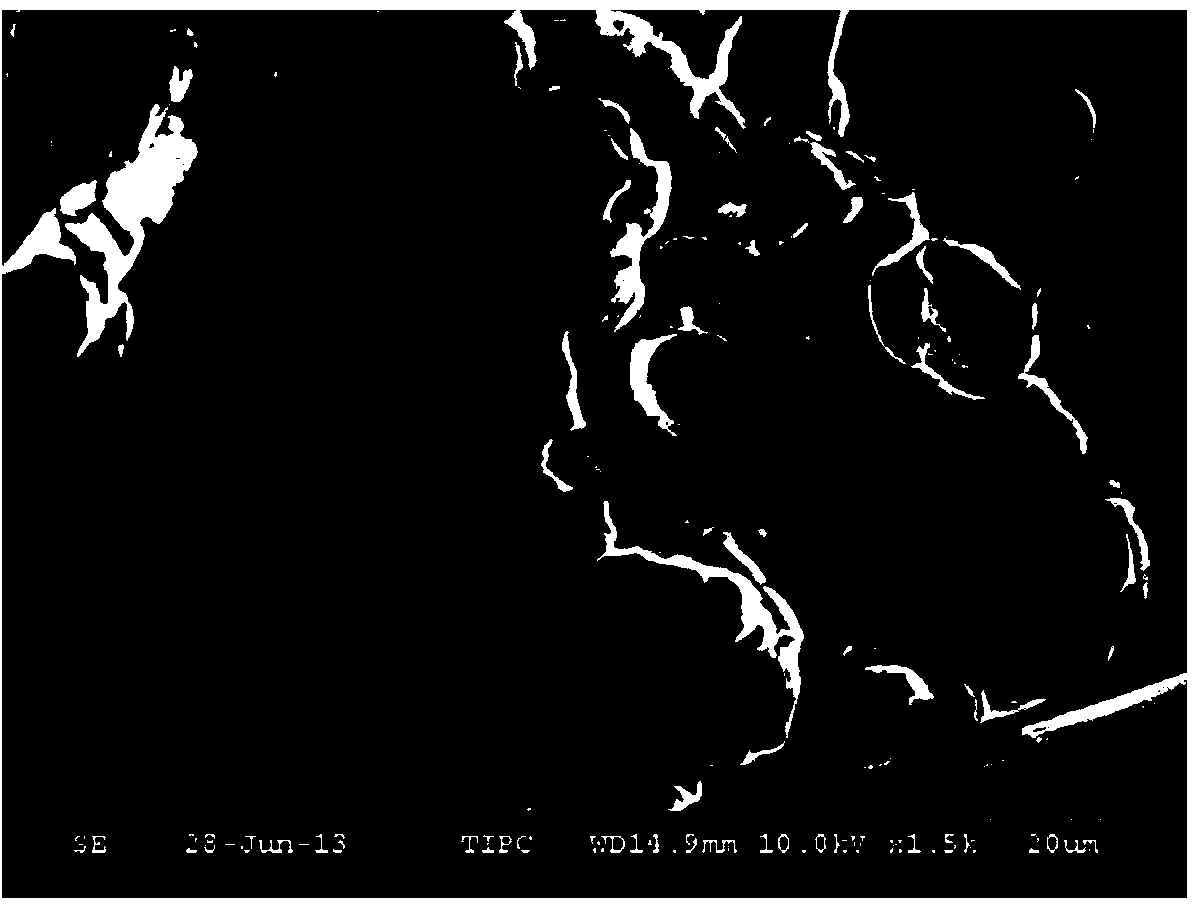

[0029] 1) Weigh 2 g of the phenolic resin crosslinking precursor and dissolve it in the ethanol solution, stir evenly, and prepare a phenolic resin ethanol coating solution with a total amount of 200 ml and a concentration of 0.05 g / ml;

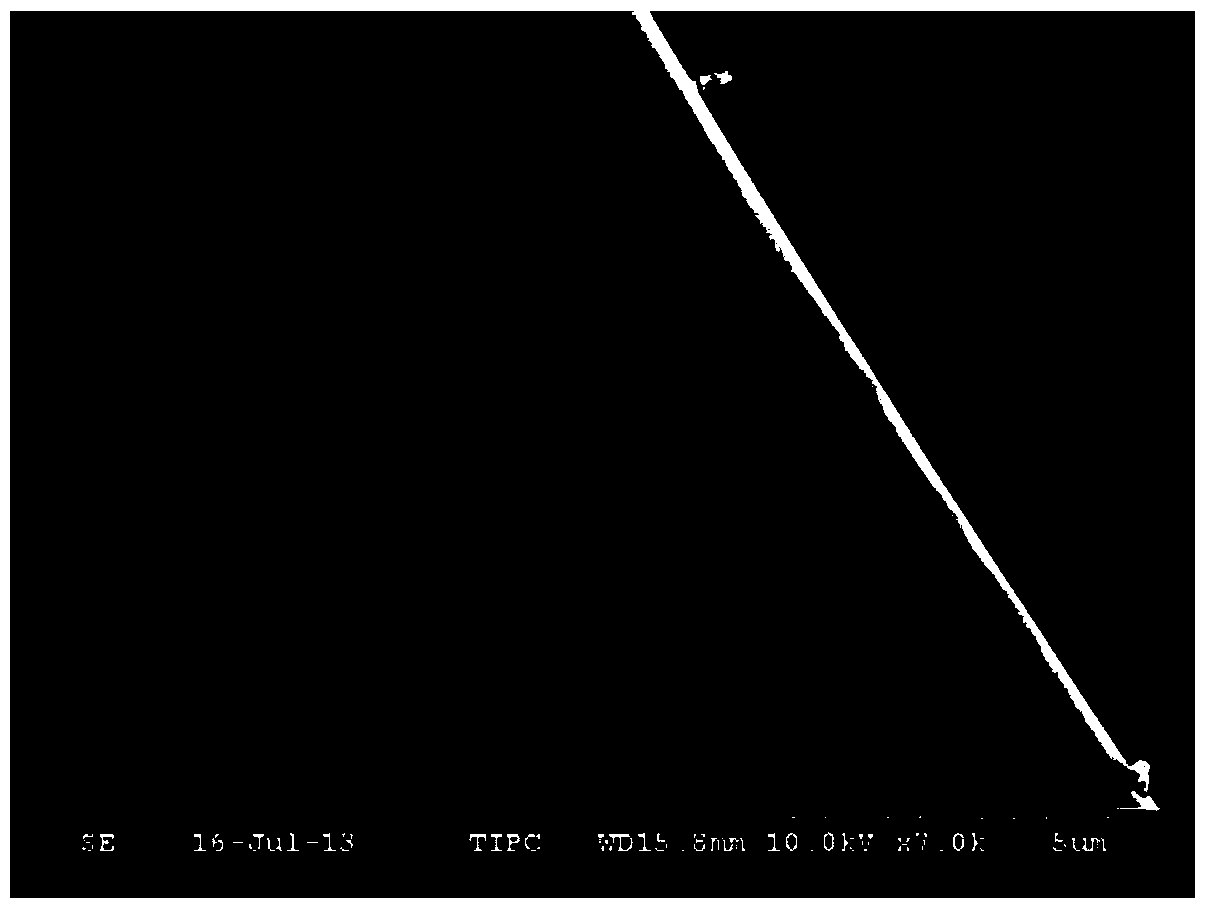

[0030] 2) Take by weighing 200g of high-density polyethylene short-cut fibers, the fiber length is 500 μm, clean the high-density polyethylene short-cut fibers with acetone in a Soxhlet extraction device for 12 hours, and dry to obtain the dried high-density polyethylene after the acetone treatment. Density polyethylene chopped fibers;

[0031] 3) Then add the prepared phenolic resin ethanol coating solution to the dry high-density polyethylene chopped fibers, compact the chopped high-density polyethylene fibers so that they are all immersed in the phenolic resin ethanol coating solution, and seal Soak for two hours, during this period, open the seal and stir once every 20 minutes, and stir evenly;

[0032] 4) After two hours, place the soak...

Embodiment 2

[0037] 1) Weigh 5 g of the phenolic resin crosslinking precursor and dissolve it in the ethanol solution, stir evenly, and prepare a total amount of 100 ml of novolac ethanol coating solution whose concentration is 0.05 g / ml;

[0038] 2) Take by weighing 100g chopped aramid fiber (poly-p-phenylene terephthalamide fiber), the fiber length is 0.6cm, clean the chopped aramid fiber with acetone in a Soxhlet extraction device for 18 hours, and After being dried, the chopped aramid fibers treated with acetone and dried;

[0039] 3) Then add the prepared novolac ethanol coating solution to the dried chopped aramid fibers, compact the chopped aramid fibers so that they are all immersed in the novolak alcohol coating solution, seal and soak for two hours, During this period, open the seal and stir once every 15 minutes, and stir evenly;

[0040] 4) After two hours, place the soaked chopped aramid fibers in a fume hood to completely volatilize the ethanol. During the volatilization and...

Embodiment 3

[0045] 1) Weigh 10 g of phenolic resin crosslinking precursor and dissolve it in ethanol solution, stir evenly, and prepare a total amount of 100ml of novolac ethanol coating solution with a concentration of 0.1g / ml;

[0046] 2) Weigh 100 g of chopped glass fibers with a fiber length of 500 μm, wash and treat the chopped glass fibers with acetone in a Soxhlet extraction device for 20 hours, and dry to obtain chopped glass fibers treated with acetone and dried;

[0047] 3) Then add the prepared phenolic ethanol coating solution to the dried chopped glass fibers, compact the chopped glass fibers to make them all immersed in the phenolic alcohol coating solution, seal and soak for two hours, during which each Open the seal and stir once every 35 minutes, and stir evenly;

[0048] 4) After two hours, place the soaked chopped glass fibers in a fume hood to completely volatilize the ethanol. During the volatilization and drying process, stir once every 35 minutes to prevent uneven c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com