Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Moderate volatilization speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluororubber cloth clamp combination V seal ring and method for producing the same

The invention provides a V-shaped seal ring with a fluororubber canvas combination which is characterized in that the seal ring is produced by materials with the following portions by weight: 100 portions of peroxide vulcanized fluororubber, 20-50 portions of light-colored filler, 3-5 portions of zinc oxide, 2-5 portions of iron oxide red, 3-5 portions of 2,5-dimethyl-2,5-di-(tert-butyl peroxide) hexane, 4-6 portions of triallyl glycicy isocyanuratel and 0.5-1.5 portion of processing agent. A preparation method of the invention indicates that the materials with the portions by weight are first made into fluororubber dry mix which is then dissolved in mixed solvent so as to prepare adhesive cement; then the adhesive cement is dip coated on glass fiber cloth to prepared the fluororubber glass fiber canvas which is then die pressed by a vulcanized product combination to prepare the V-shaped seal ring with the fluororubber canvas combination. In addition, the obtained V-shaped seal ring with the fluororubber canvas combination has long service life and is resistant to high temperature, high pressure and hydraulic safety fluid.

Owner:GUANGZHOU MECHANICAL ENG RES INST

Halogen free environment-friendly cleaning agent

InactiveCN101748003AAvoid harmEasy to cleanNon-ionic surface-active compoundsOrganic detergent compounding agentsNon toxicityAlcohol

The invention discloses a halogen free environment-friendly cleaning agent, consisting of the following materials by weight: 5-10 percent of C9-C12 isoparaffin, 1-8 percent of degreasing agent, 5-12 percent of binary alcohol ether, 1-5 percent of non-ionic surfactant and the balance alkyl alcohol. The invention has the beneficial effects that the halogen free environment-friendly cleaning agent has excellent cleaning capability of cleaning the residual soldering flux on circuit boards in the electronics industry, has rapid cleaning speed, moderate volatilization speed and non-toxicity, is halogen free, has non pungent smell and no harm to the human body, and the cleaned board can not become white and has no water mark. The invention has no pollution to the atmospheric environment, is a cleaning agent with high cleaning capability and high environment protection.

Owner:深圳市唯特偶新材料股份有限公司

Industrial paint film separating agent and application thereof

InactiveCN104231716AWide range of applicationsModerate volatilization speedChemical paints/ink removersOrganic acidSeparating agent

The invention discloses an industrial paint film separating agent and application thereof. The industrial paint film separating agent comprises the following components in percentage by weight: 50-75 percent of organic acid, 2-20 percent of alcohols, 0.5-5 percent of fatty alcohol-polyoxyethylene ether and alkylphenol ethoxylates, 0.5-2.5 percent of an anionic surfactant and 5-25 percent of water. According to the prepared separating agent disclosed by the invention, an acrylic ester paint film and epoxy paint films on the surface of a plastic part can be effectively removed and the damage to the plastic part is avoided. After the paint films on the surface of the plastic part are separated by using the separating agent, the surface of the plastic part is cleaned by using a plastic cleaning agent, so that the plastic part can be directly and continuously used as a spraying or printing substrate. The separating agent is mild in volatilization speed and can be reused.

Owner:NANTONG MEMTECH TECH

Printing ink

The invention provides a sort of ink manufactured by raw materials with the following mass percent: 10-15 percent of butadiene acrylonitrile rubber, 9-15 percent of neoprene, 5-10 percent of acetone, 5-10 percent of toluene, 10-15 percent of glycol butyl et her, 9-15 percent of linseed oil, 5-11 percent of silicon oil, 1-5 percent of titanate coupling agent, 10-25 percent of pigment, 1-4 percent of polyethylene wax, and 0.5-3 percent of aluminum stearate; the ink of the invention is mainly applicable to printing of various plastic material carriers and is provided with high adhesive attraction and good adhesive effect. In the applying facet, superficial treatment is not needed to be carried out to the plastic material carrier when used; printing can be carried out directly, thus guaranteeing good printing effect.

Owner:郜爱民 +1

Alcohol-dissoluble polyurethane resin compound printing ink and preparation method thereof

The invention discloses an alcohol-dissoluble polyurethane resin compound printing ink and a preparation method thereof. The printing ink is prepared by processing the following components by weight percent: 25-35% of alcohol-dissoluble polyurethane resin liquor, 1-3% of polyvinyl butyral resin, 1% of extinction powder, 8-33% of pigment, 0-0.5% of an adhesion reinforcing agent, 15-40% of ethanol and 15-25% of ethyl acetate; and polyurethane resin in the alcohol-dissoluble polyurethane resin liquor accounts for 30-35% by weight percent. The printing ink has the advantages of environmental friendliness, safety, wide application scope, good thermal stability and the like.

Owner:HUIZHOU SURE SCI & TECH CO LTD +1

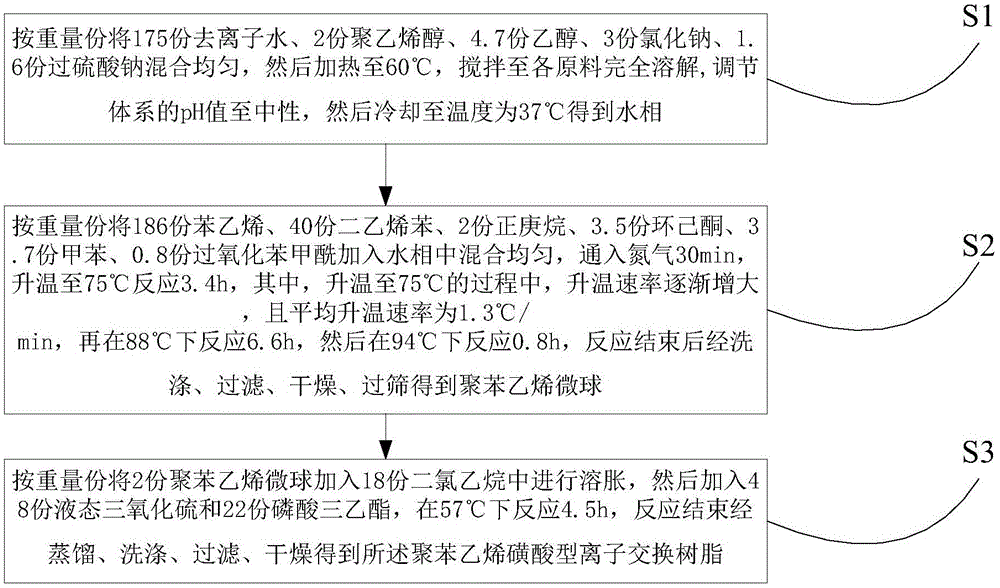

Preparation method of polystyrene sulfonic acid type ion exchange resin

InactiveCN105061655AImprove efficiencyReduce reactivityAnion exchangersIon exchangePolystyrene microsphere

The invention discloses a preparation method of polystyrene sulfonic acid type ion exchange resin. The preparation method comprises steps as follows: deionized water, polyvinyl alcohol, ethanol, sodium chloride and sodium persulfate are mixed uniformly, and an aqueous phase is obtained; styrene, divinylbenzene, n-heptane, cyclohexanone, methylbenzene and benzoyl peroxide are added to the aqueous phase to be uniformly mixed, react for 2.5-4 h at the temperature ranging from 70 DEG C to 80 DEG C, react for 5-8 h at the temperature ranging from 85 DEG C to 90 DEG C, react for 0.5-1 h at the temperature ranging from 91 DEG C to 95 DEG C and is washed, filtered, dried and screened, and then polystyrene microspheres are obtained; the polystyrene microspheres are added to dichloroethane to be swollen, a sulfonating agent is added, the mixture reacts for 4-5 h at the temperature ranging from 50 DEG C to 60 DEG C, and the polystyrene sulfonic acid type ion exchange resin is obtained. According to the preparation method of the polystyrene sulfonic acid type ion exchange resin, the operation is simple, conditions are mild, and the obtained polystyrene sulfonic acid type ion exchange resin has high mechanical strength, good heat resistance, a high ion exchange rate and a large specific surface area.

Owner:ANHUI WANDONG CHEM

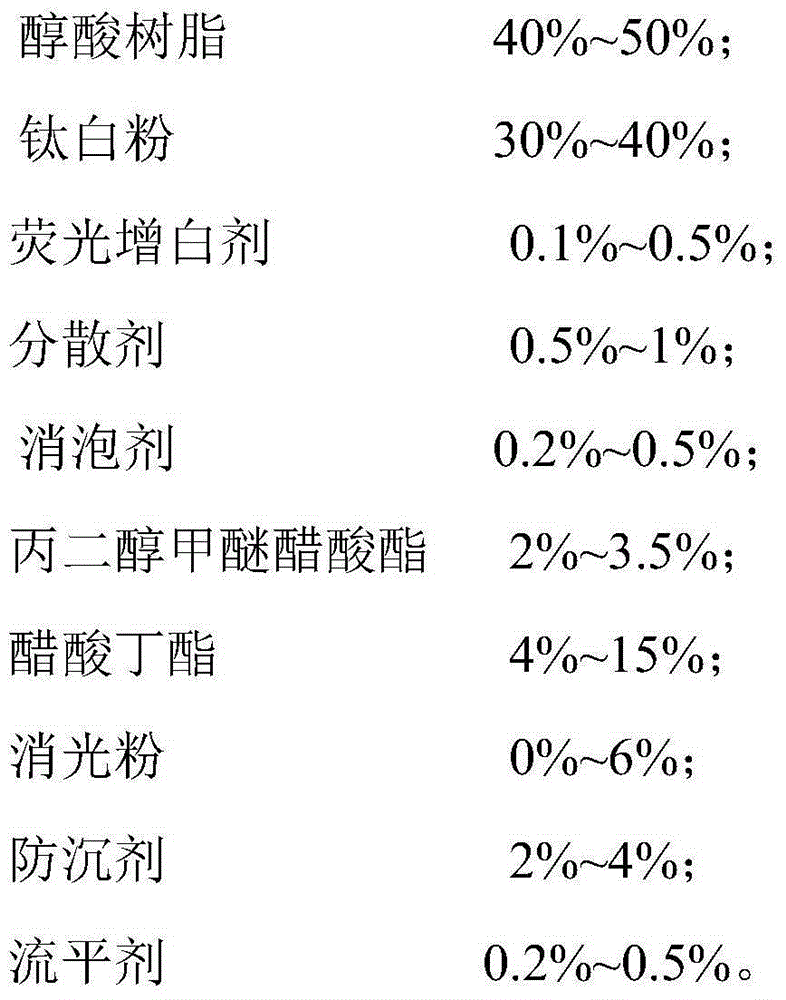

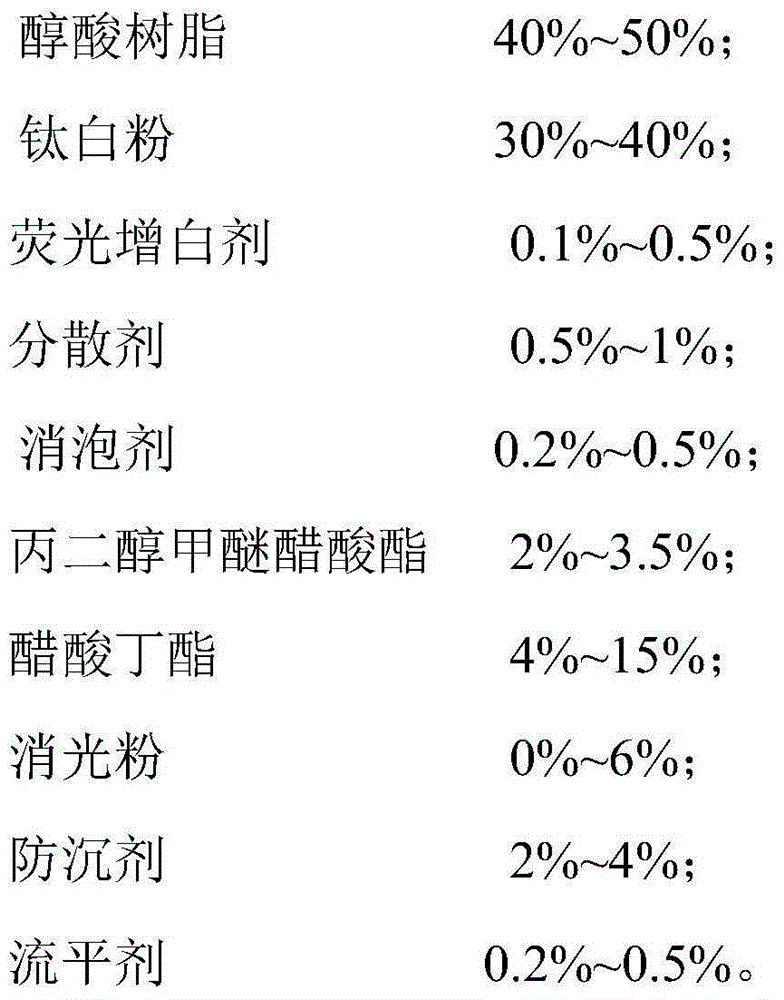

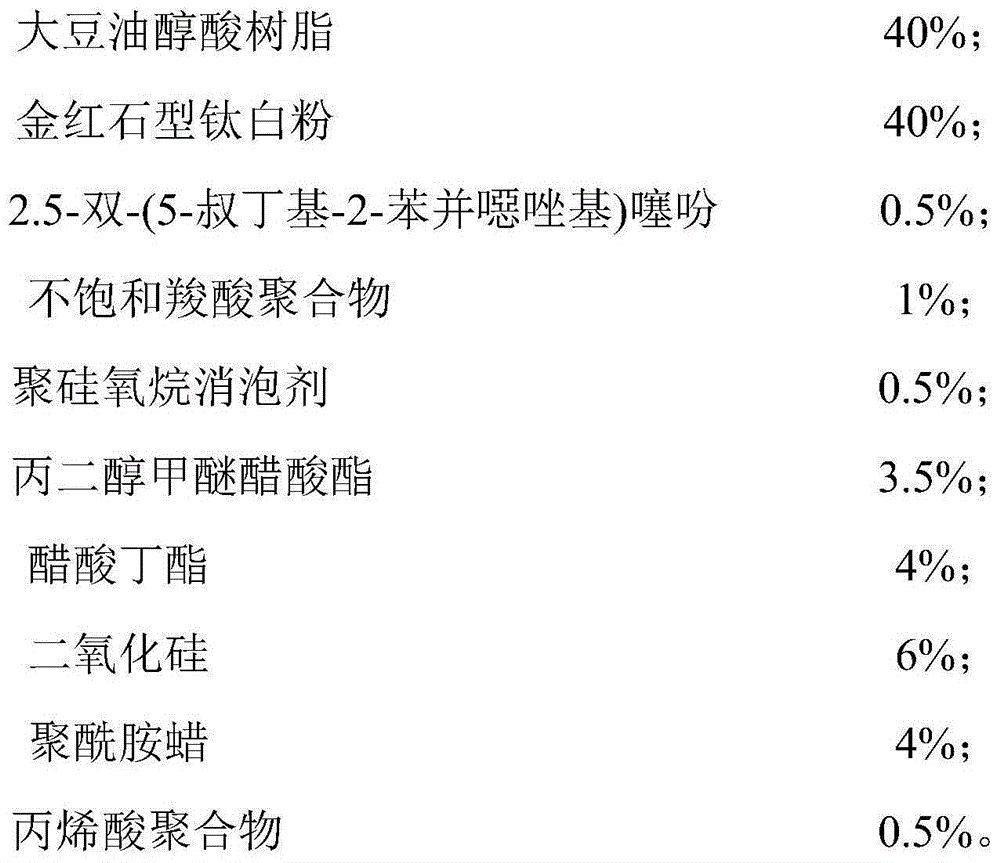

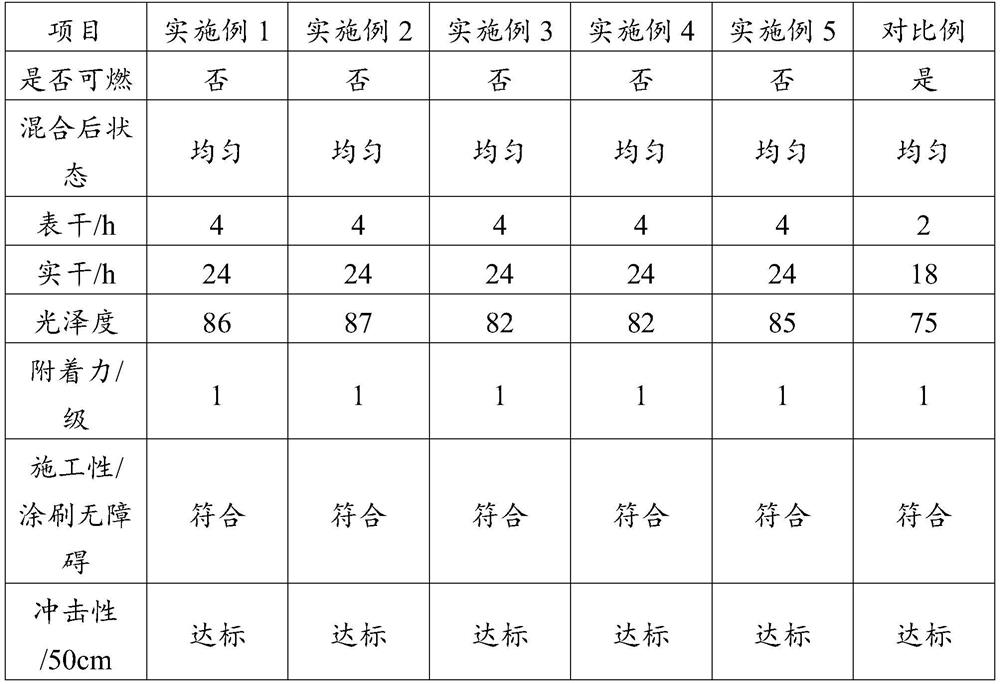

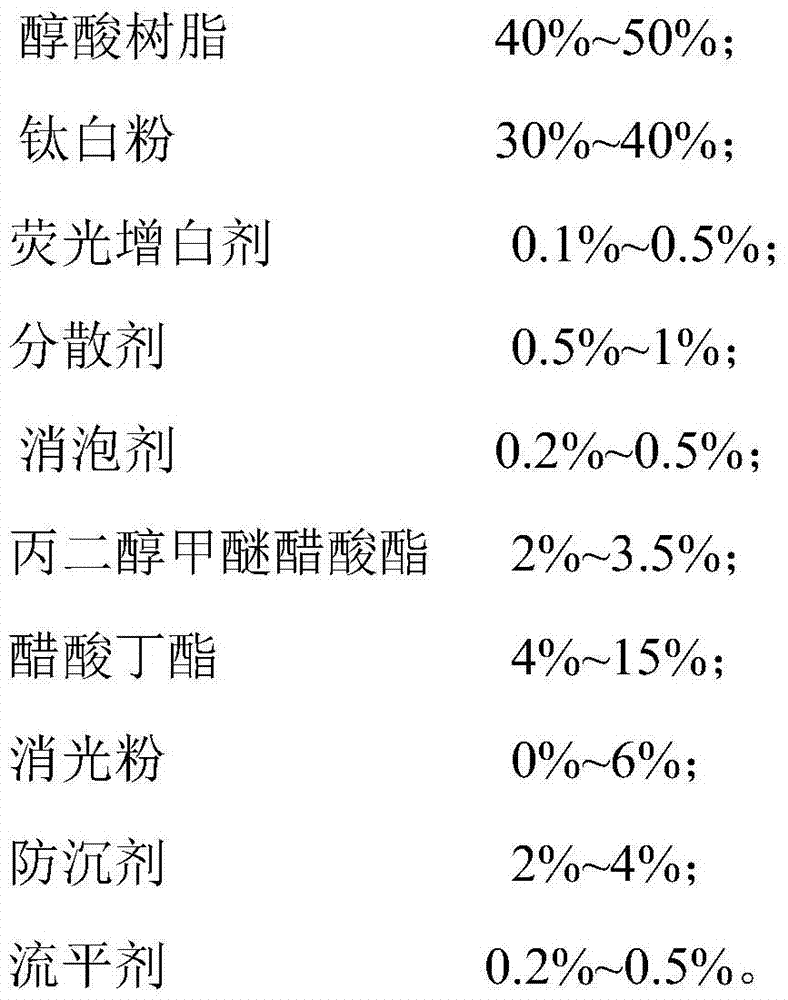

Polyurethane white paint as well as preparation method and application thereof

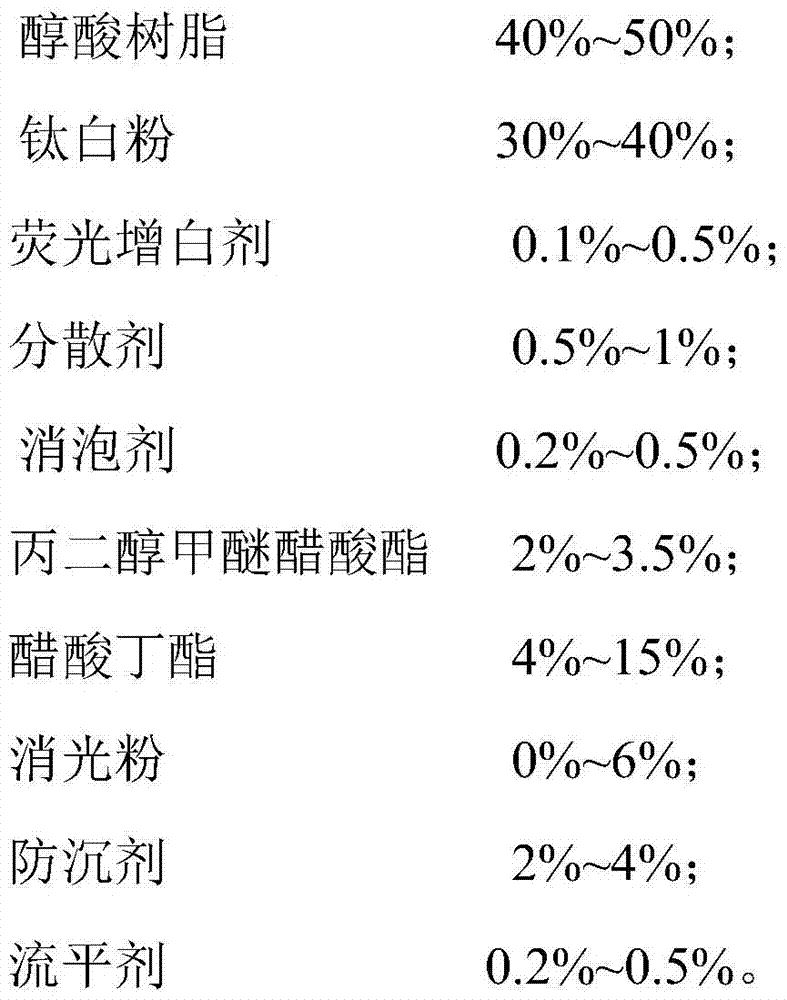

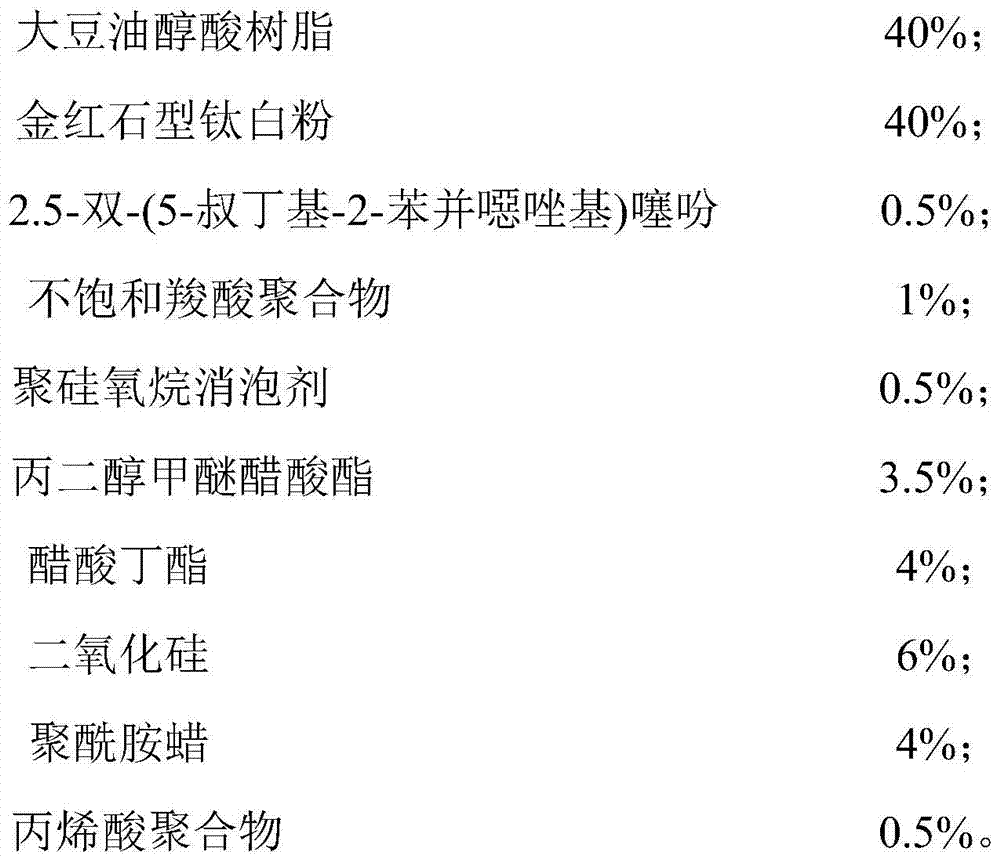

The invention relates to the technical field of coatings, and particularly discloses a polyurethane white paint as well as a preparation method and application thereof. The polyurethane white paint comprises the following formula components in percentage by weight: 40-50% of alcohol acid resin, 30-40% of titanium dioxide, 0.1-0.5% of a fluorescent brightening agent, 0.5-1% of a dispersing agent, 0.2-0.5% of an antifoaming agent, 2-3.5% of propylene glycol methyl ether acetate, 4-15% of butyl acetate, 0-6% of a matting agent, 2-4% of an anti-settling agent, and 0.2-0.5% of a flatting agent. According to the polyurethane white paint, rutile type titanium dioxide and fluorescent whitening powder are added, mixed and ground, so that the effect of obviously whitening can be achieved, and the polyurethane white paint has favorable covering power and weather resistance. What's more, according to the preparation method, the titanium dioxide and the fluorescent brightening agent are controlled to be ground into titanium dioxide pulp together, so that the whitening effect of the coating is ensured to be achieved.

Owner:中华制漆(新丰)有限公司

Preparation method of polystyrene anion-type ion exchange resin

InactiveCN105017464AImprove heat resistanceImprove completenessAnion exchangersBenzoyl peroxideN dimethylformamide

The invention discloses a preparation method of polystyrene anion-type ion exchange resin. The method comprises the following steps: deionized water, polyvinyl alcohol, gelatin, sodium chloride and sodium persulfate are well mixed, such that an aqueous phase is obtained; p-chlorostyrene, divinyl benzene, a pore-foaming agent and benzoyl peroxide are added, and the mixture is well mixed; the temperature is increased to 70-80 DEG C, and a reaction is carried out for 3-5h; a reaction is carried out for 4-8h under a temperature of 85-90 DEG C; a reaction is carried out for 0.3-1h under a temperature of 92-98 DEG C; washing, filtering, drying and sieving are carried out, such that polystyrene microspheres are obtained; the polystyrene microspheres are well mixed with 1,4-dichloromethoxybutane; phosphorus pentoxide is added, and a reaction is carried out for 5-10h under a temperature of 30-40 DEG C; filtering and washing are carried out, such that chloromethylated microspheres are obtained; the chloromethylated microspheres added into N,N-dimethylformamide; dimethylethanolamine is added; the temperature is increased to 40-45 DEG C and a reaction is carried out for 6-9h; and washing is carried out, such that the polystyrene anion-type ion exchange resin is obtained.

Owner:ANHUI WANDONG CHEM

Multifunctional environmental-friendly recyclable hydrocarbon detergent

InactiveCN102041195ANon-toxicAvoid disadvantagesOrganic non-surface-active detergent compositionsHalohydrocarbonAlcohol

The invention relates to a detergent, in particular to a multifunctional environmentally friendly recyclable hydrocarbon detergent used in a novel vacuum recycling hydrocarbon cleaning machine. The detergent comprises the following components in parts by weight: 50-60 parts of C11H24, 30-40 parts of C12H26 and 5-10 parts of alcohol ether compound or C5-C7 isomeric alcohol. The hydrocarbon detergent has the advantages that residual greasy dirt, moisture, fingerprint, metal dust and other dirts on hardware and plastic parts can be rapidly and effectively cleaned, residues of solder paste, soldering flux and the like also can be cleaned, volatilization speed is moderate, no residue is produced, and the detergent can be recycled in an appropriate pressure relief device, has longer service life and economy compared with a hydrocarbon detergent used in the current market, is not toxic or harmful to human body and is a non-ODS (ozone-depleting substance) product, thus the hydrocarbon detergent is the optimal substitute of the traditional Freon, halohydrocarbon solvent and common hydrocarbon detergent.

Owner:东莞市智高化学原料有限公司

High-weather-resistance heat-reflection steel plate coil metal paint and preparation method thereof

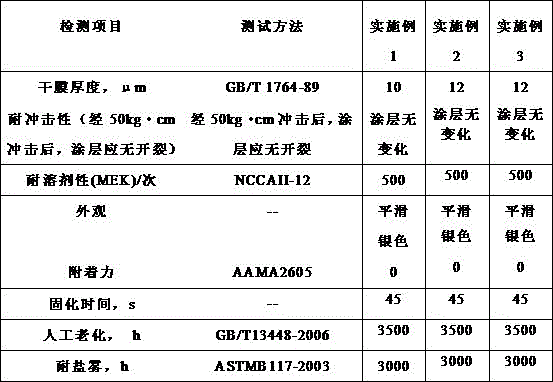

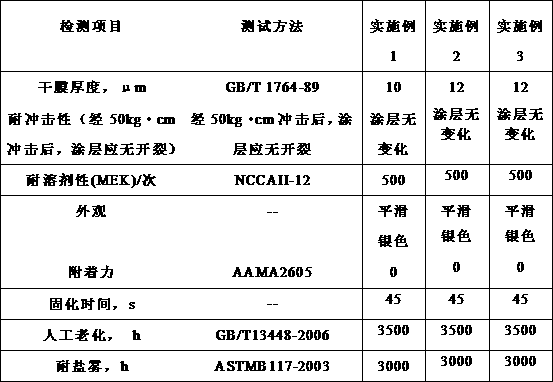

ActiveCN106280751AImprove stabilityImprove performanceReflecting/signal paintsAcrylic resinPolymethyl methacrylate

The invention relates to a high-weather-resistance heat-reflection steel plate coil metal paint and a preparation method thereof, belonging to the technical field of steel plate coil paints. The high-weather-resistance heat-reflection steel plate coil metal paint comprises the following components in percentage by mass: 20-25% of PVDF (polyvinylidene fluoride) resin, 8-11% of acrylic resin, 2-5% of polymethyl methacrylate, 10-12% of aluminum powder, 45-50% of organic solvent, 0.3-0.6% of defoaming agent, 0.5-0.8% of silane coupling agent, 0.4-0.6% of UV absorbent, 0.4-0.7% of leveling aid, 3-6% of titanium dioxide and 0.5-0.9% of directional alignment agent, totaling 100%. The paint has excellent weather resistance and favorable physical properties.

Owner:JINJIANG ANNENG BUILDING MATERIALS MFG

Carburetor cleaning agent and preparation method thereof

ActiveCN106085649AGood cleaning effectStable cleaning effectOrganic non-surface-active detergent compositionsDichloromethaneChemistry

The invention relates to a carburetor cleaning agent and a preparation method thereof and belongs to the field of automobile aerosol fine chemicals. The carburetor cleaning agent comprises a material liquid and a propellant. The material liquid comprises, by weight, 10-60 parts of toluene, 10-60 parts of dichloromethane, 1-10 parts of ethanol, 1-10 parts of ethylene glycol ethyl ether, 1-10 parts of propylene glycol methyl ether, 0.01-3 parts of polyisobutylene phenol, 0.01-3 parts of polyisobutene succinimide and 0.01-0.5 parts of a corrosion inhibitor. The propellant comprises, by weight, 30-90 parts of dimethyl ether, 10-40 parts of propane and 5-25 parts of butane. The carburetor cleaning agent has good and stable cleaning effects, a good decontamination capability, large pressure and a low price.

Owner:广州保赐利化工有限公司

Efficient carburetor cleaning agent and preparation method thereof

ActiveCN106010825AImprove solubilityLow priceDetergent mixture composition preparationOrganic non-surface-active detergent compositionsCarburetorCleansing Agents

The invention relates to an efficient carburetor cleaning agent and a preparation method thereof, and belongs to the field of aerosol fine chemicals for automobiles. The carburetor cleaning agent is composed of material liquid and a propellant, the material liquid is prepared from, by weight, 10-60 parts of methylbenzene, 10-60 parts of dichloromethane, 1-10 parts of ethyl alcohol, 1-10 parts of ethylene glycol ethyl ether, 1-10 parts of propylene glycol methyl ether, 0.01-3 parts of polyisobutylene phenol, 0.01-3 parts of polyisobutene succinimide, 0.01-10 parts of isopropylbenzene and 0.01-0.5 part of corrosion inhibitor, and the propellant is prepared from, by weight, 95-99 parts of dimethyl ether and 1-5 parts of compressed carbon dioxide. The carburetor cleaning agent is good and stable in cleaning effect, high in stain removing capacity, high in pressure and low in price.

Owner:广州保赐利化工有限公司

Marine low-surface-energy anti-fouling coating

InactiveCN104946065AGood hydrophobicityLow surface energy and elastic modulusAntifouling/underwater paintsPaints with biocidesChemistryEthylene glycol

The invention discloses a marine low-surface-energy anti-fouling coating. Raw materials of the coating comprise modified silicone-acrylate resin, chlorosulfonated polyethylene, teflon, a vinylidene fluoride-hexafluoropropene copolymer, epoxy resin, waterborne polyamide, zinc phosphate, carbon nanotube, silicon nitride, nano-sized iron oxide, nano-zinc oxide, mica powder, cerium stearate, fiber fluff, paprika, ground pepper, 3-(3,4-dichlorophenyl)-1,1-dimethylurea, PTPB, 4,5-dichloro-2-n-octyl-3-isothiazolinone, xylene, ethyl acetate, acetone, ethylene glycol monobutyl ether, cyclohexanone and an auxiliary agent. The marine low-surface-energy anti-fouling coating brought forward in the invention has high strength and a good antifouling effect, is resistant to seawater corrosion when in use and is environmentally friendly.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Three-dimensional printing material based on modification of gypsum base powder

InactiveCN106278087AFast hardeningImprove dispersion performanceAdditive manufacturing apparatusSolventGypsum

The invention discloses a three-dimensional printing material based on modification of gypsum base powder. Basic composite powder comprises the following components in parts by weight: 50-90 parts of calcium sulphate dihydrate, 25-45 parts of a modifying agent, 1-5 parts of a filling material, 0-2 parts of fibers, and 60-80 parts of a modified solvent. A water-based bonding solution comprises 70-80 parts of distilled water, 5-10 parts of glycerin, 8-10 parts of potassium sulphate, 5-10 parts of absolute alcohol and 1-2 parts of a surfactant. According to the three-dimensional printing material disclosed by the invention, a three-dimensional shaping principle is combined, and the gypsum base powder is modified, so that the hardening speed of gypsum powder is increased, and the rapid shaping requirements of the printing material are met.

Owner:SUZHOU BC TECH

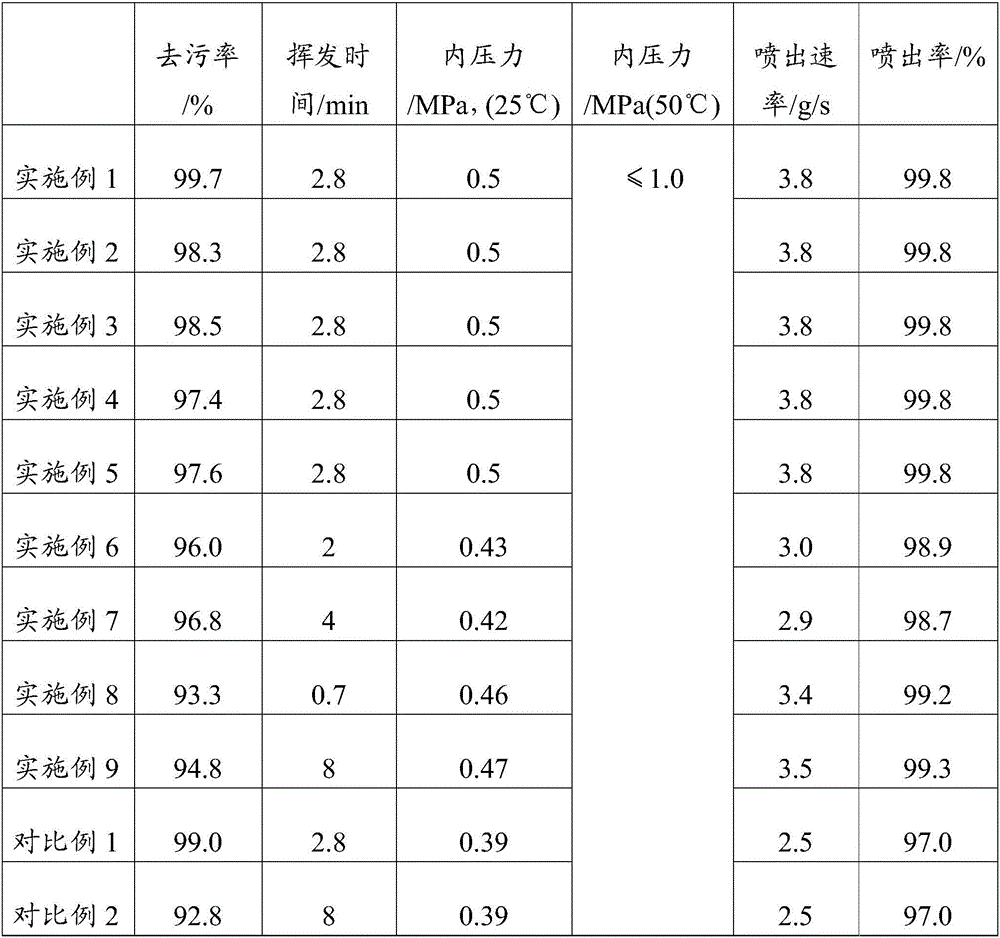

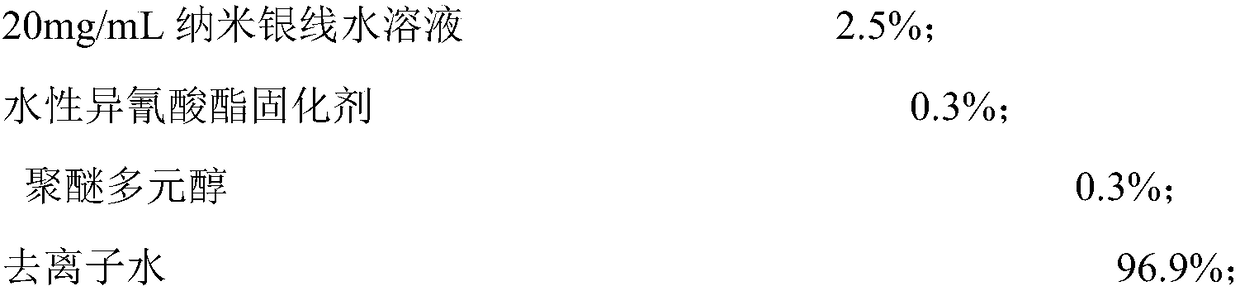

UV-type graphene quantum dot/nano-silver wire composite solvent-based conductive ink and flexible transparent conductive film based thereon

The invention discloses a UV-type graphene quantum dot / nano-silver wire composite solvent-based conductive ink and a flexible transparent conductive film based thereon. The conductive ink is preparedby uniformly mixing graphene quantum dots, prepared from graphene oxide in an ethanol solution of nano-silver wires, UV resin, a UV monomer, a photoinitiator, a dispersant and a mixed solvent according to a certain ratio; and the flexible transparent conductive film is obtained by coating the non-hardened surface of a substrate with the conductive ink through a dimpled coating process, drying theink by a tunnel furnace and carrying out UV curing. The flexible transparent conductive film has the characteristics of simple structure, good flexibility, high stability, low square resistance, excellent optical performances, simple preparation process and easiness in industrial production, and is suitable for large-size display and flexible display.

Owner:合肥微晶材料科技有限公司

Single-solvent high-speed printing plastic composite white ink and preparation method thereof

The invention provides single-solvent high-speed printing plastic composite white ink and a preparation method thereof. The single-solvent high-speed printing plastic composite white ink comprises thefollowing components: 25-35% of modified polyurethane resin, 10-12% of ternary vinyl chloride-vinyl acetate resin, 10-35% of pigment, 10-30% of ester solvent, 0-1% of polyethylene wax, 0-1% of extinction powder, 0.2-0.5% of dispersing agent, 0.5-2% of adhesion promoter and 0.2-1.5% of other auxiliaries. According to the invention, a single ester solvent is used as an ink solvent, the dissolving power and volatilization speed are moderate, and the requirements of resin synthesis and printing equipment are met. The solvent in the printing ink is a single ester, so that the recovery and rectification of a recovery system are facilitated, the rectification purity can reach 99% or above, the recovered solvent can be normally used in printing and compounding processes, and the VOC emission canbe reduced to 5% or below before recovery. Meanwhile, by optimizing the formula and raw materials of the ink, the ink can be used for printing at the printing speed of 400 m / min or above.

Owner:HUANGSHAN SHINING INK TECH

PIA (meta-phthalic acid)/nanometer titania modified alkyd resin and preparation method thereof

The invention discloses a PIA (meta-phthalic acid) / nanometer titania modified alkyd resin and a preparation method thereof. The PIA / nanometer titania modified alkyd resin comprises the following raw materials: acrylic acid, methylacrylic acid, methyl methacrylate, vinyltriethoxysilane, nanometer titania, epoxy resin, castor oil, trimethylolpropane, 2,2,4-trimethyl-1,3-pentanediol, tetrachlorophthalic anhydride, PIA waste, trimellitic anhydride, triethylamine, ethyl eneglycol monobutyl ether, propylene glycol mono-n-butyl ether, lauric acid, catalytic auxiliary, benzoyl peroxide, dimethylbenzene and water. The PIA / nanometer titania modified alkyd resin provided by the invention is good in water resistance, high in hardness and excellent in comprehensive performance; the PIA waste is used, so that the cost is saved.

Owner:ANHUI JINDUN PAINT

Metallic coating for high weather resistance heat reflective steel sheet and preparation method thereof

ActiveCN106280751BImprove stabilityImprove performanceReflecting/signal paintsAcrylic resinUltraviolet

The invention relates to a highly weather-resistant heat-reflecting steel coil metal coating and a preparation method thereof, belonging to the technical field of steel coil coatings. The highly weather-resistant heat-reflective steel coil metal coating includes the following components in terms of mass percentage: 20-25% of PVDF resin, 8-11% of acrylic resin, 2-5% of polymethyl methacrylate, and 10-10% of aluminum powder 12%, organic solvent 45-50%, defoamer 0.3-0.6%, silane coupling agent 0.5-0.8%, UV ultraviolet absorber 0.4-0.6%, leveling aid 0.4-0.7%, titanium dioxide 3-6%, Alignment agent 0.5-0.9%, the sum of each component is 100% in total. The coating has excellent weather resistance and good physical properties.

Owner:JINJIANG ANNENG BUILDING MATERIALS MFG

Aerosol type precise instrument cleaning agent and preparation method thereof

InactiveCN111826238AFlexible construction operationSimple construction operationOrganic detergent compounding agentsNon-ionic surface-active compoundsAerosol sprayActive agent

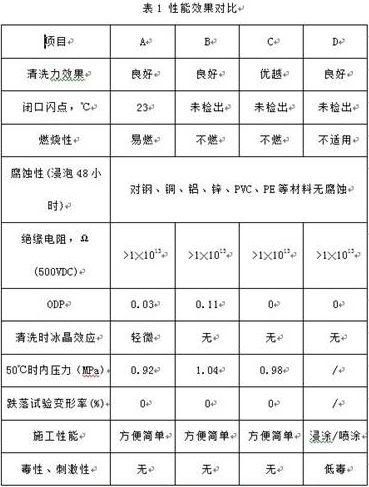

The invention provides an aerosol type precise instrument cleaning agent and a preparation method. The formula of the aerosol type precise instrument cleaning agent comprises the following componentsin parts by weight: 75.0-90.0 parts of an environment-friendly solvent, 0.01-1.0 part of a surfactant, 1.0-10.0 parts of a cosolvent and 5.0-10.0 parts of a propellant. According to the invention, thecleaning agent for the precise instrument has the following beneficial effects that 1, the cleaning agent is excellent in performance, safe and reliable, and can quickly remove dust, oil stains, moisture and the like of the precise instrument under the condition of no power failure; 2, the construction operation is flexible, simple and convenient, and the product safety is high; 3, the cleaning agent product is safe to use, free of flash point, non-combustible, zero in ODP and low in GWP value, and meets the environmental protection requirement; and 4, the volatilization speed is moderate, the ice crystal effect and the condensation phenomenon are avoided in the cleaning process, the surface insulation value of the equipment is not obviously reduced, and the equipment is not corroded anddamaged. The invention further discloses a preparation method of the precise instrument cleaning agent.

Owner:GUANGDONG SANVO CHEM IND TECH

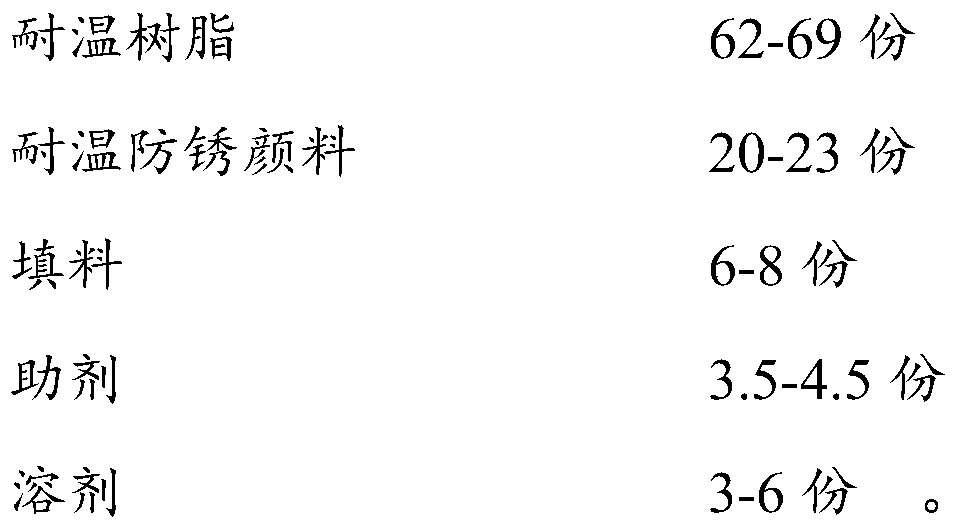

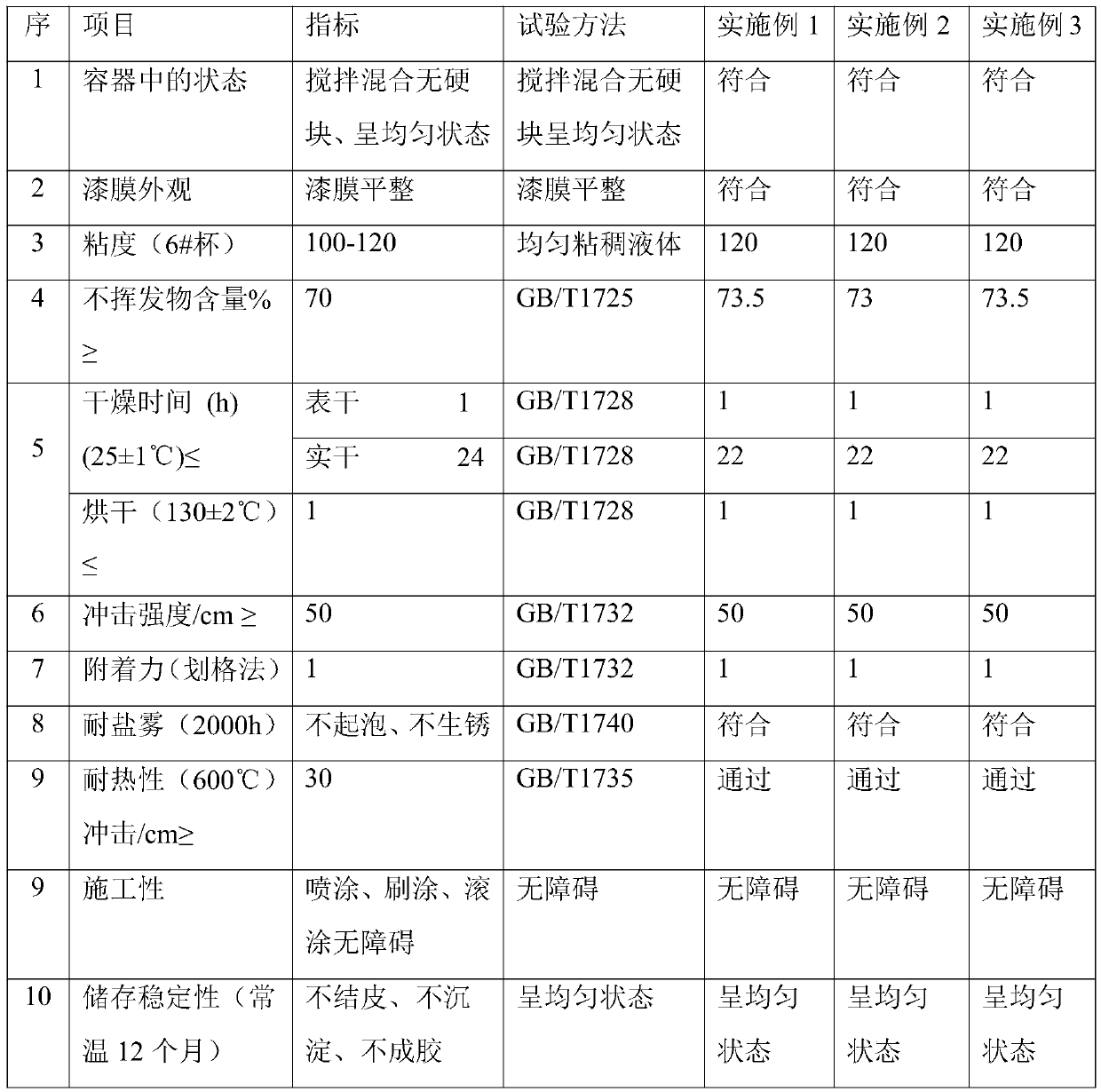

High-temperature-resistant anticorrosive primer for surface of metal structure and preparation method thereof

PendingCN111154397AExtended service lifeLong-term anti-rust and anti-corrosion effectFireproof paintsAnti-corrosive paintsSolid contentHigh heat

The invention discloses a high-temperature-resistant anticorrosive primer for a metal structure surface. The high-temperature-resistant anticorrosive primer is prepared from the following components in parts by weight: 62 to 69 parts of temperature-resistant resin, 20 to 23 parts of a temperature-resistant antirust pigment, 6 to 8 parts of a filler, 3.5 to 4.5 parts of an auxiliary agent and 3 to6 parts of a solvent. The invention also discloses a preparation method for preparing the high-temperature-resistant anticorrosive primer from the components mentioned above. The high-temperature-resistant anticorrosive primer is matched with an organic silicon high-temperature finish paint for coating construction; the formed coating has good physical and chemical properties and corrosion resistance, the service life of a coated object is prolonged within a certain high temperature range, the preparation method is simple and convenient, the primer has a high solid content and low VOC emission, and thus is environmentally friendly, the energy is saved, and the cost is low.

Owner:浙江钱浪涂料科技有限公司

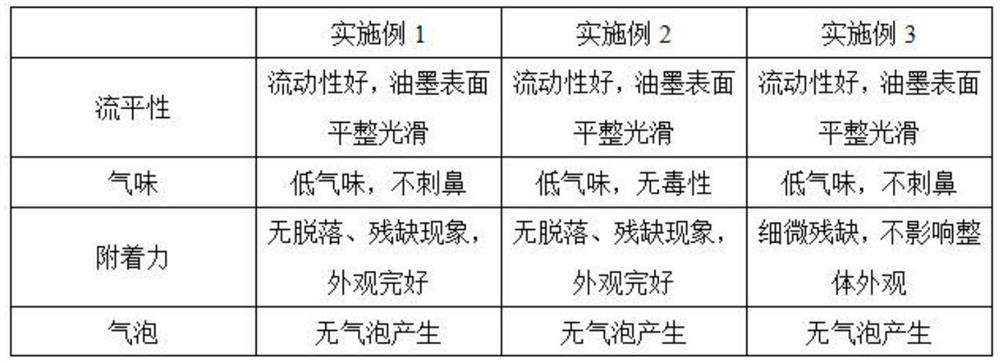

High-performance alcohol-soluble ink for PVC decorative paper

InactiveCN110240826AOvercome the problem of poor dryingModerate volatilization speedInksWaxWater based

The invention relates to high-performance alcohol-soluble ink for PVC decorative paper, the high-performance alcohol-soluble ink omprises 6-10% by weight of pure water, 23-27% by weight of an alcohol mixed solvent, 2% by weight of a wetting agent, 2% by weight of a film-forming auxiliary agent, 41-45% by weight of acrylic emulsion, 1% by weight of water-based wax emulsion, 2% by weight of a thickening agent and 11-15% by weight of a pigment, and the total weight of the components is 100% by weight. The high-performance alcohol-soluble ink for the PVC decorative paper has good rheological property, fast fixation property, transfer property and good stability.

Owner:杭州万海纳米科技有限公司

Strong cleaning compound used for equipment

The invention discloses a strong cleaning compound used for equipment, which comprises the following raw materials by weight part: 1.2-3.4 parts of nonylphenol ethoxylate sodium silicate, 1.5-3.2 parts of polyether modified silicone, 2.3-5.7 parts of valine, 3.2-5.5 parts of cypermethrin, 6.5-8.7 parts of lemon oil, 6.3-8.4 parts of alcohol polyoxyethylene ether phosphate, 1.2-2.5 parts of adsorbent, and 3.5-5.5 parts of emulsifier. The strong cleaning compound has strong decontamination capability, can rapidly and thoroughly remove the impurities such as oil stain, dust and copper cuttings on the surface of the copper pipe; has moderate volatilization speed, can satisfy twining requirement, and can prevent waste due to fast volatilization of the cleaning compound; the cleaning compound can be thoroughly volatilized without residues, thoroughly volatilization can be ensured in time from cleaning step to annealing step, and damage of the external surface of the copper pipe and equipment due to annealing can be avoided.

Owner:王璐

Solvent type toughened glass ink diluent and preparation method thereof

The invention discloses a solvent type tempered glass ink diluent, which belongs to the field of fine chemical engineering, the product comprises the raw material components in percentage by weight: 30-50% of a high-boiling-point medium-low polar solvent, 20-40% of a medium-boiling-point medium-low polar solvent and 20-40% of terpilenol system varnish. The invention further discloses a preparationmethod of the solvent type toughened glass ink diluent. The diluent prepared by the method is relatively small in smell and has good compatibility with high-temperature sintered glass ink of variousflux systems; the solvent-type high-temperature sintered glass ink diluent has the advantages of simple preparation process, proper volatilization speed, good leveling performance, extremely high dilution efficiency, improvement of the drying adhesion of ink, defoaming and foam inhibition effects on the ink, and general applicability to the market.

Owner:湖南衡义材料科技有限公司

Printing ink

The invention provides a sort of ink manufactured by raw materials with the following mass percent: 10-15 percent of butadiene acrylonitrile rubber, 9-15 percent of neoprene, 5-10 percent of acetone, 5-10 percent of toluene, 10-15 percent of glycol butyl et her, 9-15 percent of linseed oil, 5-11 percent of silicon oil, 1-5 percent of titanate coupling agent, 10-25 percent of pigment, 1-4 percent of polyethylene wax, and 0.5-3 percent of aluminum stearate; the ink of the invention is mainly applicable to printing of various plastic material carriers and is provided with high adhesive attraction and good adhesive effect. In the applying facet, superficial treatment is not needed to be carried out to the plastic material carrier when used; printing can be carried out directly, thus guaranteeing good printing effect.

Owner:郜爱民 +1

Non-combustible safe solvent and application thereof

InactiveCN113292881AStop combustion reactionTo achieve the effect of terminating the combustion reactionCoatingsXylyleneButyl acetate

The invention provides a non-combustible safe solvent and application thereof, which belong to the technical field of coatings. The non-combustible safe solvent disclosed by the invention is prepared from 80 to 100 parts of a high-flash-point solvent and 5 to 15 parts of a phosphorus-containing flame retardant. The volatilization speed of the used high-flash-point solvent is lower than that of conventional solvents such as xylene and butyl acetate, after the low-volatility flame retardant is added, the volatilization speed is further reduced, and the effect of moderate volatilization speed is achieved; in the coating process after the paint is mixed with the diluent, the phenomenon that a paint film is softened due to the fact that a small amount of solvent is left due to the low volatilization speed of the diluent is avoided, and the leveling property and gloss of the paint film can be improved.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

Method for rapidly preparing high-purity sodium thiosulfate crystals

InactiveCN107963614AFast precipitationReduce wasteThiosulfates/dithionites/polythionitesSulfite saltFiltration

The invention discloses a method for rapidly preparing high-purity sodium thiosulfate crystals. The method comprises the following steps: adding 6.3 g of sodium sulfite, 3.2 g of sulfur powder and 30mL of distilled water into a small beaker, covering the small beaker with a large beaker, carrying out a microwave heating reaction for 1 min, cooling the obtained reaction product to normal temperature, and carrying out suction filtration to recover the sulfur powder; adding 150 mL of acetone to the obtained filtrate, stirring the filtrate and the acetone for 5-6 min to make crystals appear, carrying out suction filtration, washing the obtained crystals with 10 mL of acetone to obtain sodium thiosulfate crystals, carrying out vacuum drying for 2 h, and weighing the dried sodium thiosulfate crystals; distilling the obtained filtrate to recover the acetone for reuse; and recovering the obtained remaining solution for next preparation. The method has the advantages of high substance utilization rate, less experiment devices, simplicity and convenience in operation, safety and simplicity in the experiment devices, short experiment time, high yield, high purity, good crystal precipitationspeed, omission of the evaporative concentration link in traditional experiments, reduction of requirements of the experiments for the devices, low experiment cost, less raw material waste, energy saving, environmental protection and no pollution.

Owner:王亚玲

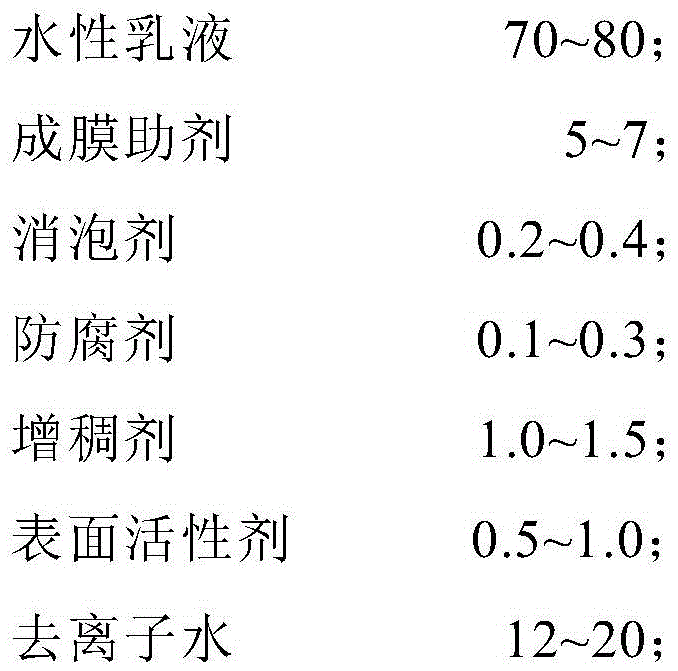

A kind of water-based coating for magnesite handicraft and preparation method thereof

The invention relates to a water-based paint for magnesite handicrafts and a preparation method thereof. The water-based paint is made of the following components and raw materials in parts by weight: 70-80 parts of water-based emulsion, 5-7 parts of film-forming aids, and 0.2 parts of defoaming agent ~0.4, preservative 0.1~0.3, thickener 1.0~1.5, surfactant 0.5~1.0, deionized water 12~20; the preparation method is: put the water-based emulsion into the dispersion tank, start stirring, at a speed of 300~500r / Add film-forming aids, defoamers, surfactants, deionized water, thickeners and preservatives in sequence, and keep stirring for 15-30 minutes; adjust the viscosity of the obtained solution with deionized water, and let the obtained solution flow through The time for ISO 6# to flow out of the cup is 30-50s; weigh and pack. Compared with the prior art, the water-based paint for magnesite handicrafts prepared by the present invention has good adhesion, the drying time of the water-based paint is short, the anti-blocking property and stain resistance are good, and the total volatile organic compound content of the water-based paint less, good for the environment.

Owner:FUJIAN TENGLONG IND

A kind of carburetor cleaning agent and preparation method thereof

ActiveCN106010825BImprove solubilityLow priceDetergent mixture composition preparationOrganic non-surface-active detergent compositionsCarburetorCleansing Agents

Owner:广州保赐利化工有限公司

Online cleaning agent for copper pipes

The invention discloses an online cleaning agent for copper pipes. The online cleaning agent comprises components of raw materials in parts as follows: 20-25 parts of petroleum ether, 5-10 parts of turpentine, 10-12 parts of diethylene glycol, 50-60 parts of ethylene tar, 4-5 parts of paraffin, 2-3 parts of methyl pyrrolidone, 3-4 parts of cyclohexylamine, 5-6 parts of p-cresol, 3-5 parts of methyl isobutyl ketone, 5-6 parts of ethyl acetate, 2-5 parts of triphenyl phosphite, 3-5 parts of an aluminate coupling agent, 5-8 parts of superfine white carbon black and 8-10 parts of hydrogenated petroleum resin. The online cleaning agent for the copper pipes has the good cleaning capacity and the more appropriate volatilization speed, so that the good cleaning effect is realized, surfaces of the copper pipes are lubricated, scratches of the copper pipes are reduced, meanwhile, the online cleaning agent has good copper pipe corrosion inhibition capacity and oxidation resistance, and the service life of the cleaning agent is prolonged.

Owner:周彩球

Polyurethane white paint and its preparation method and application

The invention relates to the technical field of coatings, and specifically discloses a polyurethane white paint and a preparation method and application thereof. The polyurethane white paint comprises the following formula components in weight percent: 40%-50% of alkyd resin; 30%-40% of titanium dioxide; 0.1%-0.5% of fluorescent whitening agent; 0.5%-1% of dispersant; Foaming agent 0.2%~0.5%; Propylene glycol methyl ether acetate 2%~3.5%; Butyl acetate 4%~15%; Matting powder 0%~6%; Anti-settling agent 2%~4%; Leveling agent 0.2% ~0.5%. The polyurethane white paint is mixed with rutile titanium dioxide and fluorescent whitening powder, which can be obviously whitened, and has good hiding power and weather resistance. More importantly, the preparation method controls the grinding of the titanium dioxide and the fluorescent whitening agent together to form a titanium dioxide slurry, so as to ensure the whitening effect of the coating.

Owner:中华制漆(新丰)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com