Preparation method of polystyrene sulfonic acid type ion exchange resin

A polystyrene sulfonic acid type, ion exchange resin technology, applied in the direction of ion exchange, anion exchange, chemical instruments and methods, etc., can solve the problems of mechanical strength, heat resistance, ion exchange rate and specific surface area, etc. Low chemical efficiency, many by-products, etc., to achieve the effect of improving efficiency, reducing side reactions, and reducing reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

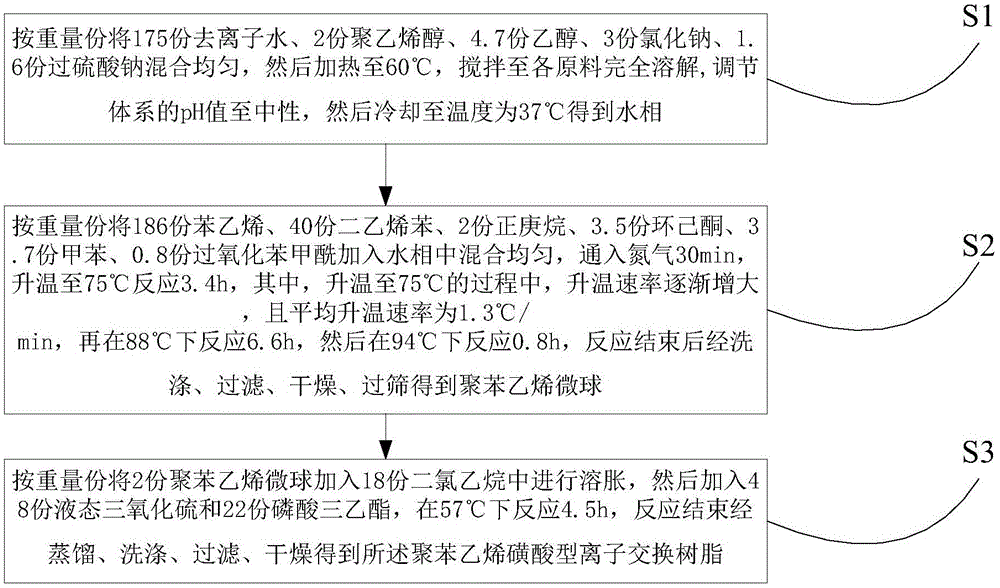

[0030] A kind of preparation method of polystyrene sulfonic acid type ion-exchange resin that the present invention proposes, comprises the following steps:

[0031] S1. Mix 130 parts of deionized water, 3 parts of polyvinyl alcohol, 3 parts of ethanol, 5 parts of sodium chloride, and 0.5 parts of sodium persulfate in parts by weight, then heat to 65 ° C, stir until all raw materials are completely dissolved, and adjust The pH value of the system is neutral, and then cooled to a temperature of 30° C. to obtain an aqueous phase;

[0032] S2. Add 150 parts of styrene, 50 parts of divinylbenzene, 1 part of n-heptane, 5 parts of cyclohexanone, 3 parts of toluene, and 1 part of benzoyl peroxide into the water phase by weight and mix evenly, and then pass nitrogen gas After 20 minutes, raise the temperature to 80°C for 2.5h, then react at 90°C for 5h, and then react at 95°C for 0.5h. After the reaction, wash, filter, dry, and sieve to obtain polystyrene microspheres;

[0033] S3. A...

Embodiment 2

[0035] A kind of preparation method of polystyrene sulfonic acid type ion-exchange resin that the present invention proposes, comprises the following steps:

[0036] S1. Mix 200 parts of deionized water, 1 part of polyvinyl alcohol, 5 parts of ethanol, 1 part of sodium chloride, and 2 parts of sodium persulfate in parts by weight, then heat to 55 ° C, stir until all raw materials are completely dissolved, and adjust The pH value of the system is neutral, then cooled to a temperature of 40°C to obtain an aqueous phase;

[0037]S2, add 200 parts of styrene, 30 parts of divinylbenzene, 3 parts of n-heptane, 2 parts of cyclohexanone, 4 parts of toluene, and 0.5 parts of benzoyl peroxide into the water phase and mix evenly, and pass into nitrogen After 35 minutes, heat up to 70°C for 4 hours, then react at 85°C for 8 hours, and then react at 91°C for 1 hour. After the reaction, wash, filter, dry, and sieve to obtain polystyrene microspheres;

[0038] S3. Add 1 part of polystyrene ...

Embodiment 3

[0040] A kind of preparation method of polystyrene sulfonic acid type ion-exchange resin that the present invention proposes, comprises the following steps:

[0041] S1. Mix 150 parts of deionized water, 2.3 parts of polyvinyl alcohol, 4.2 parts of ethanol, 3.2 parts of sodium chloride, and 1.2 parts of sodium persulfate in parts by weight, then heat to 63 ° C, stir until all raw materials are completely dissolved, and adjust The pH value of the system is neutral, and then cooled to a temperature of 36° C. to obtain an aqueous phase;

[0042] S2. Add 190 parts of styrene, 39 parts of divinylbenzene, 2.4 parts of n-heptane, 3 parts of cyclohexanone, 3.8 parts of toluene, and 0.7 parts of benzoyl peroxide into the water phase and mix evenly, and pass into nitrogen 33min, heat up to 73°C and react for 3.6h, wherein, during the process of heating up to 73°C, the heating rate gradually increases, and the average heating rate is 1°C / min, then react at 87°C for 7h, and then react at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com