Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Increase hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tungsten carbide coating and method for producing the same

InactiveUS6800383B1Increase hardnessEnhanced tribotechnical propertyRecord information storageMachines/enginesBuilding materialFluorocarbon

New tungsten carbides alloyed with fluorine in amounts up to 0.5 wt % and possibly with fluorocarbon compositions are described. It is possible to produce them by means of a new process of chemical vapor deposition, in which tungsten hexafluoride, hydrogen and a carbon-containing gas are used. A specific feature of the new process is the preliminary thermal activation of the carbon-containing gas. The tungsten carbide coatings are deposited on construction materials and items made from them. They possess enhanced resistance to wear, corrosion and chemicals.

Owner:HARDIDE LTD

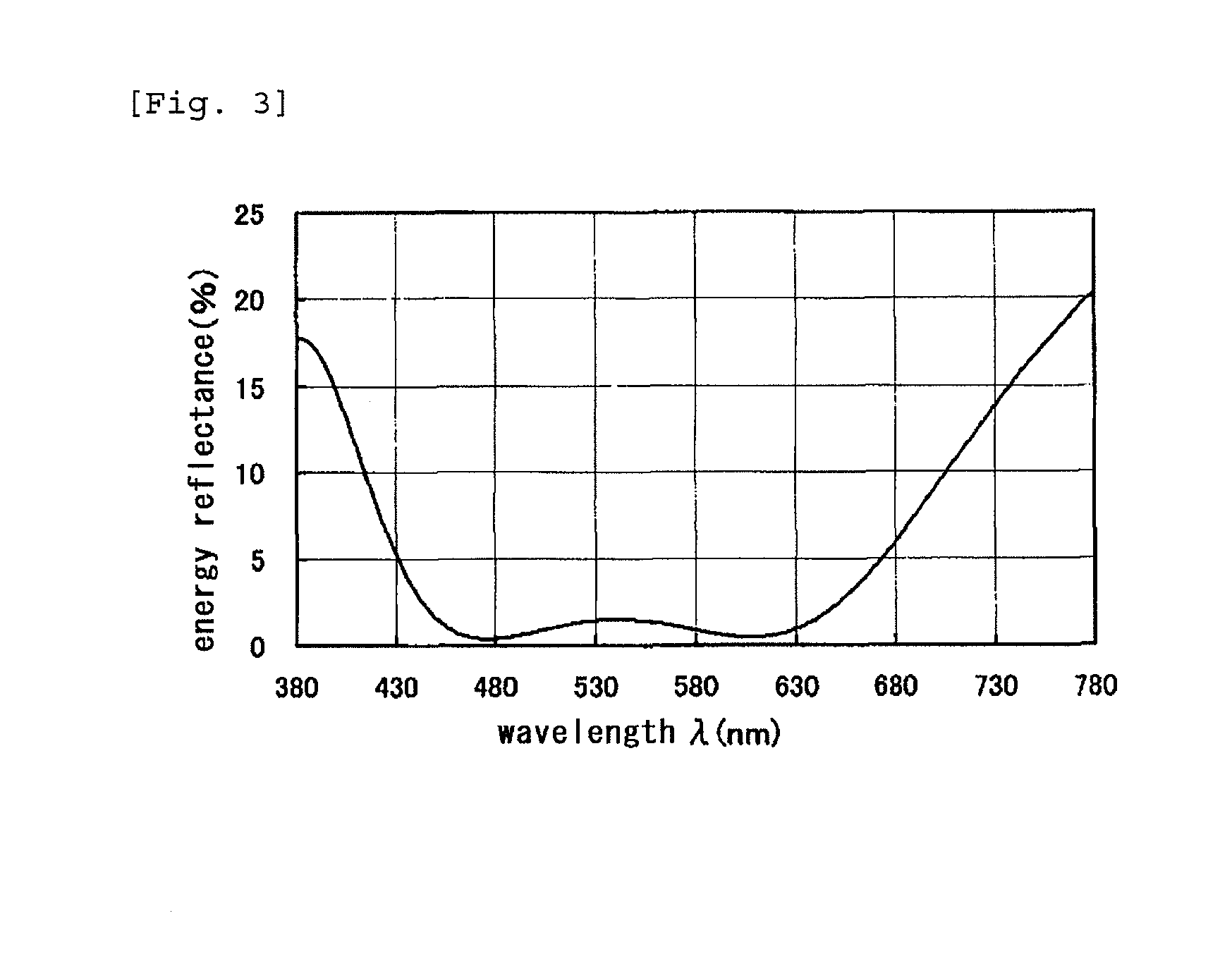

Watch cover glass

InactiveUS20100196685A1Increase hardnessAbrasion resistance be improveVacuum evaporation coatingSputtering coatingCover glassReflection function

The present invention provides a watch cover glass having high hardness and excellent abrasion, and also having flaw resistance and antireflection function even after being used for a long period of time.[Means for Solving]The watch cover glass of the present invention comprises a transparent substrate and, provided on at least one surface of the substrate, an antireflection film having a lamination structure that a SiO2 and Si3N4 mixed film (hereinafter, referred to as SiON film) and a Si3N4 film are laminated and the outermost layer is the SiON film. According to the lamination structure, the proper antireflection effect can be obtained, the hardness of the antireflection film is increased and the abrasion resistance is remarkably increased. As a result, the watch cover glass provided by the present invention has properties such that even after being used for a long period of time, the surface of the antireflection film is not finely flawed and is not peeled off, and it hardly occurs that the hands or dial plate are invisible due to surface mist and the antireflection function can be maintained.

Owner:CITIZEN WATCH CO LTD

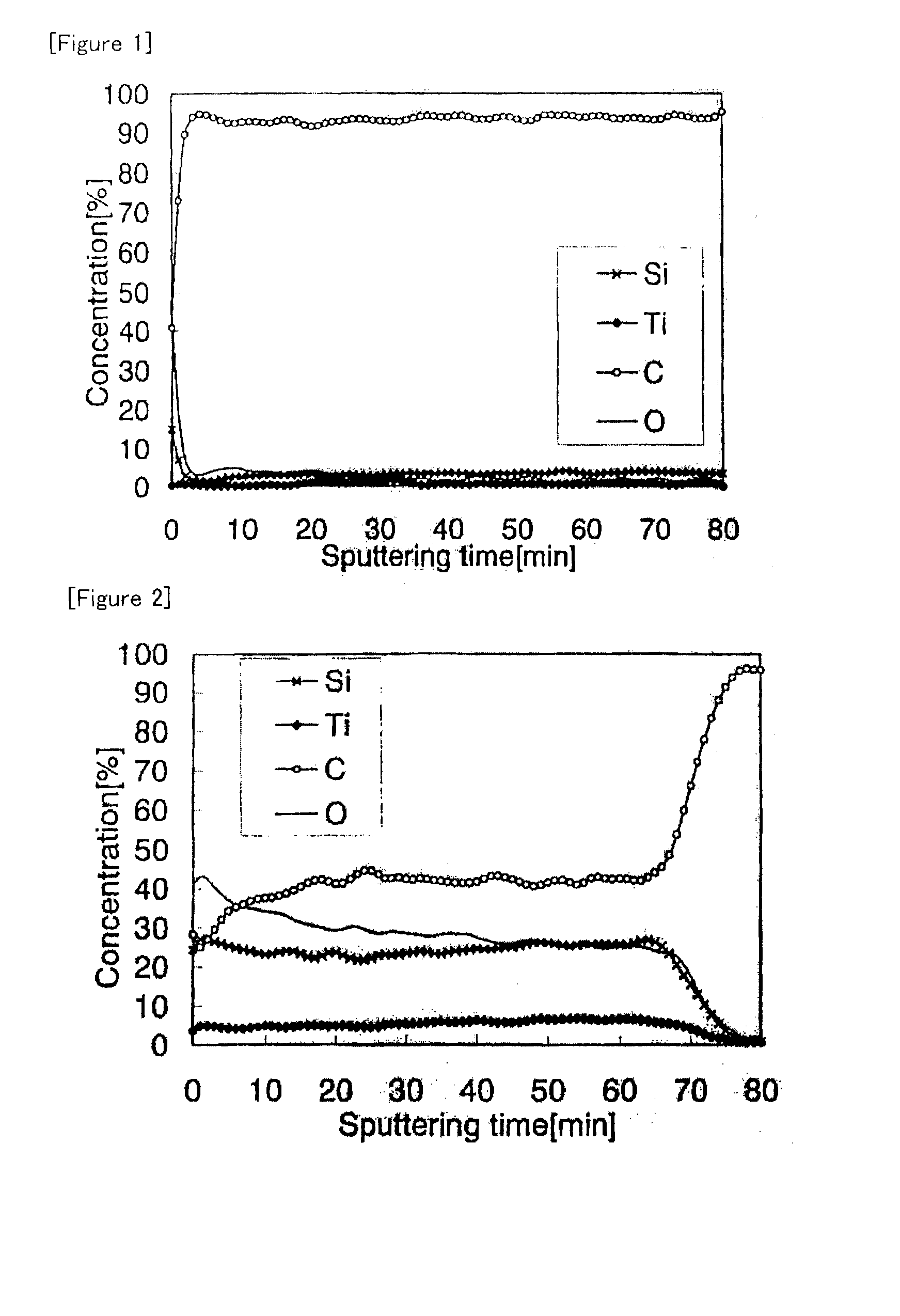

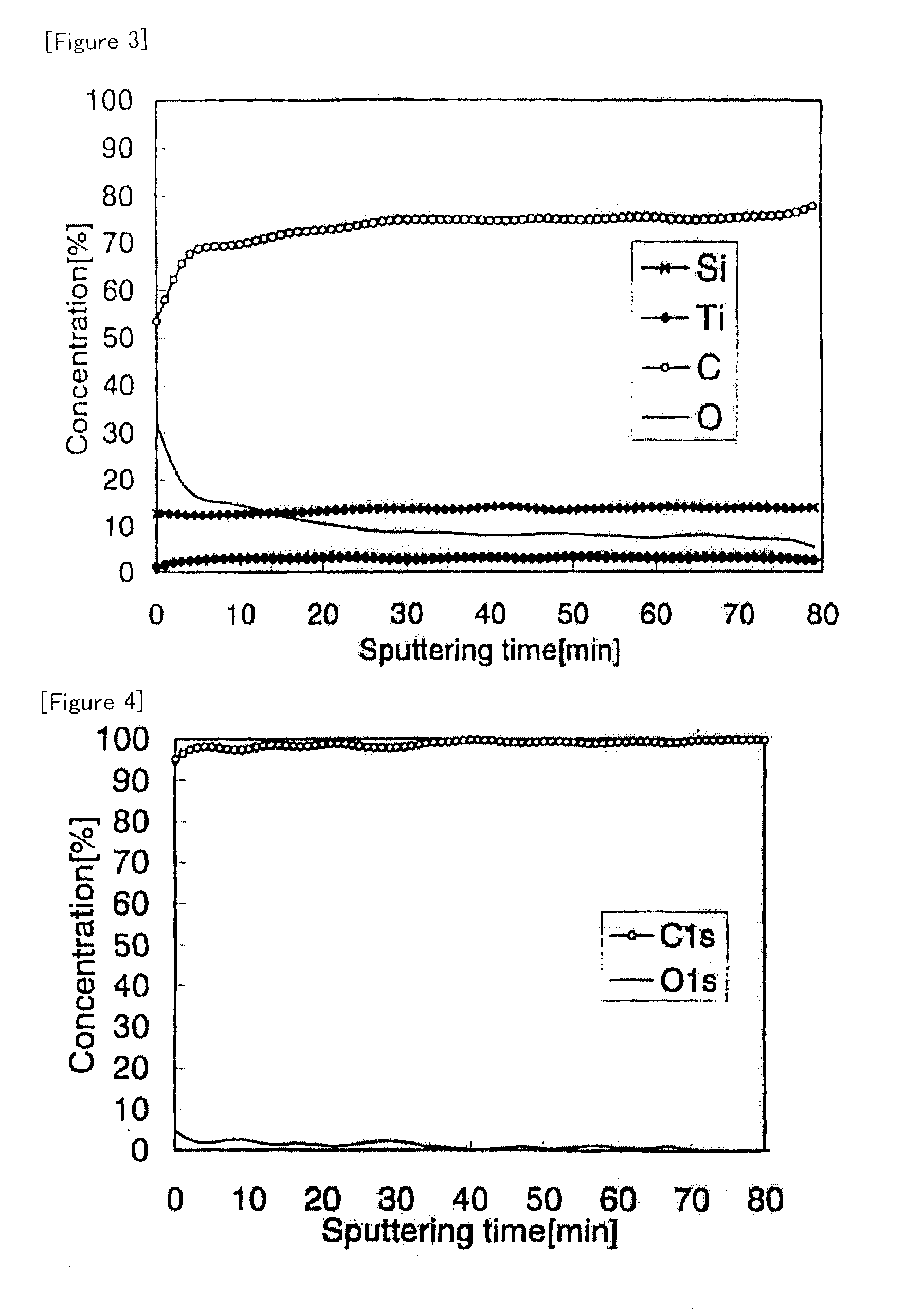

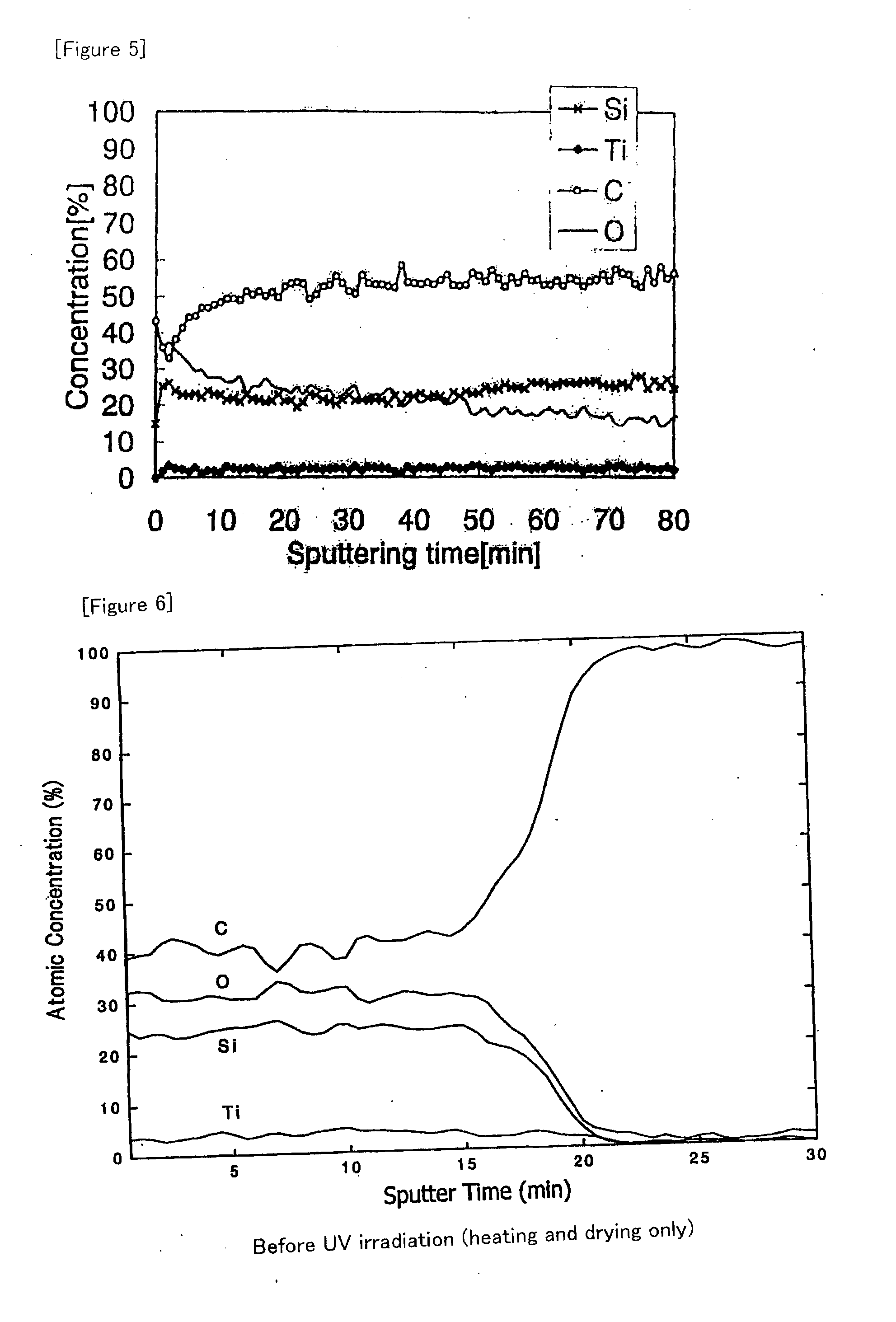

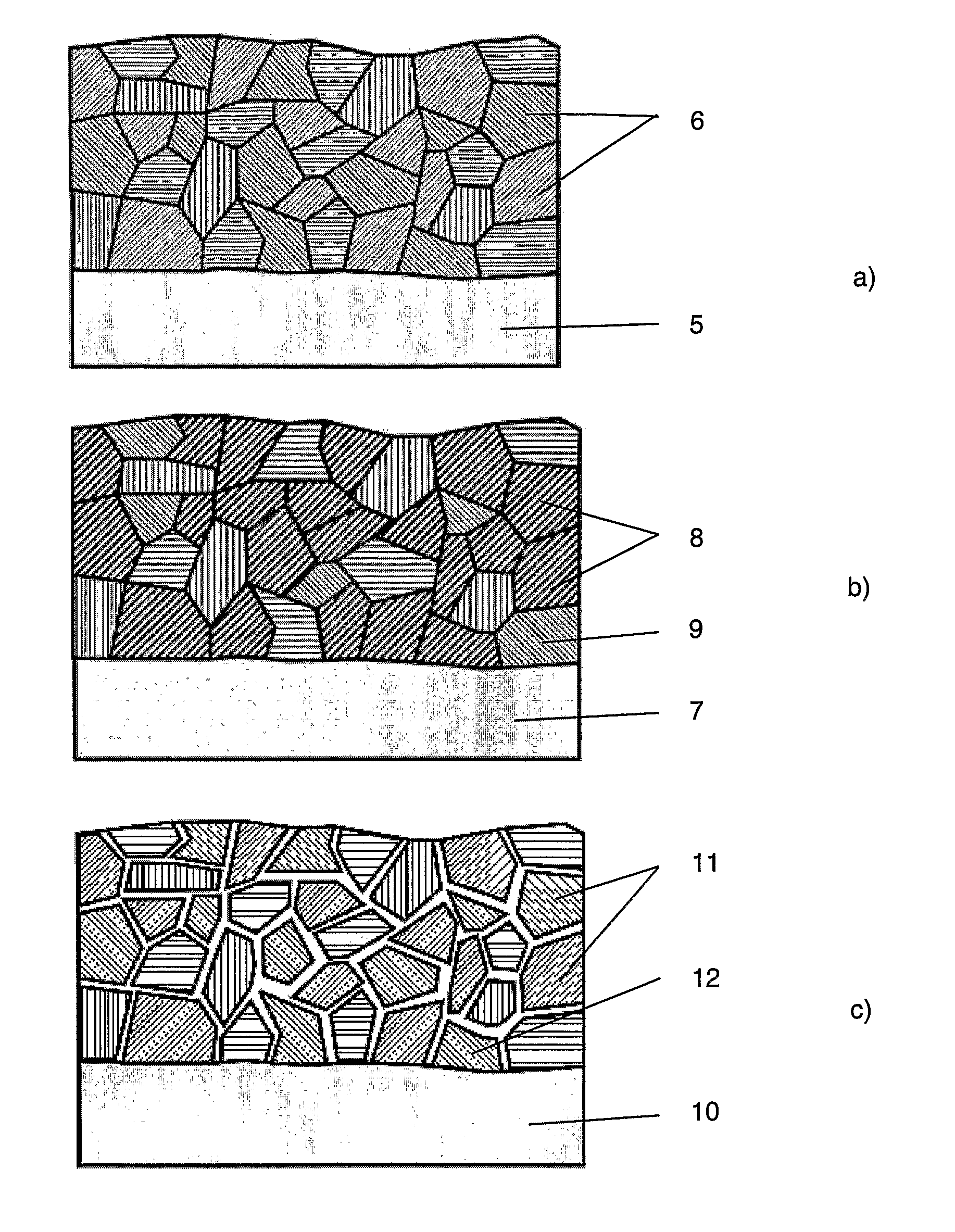

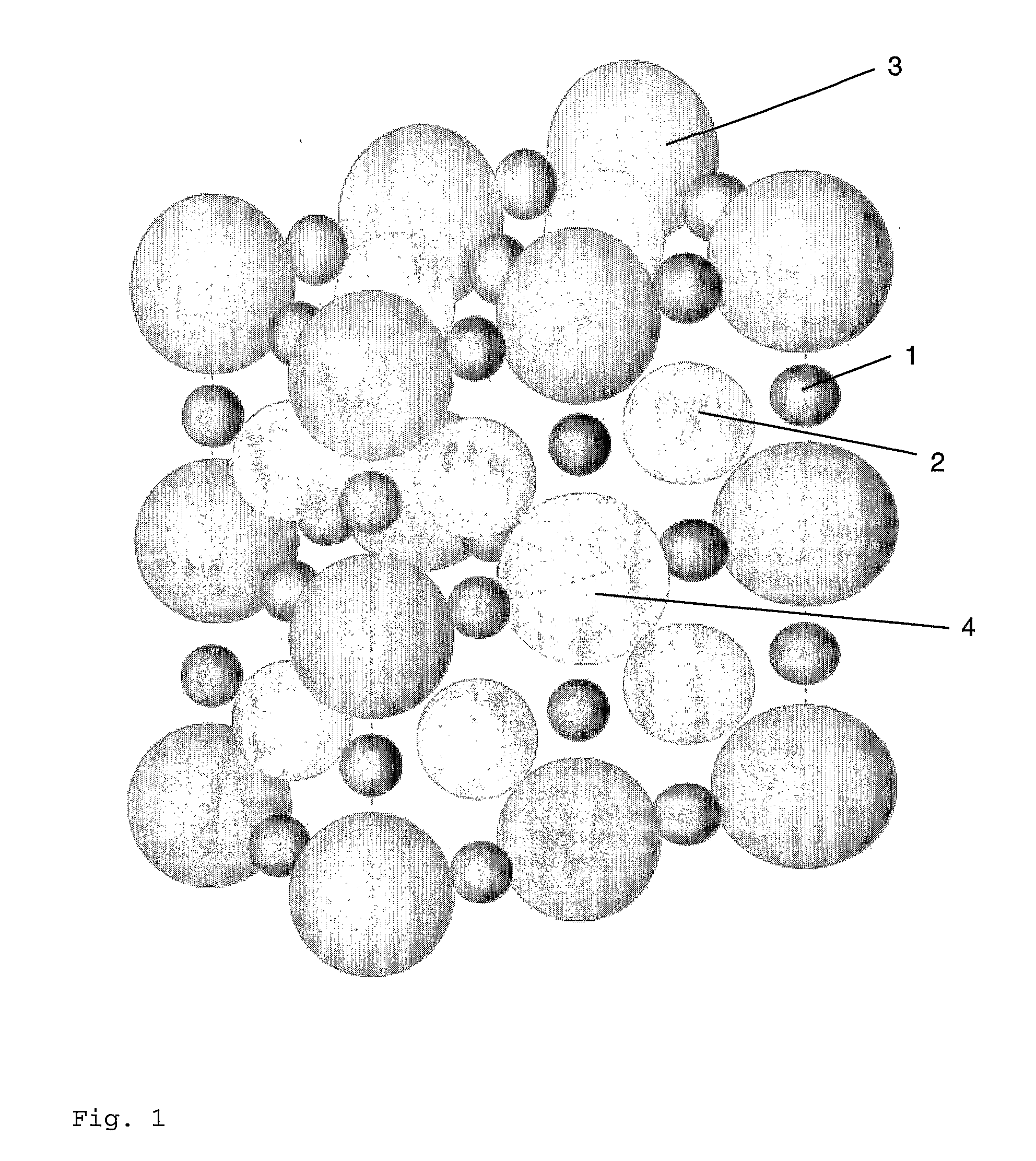

Organic-inorganic composite body

Disclosed is an organic-inorganic composite body having a very high hardness on the surface and an adequate hardness in the interior and on the back surface while having excellent adhesion to a substrate. Specifically disclosed is an organic-inorganic composite body mainly comprising a) a condensate of an organosilicon compound represented by Formula (I): RnSiX4-n, (wherein R represents an organic group having a carbon atom directly bonded to Si, and X represents a hydroxy group or a hydrolyzable group; n represents 1 or 2, with the proviso that when n is 2, each R may be the same or different, and when (4-n) is 2 or more, each X may be the same or different) and further comprising b) at least one photosensitive compound sensitive to light having a wavelength of 350 nm or less selected from the group consisting of metal chelate compounds, metal-organic acid salt compounds, metal compounds having 2 or more hydroxy groups or hydrolyzable groups, hydrolysates thereof, and condensates thereof; and / or a compound derived from the photosensitive compound, and c) a cured product of an ultraviolet-curable compound.

Owner:NIPPON SODA CO LTD

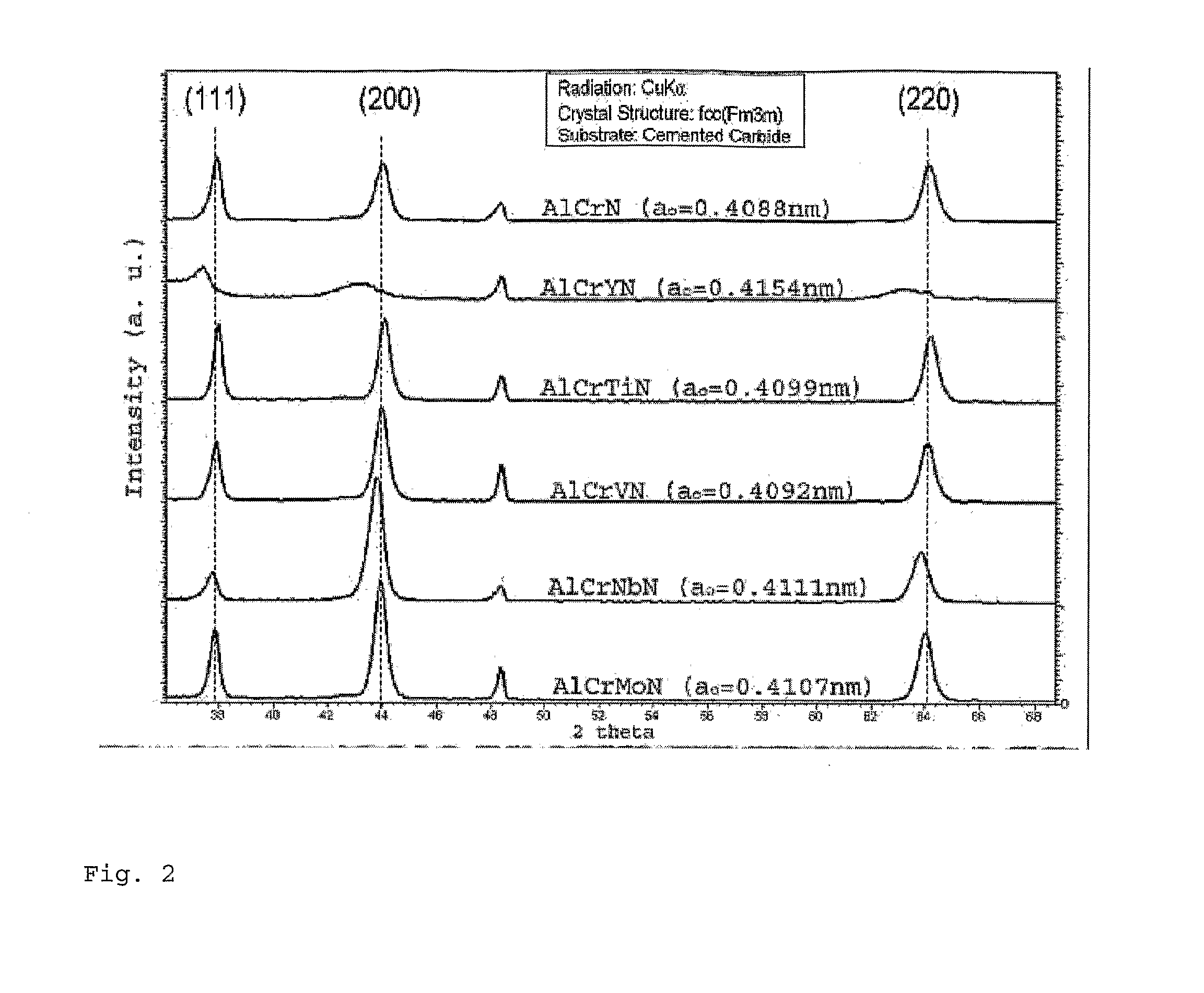

High Oxidation Resistant Hard Coating for Cutting Tools

ActiveUS20080318062A1Increase hardnessIncrease service lifePigmenting treatmentChromatisationOxidation resistantWear resistant

An inventive workpiece features on at least parts of its surface a wear resistant hard coating comprising the following composition Al1-a-b-c-dCraXbSicBdZ, where x is at least one element from Nb, Mo, W or Ta; Z is one element or compound from N, C, CN, NO, CO, CNO; and 0.2<=a<=0.5; 0.01<=b<=0.2; 0<=c<=0.1; 0<=d<=0.1. Further a PVD process for depositing such a wear resistant coating is disclosed whereby at least one workpiece is installed in a vacuum coating system and said system is operated in a low pressure argon atmosphere utilizing at least two metal or metal alloy targets with at least temporarily addition of a reactive gas.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

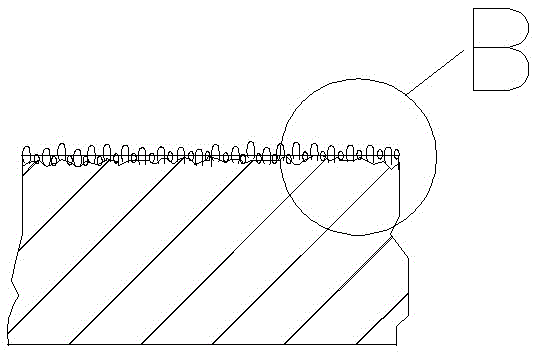

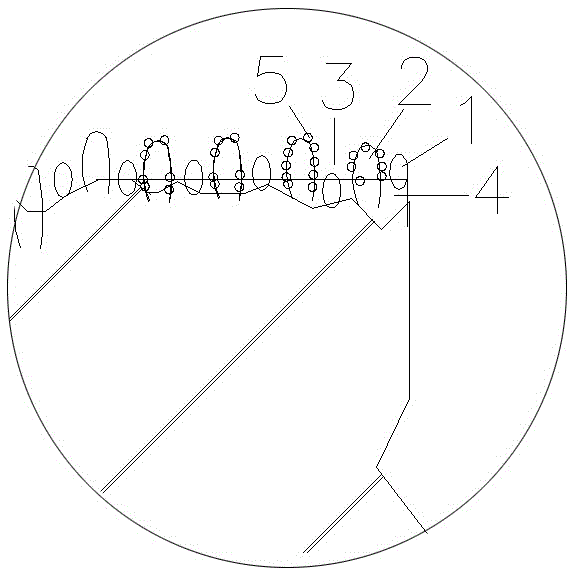

Cookware with high wear resistance and manufacturing method of cookware

InactiveCN105476490AIncrease hardnessImprove scratch resistanceCooking-vessel materialsMolten spray coatingHigh pressureAdhesion strength

The invention relates to the field of metal cookware manufacturing, in particular to cookware with high wear resistance and aims to overcome the defects in the prior art. The cookware is high in non-stick layer adhesion strength, high in abrasion resistance and high in wear resistance. According to the technical scheme, a manufacturing method of the cookware includes the steps of firstly, forming a cookware body through die-casting; secondly, using a numerically controlled lathe to perform metal processing; thirdly, finishing and polishing; fourthly, removing oil on the surface of the cookware body; fifthly, cleaning the cookware body with purified water, 3% alcohol solution and oil dissolving agent, and drying; sixthly, guaranteeing that the base material of the cookware body is clean before spraying, sand blasting the surface of the cookware body after preheating, and using the high-pressure gas of a sand blasting machine to further roughen the surface of the cookware body; seventhly, spraying the cookware body for the first time, cleaning the cookware body, then loading the cookware body onto a spraying machine, and spraying metalizing materials which include TiO2 and Al2O3 to the cookware body.

Owner:ZHEJIANG CHUNZHOU ALUMINUM IND

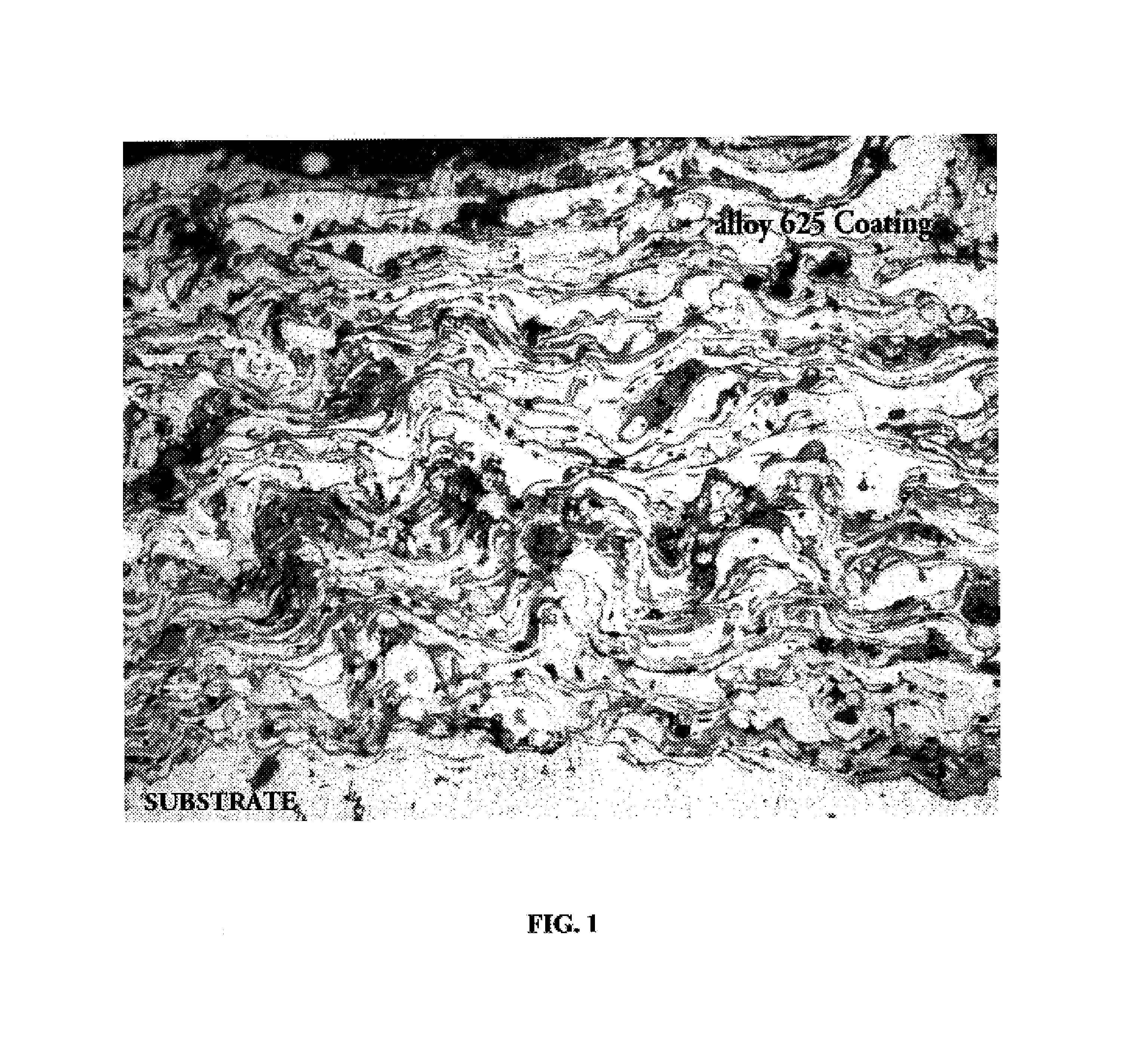

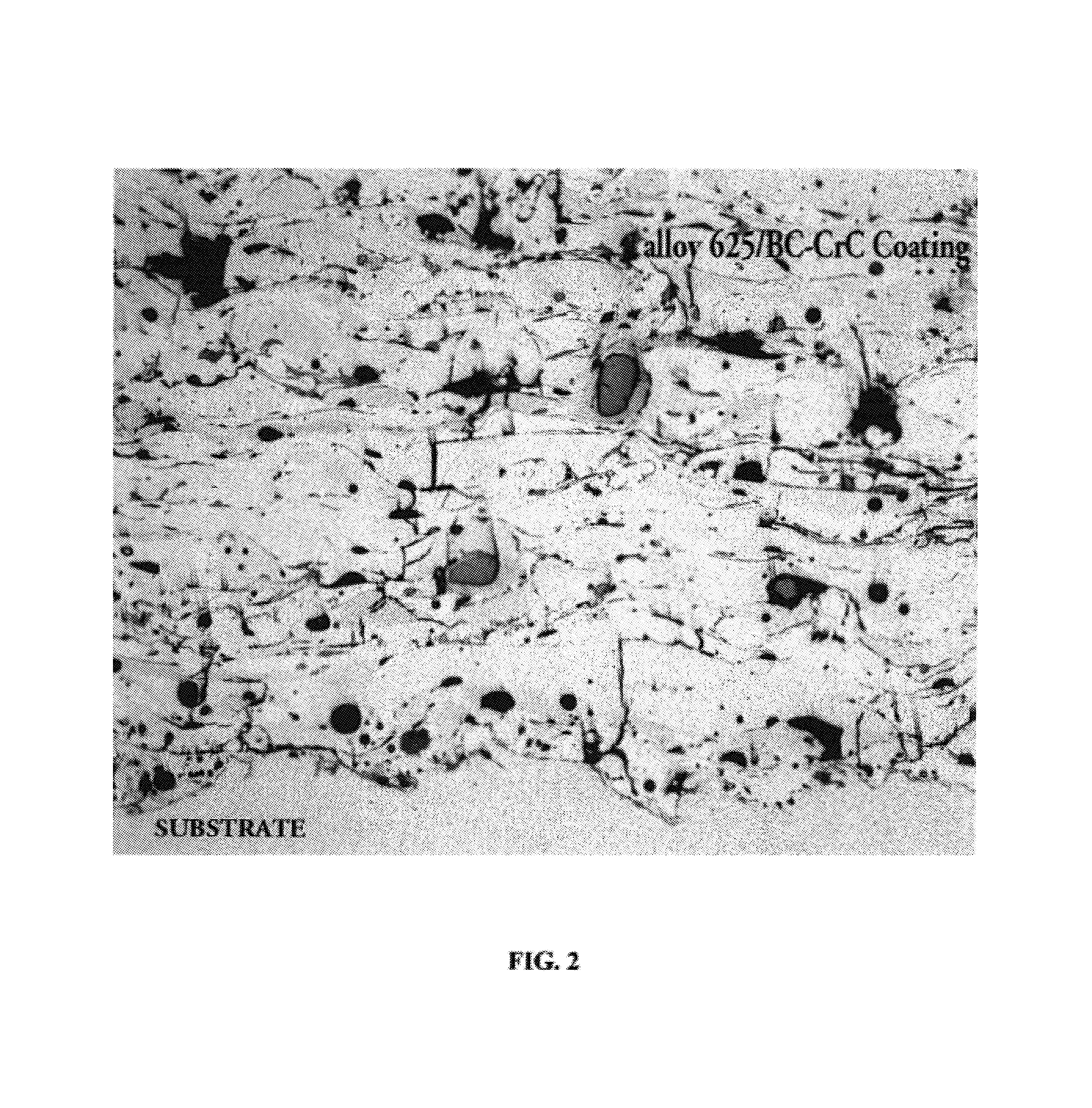

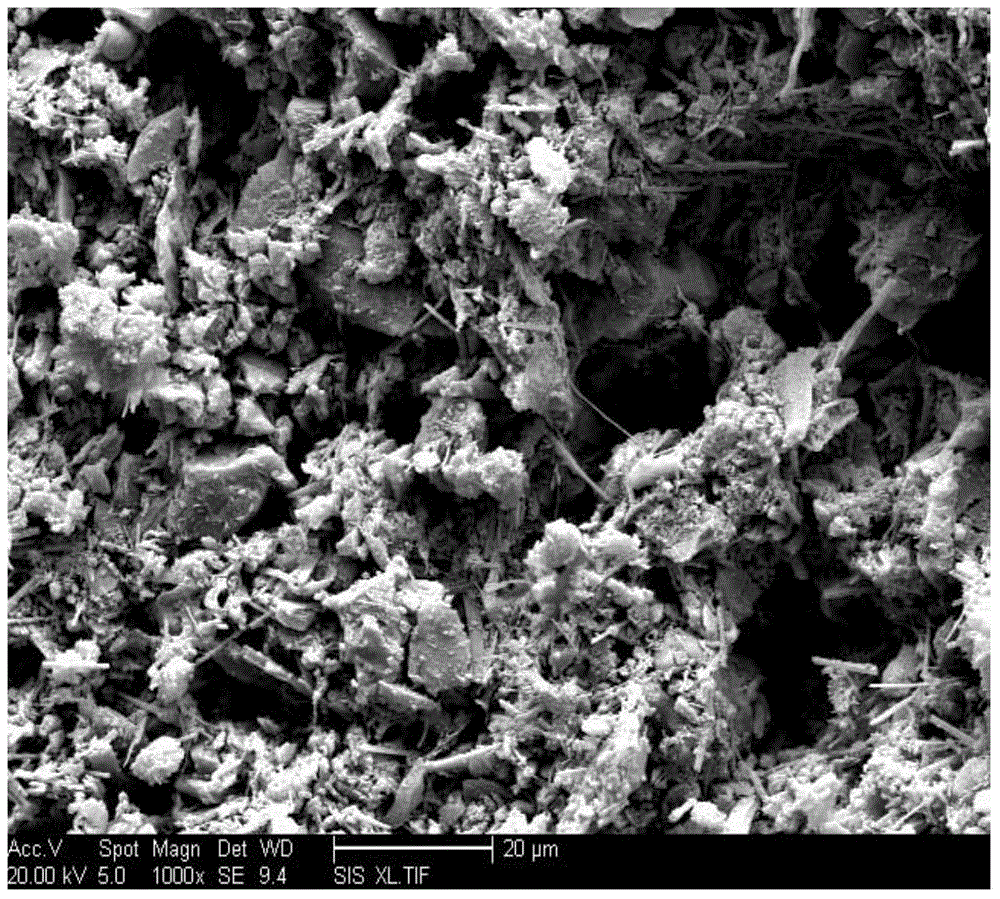

Composite wires for coating substrates and methods of use

ActiveUS7256369B2Add wear resistanceIncrease hardnessLiquid surface applicatorsMolten spray coatingChromium carbideCorrosion resistant

A composite wire for producing a wear resistant and corrosion resistant coating on a substrate by thermal spraying, spray and fuse, or welding techniques are disclosed. The physical properties of the coating are particularly suited for high-temperature erosion-corrosion environments. The resultant coating exhibits good hardness, toughness, and bonding characteristics. The composite wire comprises a metallic outer sheath and an inner core containing boron carbide and chrome carbide.

Owner:INTEGRATED GLOBAL SERVICES

Sympodial bamboo integration profile manufacturing method

ActiveCN103737692AHigh densityImprove the bactericidal effectPressure wood treatmentWood treatment detailsCarbonizationHigh pressure

The invention discloses a sympodial bamboo integration profile manufacturing method. The method is characterized by including the following steps: S1, soaking bamboo filaments of sympodial bamboo which are subjected to green planing and yellow removing in water for high-temperature stewing at temperature of 100-120 DEG C for at leat four hours, wherein the water contains, by mass, 5-10% of hydrogen peroxide and 0.5-1% of sodium hydroxide; S2, disposing wet bamboo filaments in a carbonization furnace for carbonizing at temperature of 130-15o DEG C and at pressure of 3-4 MPa for 4-6 hours; S3, drying for the first time, dipping in glue, and drying for the second time after glue dipping; S4, performing high-pressure forming at pressure of being not less than 1.2 t / cm2; S5, performing thermosetting for more than 10 hours at temperature of 80-150 DEG C under the condition that the pressure of being not less than 1.2 t / cm2 is maintained. By the sympodial bamboo integration profile manufacturing method, sympodial bamboo integration profiles meeting structural profile requirements can be manufactured.

Owner:SHENZHEN KANGER BAMBOO & WOOD

Novel non-sintered biological stuffing rapid in biofilm formation and preparation method thereof

InactiveCN103951044ALarge specific surface areaHigh porositySustainable biological treatmentBiological water/sewage treatmentSolid componentPolyvinyl alcohol

The invention provides novel non-sintered biological stuffing rapid in biofilm formation and a preparation method thereof, relating to biological stuffing and preparation methods thereof and solving the technical problems that the existing biological stuffing has long biofilm formation time and poor effluent quality in water treatment processes and preparation processes are high in energy consumption and pollute the environment. The biological stuffing is prepared from sepiolite, medical stone, cement, polyvinyl alcohol, sodium alginate, hydrogen peroxide, ferric chloride, manganese sulfate, cobalt chloride and agar. The method comprises the following steps: I. heating and dissolving polyvinyl alcohol and sodium alginate, adding hydrogen peroxide after cooling, and mixing the components uniformly, thus obtaining a liquid mixture; II. mixing the liquid mixture with other solid components, granulating the mixture, putting the granules at normal temperature, drying and sieving the granules, curing the granules at high pressure and low temperature, steam-curing the granules at constant temperature, and cooling the granules at normal temperature, thus obtaining the biological stuffing. Compared with the common ceramsite, the biological stuffing has short biofilm formation time, good effluent quality and coarse surface and is beneficial for microorganism growth. The biological stuffing is applied to the fields of environmental applied materials and sewage treatment.

Owner:HARBIN UNIV OF SCI & TECH

Improved metal alloys for medical devices

ActiveUS20170216494A1Positively affectIncrease hardnessSurgeryCatheterMetal alloyBiomedical engineering

A medical device and a method and process for at least partially forming a medical device, which medical device has improved physical properties. The one or more improved physical properties of the novel metal alloy can be achieved in the medical device without having to increase the bulk, volume and / or weight of the medical device.

Owner:MIRUS LLC

Electroless plating with nanometer particles

InactiveUS20060024514A1Increase hardnessImprovement to overall physical structureMaterial nanotechnologyLiquid surface applicatorsElectroless platingCorrosion

The addition of nanometer particles to electroless metal plating baths reduces or eliminates seeding in the electroless plating baths. The reduced seeding results in less inclusions or pitting in the coating. Usually the maintenance and frequent tank-cleaning schedule can be increased beyond the normal 2-3 day. The properties of the coating can be improved by the co-deposition of the particles into the bath. Properties such as hardness, corrosion resistance, and wear resistance were improved.

Owner:MCCOMAS EDWARD

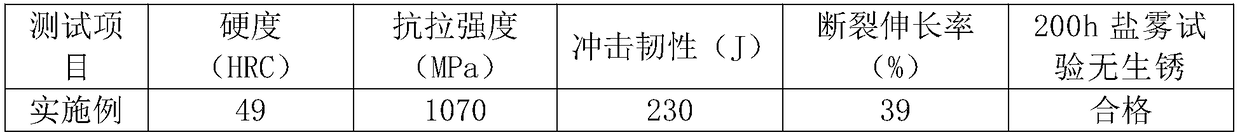

Wear-resistant corrosion-resistant stainless steel cup material and preparation method thereof

The invention discloses a wear-resistant corrosion-resistant stainless steel cup material. The material comprises the following chemical components of, by mass, 0.35-0.55% of C, 0.75-1.15% of Si, 0.80-1.20% of Mn, 5.50-8.50% of Cr, 0.55-0.85% of Cu, 0.18-0.38% of Mo, 0.20-0.40% of V, 0.20-0.06% of Co, 0.03-0.05% of Nb, 0.02-0.04% of Ti, 0.01-0.03% of Ce, 0.0010-0.0040% of Yb, 0.0010-0.0035% of B,the balance Fe and inevitable impurities. The stainless steel cup material has relatively high wear resistance and high corrosion resistance, low in cost, good in antibacterial performance, strength,hardness and heat resistance and excellent in comprehensive performance.

Owner:合肥久新不锈钢厨具有限公司

High red hard boron-containing high speed steel and preparation method thereof

InactiveCN108251755AImprove red hardnessIncrease hardnessProcess efficiency improvementChemical compositionWear resistant

The invention discloses a high red hard boron-containing high speed steel and a preparation method thereof, and belongs to the technical field of wear-resistant material. The high red hard boron-containing high speed steel comprises the compositions of, by weight, 1.0-3.0 of B, 0.2-0.8 of C, 5.0-7.0 of Cr, 3.0-6.0 of Mo, 0.5-2.0 of Al, 0.5-1.5 of Si, 0.5-1.5 of V, 0.5-1.5 of Mn, and the balance Fe. The high red hard boron-containing high speed steel has excellent wearresistance, red hardness, and excellent harden ability. High hardness can be obtained by cooling only in the air, thus the highred hard boron-containing high speed steel is very suitable for the preparation of parts for use in high temperature wear conditions such as rolls. In addition, the production cost is low, productionprocess is simple, and promotion and application value is good.

Owner:XI AN JIAOTONG UNIV +1

Colored film substrate and display device

InactiveCN107390420AIncrease hardnessReduced hygroscopic propertiesNon-linear opticsActive agentDisplay device

The invention provides a colored film substrate and a display device. The colored film substrate comprises a black matrix layer and a RGB layer, and each of the black matrix layer and the RGB layer is covered with a protection layer which is composed of binder polymer, hardener, multifunctional monomer and active agent, wherein molecular weight of the binder polymer is 4000-10000mw. Through the scheme, hardness of the protection layers can be improved, moisture absorptivity of the protection layers can be lowered, surface flatness of the protection layers can be optimized, and surface tension of the protection layers can be improved, so that gas overflow of the protection layer can be reduced, and the objectives of reducing ODF Tact Time and increasing product yield of factories are achieved.

Owner:BOE TECH GRP CO LTD +1

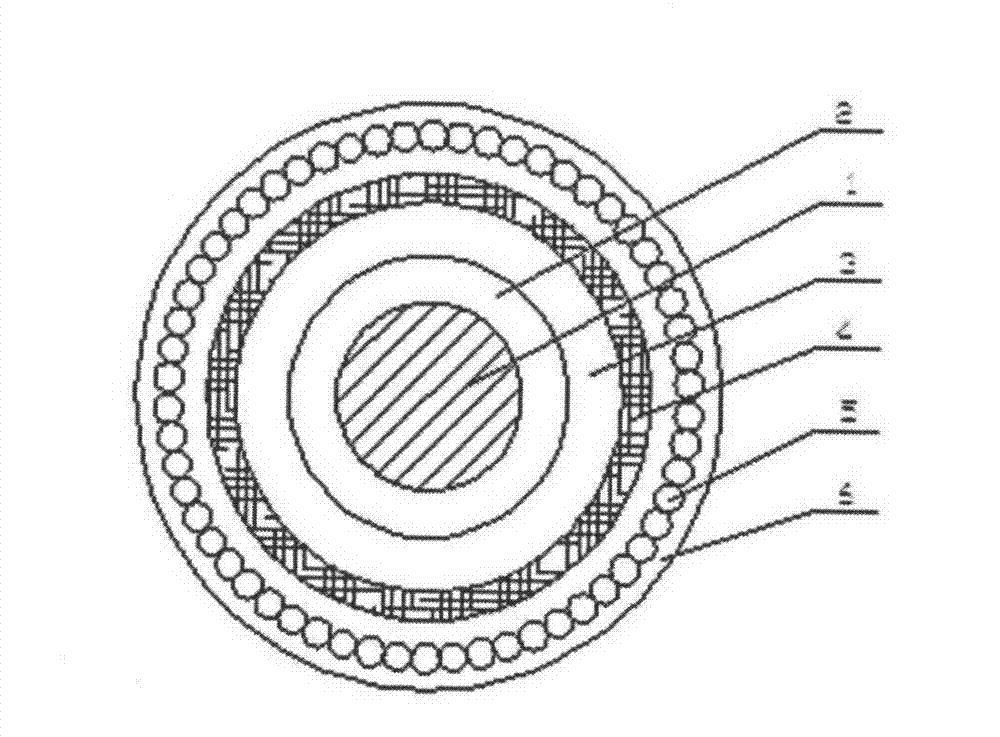

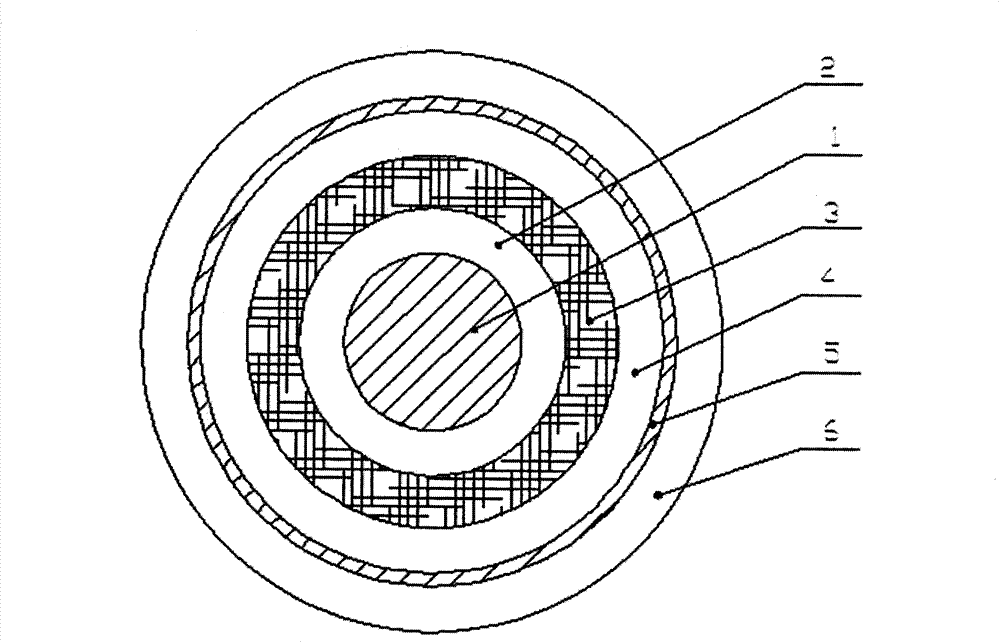

Termite-proof cable

InactiveCN103093884AIncrease hardnessStop bitingClimate change adaptationInsulated cablesYarnHardness

The invention provides a termite-proof cable. A nylon protecting layer is outside an insulating layer and water-proof yarns are outside the nylon protecting layer. The water-proof yarns are a high density polyethylene outer protecting layer, wherein the high density polyethylene outer protecting layer comprises a thin steel wire layer. The nylon protecting layer and the high density polyethylene outer protecting layer can add the hardness of the termite-proof cable. The thin steel wire layer especially can prevent the termite cable from being bitten and eaten of termites. The water-proof yarn layer can slow the differentiation of the termite-proof cable caused by water incursion.

Owner:王彩霞

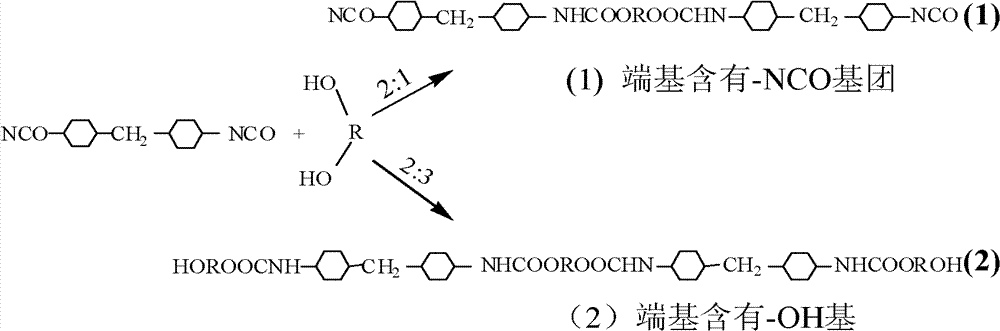

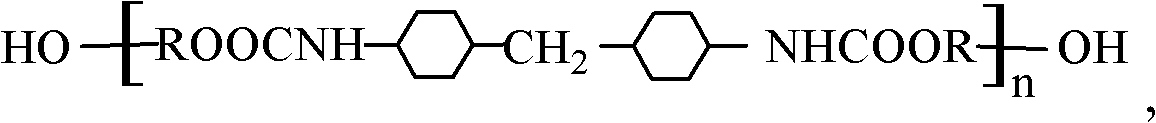

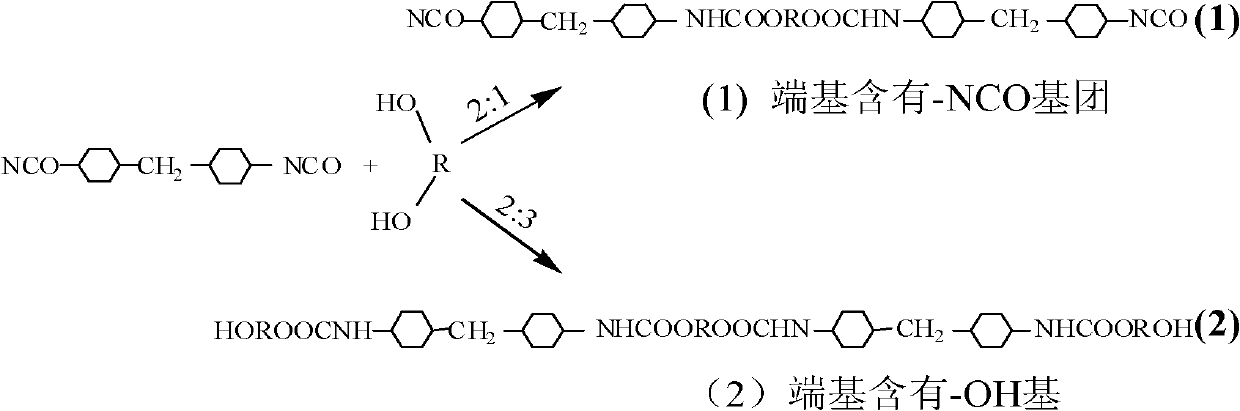

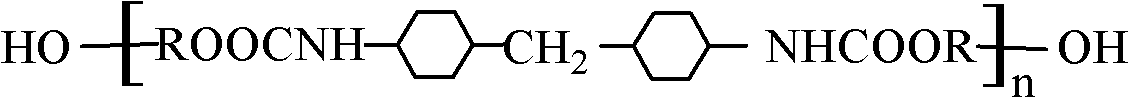

Non-yellowing polyurethane slurry for hasp, and preparation method thereof

The present invention relates to a non-yellowing polyurethane slurry for a hasp, and a preparation method thereof. The molecular general formula is as the follow, wherein R is aromatic nucleus-free alkyl. The concrete process of the preparation method comprises: (1) pouring a bottoming solvent into a reaction kettle, then pouring polyester polyol, terylene-grade ethylene glycol, 1,4-butanediol or 1,3-butanediol, neopentyl glycol and trimethylol propane into the reaction kettle, uniformly stirring, and then sealing and heating; (2) slowly adding hydrogenated phenylmethane diisocyanate to the reaction kettle in a dropwise manner, controlling a temperature to 85-90 DEG C, holding the temperature for 1-2 hours, adding a catalyst, and then carrying out a reaction for 40-90 minutes, cooling, adding a diluting solvent, uniformly stirring, adding acetone when the temperature is decreased to 54 DEG C, uniformly stirring, and taking the material and packaging at the temperature of 35-40 DEG C. The slurry of the present invention has characteristics of simple production process, easy operation and short curing time, and is suitable for long-term use under the ultraviolet illumination environment while the slurry is not yellowing in the use process.

Owner:烟台市福山区化学工业研究所有限公司

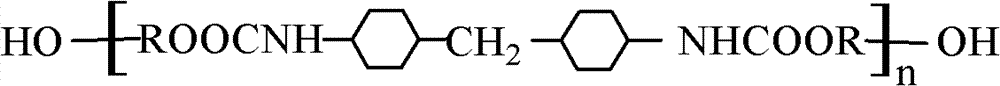

NiCrAlY coated YSZ powdered material and coating preparing method

InactiveCN106637186AHigh hardnessImprove wear resistanceMetallic material coating processesShielding gasHigh pressure water

The invention provides a thermal barrier coating preparation technology, and relates to a NiCrAlY coated YSZ thermal barrier coating powdered material preparing method. The method is characterized in that a high pressure water mist method is used for preparing a NiCrAlY alloy coated YSZ thermal barrier coating powdered material, coating powder is arranged on the surface of a high-temperature alloy sample in advanced, the sample is placed in a protection box with argon serving as protective gas, and a ladder bonding layer is prepared through laser wide-band cladding. According to the method, YSZ is coated with laser cladding NiCrAlY, and the ladder bonding layer which can reduce cracks generated by direct cladding of a ceramic layer and a metal base due to different linear expansion coefficients and improve the bonding intensity and thermal shock resistance of the coating.

Owner:TIANJIN POLYTECHNIC UNIV

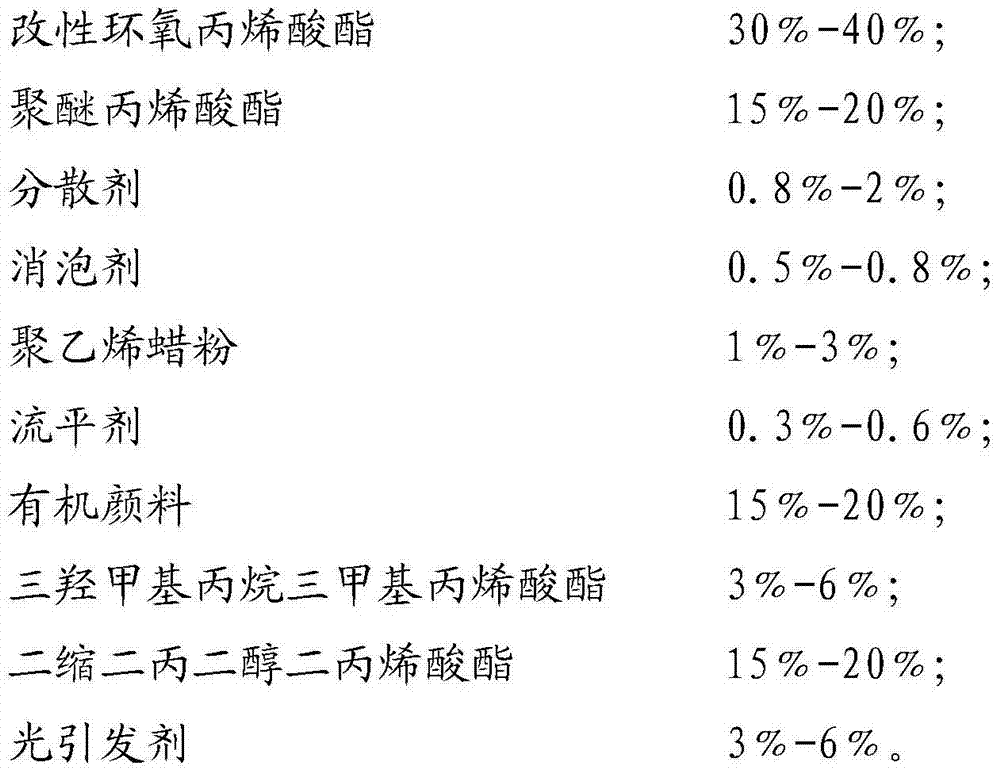

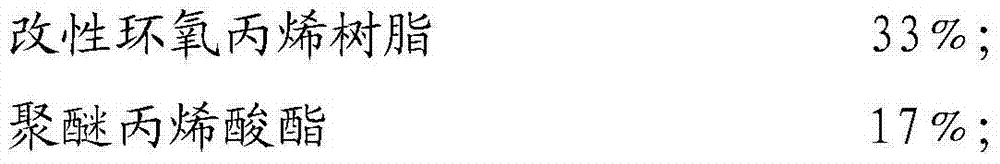

UV oil solid color paint

ActiveCN103709904AGood flexibilityImprove adhesionPolyether coatingsEpoxy resin coatingsEpoxyPolymer science

The invention relates to the technical field of paint and especially relates to UV oil solid color paint. The UV oil solid color paint comprises, by mass, 30-40% of epoxy resin, 15-20 parts of polyether-type acrylate, 0.8-2% of a dispersant, 0.5-0.8% of an antifoaming agent, 1-3% of polyethylene wax powder, 0.3-0.6% of a flatting agent, 15-20% of an organic pigment, 3-6% of trimethylol-propane trimethacrylate, 15-20% of dipropylene glycol diacrylate and 3-6% of a photoinitiator. Through use of the polyether-type acrylate, problems of use of single epoxy resin are solved, paint film performance complementation is realized, paint film flexibility is improved, adhesion is improved, residual acrylic acid ester groups in the photocured paint film are reduced, and aging resistance and yellowing resistance are improved.

Owner:广东千叶松化工有限公司

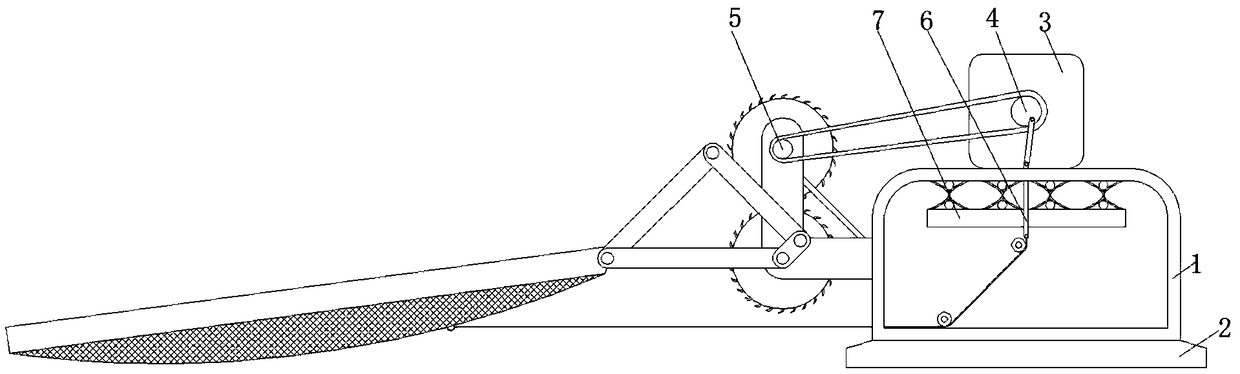

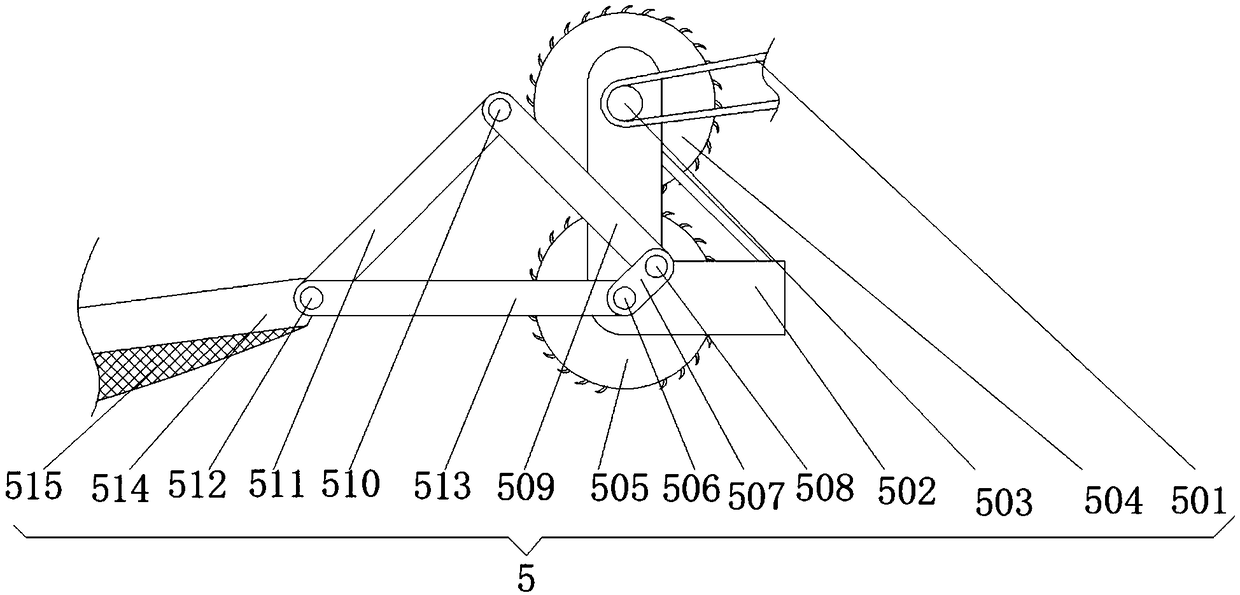

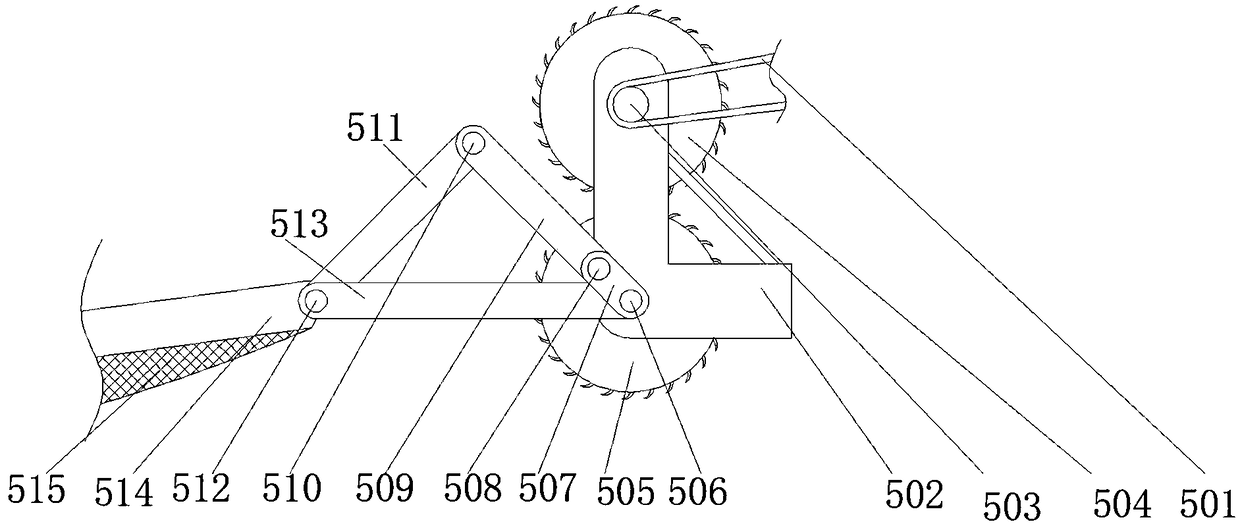

Dead fish salvaging device based on rotating type and shaking simulation mode

InactiveCN108639261AIncrease the number ofEasy to salvageWater cleaningWaterborne vesselsEngineering

The invention relates to a dead fish salvaging device and discloses a dead fish salvaging device based on the rotating type and the shaking simulation mode. The dead fish salvaging device comprises asalvaging machine body. The bottom of the salvaging machine body is fixedly connected with a floating bed. By arranging the floating bed, the dead fish salvaging device can float on the water surface,and salvaging operation is facilitated. The top of the salvaging machine body is fixedly connected with a servo motor, the output end of the front face of the servo motor is fixedly connected with arotating shaft A through a flat key, and a micromotion-type salvaging mechanism is arranged between the surface of the rotating shaft A and the left side of the salvaging machine body. The servo motorworks, thus the rotating shaft A works and drives the micromotion-type salvaging mechanism to shake in a left-right reciprocating mode, and a reciprocating-type shaking mechanism drives the bottom ofthe micromotion-type salvaging mechanism to shake in an up-down reciprocating mode through the rotating shaft, so that the salvaging effect is more diversified, and dead fishes near the water surfacecan enter the salvaging device; and the more dead fishes can be stored, and salvaging is facilitated.

Owner:李云魁

Production technology of flexible damping reclaimed rubber

The invention discloses a production technology of flexible damping reclaimed rubber. The production technology comprises the following steps: (1) tire crushing and rubber powder screening; (2) rubberpowder desulfurization; (3) kneading; (4) filtration; (5) refining; and (6) forming, wherein the rubber powder desulfurization process in step (2) comprises: adding screened rubber powder and chemical assistants into a pre-heated vulcanization tank having a temperature of 180-200 DEG C according to a mass ratio of the screened rubber powder to the chemical assistants of 1000:(163-226), raising the pressure in the vulcanization tank from normal pressure to 2.0 MPa in a programmed pressurizing manner, continuous turning materials in the tank in the pressure raising process for 80-100 min in order to complete the desulfurization process; the chemical assistants include vegetable oil, rosin, a 820 resin assistant, aromatic oil, stearic acid and zinc oxide. The production technology is adoptedto effectively solve the technical problem of small damping coefficient of a final product.

Owner:四川省隆昌海燕橡胶有限公司

Non-yellowing polyurethane slurry for hasp, and preparation method thereof

The present invention relates to a non-yellowing polyurethane slurry for a hasp, and a preparation method thereof. The molecular general formula is as the follow, wherein R is aromatic nucleus-free alkyl. The concrete process of the preparation method comprises: (1) pouring a bottoming solvent into a reaction kettle, then pouring polyester polyol, terylene-grade ethylene glycol, 1,4-butanediol or 1,3-butanediol, neopentyl glycol and trimethylol propane into the reaction kettle, uniformly stirring, and then sealing and heating; (2) slowly adding hydrogenated phenylmethane diisocyanate to the reaction kettle in a dropwise manner, controlling a temperature to 85-90 DEG C, holding the temperature for 1-2 hours, adding a catalyst, and then carrying out a reaction for 40-90 minutes, cooling, adding a diluting solvent, uniformly stirring, adding acetone when the temperature is decreased to 54 DEG C, uniformly stirring, and taking the material and packaging at the temperature of 35-40 DEG C. The slurry of the present invention has characteristics of simple production process, easy operation and short curing time, and is suitable for long-term use under the ultraviolet illumination environment while the slurry is not yellowing in the use process.

Owner:烟台市福山区化学工业研究所有限公司

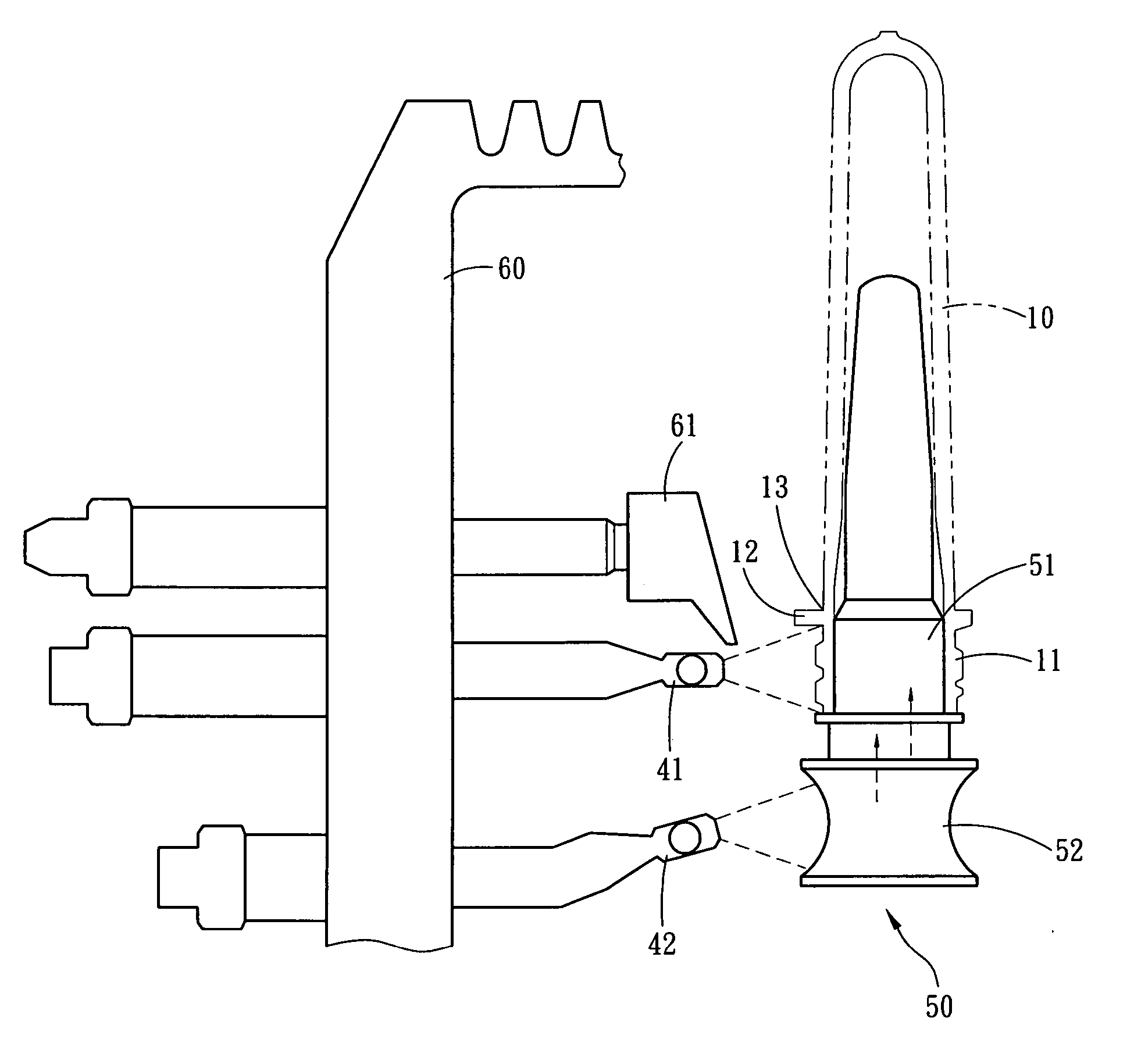

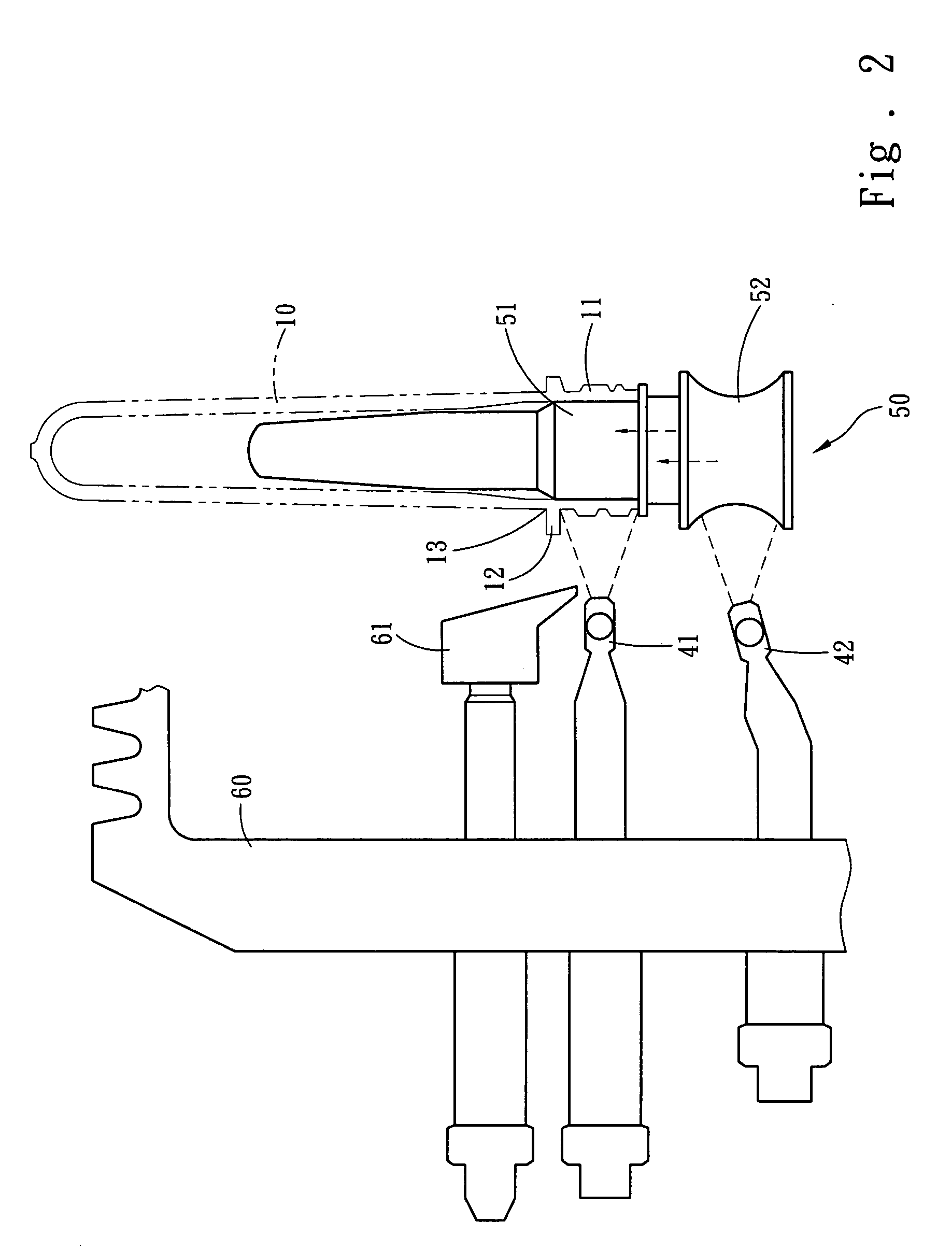

Preform neck crystallization heating method

InactiveUS20070063391A1Increase hardnessLow contract radial pressureElectric/magnetic/electromagnetic heatingEngineeringHeat energy

The present invention discloses a bottle mouth crystallization heating method, which makes use of external heat energy. When a preform is mounted onto a plug finger of a base by the preform, a first heating source directly heats the external side of the bottle mouth to crystallize the bottle mouth, and a second heating source heats the plug finger of the preform being exposed from the bottom of the plug finger, so that after a heat absorber absorbs the heat, the heat absorber conducts heat energy to the plug finger. The plug finger with heat energy heats the internal side of the bottle mouth simultaneously, therefore to disperse heat energy evenly and rapidly to the internal and external sides of the bottle mouth for crystallization.

Owner:BOTTLE TOP DEV

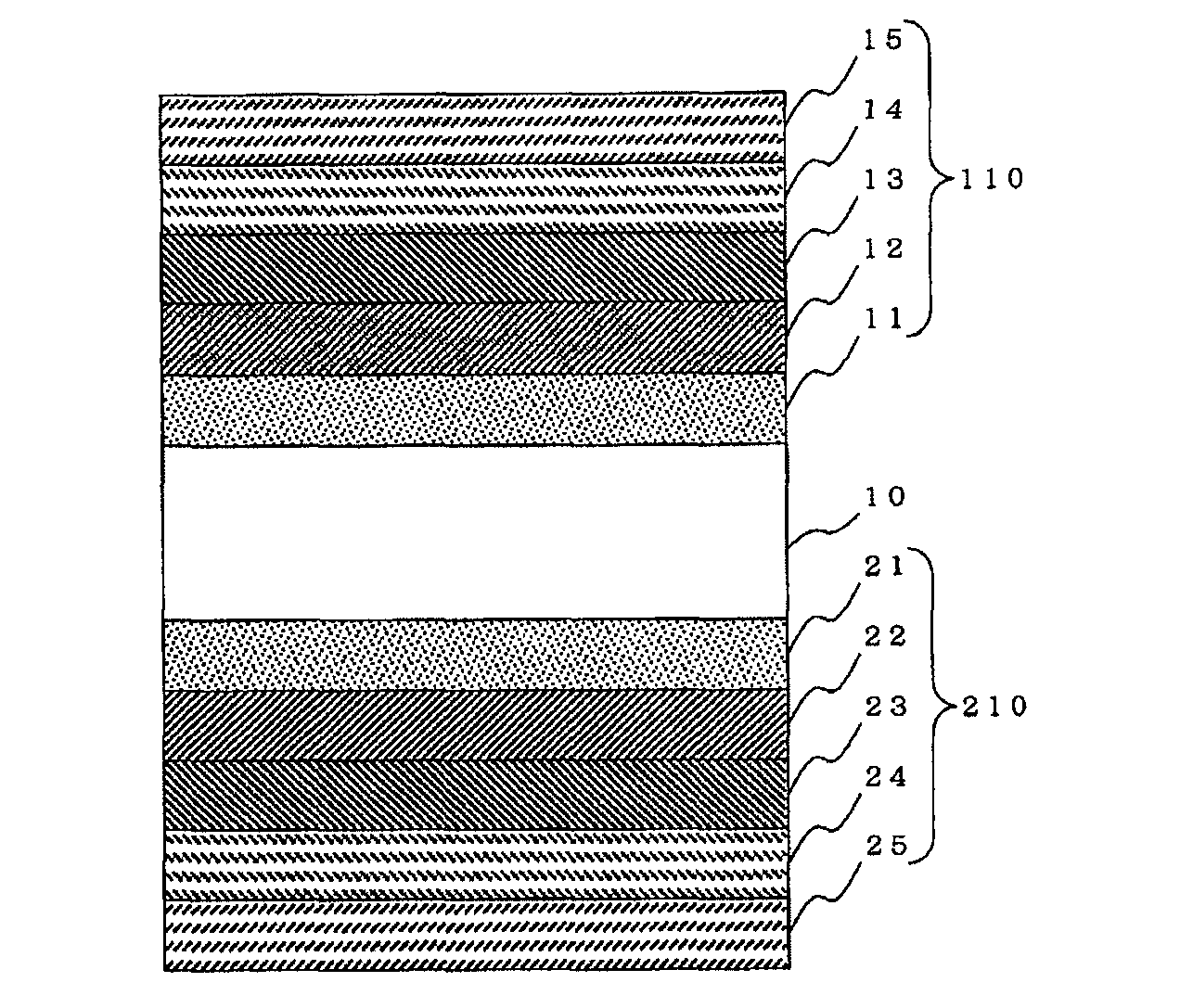

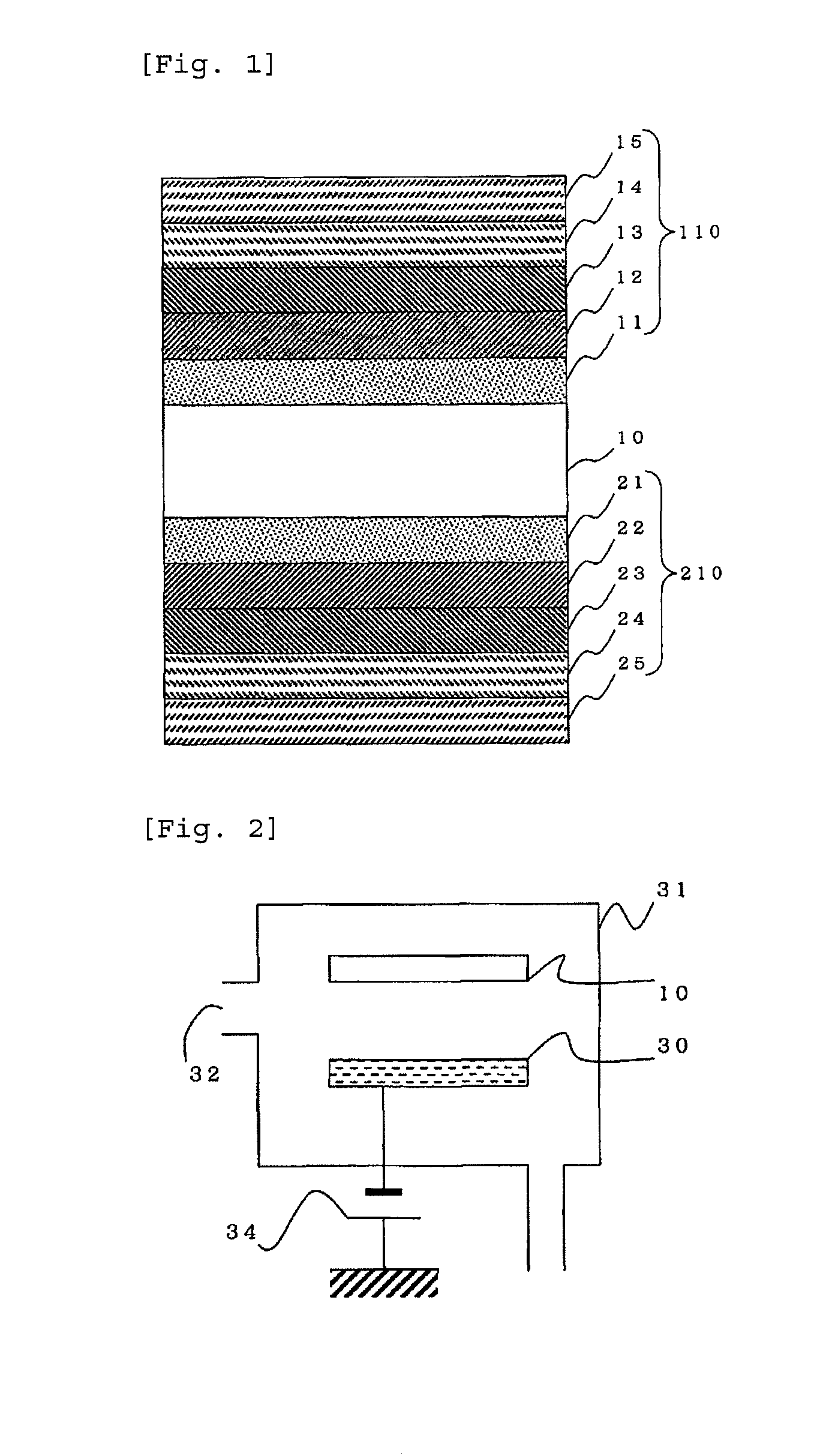

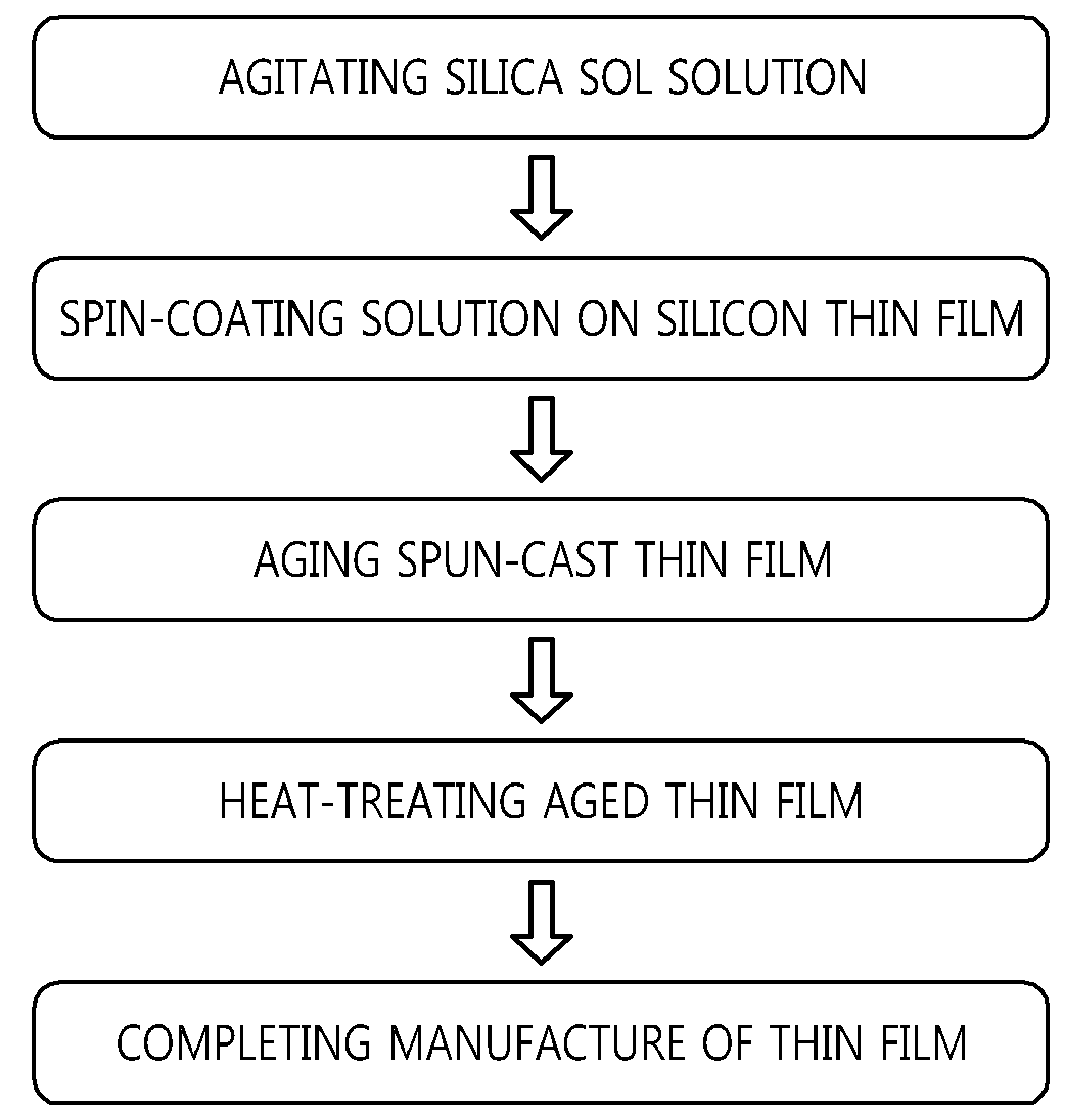

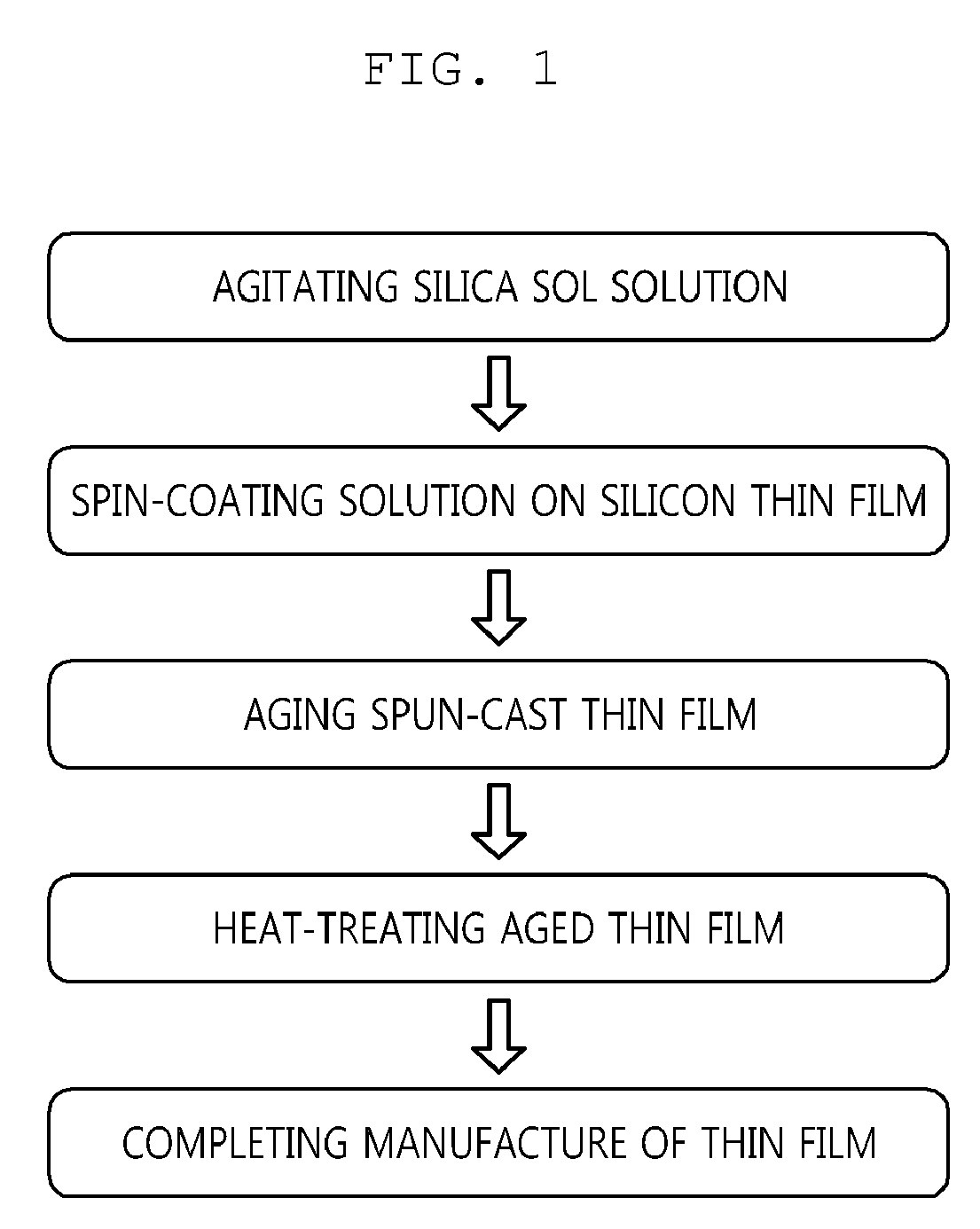

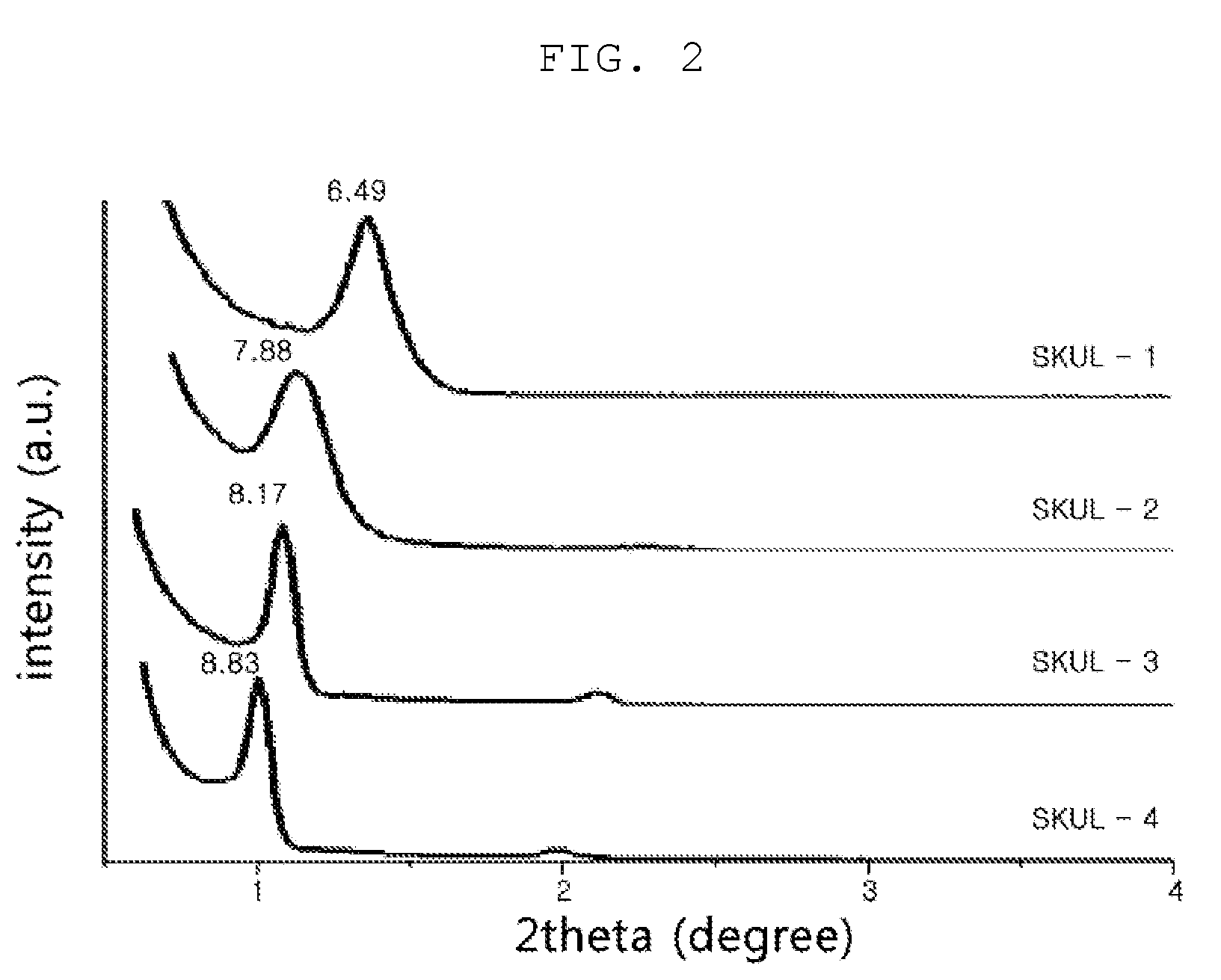

Lamella structured thin films with ultralow dielectric constants and high hardness and method for manufacturing the same

InactiveUS20090208737A1Mechanical strength be deteriorateIncrease hardnessSolid-state devicesSemiconductor/solid-state device manufacturingLow-k dielectricHardness

Owner:RES & BUSINESS FOUNDATION SUNGKYUNKWAN UNIV

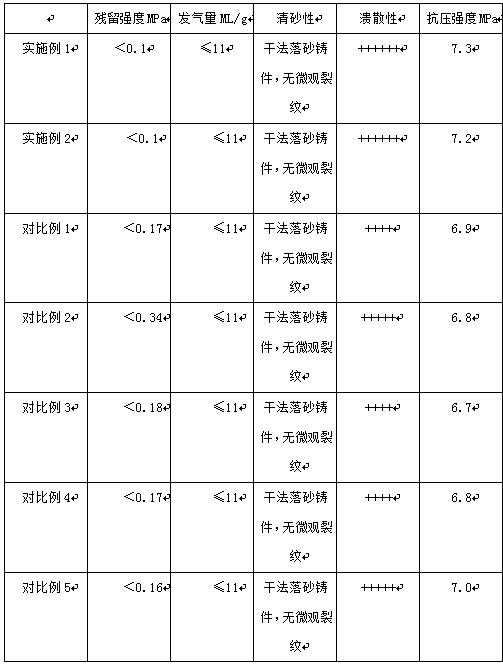

Collapsing intensifier for sodium silicate-bonded sand used for casting

The invention relates to a collapsing intensifier for sodium silicate-bonded sand used for casting. Raw materials of the collapsing intensifier for the sodium silicate-bonded sand comprise the components including ferric oxide magnetic powder, dickite powder, xanthan gum, ceramic micro powder, fluosilicate, bentonite and a surfactant. According to the collapsing intensifier, a mixture of the ferric oxide magnetic powder, the xanthan gum and the dickite powder serves as the collapsing intensifier, since the collapsing intensifier is adopted, produced combustible gas is little, most importantly,the situation that after casting-purpose sodium silicate which mainly contains sodium silicate, potassium metasilicate and lithium silicate is poured, sand removing is difficult can be reduced greatly, the collapsibility of the sand is remarkably improved, and the strength of the molding sand is obviously improved. On the premise that the gas evolution amount of a sand core is not increased, thecollapsibility of an inorganic bonding agent mainly containing the sodium silicate is greatly improved, the retained strength of the agent is greatly reduced, and the strength of the sodium silicate-bonded sand is improved.

Owner:安徽江杰实业有限公司

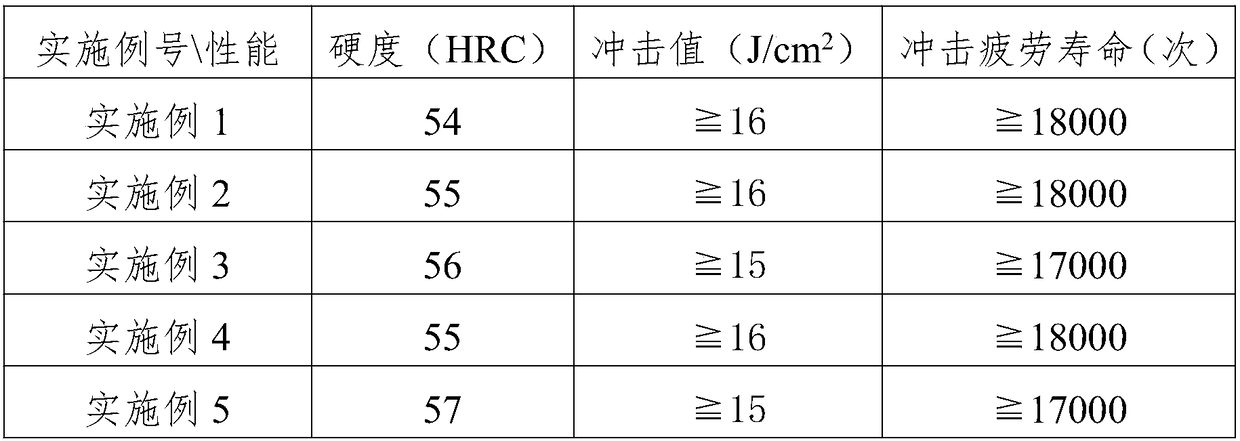

Preparation method of high-hardness strong-toughness high-manganese wear-resisting balls

InactiveCN108531827AImprove toughnessReduce internal stressFurnace typesProcess efficiency improvementHardnessMolten steel

The invention provides a preparation method of high-hardness strong-toughness high-manganese wear-resisting balls. The preparation method comprises the following steps of (1) putting various types ofscrap steel and metal raw materials into an electric furnace to conduct smelting at the smelting temperature of 1580 DEG C-1600 DEG C; (2) pouring molten steel into a steel ladle after the raw materials are totally molten, adding a compound modifier, injecting the molten steel into a die to conduct casting when the molten steel is cooled to 1460-1480 DEG C and cooling the molten steel to 300-380 DEG C; (3) putting wear-resisting ball crude products obtained intelligent the step (2) into the electric furnace to be heated to 900-920 DEG C and be subjected to ageing treatment for 5-6 h, conducting spray quenching treatment on the wear-resisting balls to cool the wear-resisting balls to 120-150 DEG C, conducting tempering to heat the wear-resisting balls to 280-300 DEG C and then conduct heatpreservation and finally air-cooling the wear-resisting balls to the indoor temperature. Through modification treatment, ageing treatment, spray quenching treatment and one-time tempering destressingtreatment, the wear-resisting balls have the properties of high hardness and high toughness, the tempering frequency is reduced, and the production cost is effectively reduced in industrial production.

Owner:NINGGUO ZHENGXING WEAR RESISTANT MATERIALS

Carbon-free high-speed steel and preparation method thereof

The invention discloses carbon-free high-speed steel and a preparation method thereof. According to the carbon-free high-speed steel provided by the invention, iron powder is introduced to replace molybdenum powder and cobalt powder, and a small amount of LaB6 is introduced to improve the tempering resistance and red hardness of the material; and through joint addition of La and B, strengthening is caused, austenite transformation is delayed, structure coarsening and desolvation of alloy elements during tempering are inhibited, so that the red hardness and the hot hardness of the Fe-Co-Mo material are improved. Meanwhile, a preparation process is simple, the cost of the raw materials is reduced, the excellent cutter material performance is shown, and a prepared cutter can keep high hardness and is not sticky under the long-time cutting action, and important application value in the industry is achieved.

Owner:XIANGTAN UNIV

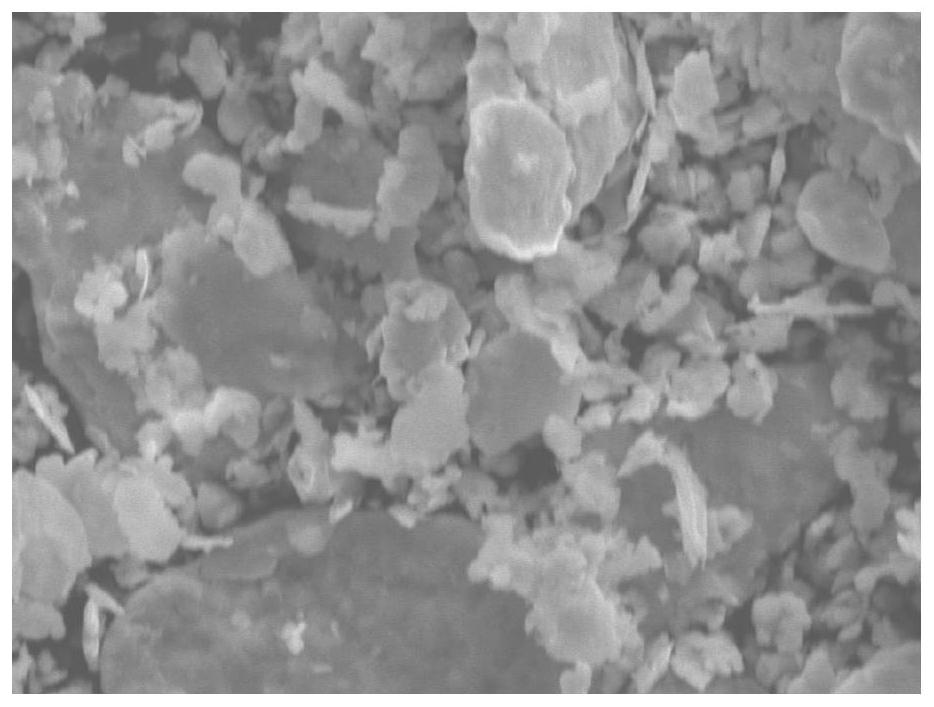

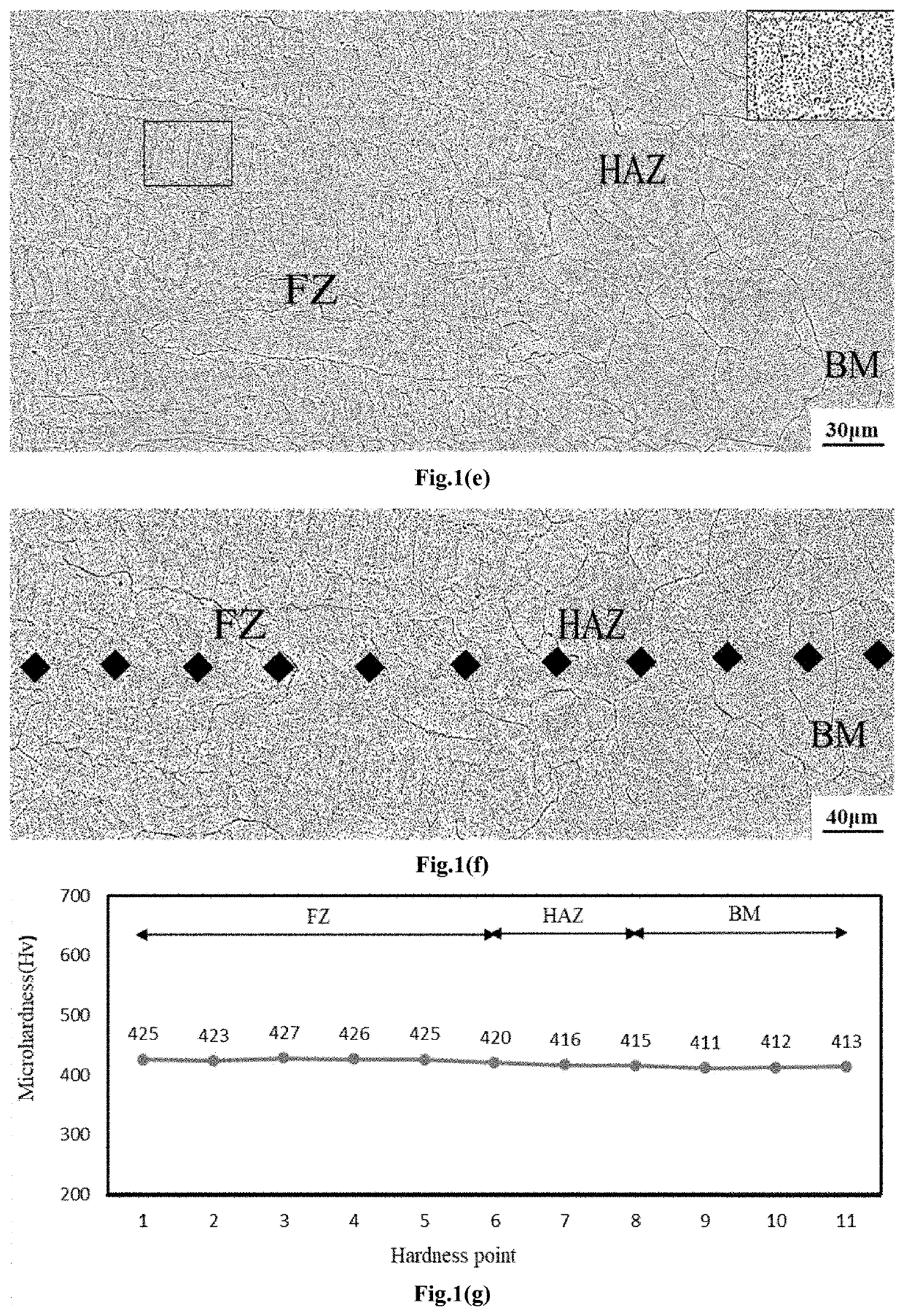

WELDING FILLER WIRE FOR FUSION WELDING PRECIPITATION-HARDENED AUSTENITIC Fe-Mn-Al-C ALLOYS

ActiveUS20220080534A1Increase hardnessHigh hardnessWelding/cutting media/materialsWelding/soldering/cutting articlesFusion weldingExtremely hard

A series of welding filler wires with innovative composition design for fusion welding precipitation-hardened lightweight austenitic Fe—Mn—Al—C alloys. The first class of the welding filler wires is composed of 23-34 wt. % Mn, 7.5-11.5 wt. % Al, 1.35-1.95 wt. % C, with the balance being essentially Fe. After fusion welding, there are high-density of nano-sized (˜3-5 nm) (Fe,Mn)3AlC carbides (κ-carbides) uniformly distributed within the austenite dendrite cells in the fusion zone (FZ). The amount of nano-sized (˜6-10 nm) κ-carbides existing within the eutectic regions is significantly increased and the size of the austenite dendrite cells is substantially reduced. The second class of welding filler wires has the composition of 23-34 wt. % Mn, 7.5-11.5 wt. % Al, 1.40-1.95 wt. % C, 0.1-2.5 wt. % Ti, 0.1-3.0 wt. % Nb, 0.1-2.5 wt. % V, with the balance being essentially Fe. The microstructure of the FZ in the as-welded condition results in formation of substantial amount of nano-sized (˜6-10 nm) face-centered-cubic structured ductile Ti-rich Ti-carbides, Nb-rich Nb-carbides and V-rich V-carbides within the eutectic regions. These carbides are extremely hard (2000˜3500 Hv), enhancing hardness of the obtained FZ.

Owner:FANG TE FU +1

Novel termite-proof cable

InactiveCN103093885AIncrease hardnessStop bitingInsulated cablesInsulated conductorsHardnessEngineering

The invention provides a novel termite-proof cable. A nylon protecting layer is outside an insulating layer and an inner protecting layer is outside the nylon protecting layer. A glass silk braid layer and a high density polyethylene outer protecting layer are outside the inner protecting layer. The high density polyethylene outer protecting layer can add the toughness of the novel termite-proof cable and the high hardness of the glass braid layer can prevent the novel termite-proof cable from being eaten and bitten of termites.

Owner:王彩霞

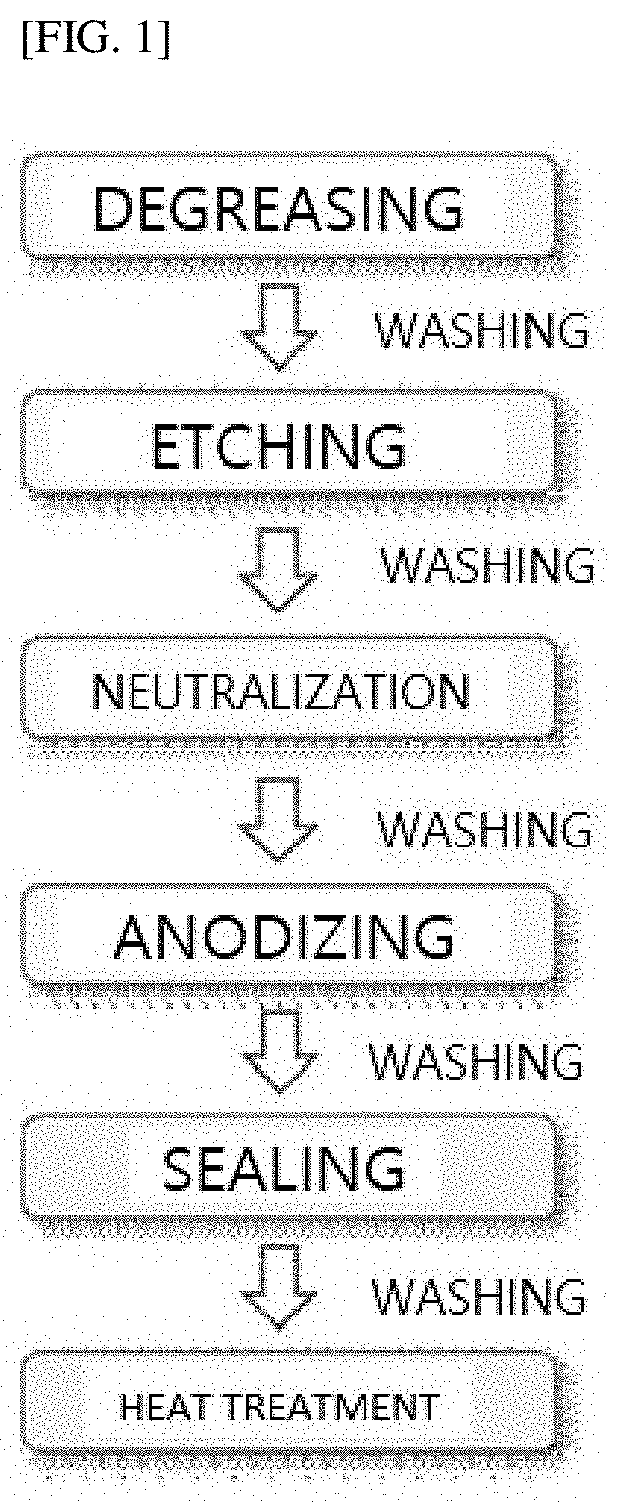

Surface hardening method using post heat treatment of aluminum alloy oxide layer

ActiveUS20210054469A1Increase hardnessEnvironmentally friendlyAnodisationSolid state diffusion coatingCase hardeningSulfuric acid

Provided is a surface hardening method for surface hardening a sulfuric acid-anodized aluminum alloy oxide layer, which includes: pre-treatment in which various foreign substances, including an oxide film, attached to a surface of an aluminum alloy are removed; sealing treatment in which the aluminum alloy having been subjected to the pre-treatment is immersed in a sealing solution, whereby fine pores formed in a film are sealed; and heat treatment in which the aluminum alloy having been subjected to the sealing treatment is charged to, and thermally treated in, a heat treatment furnace and then naturally cooled. By lowering the withstand voltage of an aluminum alloy oxide layer and increasing the hardness by subjecting the same to sealing treatment and subsequent post-heat treatment, the present invention has the effect of providing an environmentally-friendly and crack-free lightweight material that can replace steel products.

Owner:YKMC

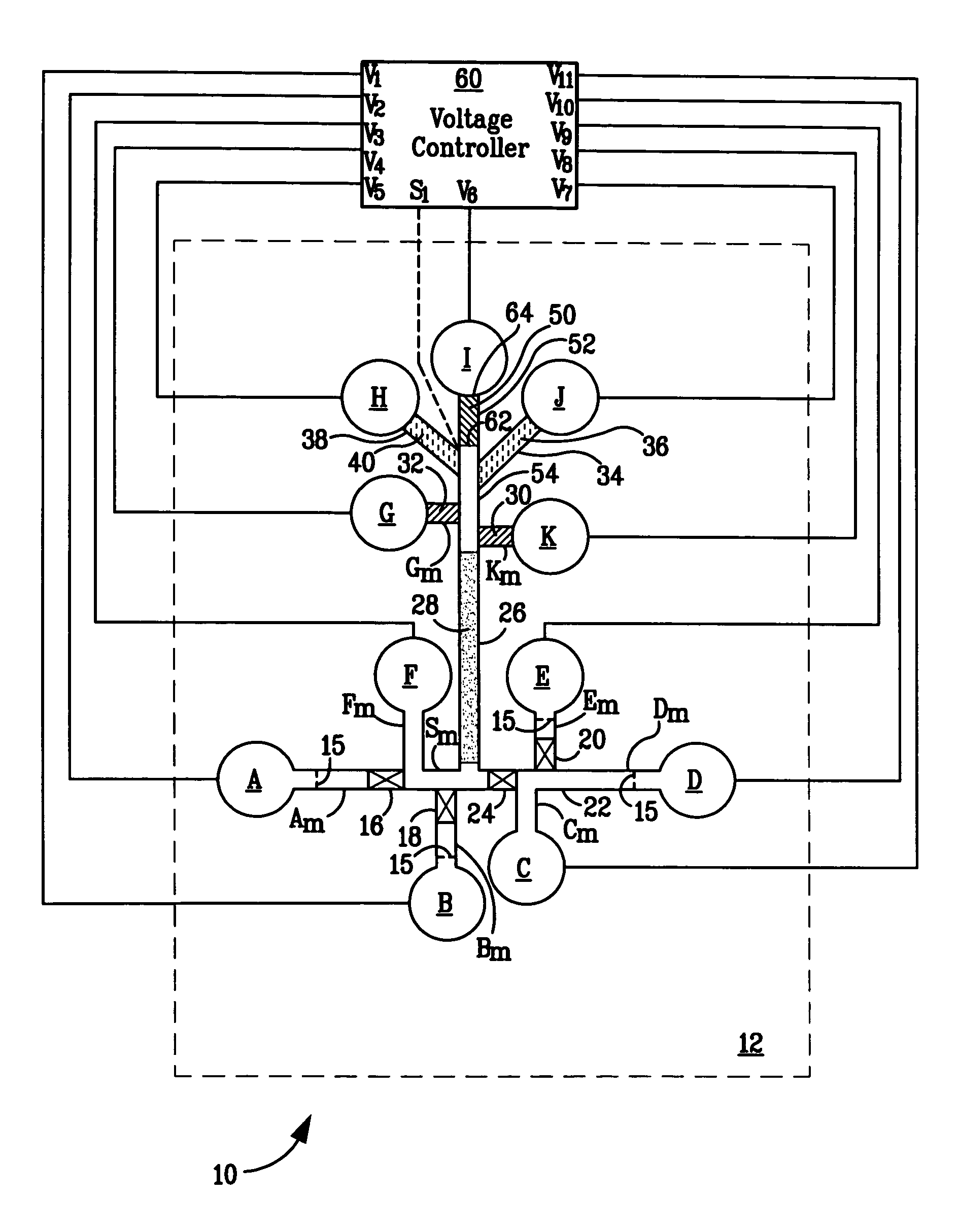

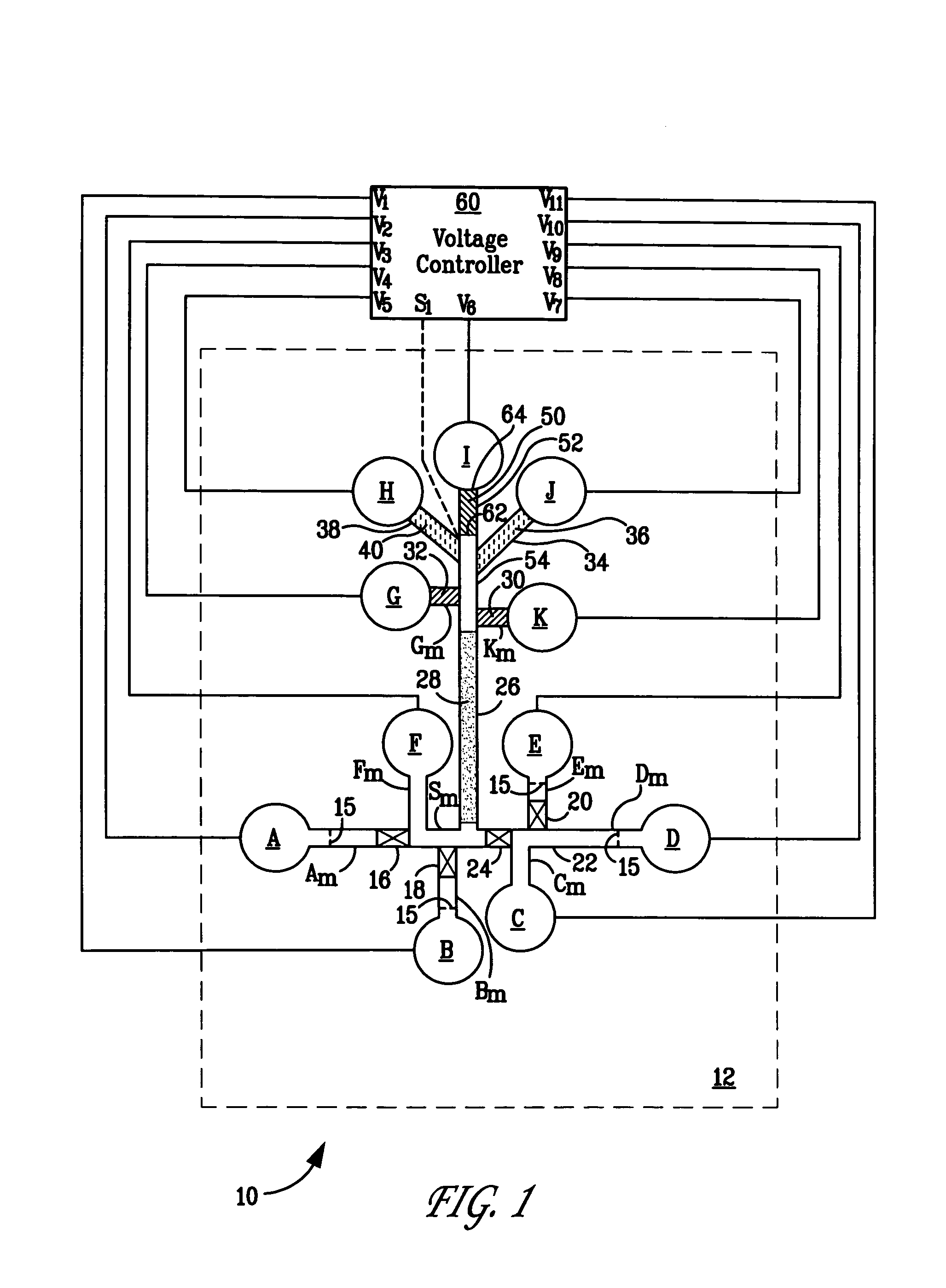

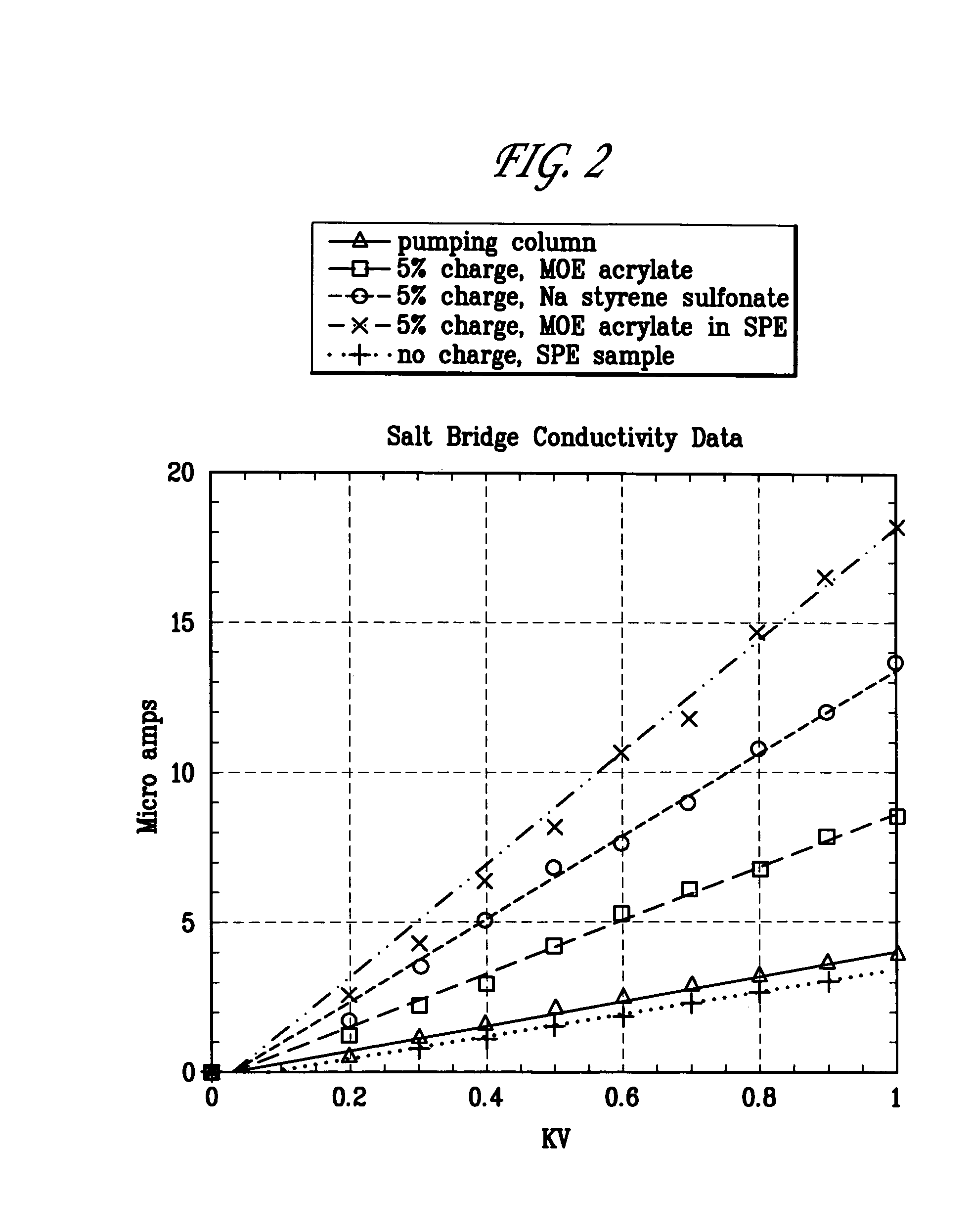

Polymeric salt bridges for conducting electric current in microfluidic devices

A “cast-in-place” monolithic microporous polymer salt bridge for conducting electrical current in microfluidic devices, and methods for manufacture thereof is disclosed. Polymeric salt bridges are formed in place in capillaries or microchannels. Formulations are prepared with monomer, suitable cross-linkers, solvent, and a thermal or radiation responsive initiator. The formulation is placed in a desired location and then suitable radiation such as UV light is used to polymerize the salt bridge within a desired structural location. Embodiments are provided wherein the polymeric salt bridges have sufficient porosity to allow ionic migration without bulk flow of solvents therethrough. The salt bridges form barriers that seal against fluid pressures in excess of 5000 pounds per square inch. The salt bridges can be formulated for carriage of suitable amperage at a desired voltage, and thus microfluidic devices using such salt bridges can be specifically constructed to meet selected analytical requirements.

Owner:SANDIA NAT LAB

A kind of coir fiber spring cushion adhesive

InactiveCN102277101AAccelerated vulcanizationIncrease productivityNatural rubber adhesivesNon-macromolecular adhesive additivesPolymer scienceVulcanization

A coir fiber spring cushion adhesive, which consists of 350-400 parts of natural rubber, 15-20 parts of 20% concentration soapy water, 2-4 parts of rubber accelerator powder, 3-5 parts of rubber anti-aging agent powder, rubber It is prepared by mixing 1-2 parts of vulcanization accelerator powder, 10-13 parts of zinc oxide powder, 1-3 parts of ZDC powder, 60-80 parts of calcium carbonate powder, and 1-2 parts of potassium hydroxide solid; among them, rubber accelerator Powder, rubber anti-aging agent powder, rubber vulcanization accelerator powder and calcium carbonate powder need to be mixed with water in a ratio of 1:4, and zinc oxide powder, ZDC powder, calcium carbonate powder need to be mixed with water in a ratio of 1:2. The adhesive has good viscosity, elasticity and long-term anti-aging effect, which can keep the spring cushion from collapsing for 10-15 years.

Owner:TIANJIN SHENGLONG RUBBERISED MATTRESS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com