Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Increase service life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

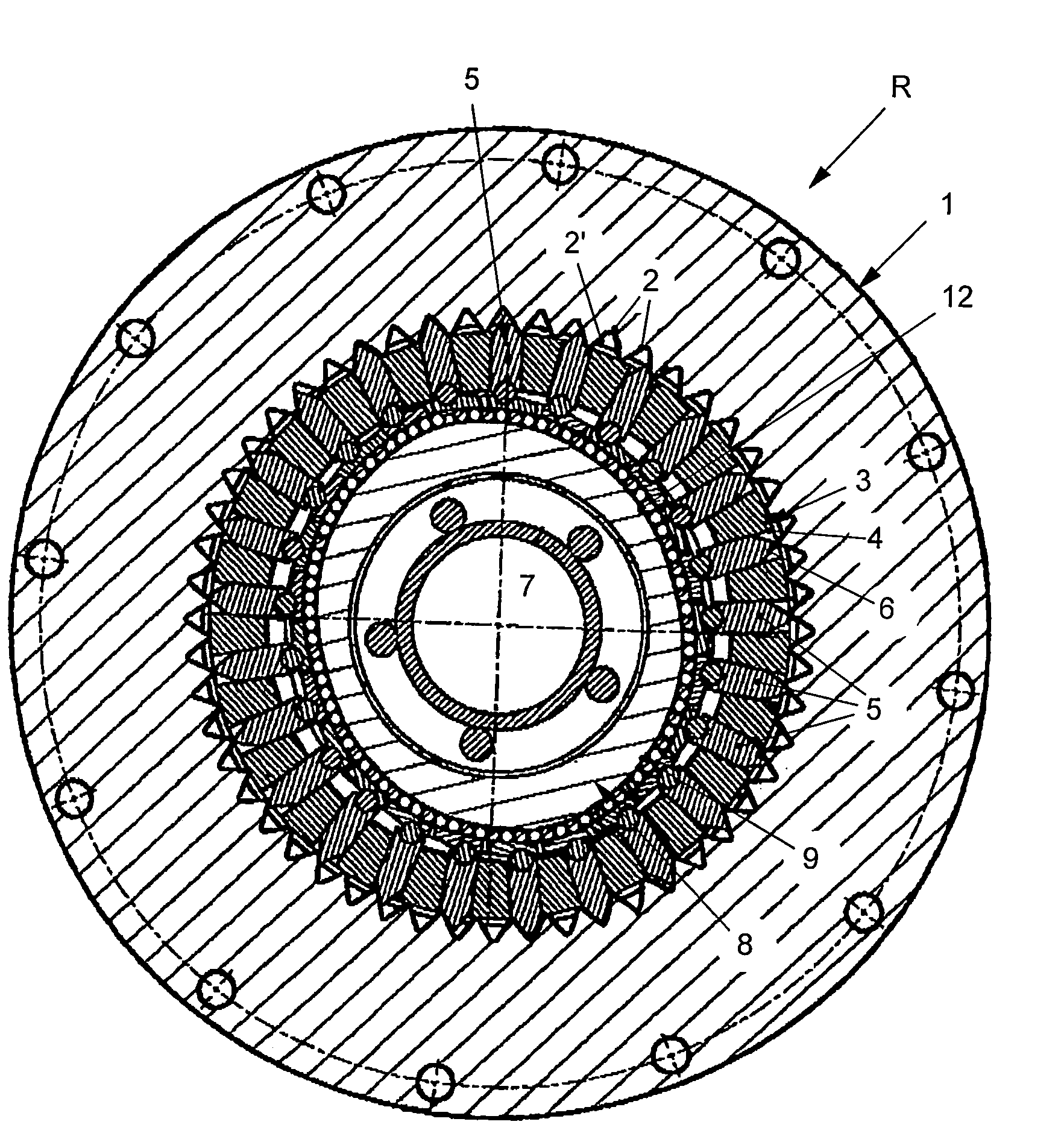

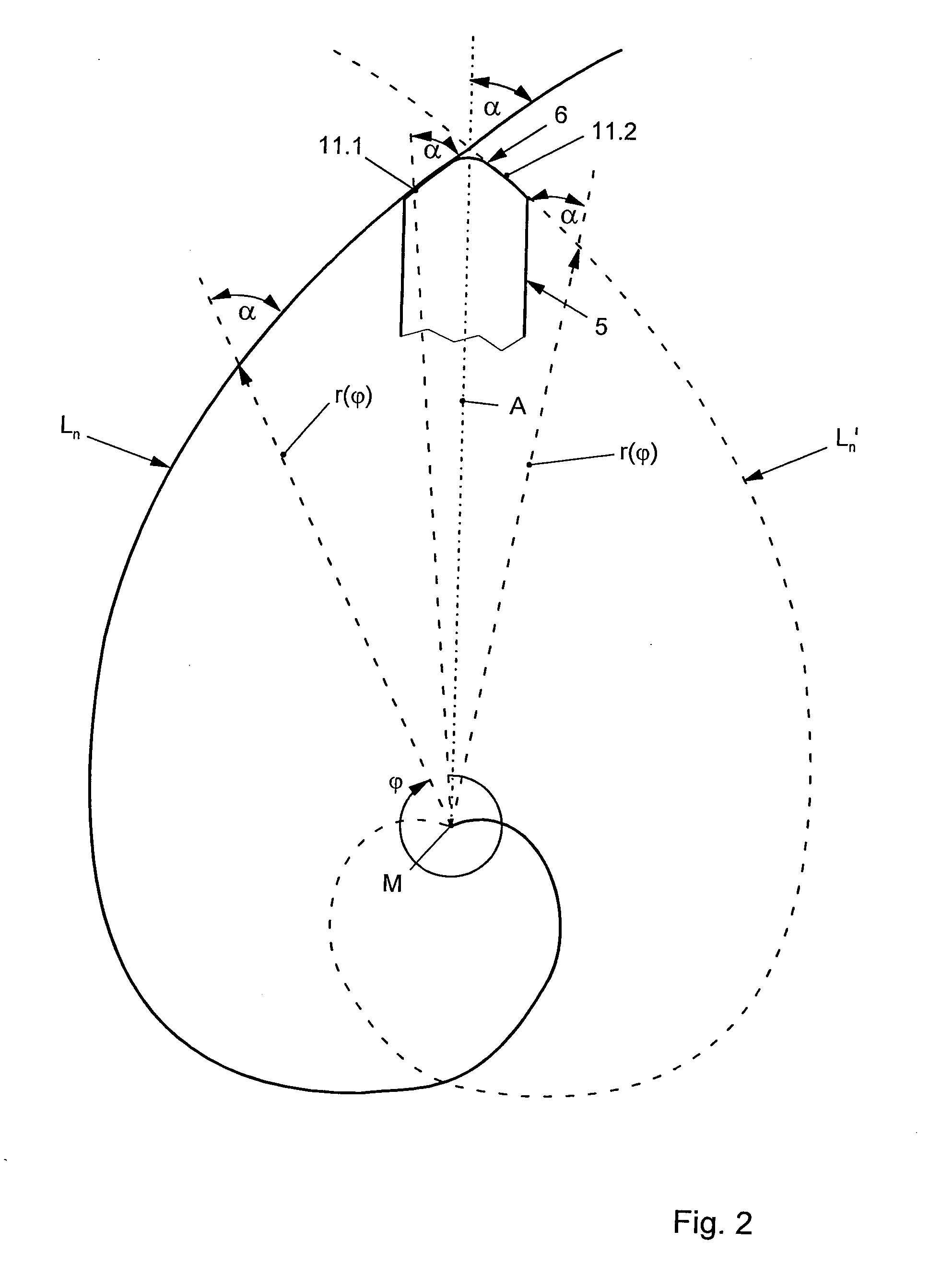

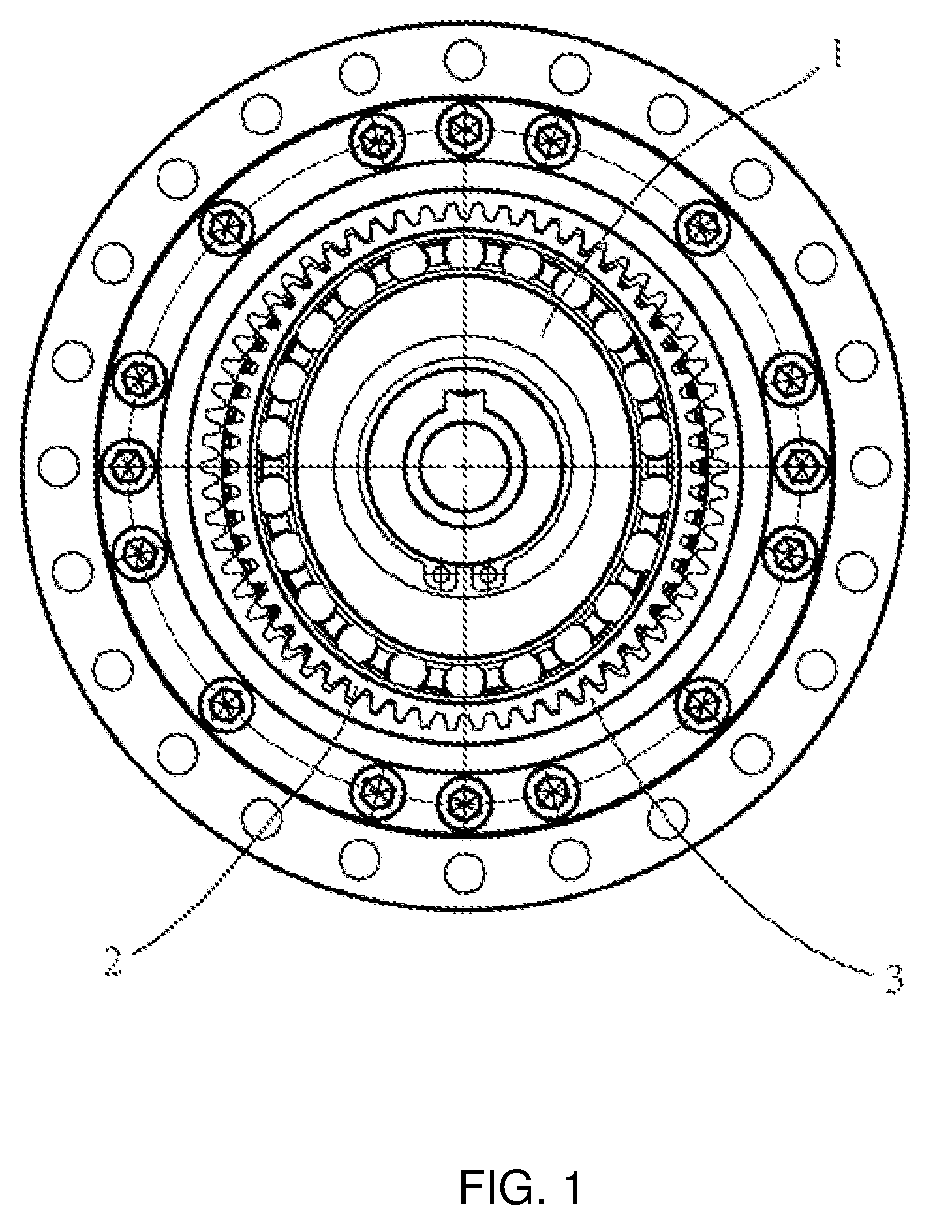

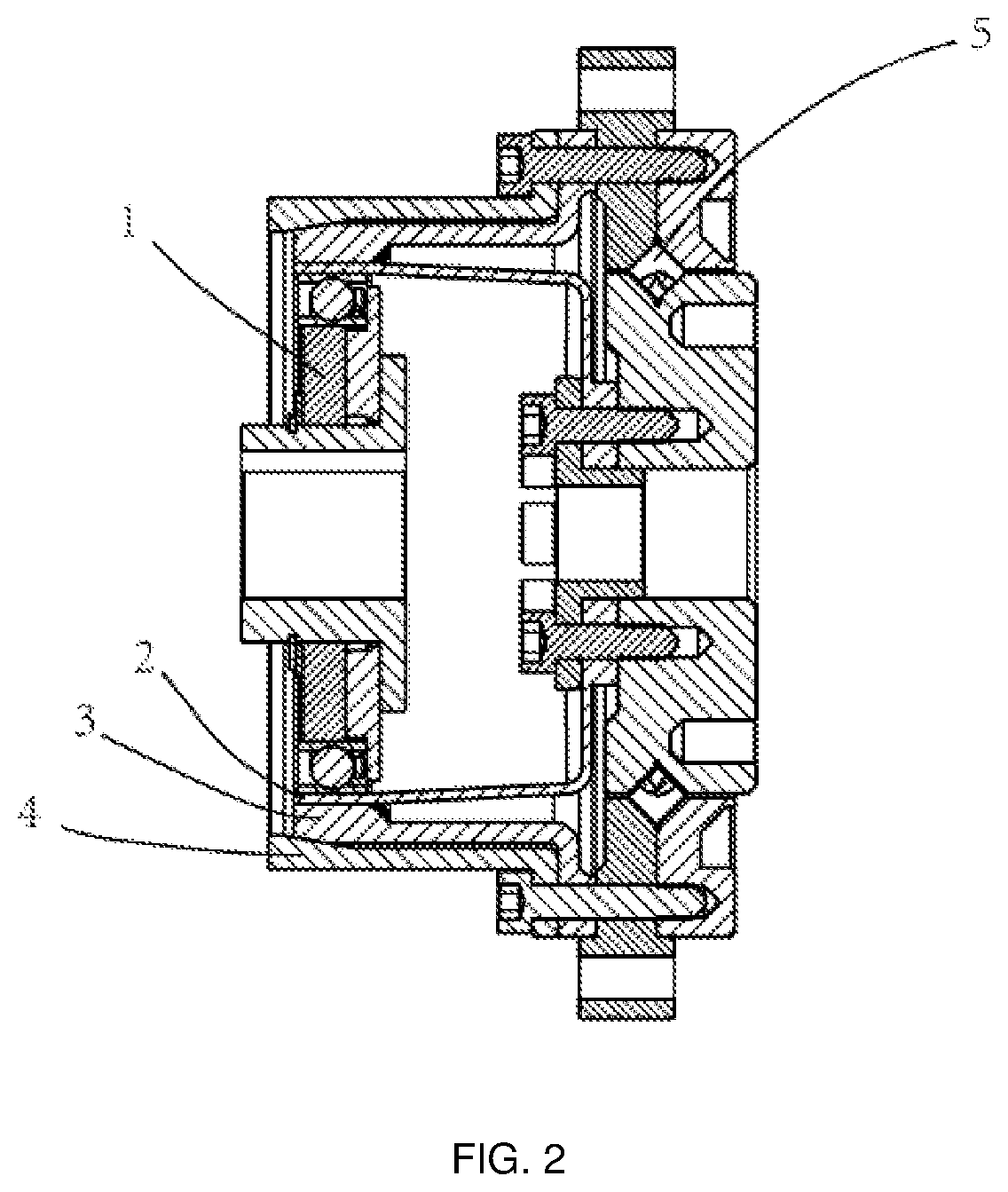

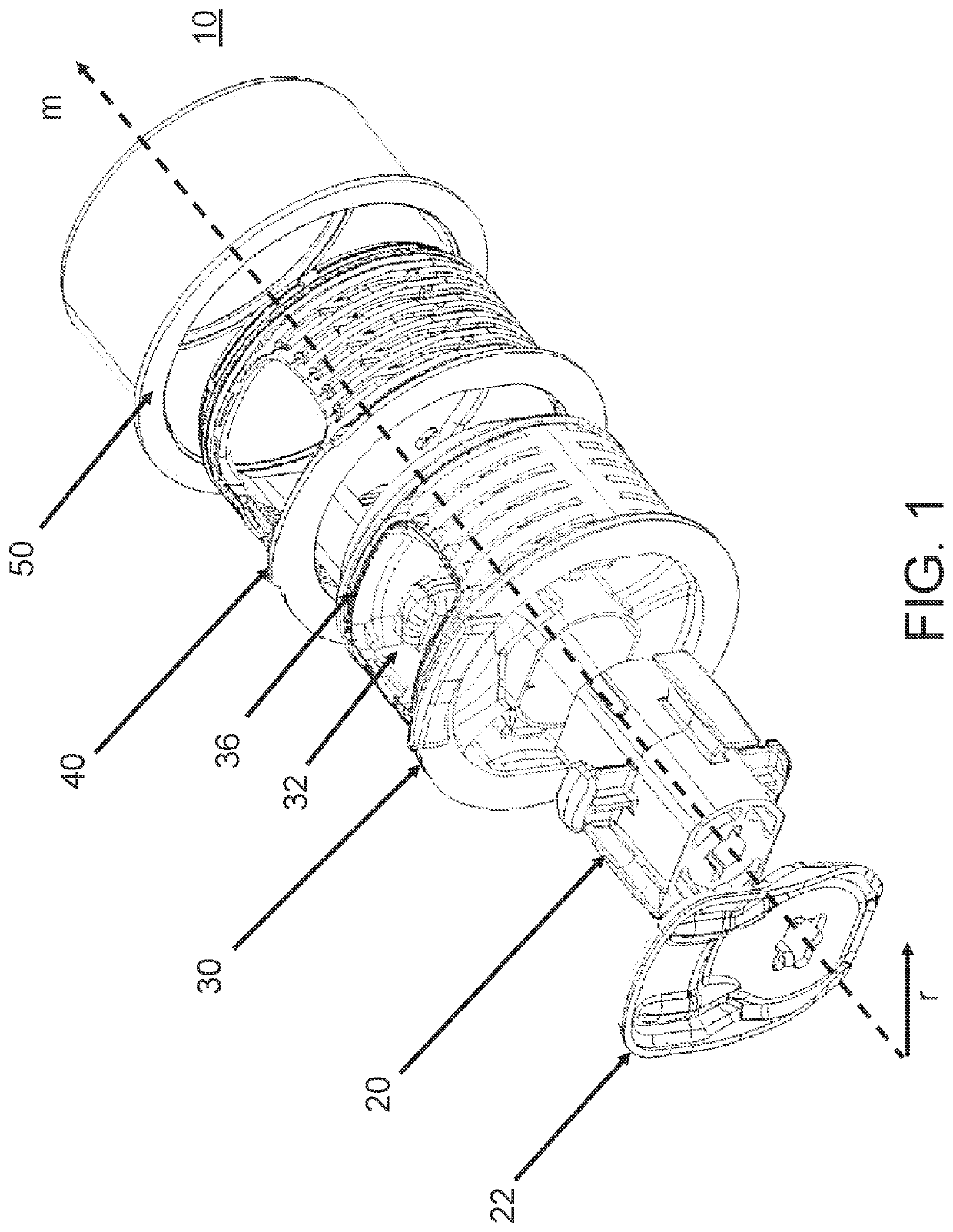

Coaxial gear set

ActiveUS20100077882A1Increase service lifeService lifeGearingPortable liftingPhysicsHigh power density

A coaxial gear set, in particular a hollow shaft gear set for industrial drive technology, having high power density, comprising a drive element (7), an element (3), and an output element, with a gear ratio and a transmission of a drive torque occurring between the drive element (7) and the output element via a plurality of radially movable tooth segments (5), an outer tooth flank contour (11.1, 11.2) of the tooth contour (6) of the tooth segments (5) and / or a flank contour (12.1, 12.2) of a gearing (13) of an inner gearing (15) of an internal wheel (1), relative to a gear axis (M), a tooth contour that allows surface contact in the engagement area comprising a logarithmic spiral.

Owner:WITTENSTEIN SE

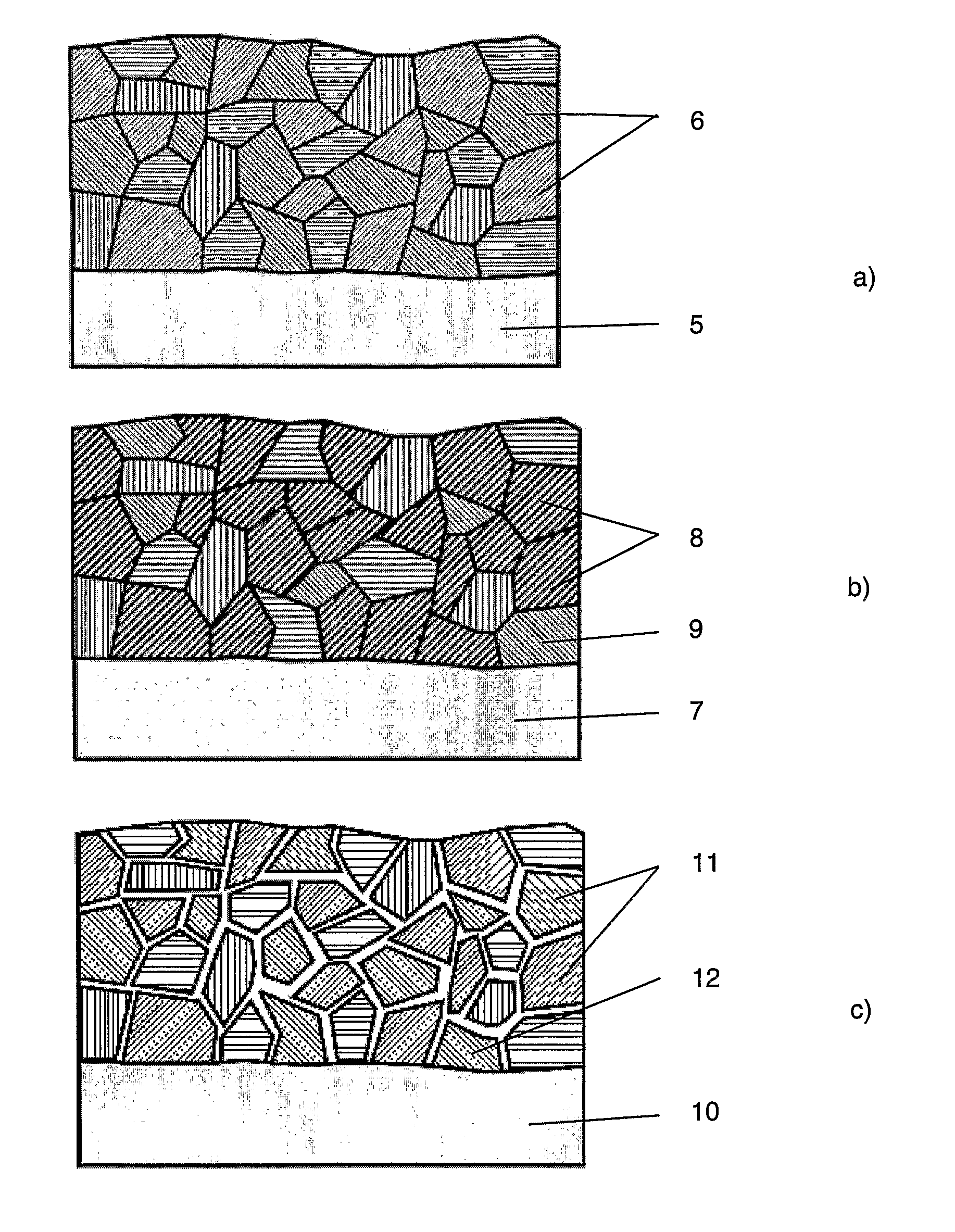

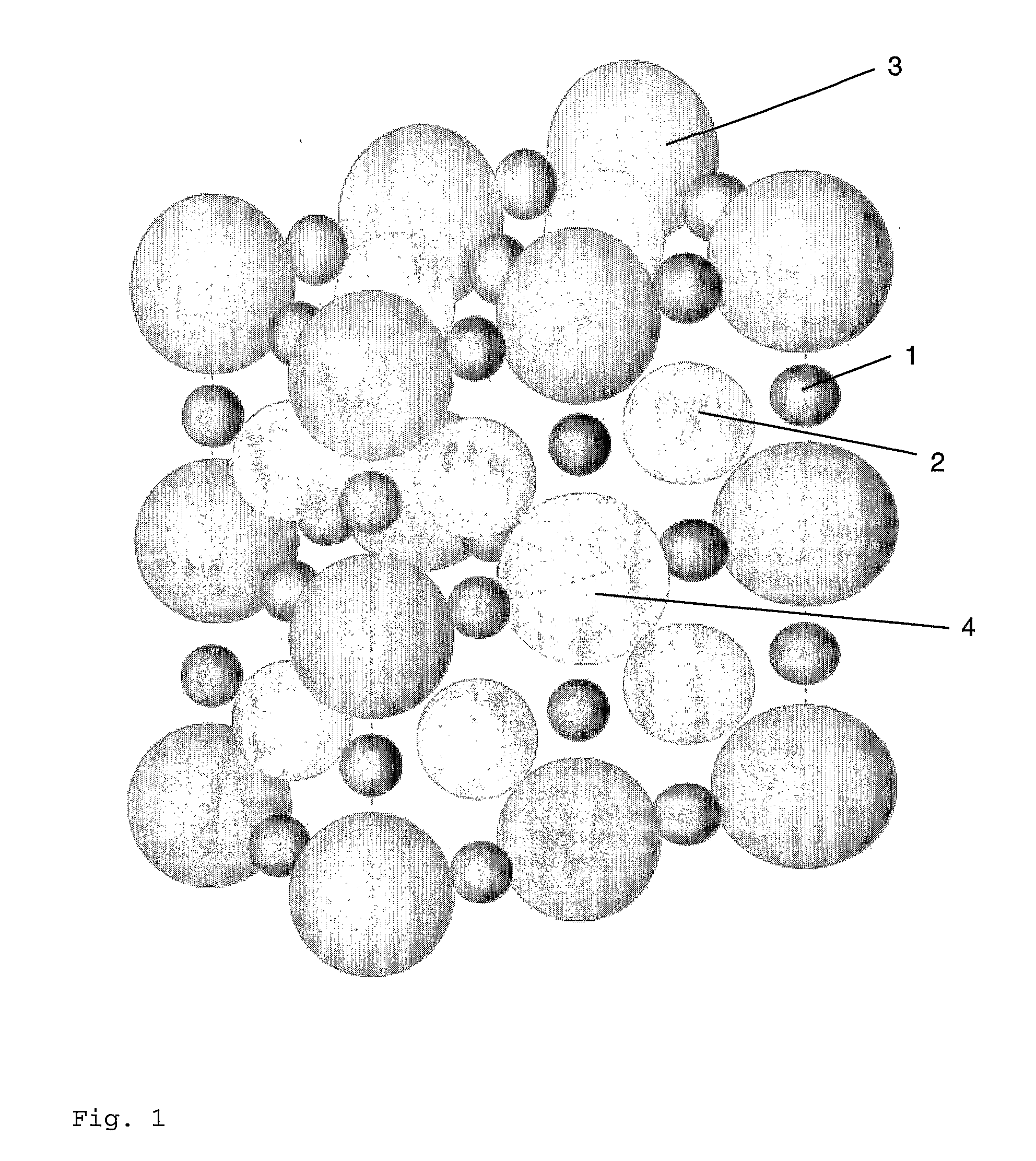

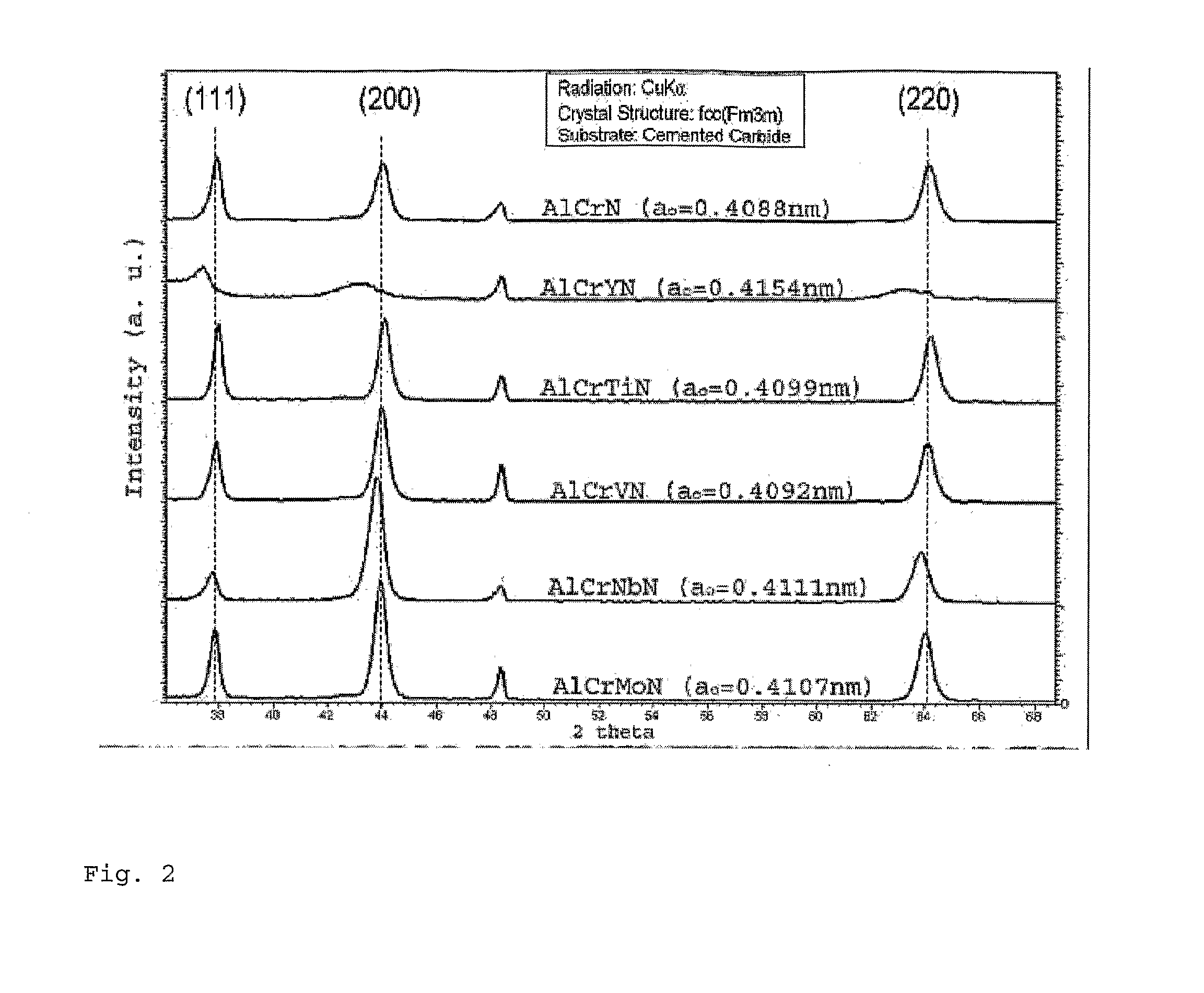

High Oxidation Resistant Hard Coating for Cutting Tools

ActiveUS20080318062A1Increase hardnessIncrease service lifePigmenting treatmentChromatisationOxidation resistantWear resistant

An inventive workpiece features on at least parts of its surface a wear resistant hard coating comprising the following composition Al1-a-b-c-dCraXbSicBdZ, where x is at least one element from Nb, Mo, W or Ta; Z is one element or compound from N, C, CN, NO, CO, CNO; and 0.2<=a<=0.5; 0.01<=b<=0.2; 0<=c<=0.1; 0<=d<=0.1. Further a PVD process for depositing such a wear resistant coating is disclosed whereby at least one workpiece is installed in a vacuum coating system and said system is operated in a low pressure argon atmosphere utilizing at least two metal or metal alloy targets with at least temporarily addition of a reactive gas.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

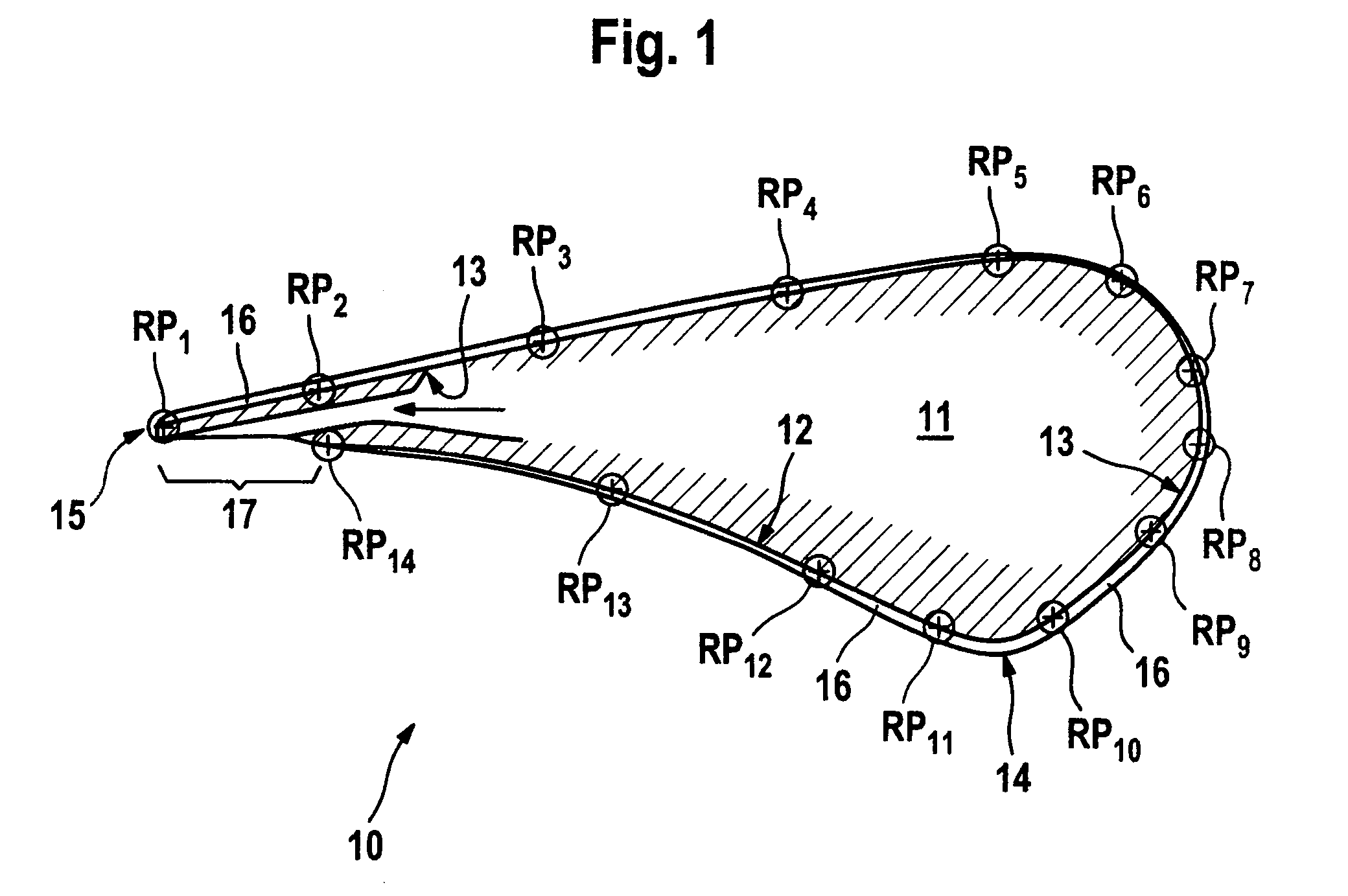

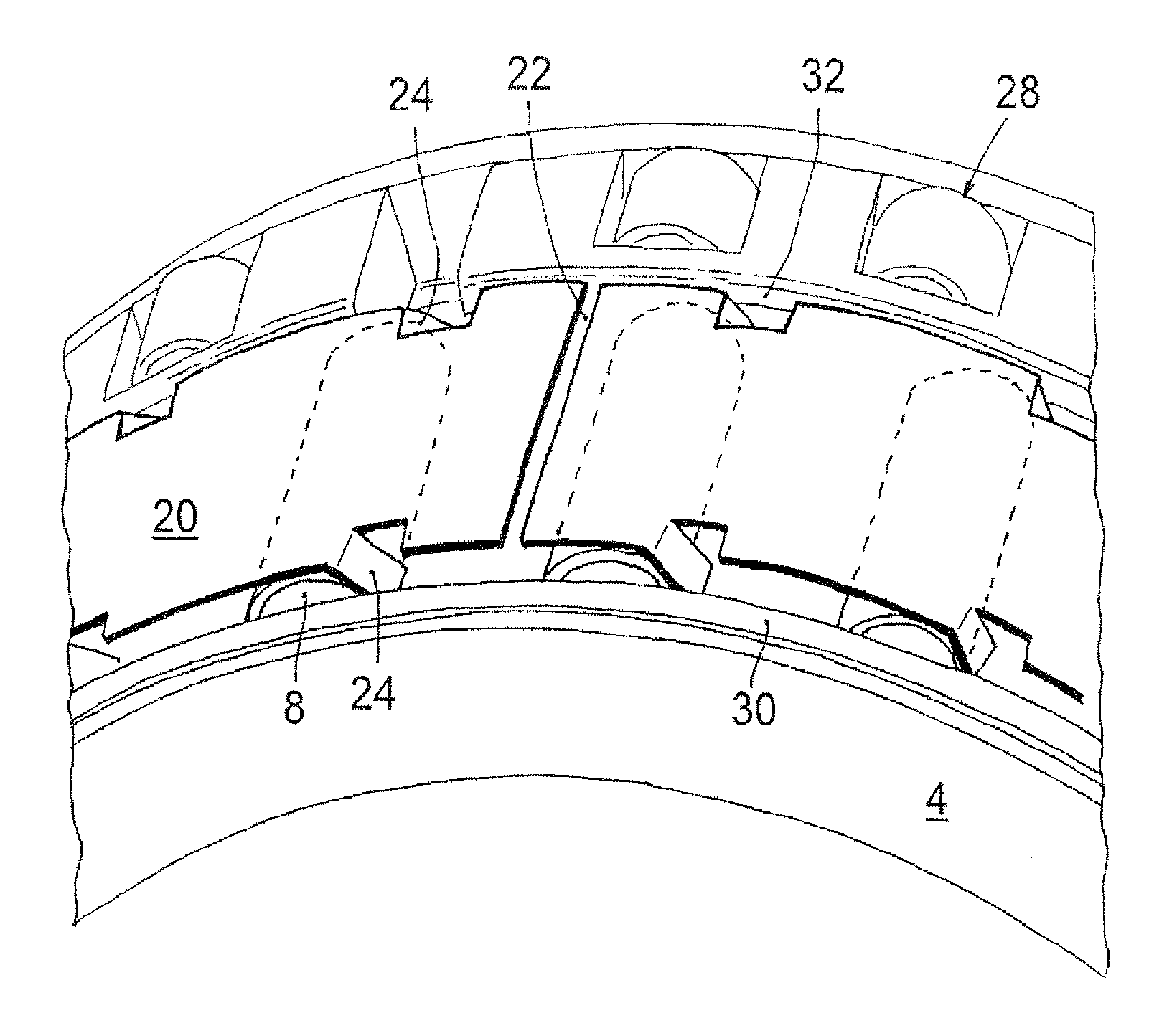

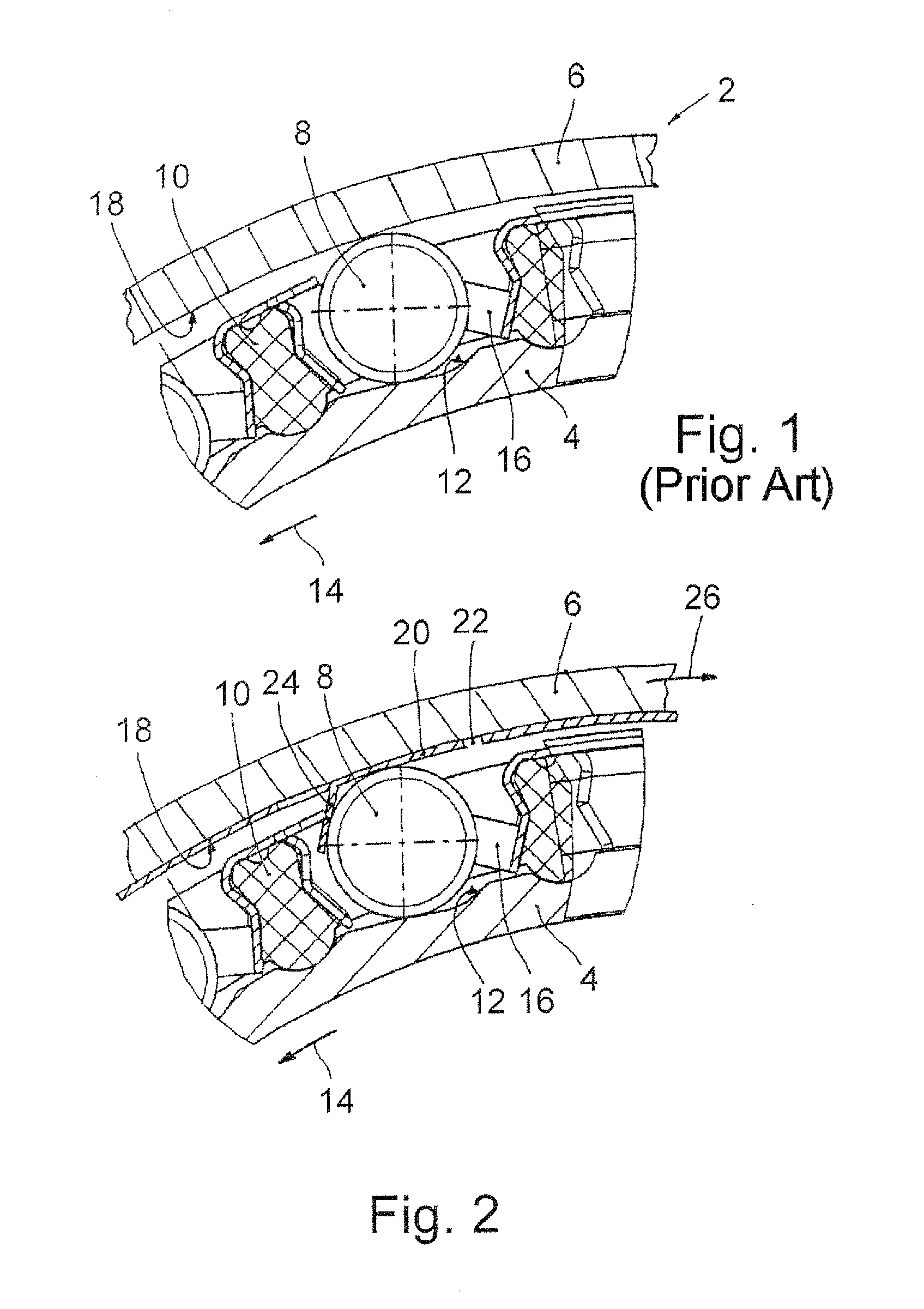

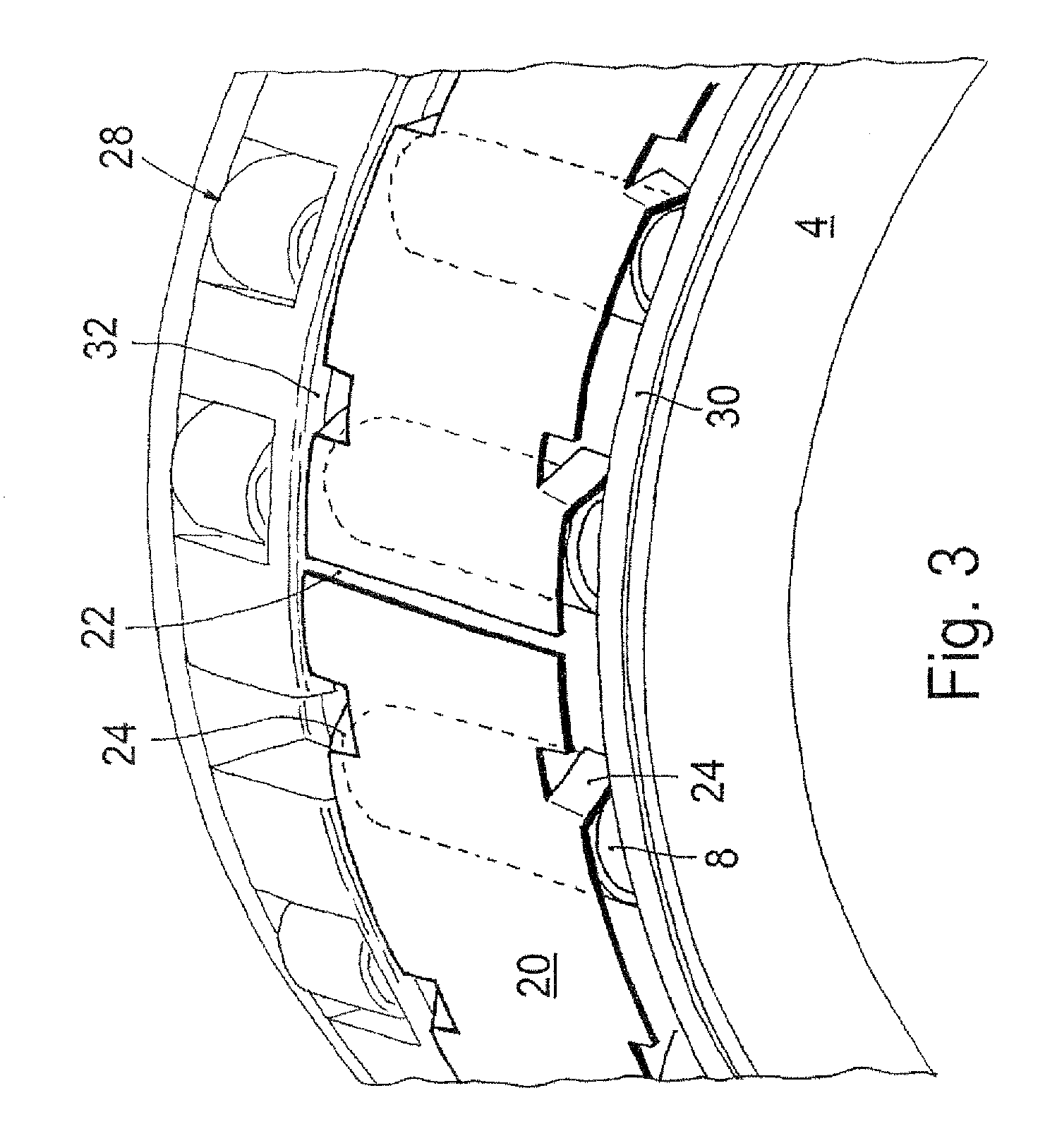

Turbine vane of a gas turbine

ActiveUS20100014962A1Increase service lifeRapidly damagedPropellersRotary propellersAirplaneGas turbines

Owner:MTU AERO ENGINES GMBH

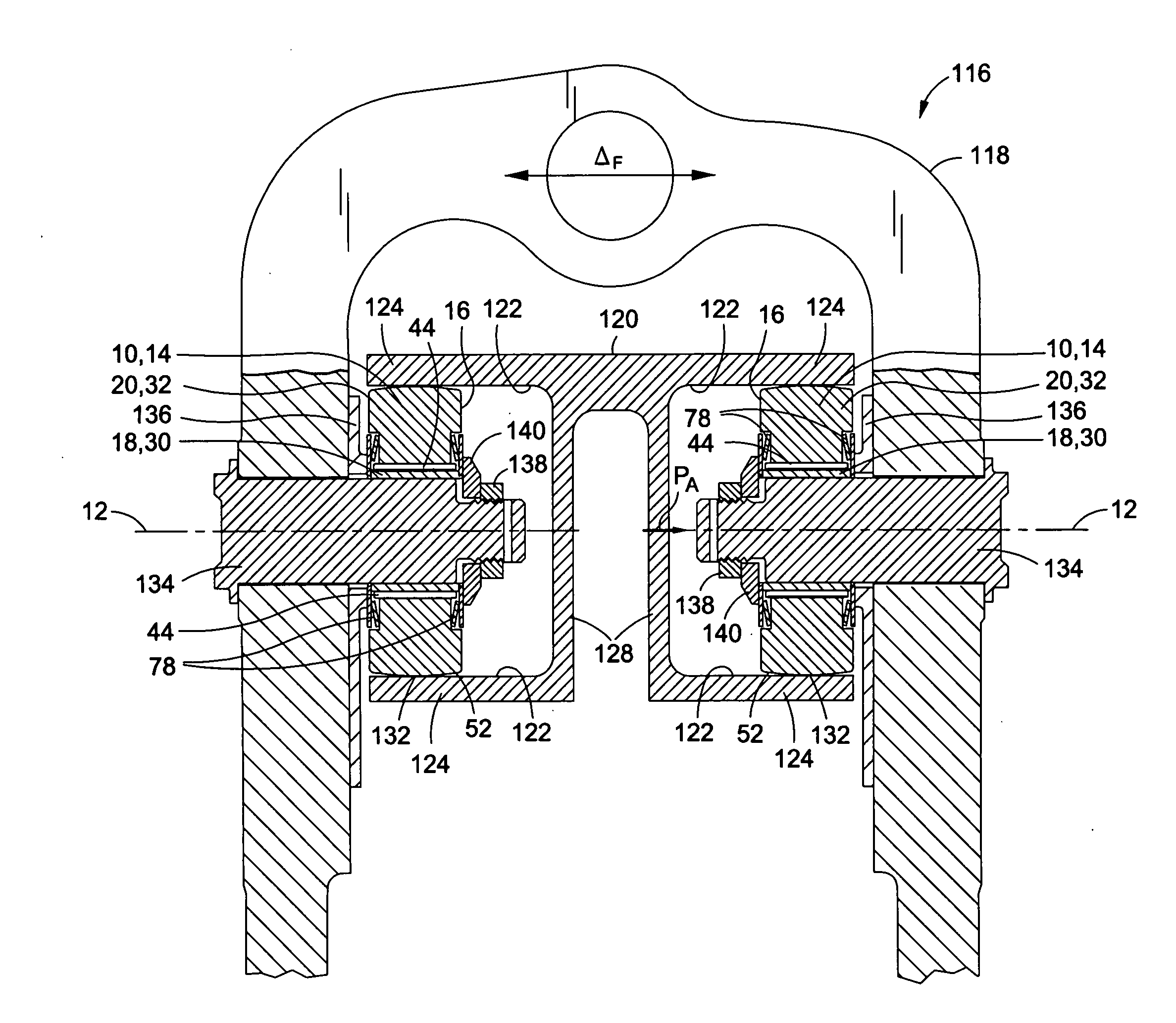

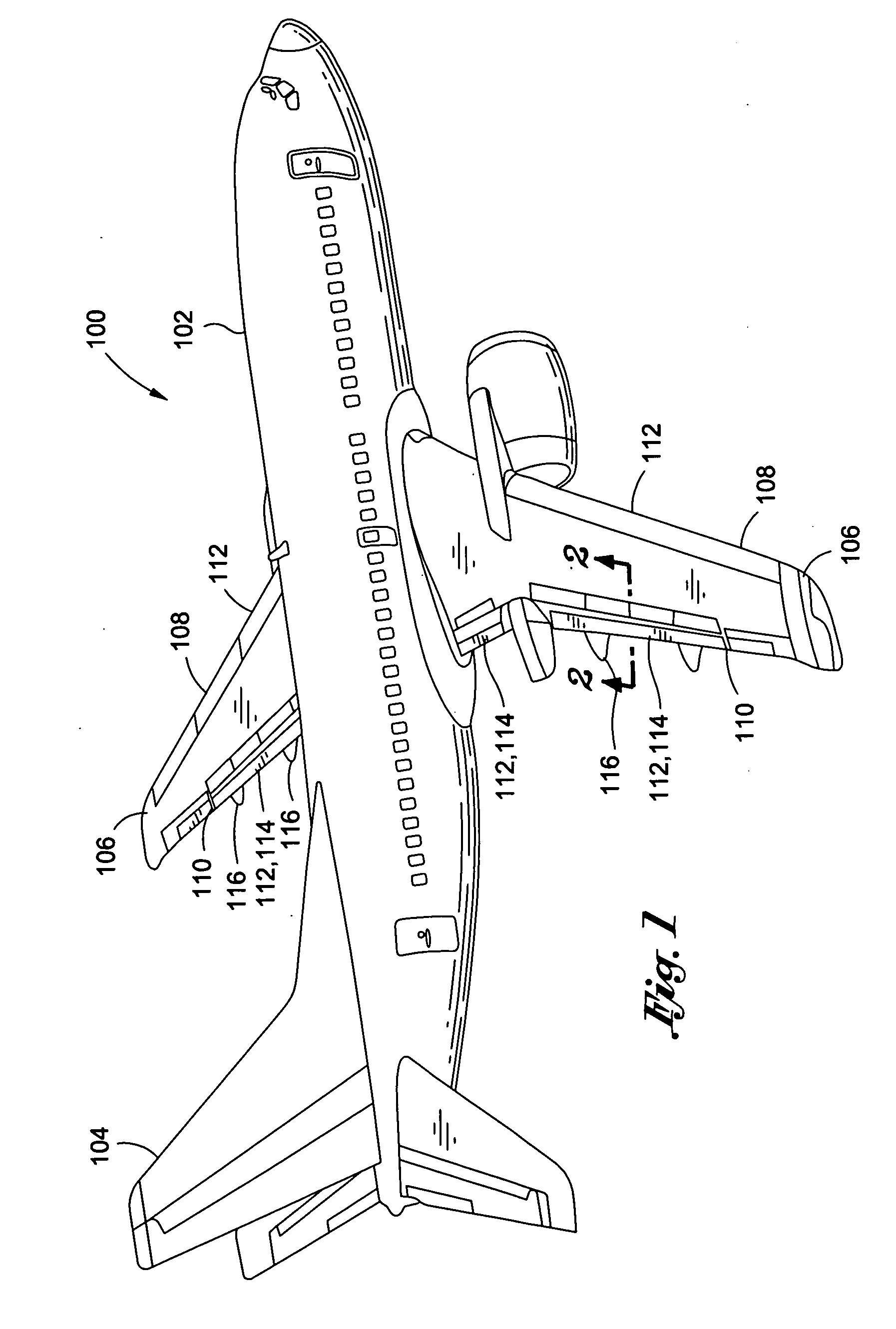

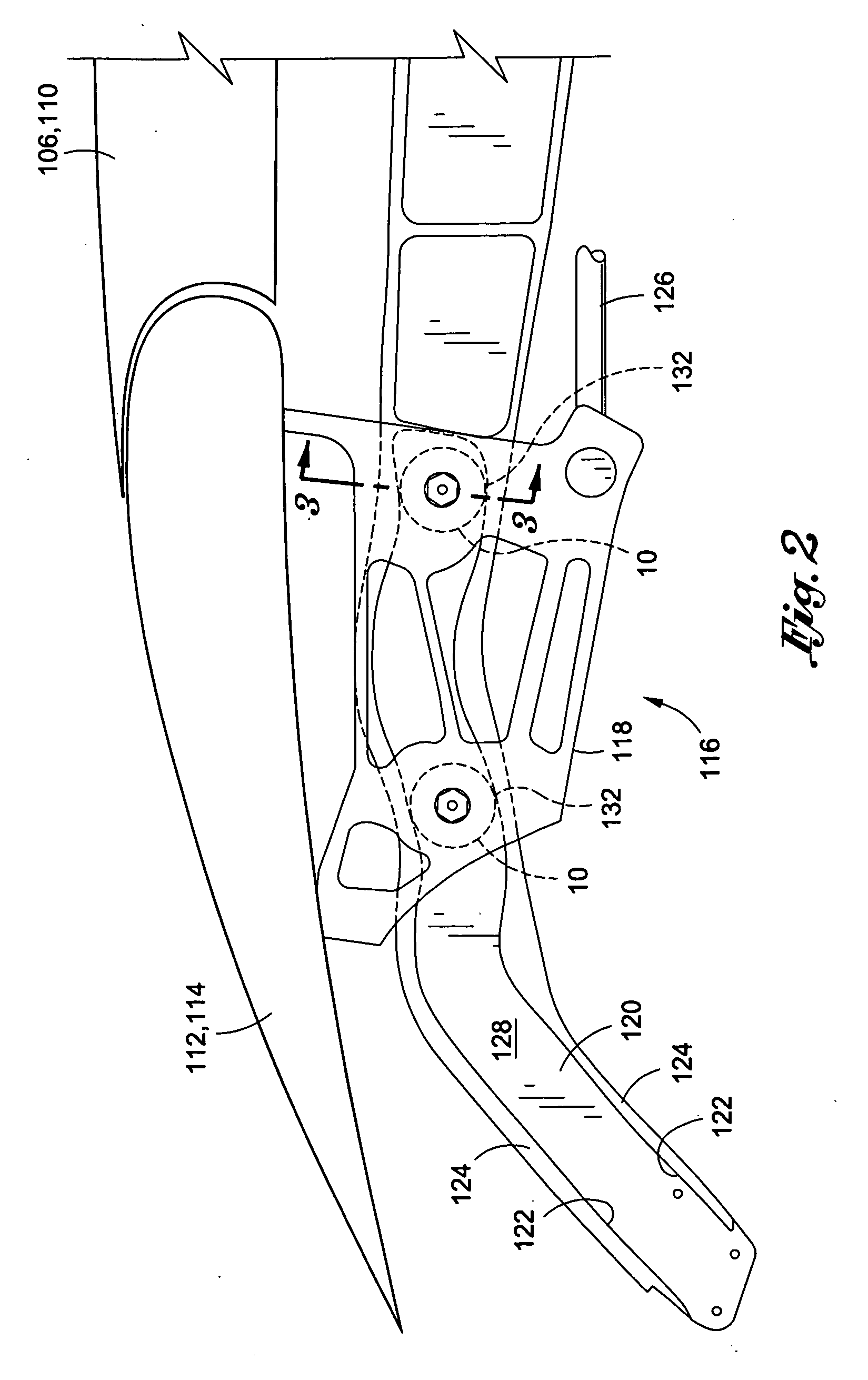

Spring track roller assembly

ActiveUS20100187367A1Increase service lifeReduce maintenance costAircraft controlBearing componentsEngineeringMechanical engineering

A roller assembly comprises a first race and a second race. The second race is coaxial with the first race and is axially movable relative to the first race. The first and second races are movable between a static axial position and a dynamic axial position relative to one another. The roller assembly includes at least one biasing member that is operative to bias the first and second races from the dynamic axial position toward the static axial position.

Owner:THE BOEING CO

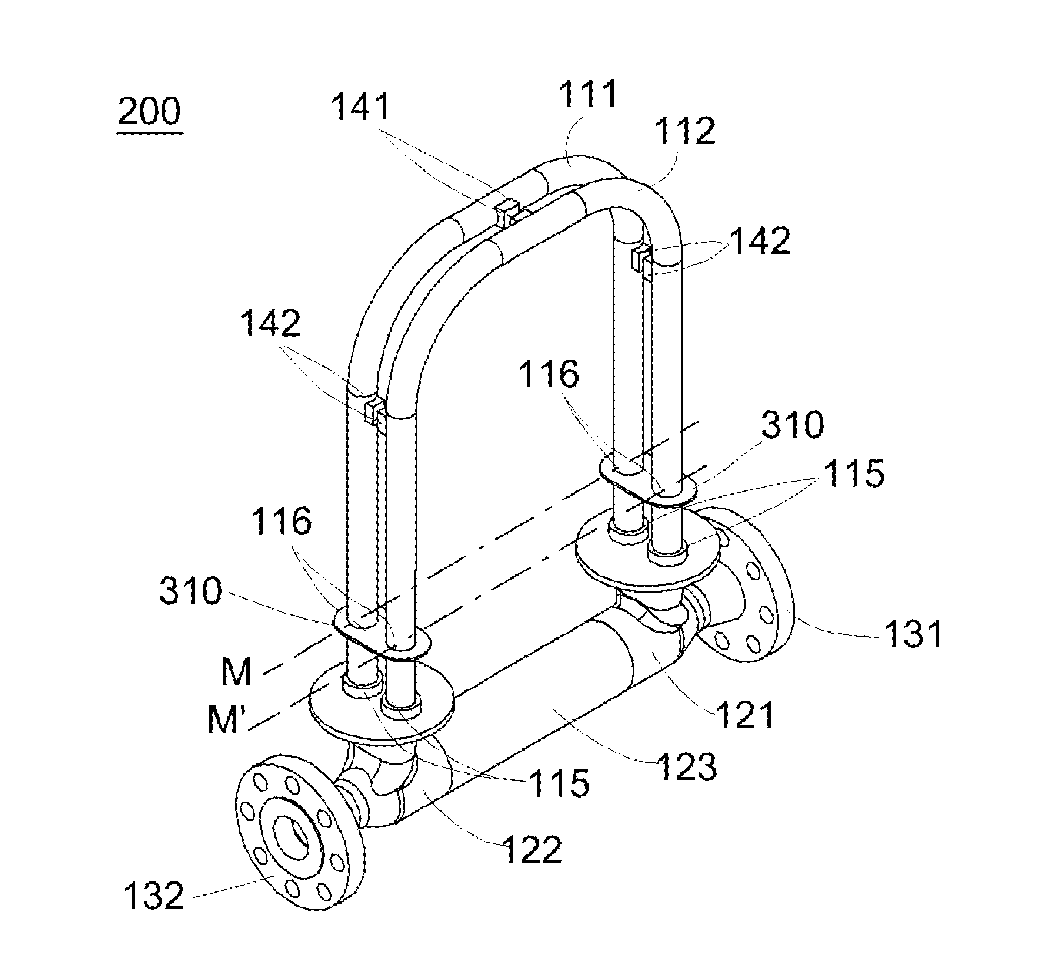

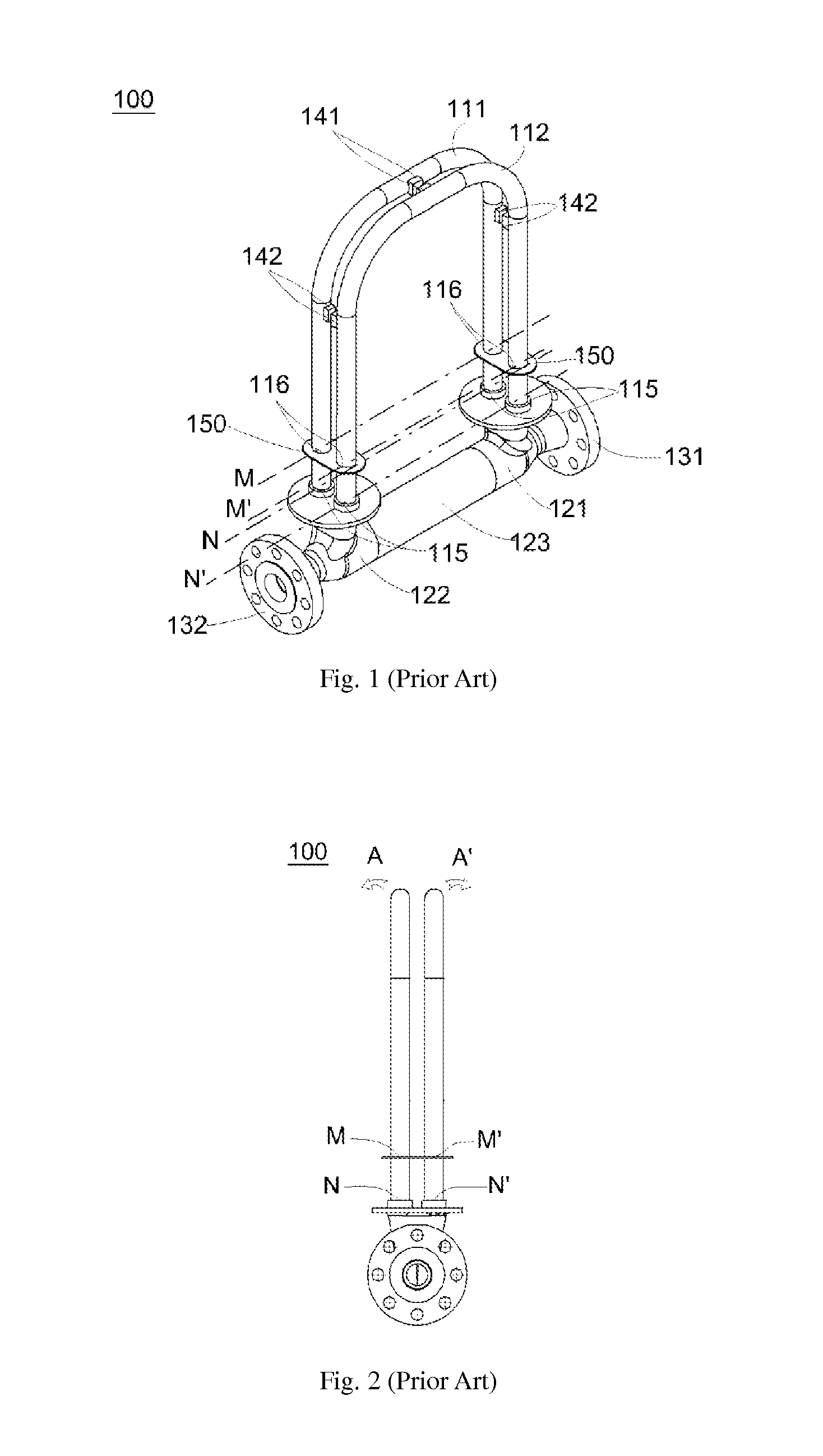

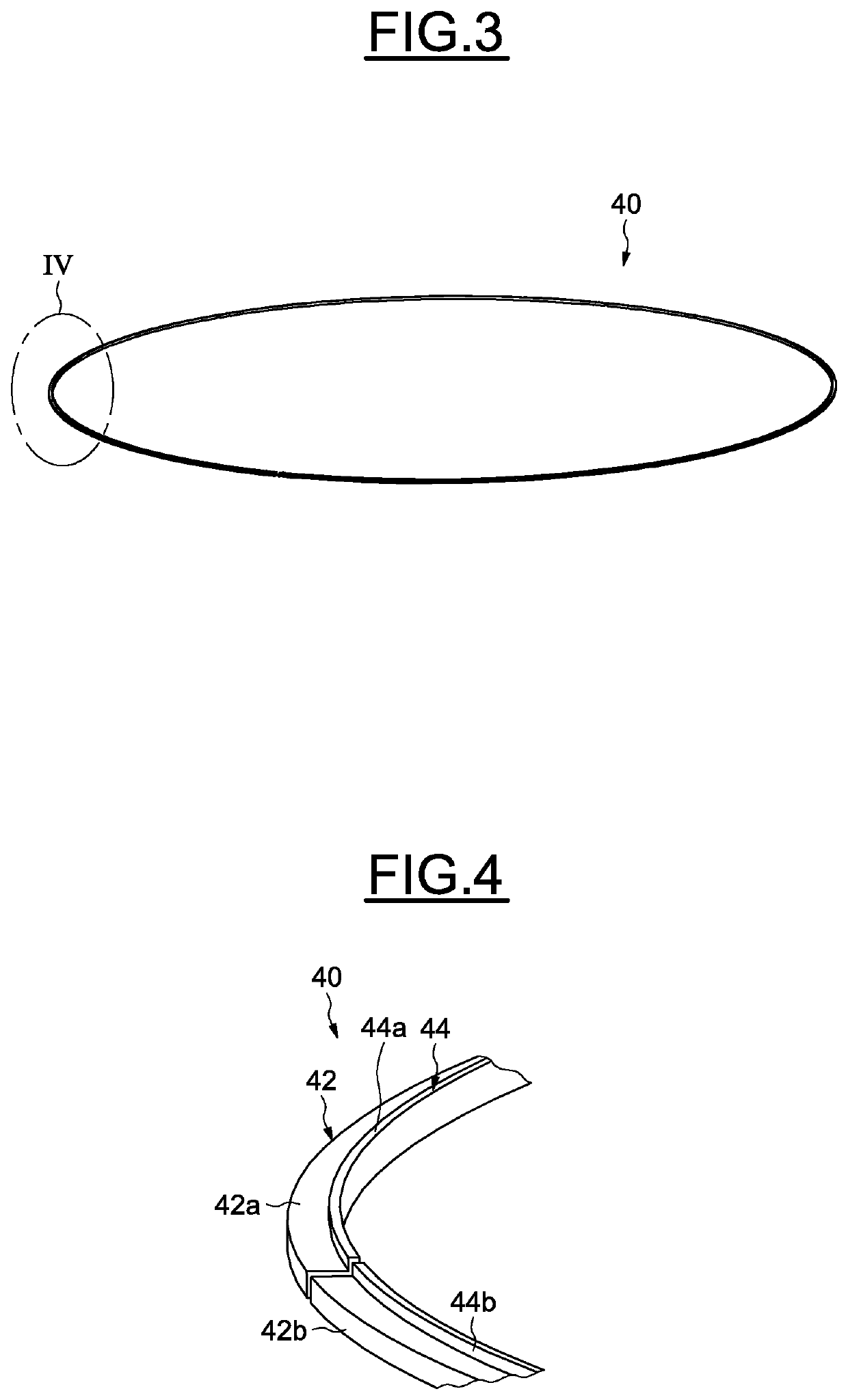

Coriolis Mass Flow Meter, Vibrating Tube Density Meter and Vibrating Sheet Used Therein

ActiveUS20150033874A1Increase service lifeImprove service lifeDirect mass flowmetersSpecific gravity measurementMeasurement precisionAccuracy and precision

The present invention relates to a Coriolis mass flow meter, a vibrating tube density meter and a vibrating sheet used therein, and more particularly, to a vibrating sheet for use in a Coriolis mass flow meter or a vibrating tube density meter, the vibrating sheet having at least one welded connecting portion that is fixedly welded to the flow tube of the Coriolis mass flow meter or the vibrating tube density meter, the flow tube being excited to vibrate around a revolving axis at the welded junction of the vibrating sheet and the flow tube. The welded connecting portions of the vibrating sheet are only formed in the stress insensitive region of the vibrating sheet, wherein the stress insensitive region is the region of the vibrating sheet which has an angle of not more than 45 degrees with respect to the revolving axis. In addition, the present invention also provides a Coriolis mass flow meter and a vibrating tube density meter using the vibrating sheet. The present invention not only simplifies the process, but also improves the measurement precision and service life of the Coriolis mass flow meter and the vibrating tube density meter.

Owner:QINGDAO ALPTEC SAFETY EQUIP

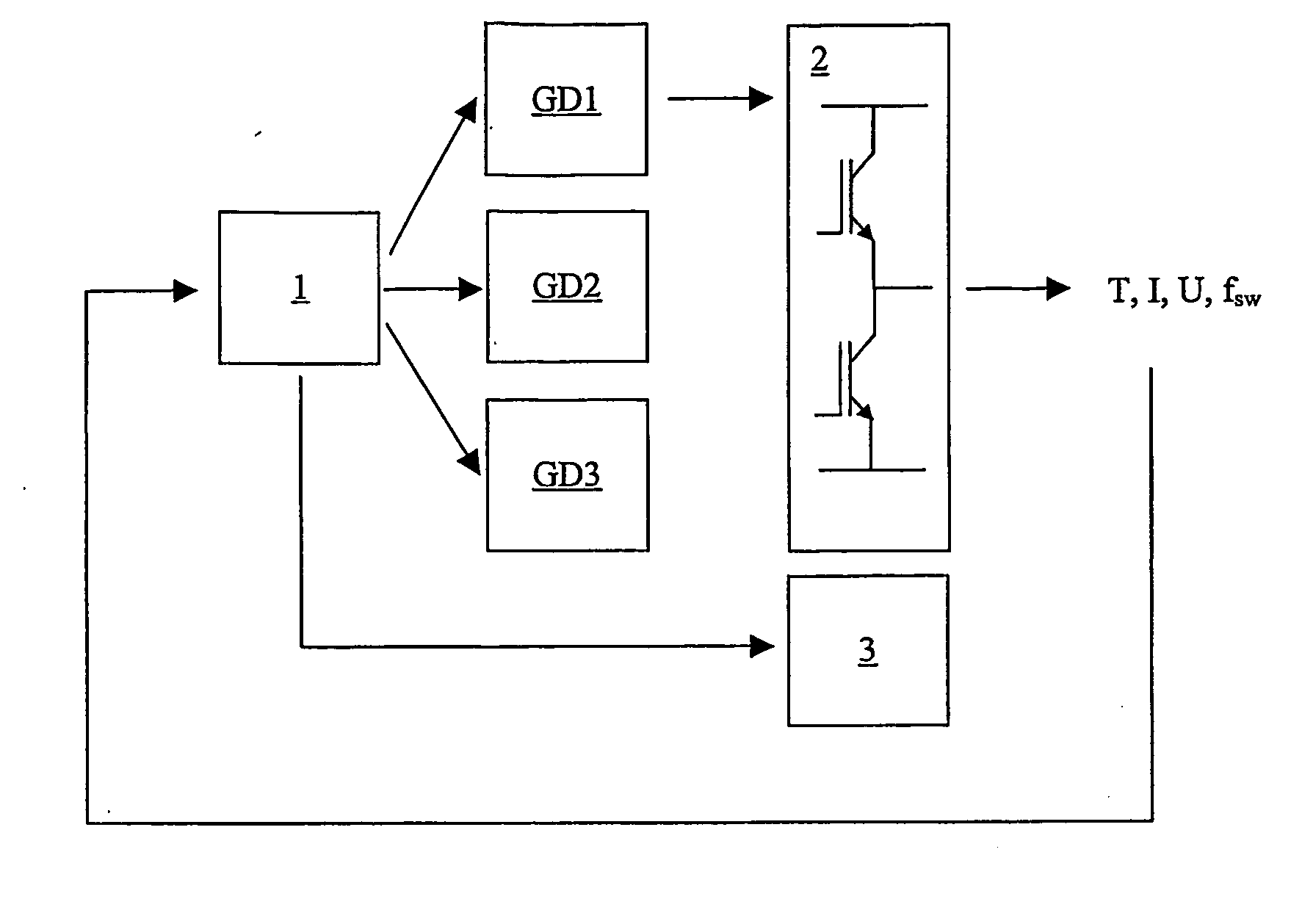

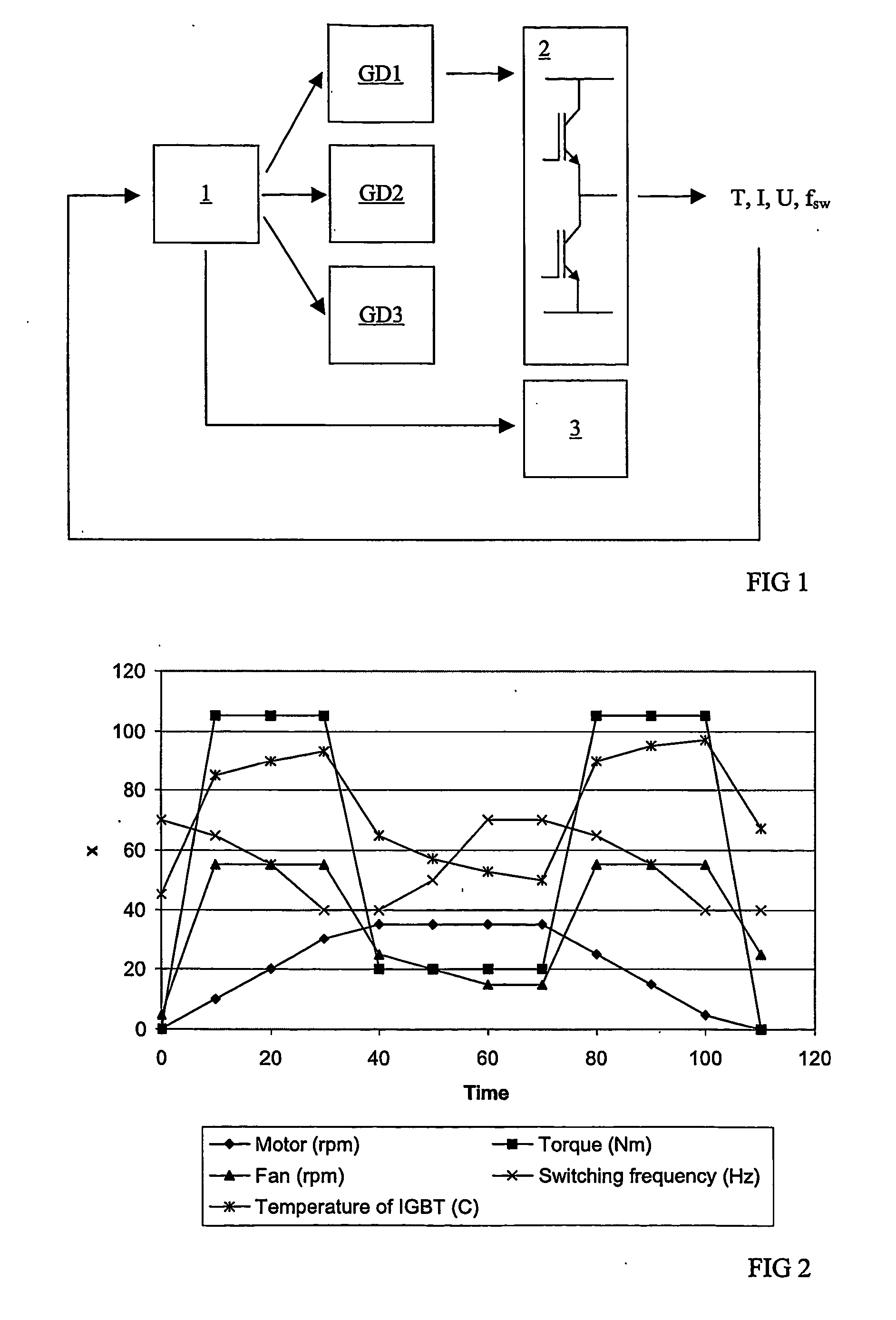

Method and arrangement in inverter

ActiveUS20070097770A1Reduce thermal stressIncrease service lifeSemiconductor/solid-state device detailsThermometers using electric/magnetic elementsVoltageSemiconductor components

A method and arrangement in connection with an inverter that comprises several power semiconductor components and a control apparatus arranged to control them, the control apparatus being arranged to control the power semiconductor components in response to a control quantity to generate an output voltage. The method comprises the steps of determining the change of the temperature or a quantity affecting the temperature of one or more power semiconductor components, and controlling with the control apparatus the power semiconductor components in response to both the control quantity to generate an output voltage and the change rate of the temperature or quantity affecting the temperature of the power semiconductor components to reduce the temperature change and the change rate.

Owner:ABB (SCHWEIZ) AG

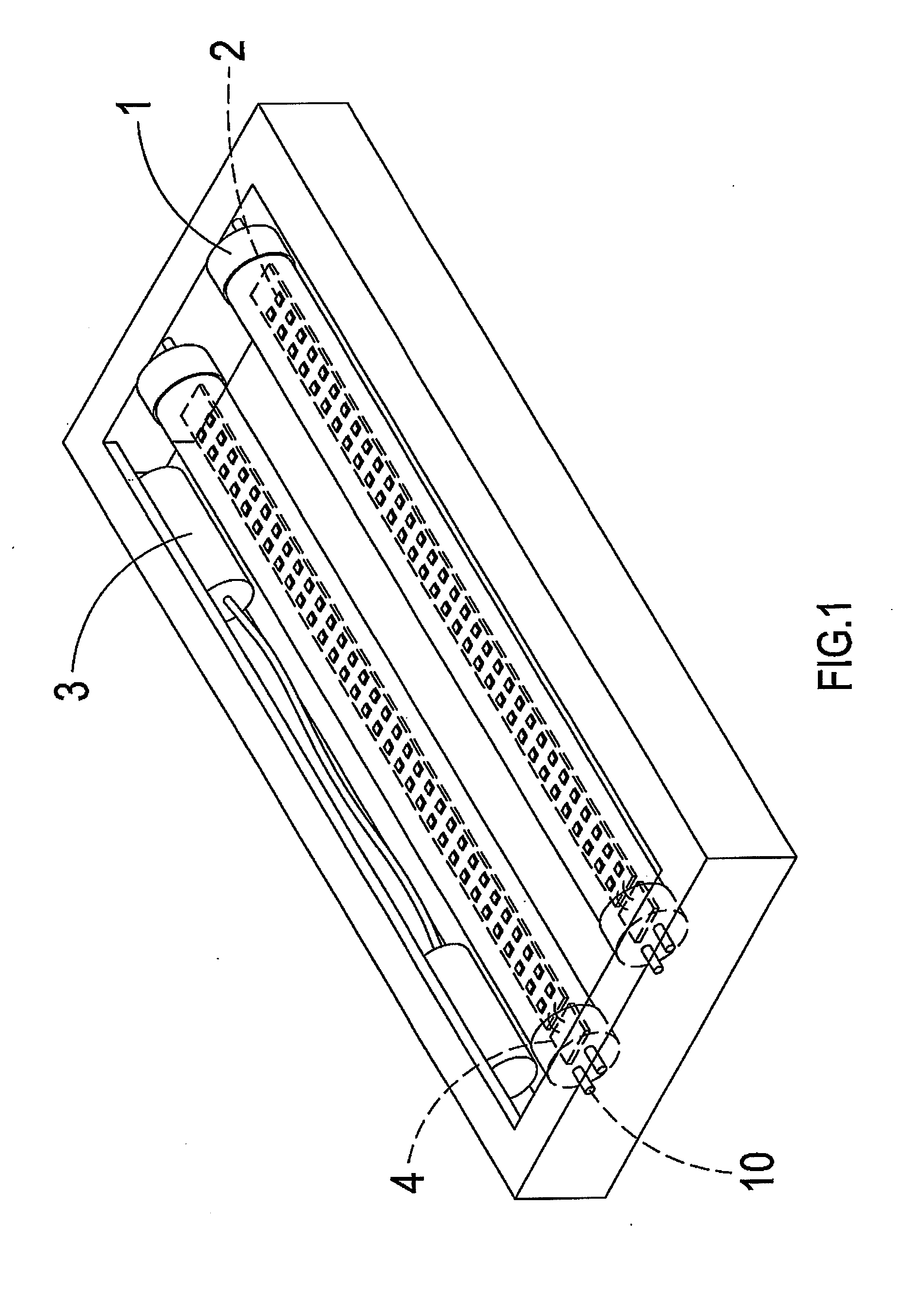

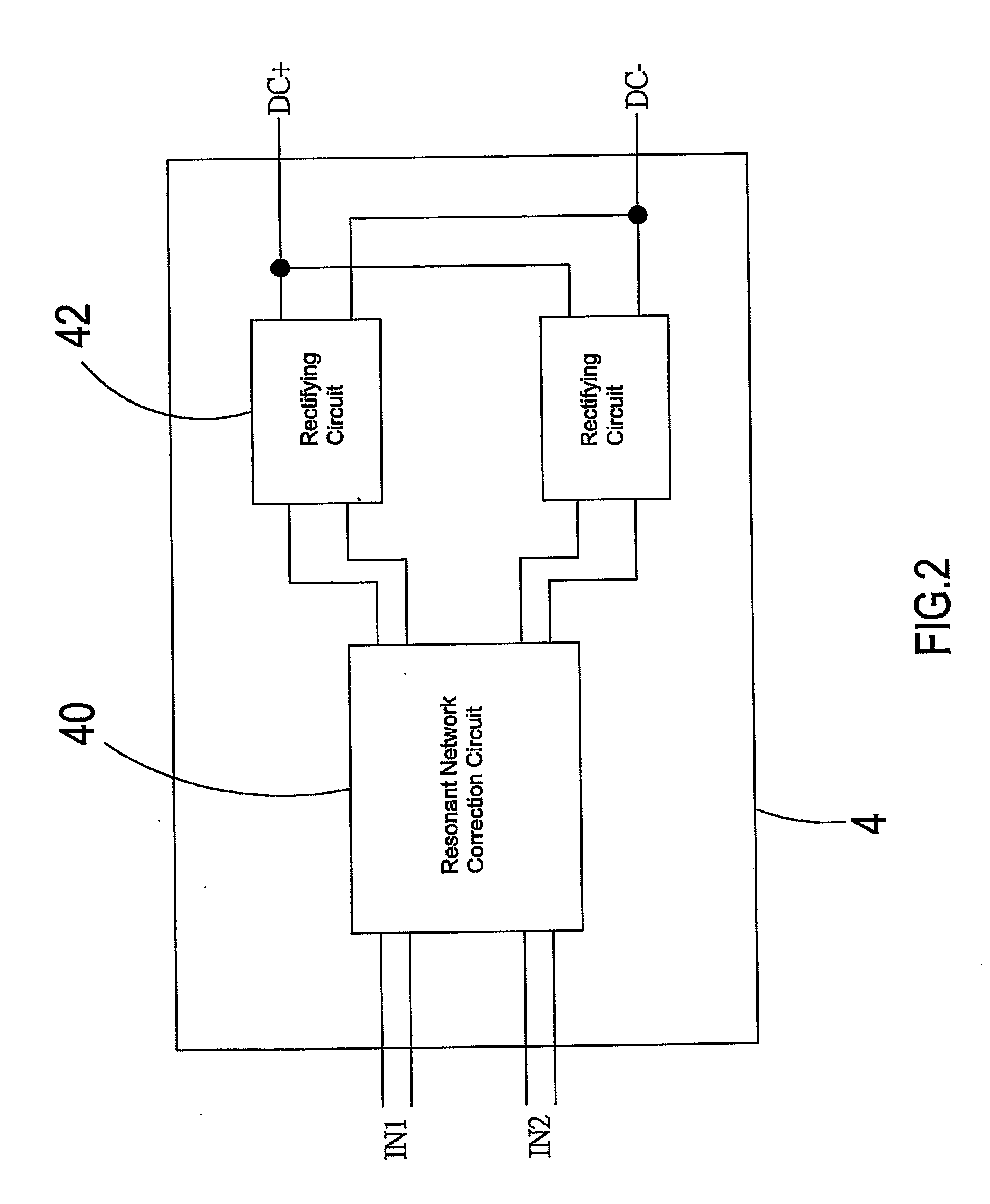

Light emitting diode drive circuit device

InactiveUS20110254465A1High compatibilityIncrease service lifeElectrical apparatusElectroluminescent light sourcesElectricityEngineering

The present invention discloses an LED drive circuit device. The LEDs are installed in a lamp-set and two ends of the lamp-set are provided respectively with two pins to receive a high frequency AC outputted from a ballast, with the two pins being further electrically connected with a drive circuit module. The drive circuit module includes primarily a resonant network correction circuit and a rectifying circuit. The resonant network correction circuit adjusts the high frequency AC received by the two pins to comply with an application range of LED current and then the rectifying circuit converts the AC into a DC which is next outputted through other two pins. By applying the aforementioned circuits, the LED lamp-set can be applied to an ordinary electronic ballast, thereby achieving high compatibility.

Owner:ARTEAST TECH CORP

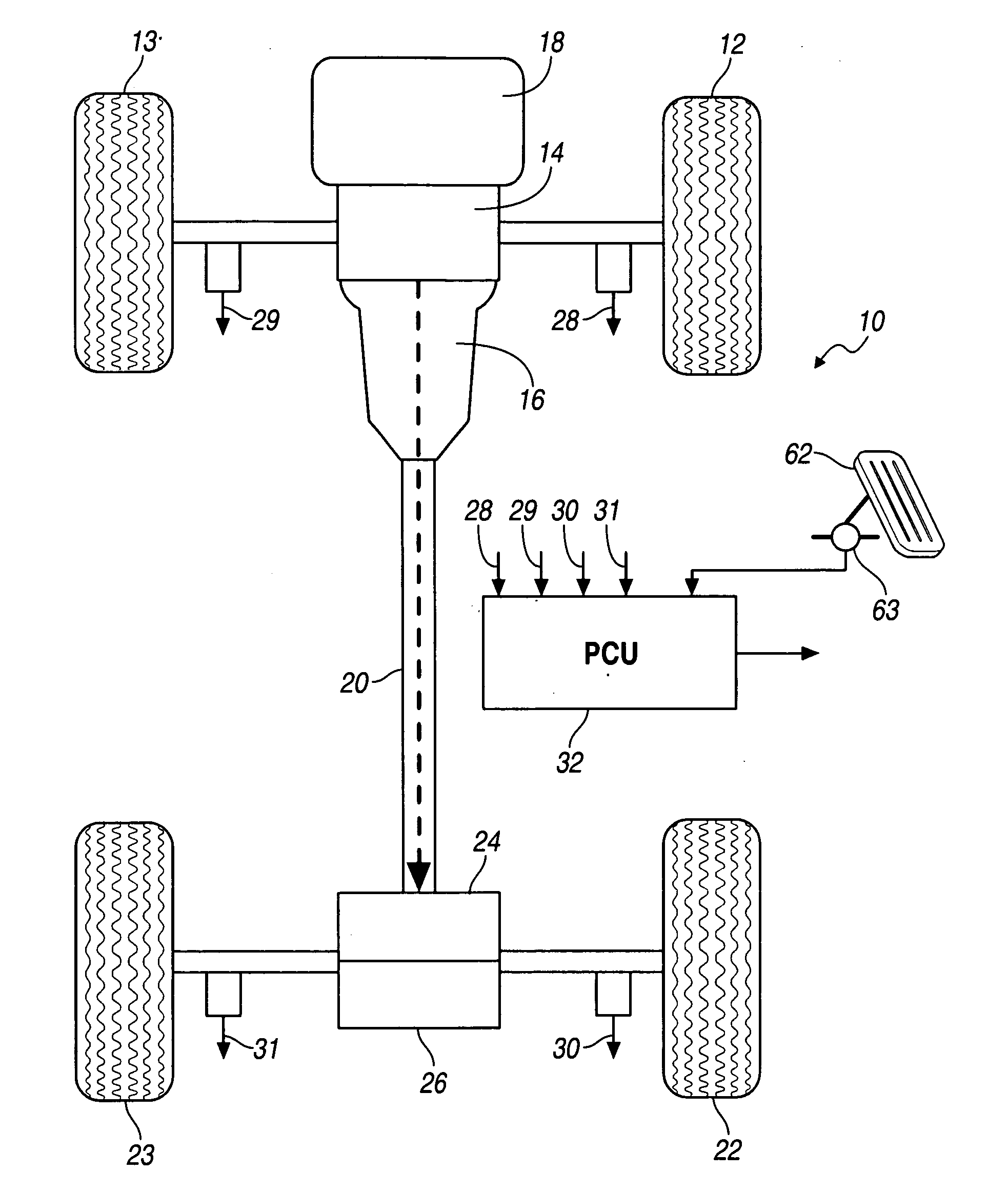

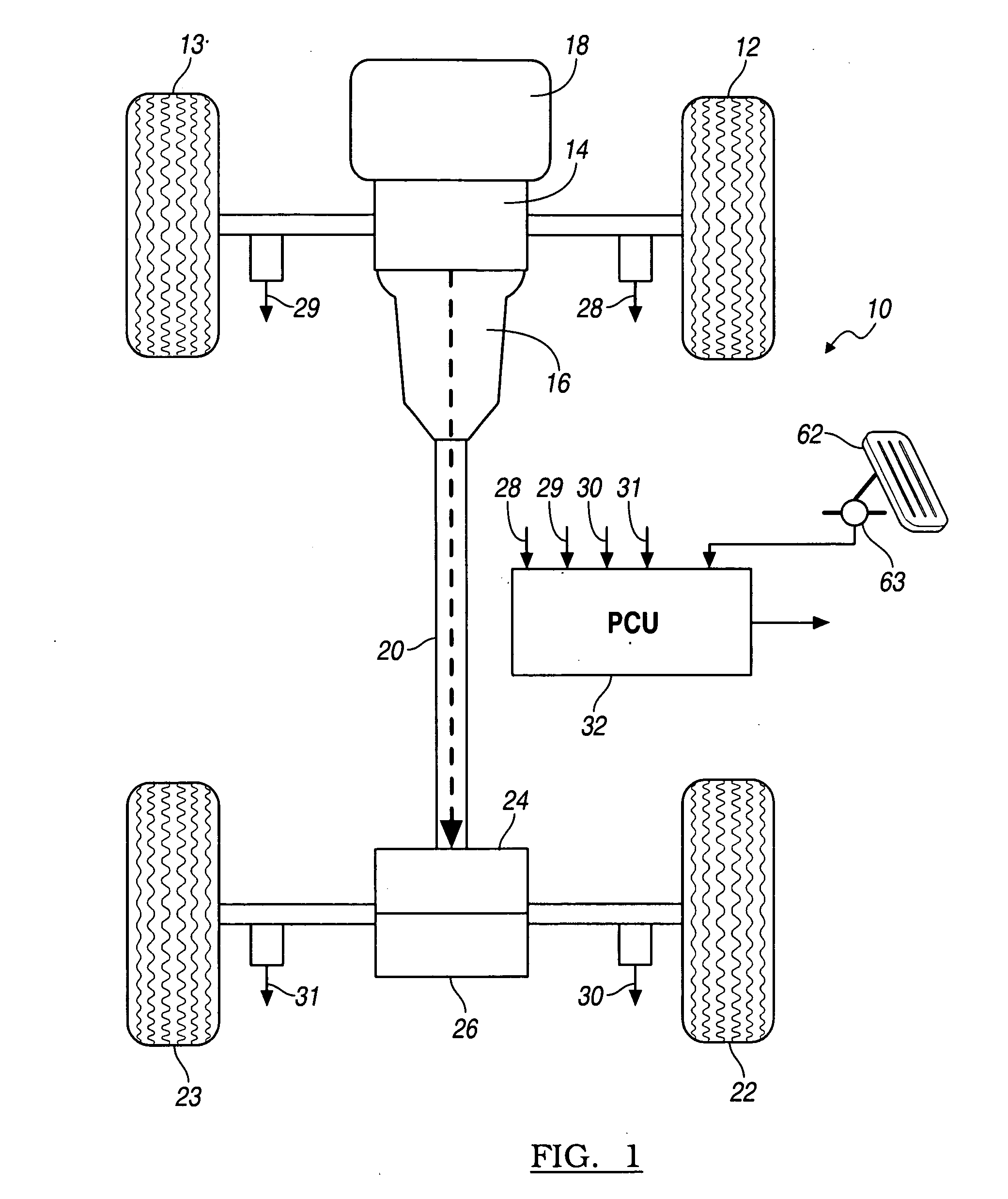

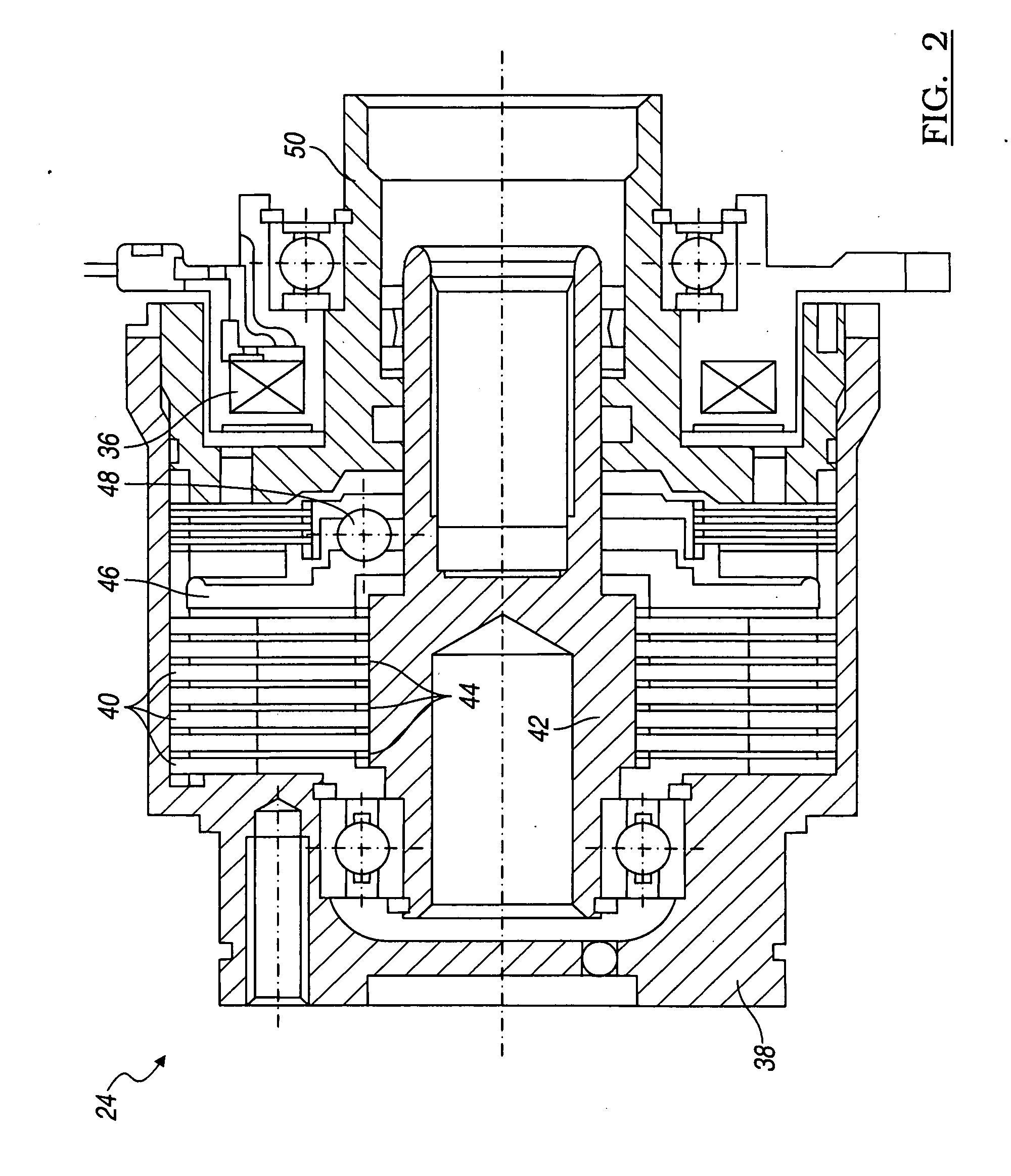

Reducing Oscillations in a Motor Vehicle Driveline

InactiveUS20100268429A1Reduce torqueIncrease service lifeDigital data processing detailsSpecial data processing applicationsEngineeringControl theory

A method for reducing oscillations in a vehicle driveline includes transmitting torque to secondary wheels of the vehicle, determining a first rate of change in speed between the secondary wheels and primary wheels, if a second rate of change in speed between secondary wheels and primary wheels is greater than the first rate of change, reducing torque transmitted to the secondary wheels proportional to a ratio of the first rate of change and the second rate of change, and if the second rate of change is less than the first rate of change, using differential and proportional control to change said torque.

Owner:FORD GLOBAL TECH LLC

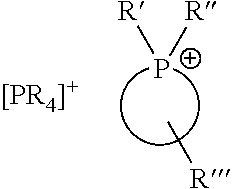

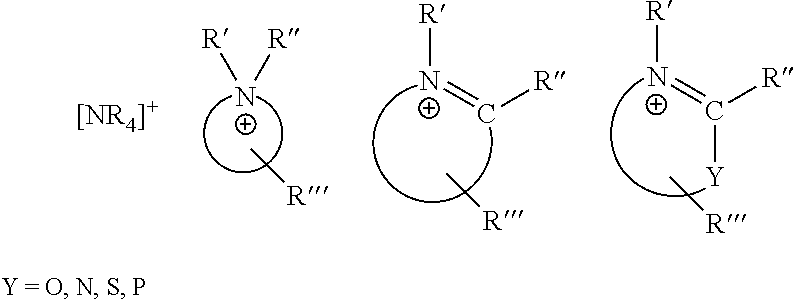

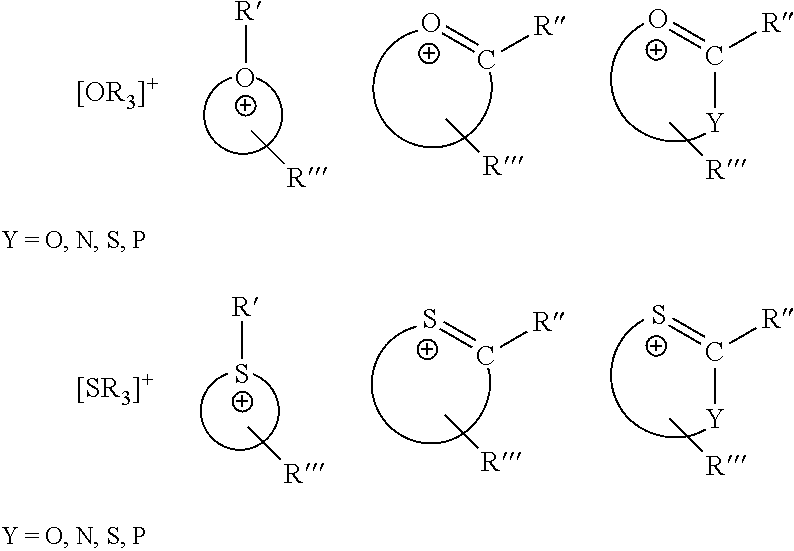

Method for the preservation of a machine element and use of an anionic liquid

InactiveUS20160304804A1Lengthen service lifeIncrease service lifeLubricant compositionEngineeringStart up

A method for the preservation of a machine element, in which, after the production and before the installation and / or start-up of the machine element, a preservative is applied on the surface thereof, wherein an ionic liquid is used as a preservative is provided.

Owner:SCHAEFFLER TECH AG & CO KG +1

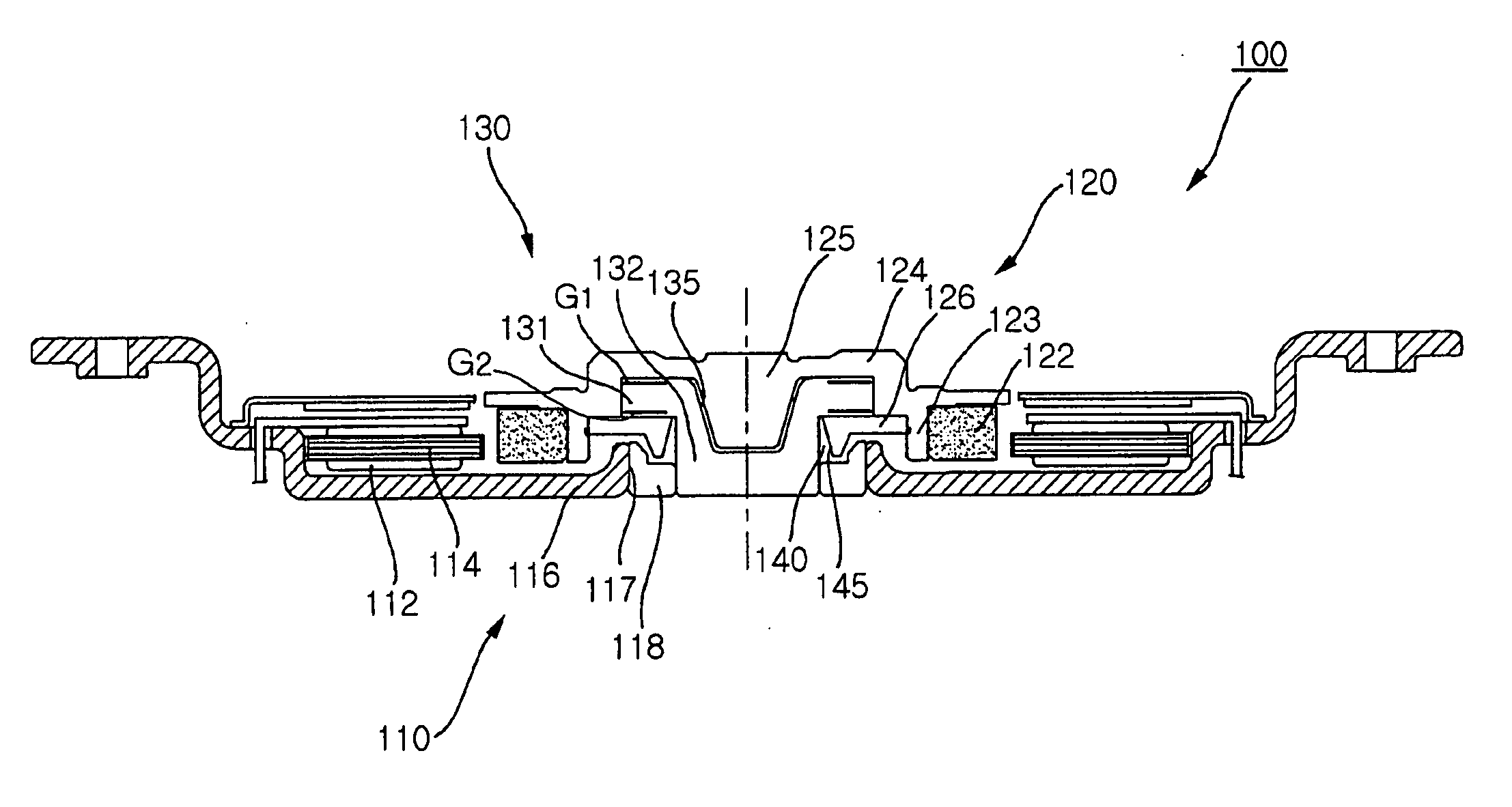

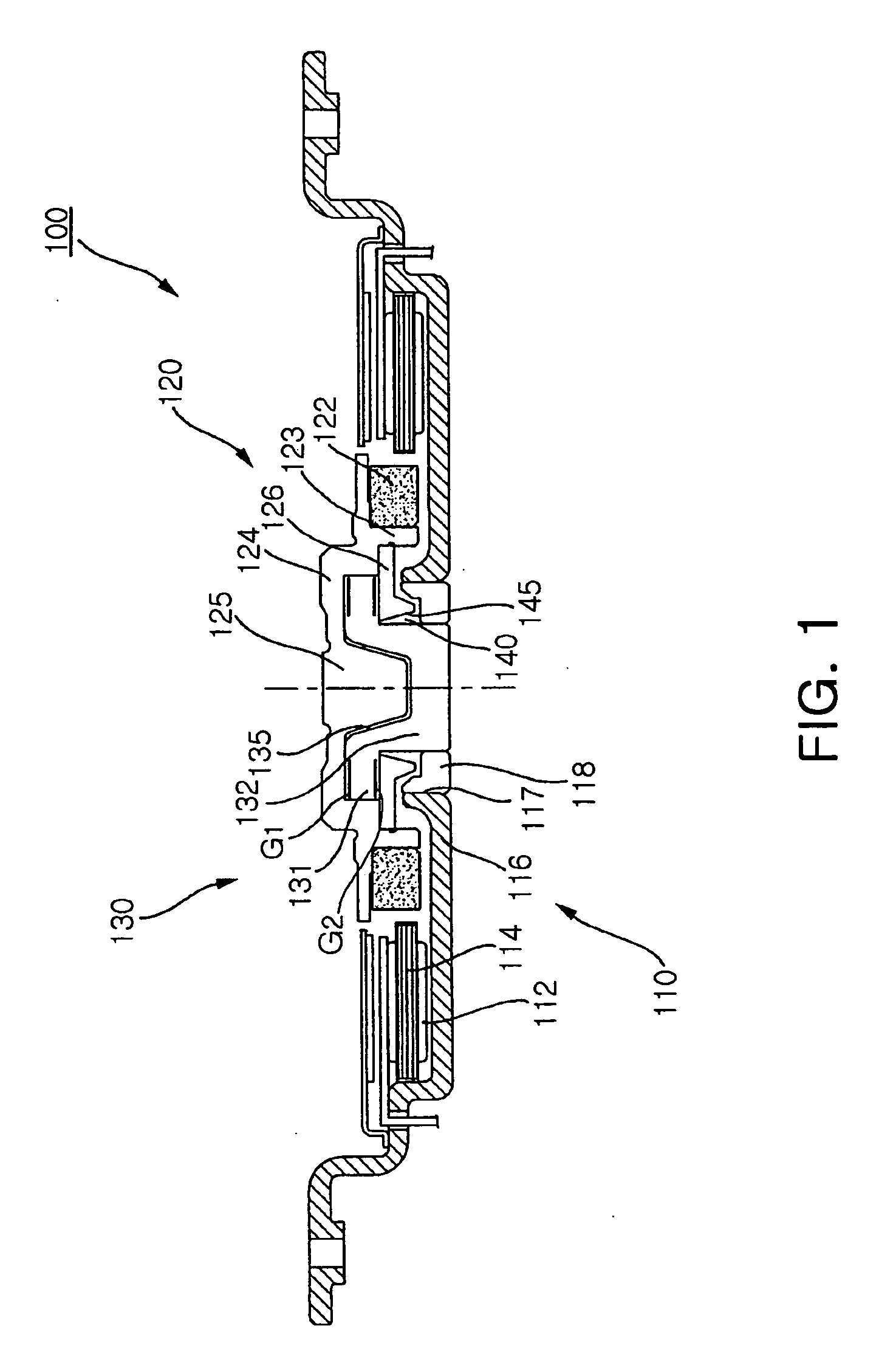

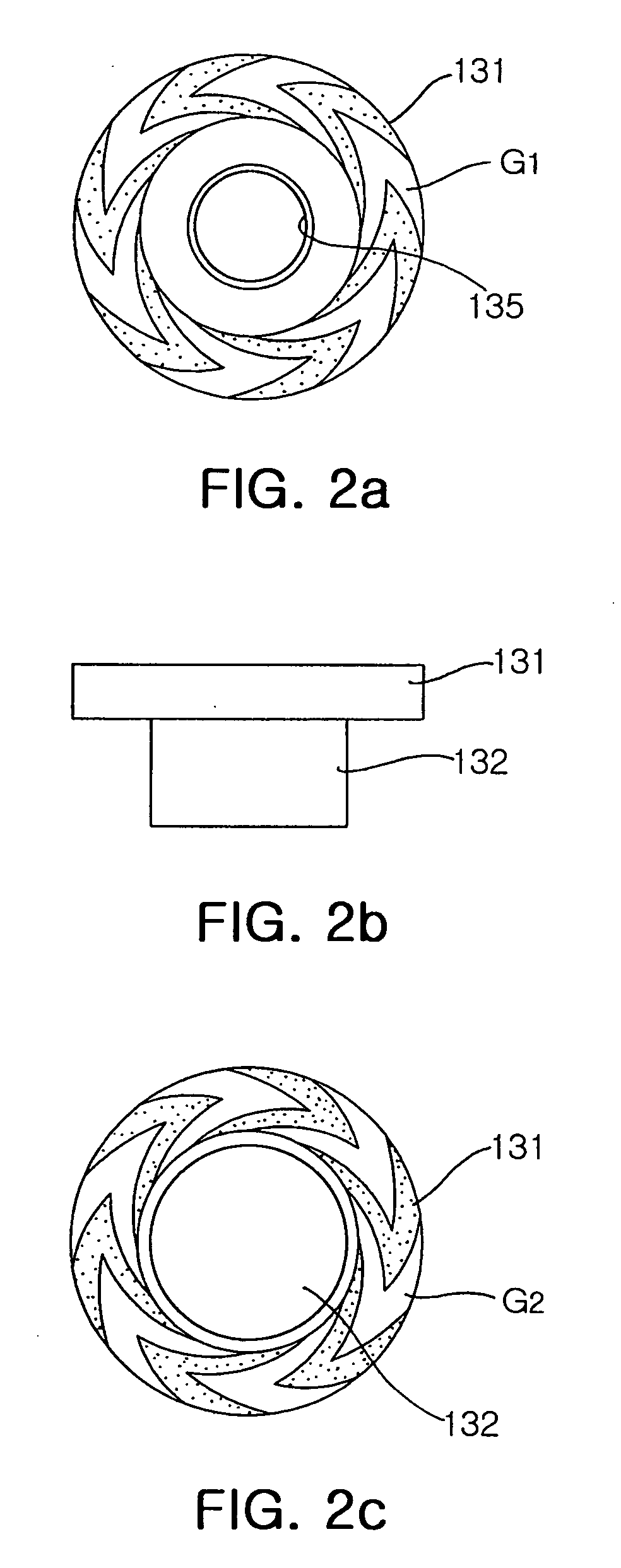

Spindle motor having hydronamic pressure bearing

InactiveUS20060147134A1Increase service lifeExtended service lifeDispensing apparatusShaftsHydrodynamic pressureStator

A spindle motor having a hydrodynamic pressure bearing comprises a stator, a rotor, and a dynamic pressure generating unit including a sleeve having an upper plate disposed opposite to the rotor and at least one thrust dynamic pressure groove formed either at the upper plate of the sleeve or at the rotor. Inside width from a neutral radius to an innermost radius of the thrust dynamic pressure groove is larger than outside width from the neutral radius to an outermost radius of the thrust dynamic pressure groove such that the neutral radius is biased to the outside of the thrust dynamic pressure groove. Dynamic pressure at the inside width of the thrust dynamic pressure groove is higher than dynamic pressure at the outside width of the thrust dynamic pressure groove such that fluid supplied into the thrust dynamic pressure groove is guided to the outer diameter side.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Rotating machine with at least one active magnetic bearing and spaced auxiliary rolling bearings

ActiveUS20160123388A1Increase service lifeGreat numberRolling contact bearingsPump componentsAbutmentMechanical engineering

A rotating machine comprises a shaft, a casing, at least one main magnetic bearing connected to the shaft for rotatably supporting said shaft inside the casing, at least one first and one second auxiliary rolling bearings positioned between the shaft and the casing to support axial and radial loads, and first and second axial abutment means positioned on the shaft to transmit axial loads to inner rings of the rolling bearings. The machine further comprises a spacer axially positioned between facing faces of the inner rings of said rolling bearings for the transmission of the axial loads between said inner rings, and at least a first axial retaining means positioned on the casing and located axially between facing faces of the outer rings for the transmission of the axial loads between at least one of said outer rings and the casing.

Owner:NUOVO PIGNONE TECH SRL

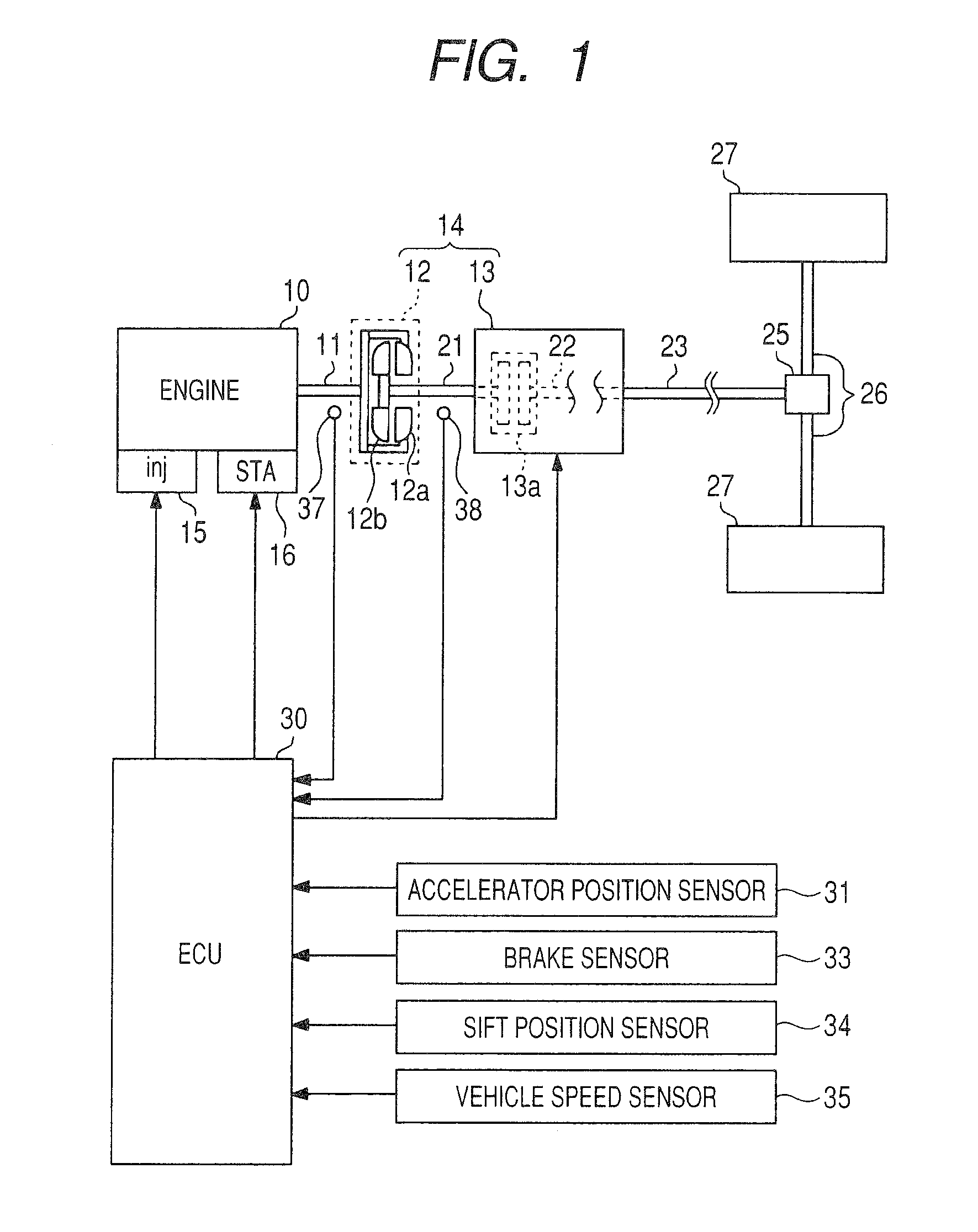

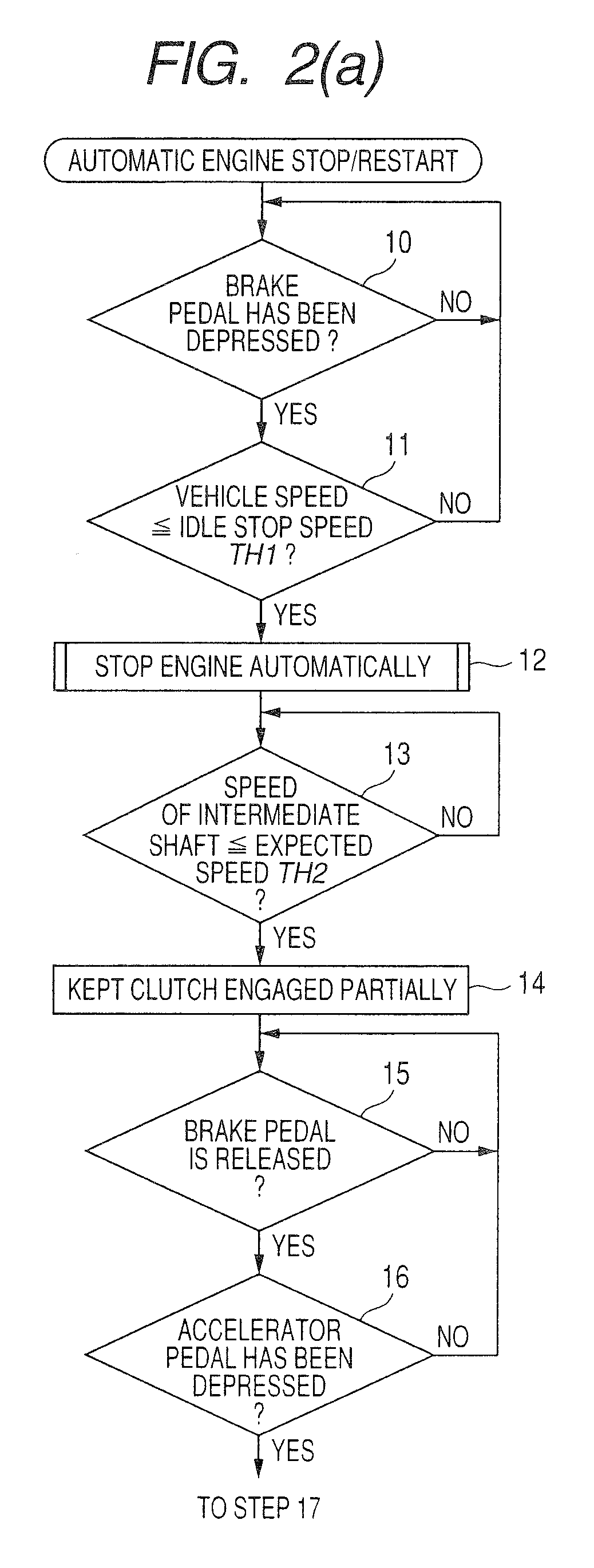

Vehicle control system designed to minimize acceleration shock

ActiveUS20100228453A1Ensure accuracyIncrease service lifeInternal combustion piston enginesDigital data processing detailsVariatorEngineering

A vehicle control system for an engine-powered vehicle equipped with an engine and an automatic transmission with a clutch. When a given engine stop requirement is met during running of the engine, the system stops the engine automatically. When a given engine restart requirement is met after stop of the engine, the system restarts the engine and enters a clutch control mode to bring the clutch in the automatic transmission into a slippable state in which the clutch is permitted to slip based on the speed of the vehicle, thereby absorbing the acceleration shock which usually occurs upon engagement of the clutch to transmit engine torque to wheels of the vehicle when the engine is restarted, and the speed of the vehicle is relatively low.

Owner:DENSO CORP

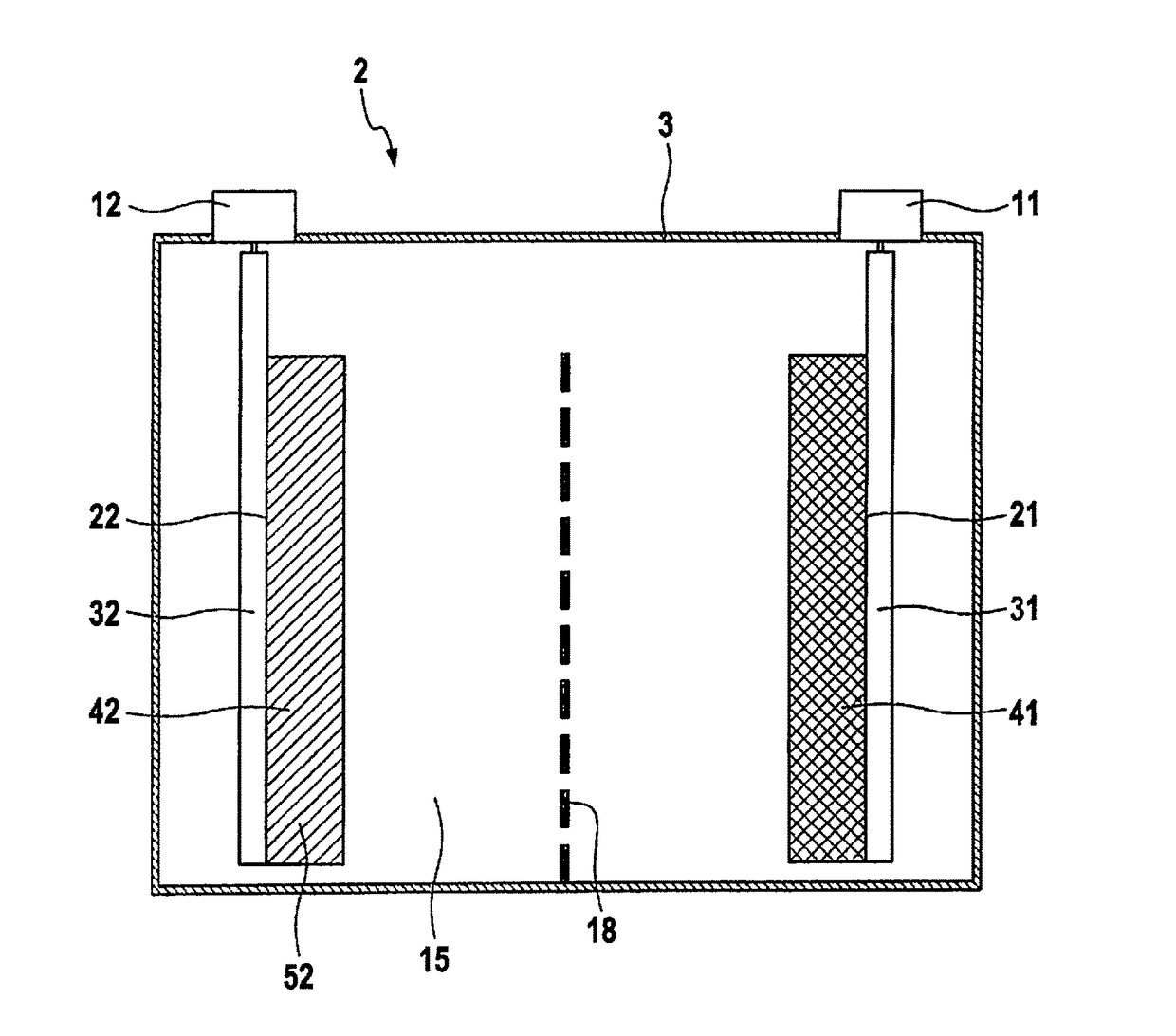

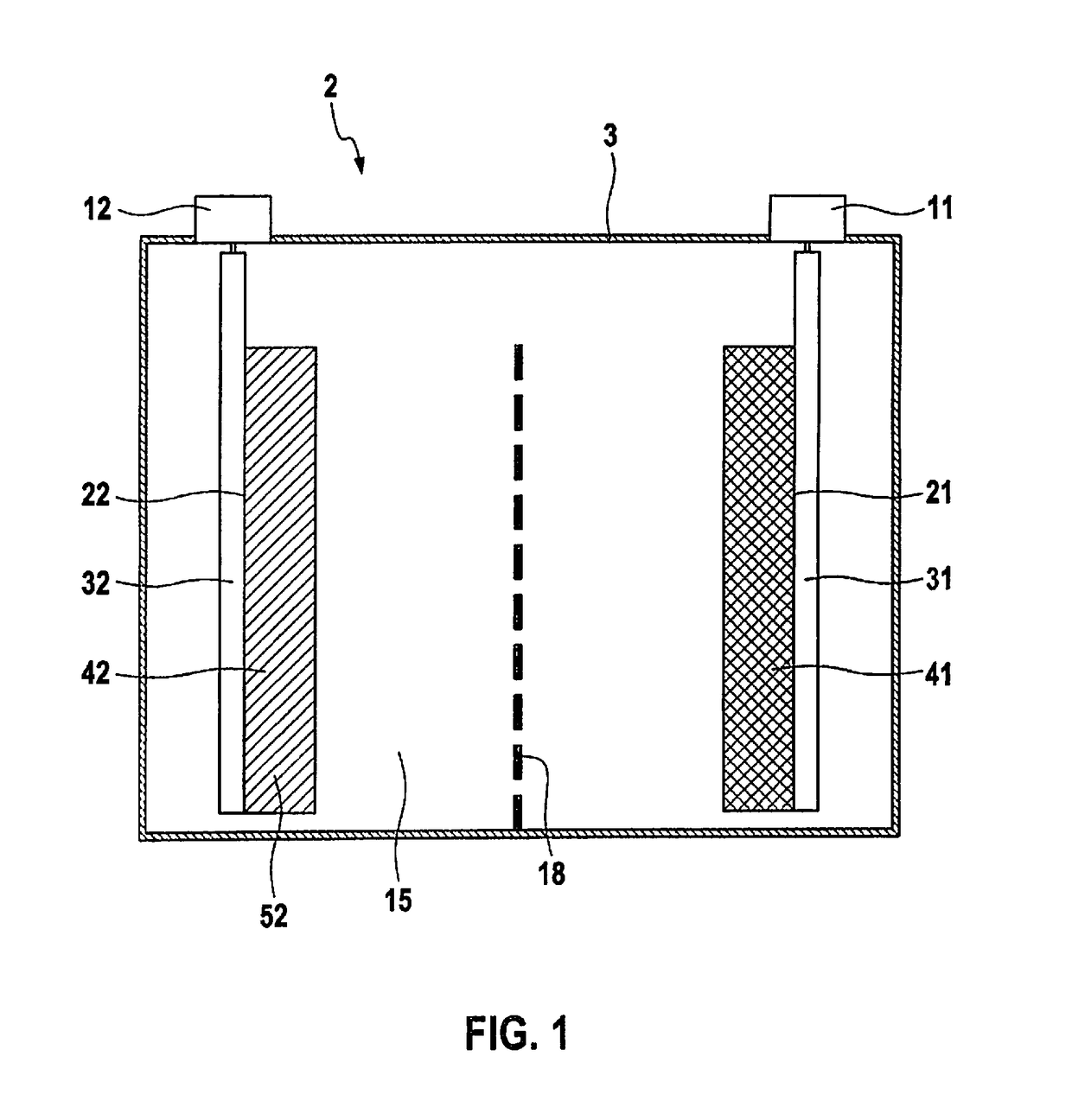

Coated cathode active material for a battery cell

ActiveUS20180261880A1Increase service lifeReduce transition metalSolid electrolytesSecondary cellsEngineeringElectrolyte

A cathode active material for a battery cell is described. A protective layer is at least partially applied to the cathode active material, and the protective layer is made of a lithium ion-conducting solid electrolyte layer.

Owner:ROBERT BOSCH GMBH

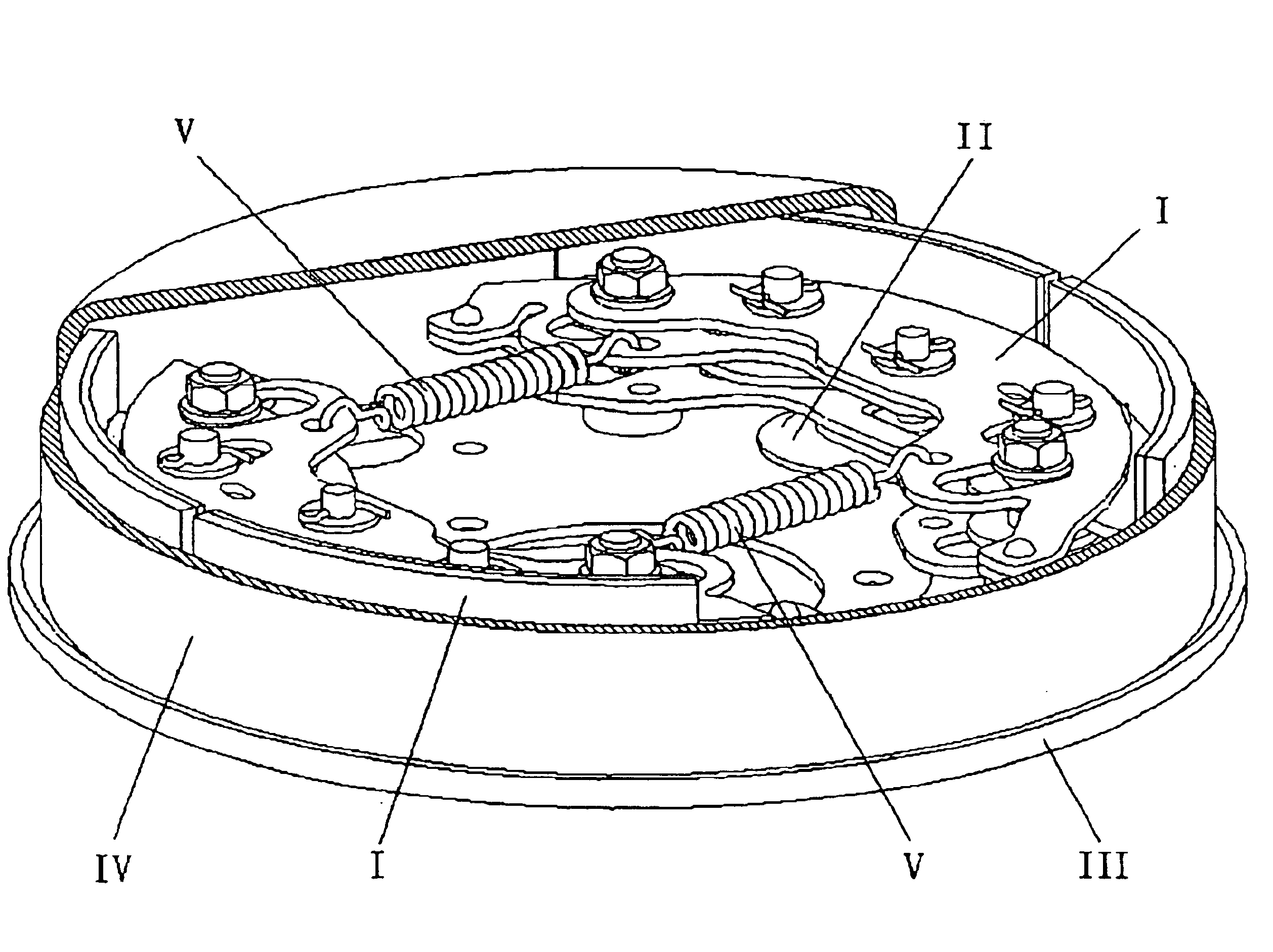

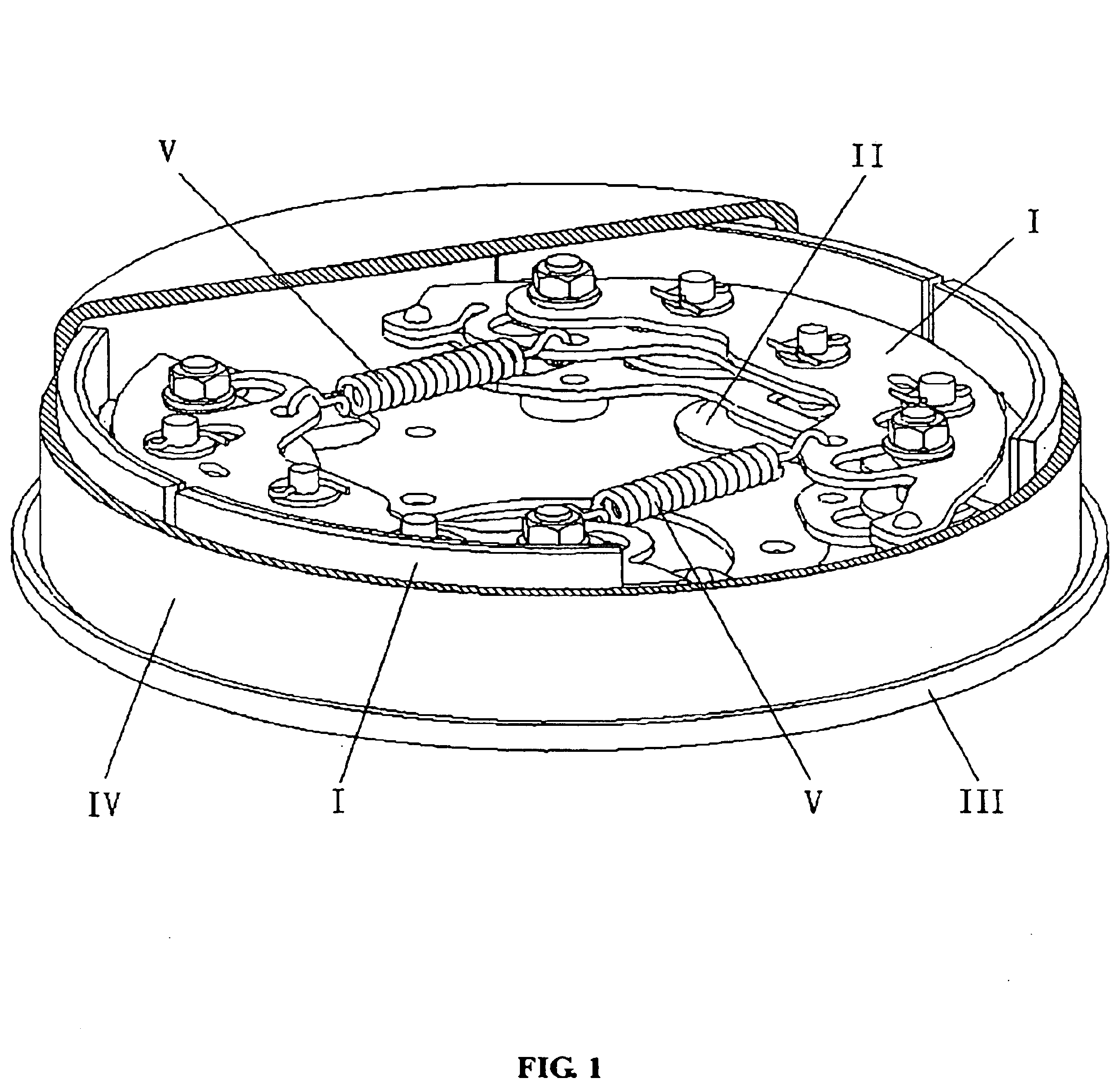

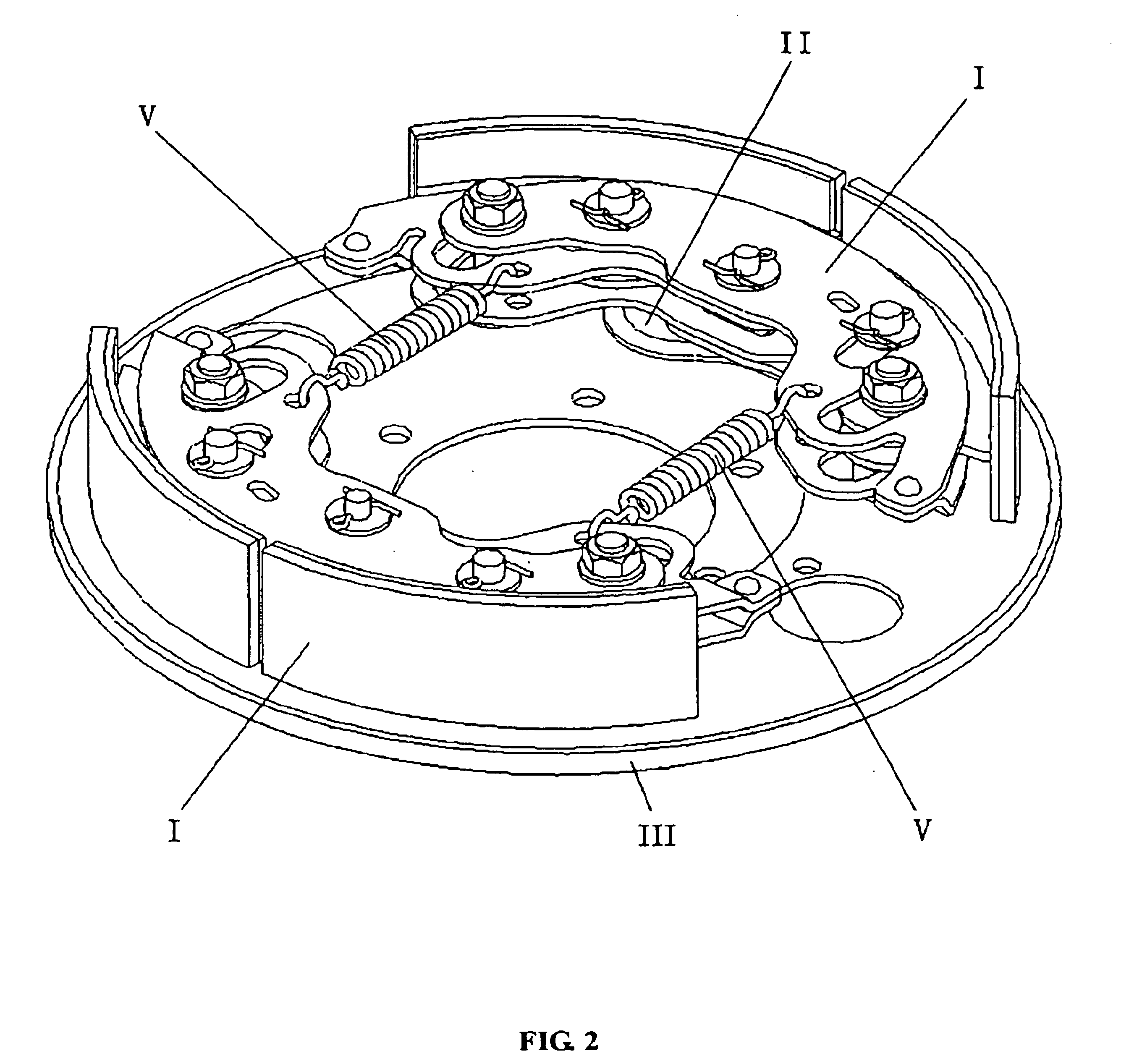

Drum brakes with interconnected multi-degrees-of-freedom shoes

InactiveUS7077249B2Increase service lifeUniform pressure distributionBraking membersDrum brakesDrum brakeMulti degree of freedom

This invention is a new type of drum brake and its variants for motor vehicles, the shoe mechanism assembly of which has at least one set of interconnected shoe mechanism and automatic adjusting mechanism of brake clearance. The interconnected shoe mechanism consists of two interconnected composite shoes of multiple degrees of freedom. Each composite shoe consists of a shoe and a driving lever. The shoe is jointed to the driving lever with a cylindrical pin or a elliptical pin matching with a cylindrical hole or a spherical joint, and the driving lever is pivoted on the backplate of brake with a cylindrical pin or a elliptical pin matching with a cylindrical hole or a spherical joint. The automatic clearance adjusting mechanism is fixed on the backplate and interconnected with the driving lever.

Owner:TSINGHUA UNIV +1

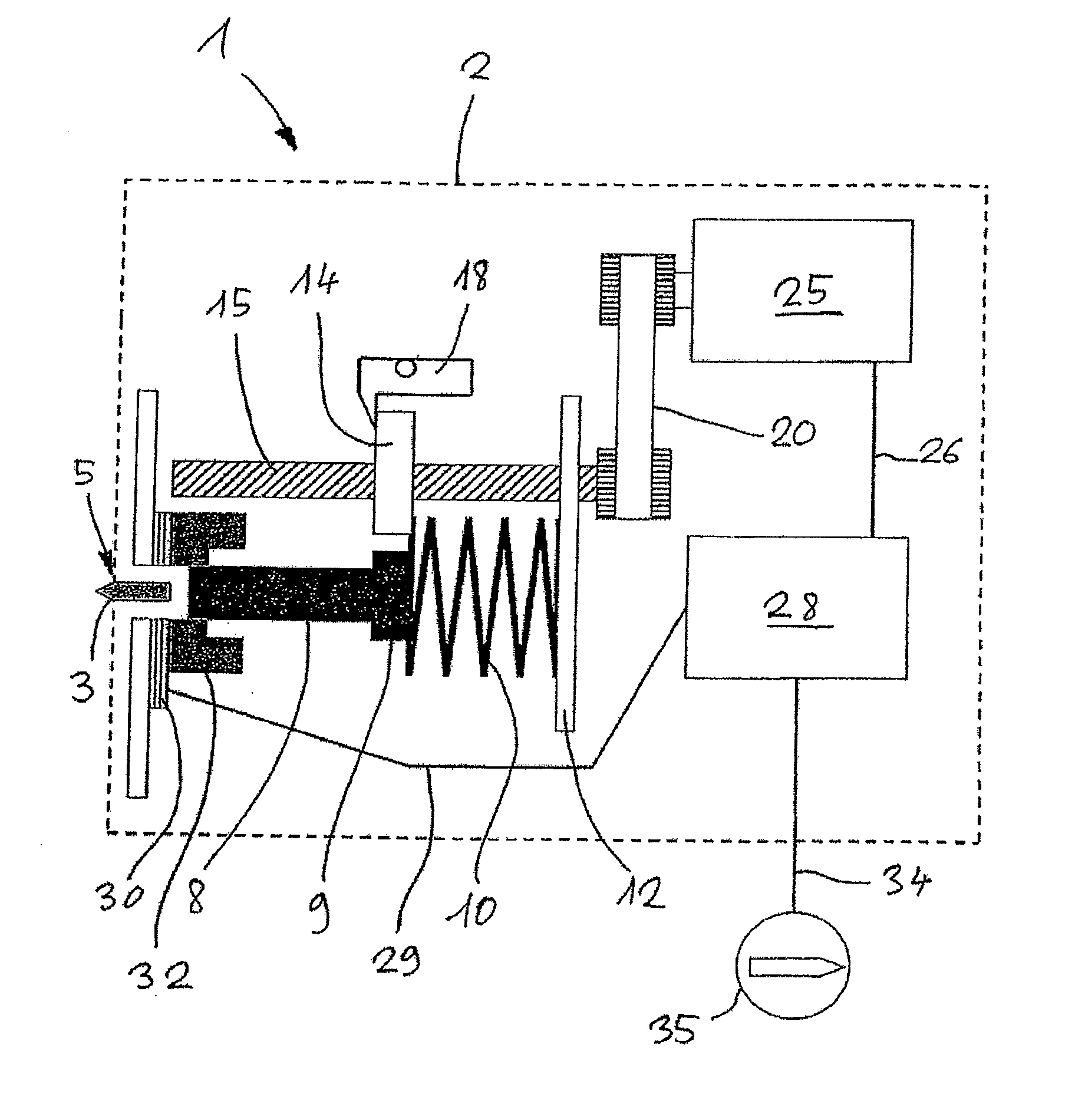

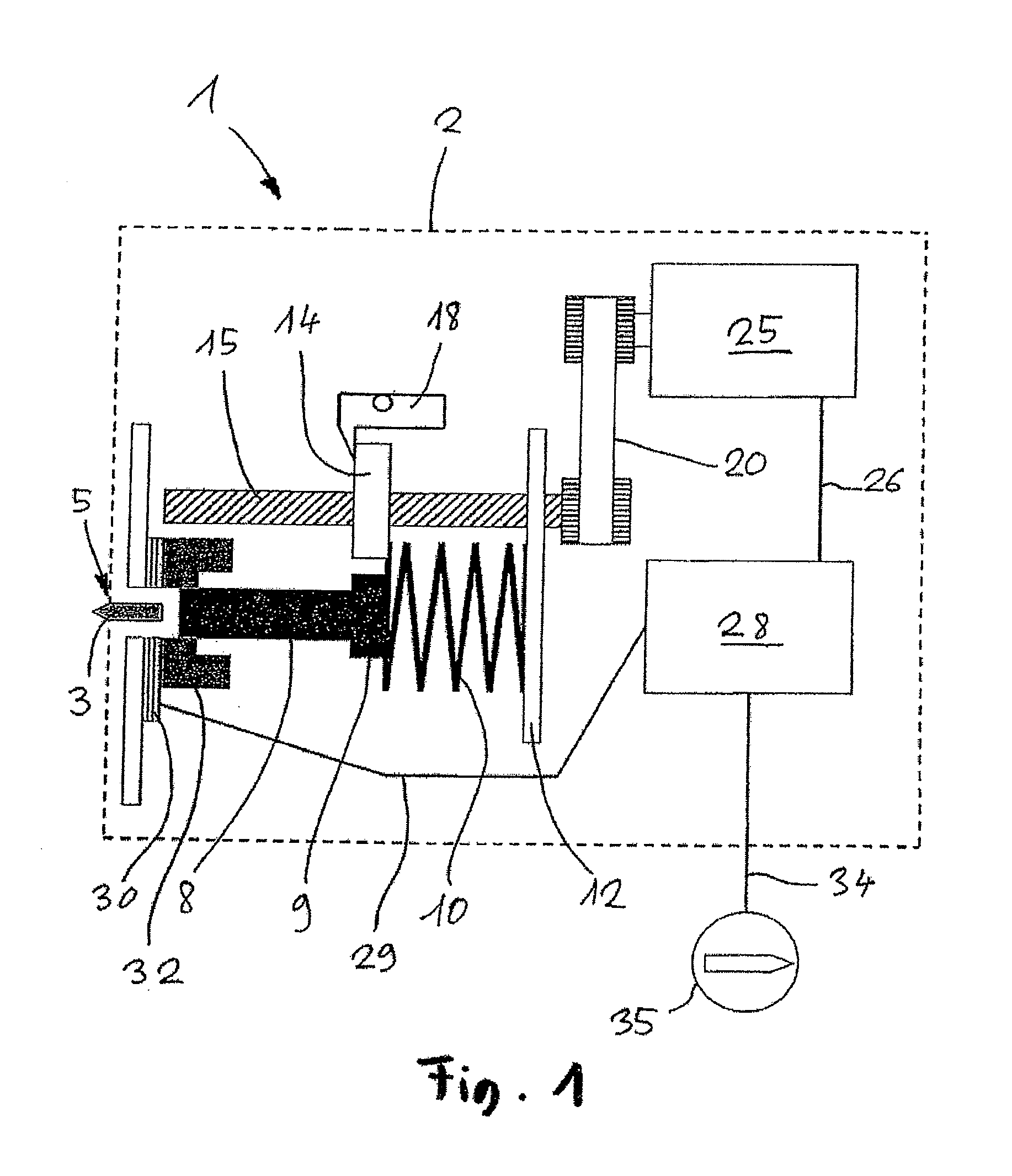

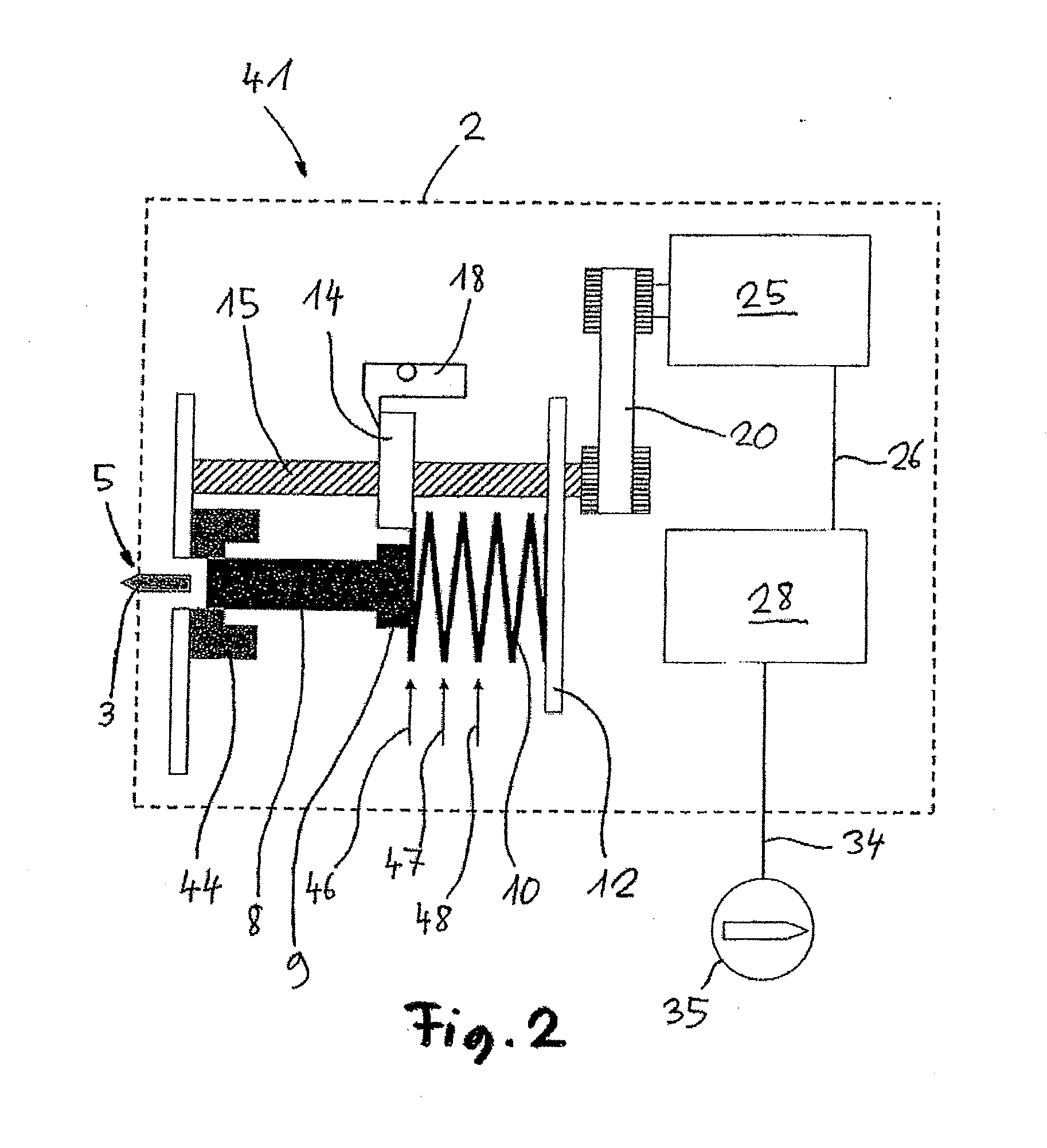

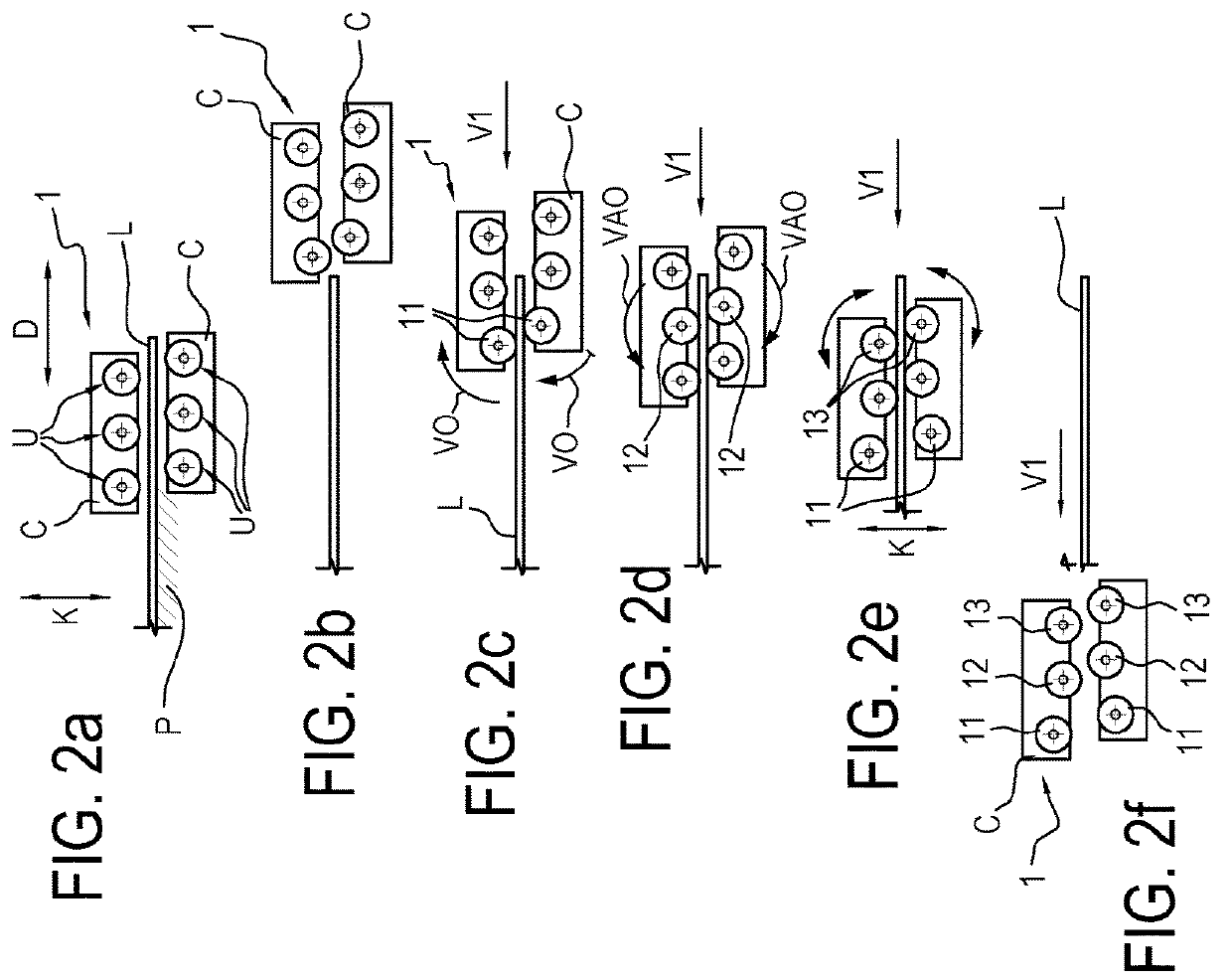

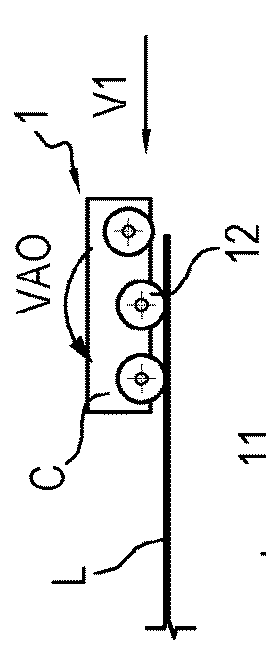

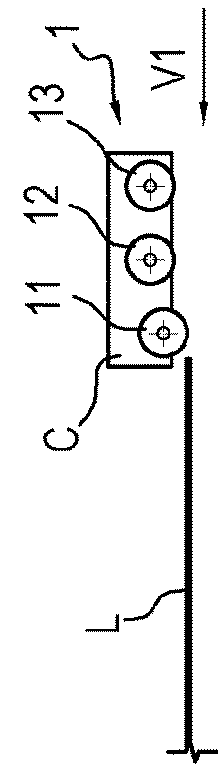

Electrically powered bolt setting device

InactiveUS20120153001A1Increase service lifeImprove qualityStapling toolsPower driven toolsElectric driveElectricity

The invention relates to an electrically powered bolt setting device (1) for setting of fastening elements (3) with a spring unit (10) which acts as an intermediate energy store in order to store energy, originating from an electric drive (25), in the bolt setting device (1), and said energy can be released suddenly during a bolt setting process.In order to create an electrically powered bolt setting device which has a simple design and can be produced at low cost and / or is low in cost to operate, the spring unit (10) cooperates with a unit to adjust the interim-stored energy.

Owner:HILTI AG

Apparatus and method for cutting slabs made of porcelain

InactiveUS20180178408A1Increase service lifeHigh safety parameterMetal sawing devicesStone-like material working toolsEngineeringPerpendicular direction

An apparatus for cutting slabs made of porcelain or like materials includes a support and blocking plane of at least a slab, and at least a cutting group of the slab, arranged superiorly thereof. The cutting group includes rotary tools associated with a carriage mobile along a parallel direction to the support plane; a component for moving the rotary tools independently of one another, in a perpendicular direction to the parallel direction, between two end positions, respectively an active neared position for working on the slab and a non-active distanced position, raised from the slab.

Owner:GIBEN TECH SRL

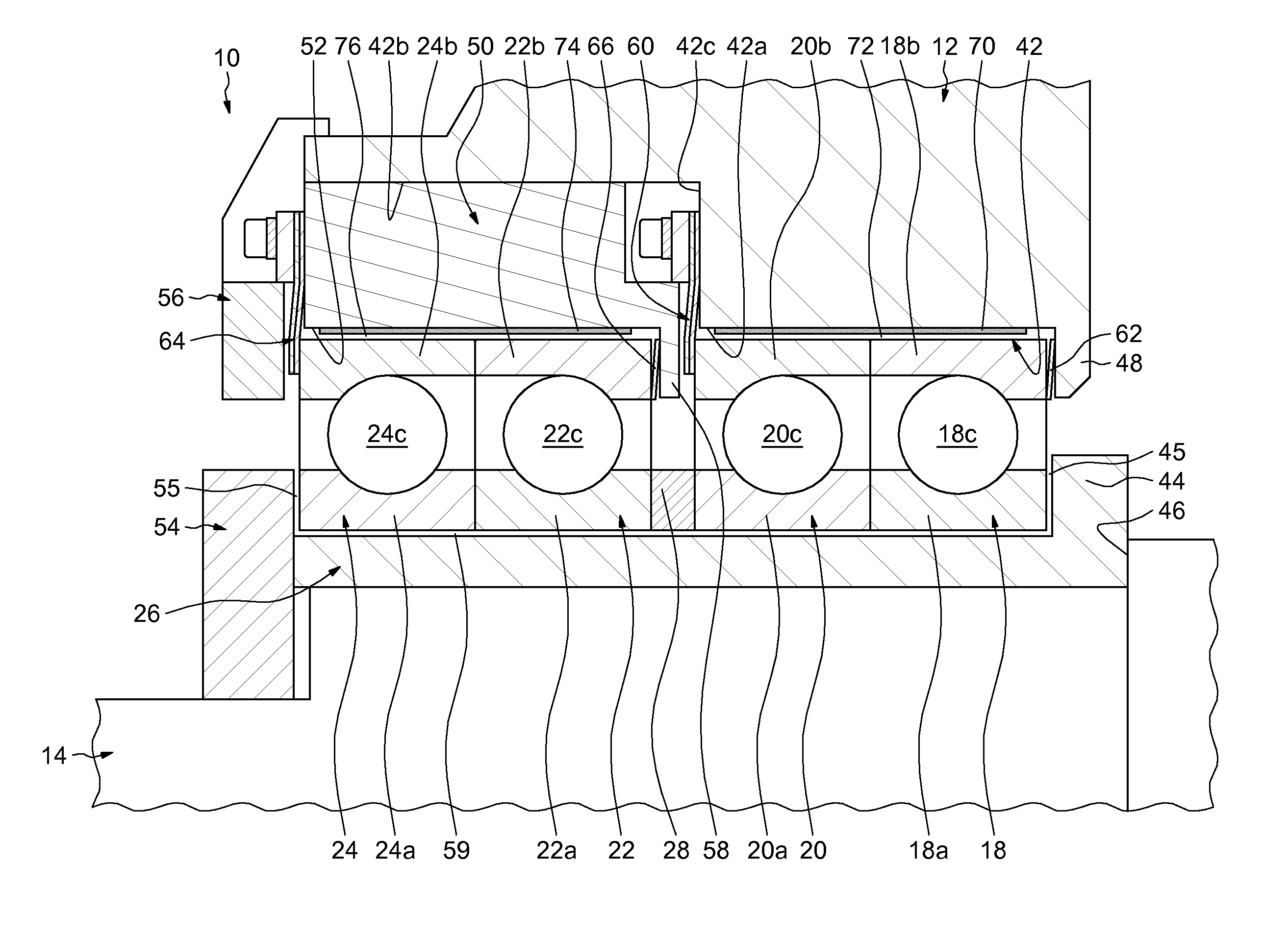

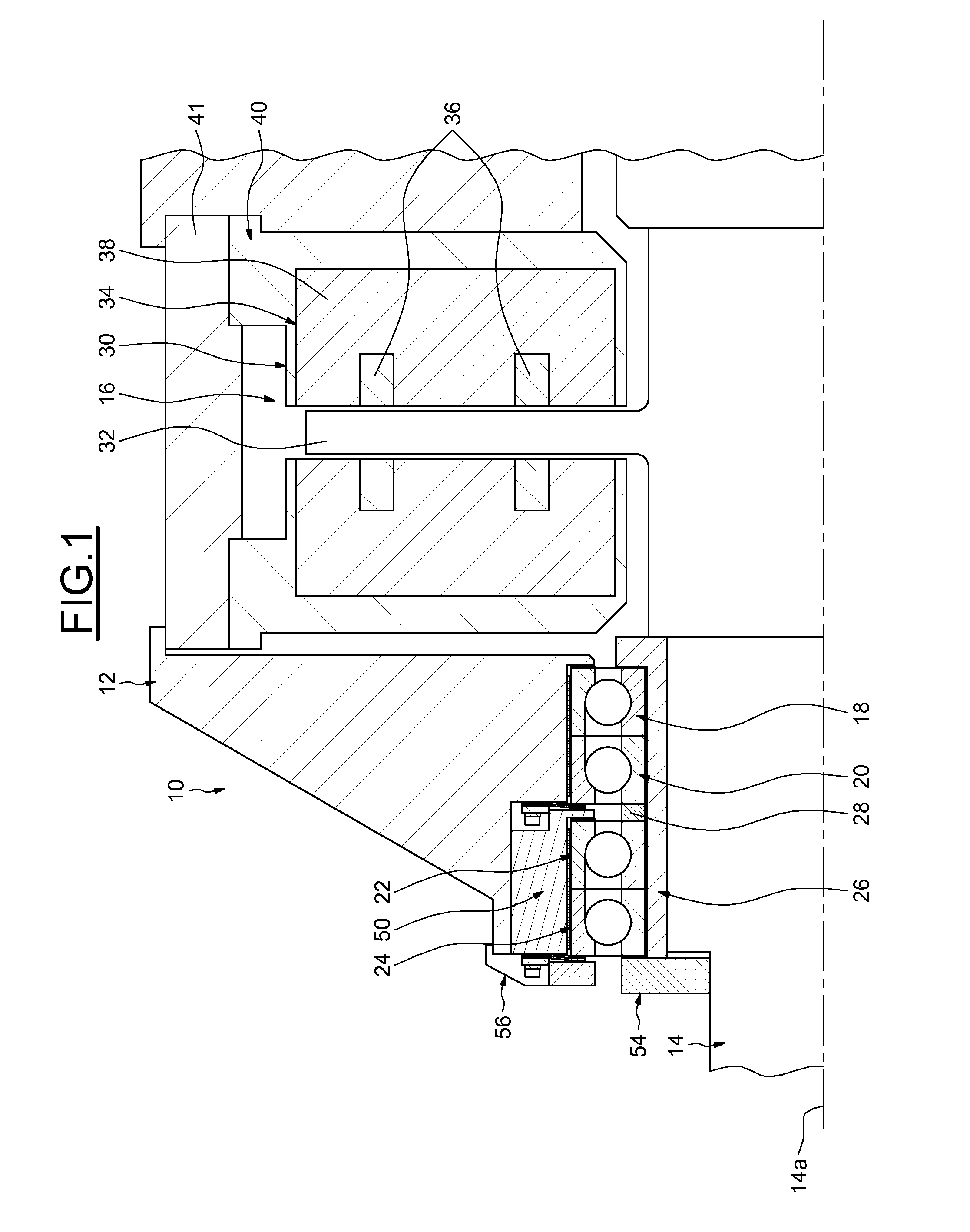

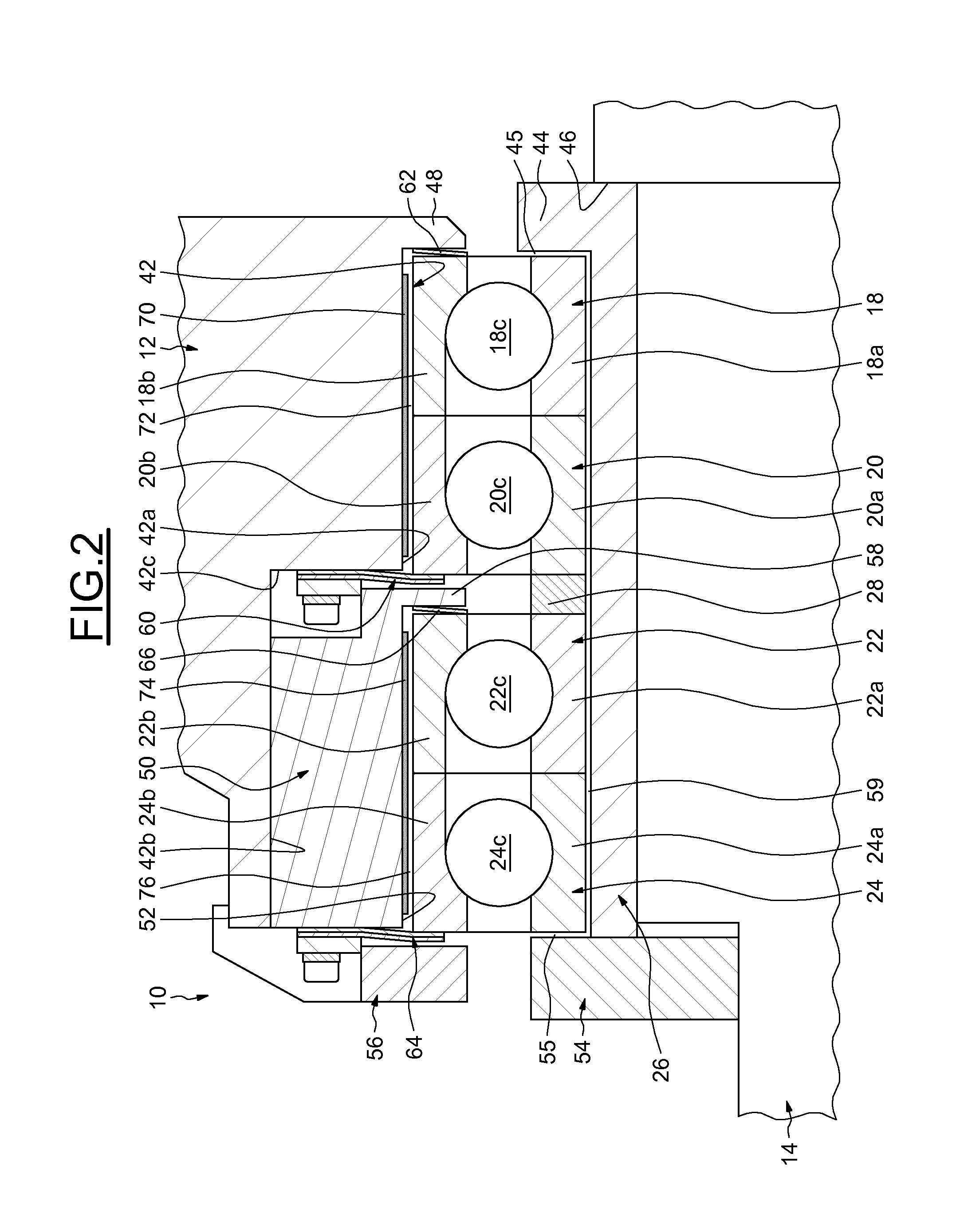

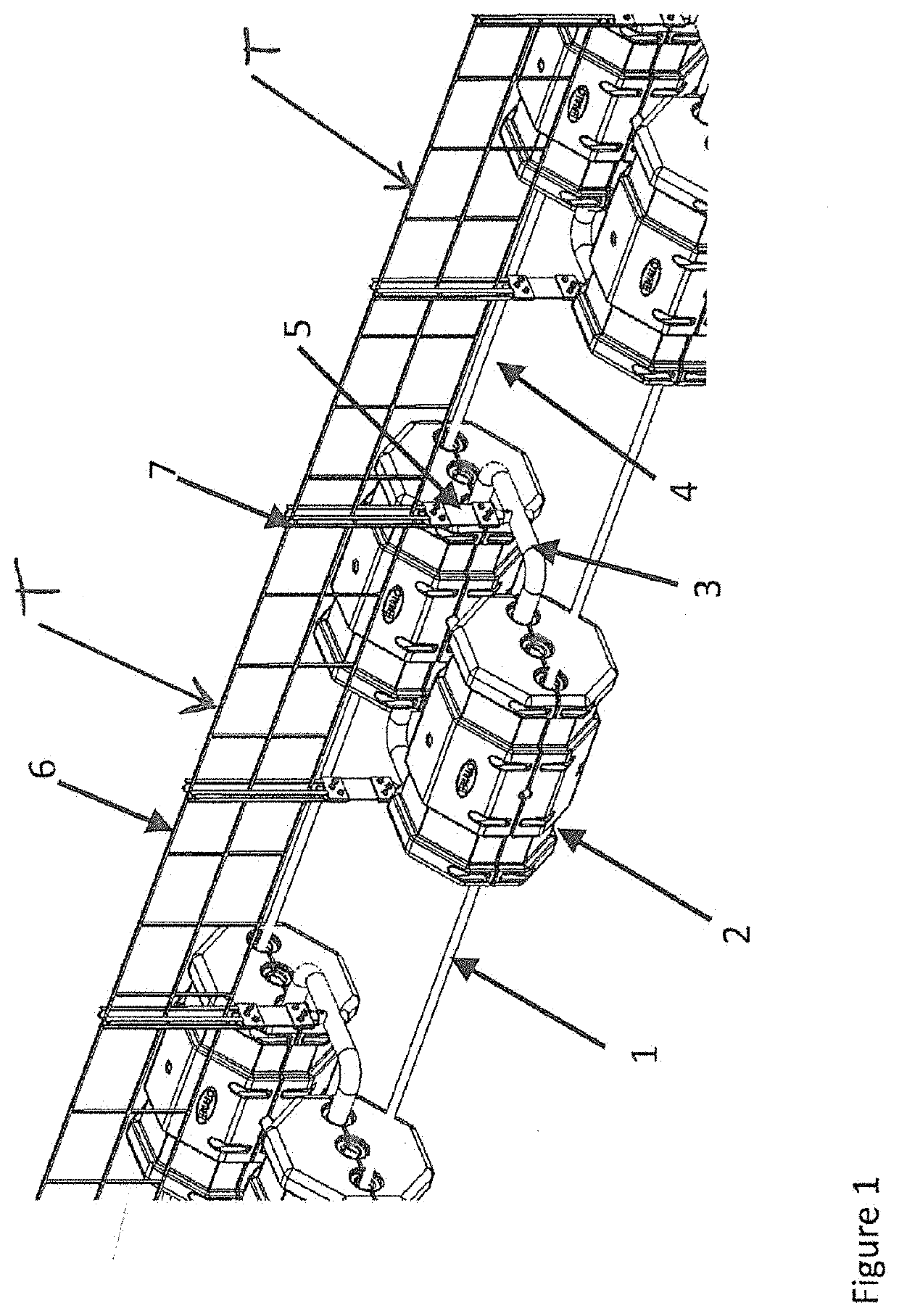

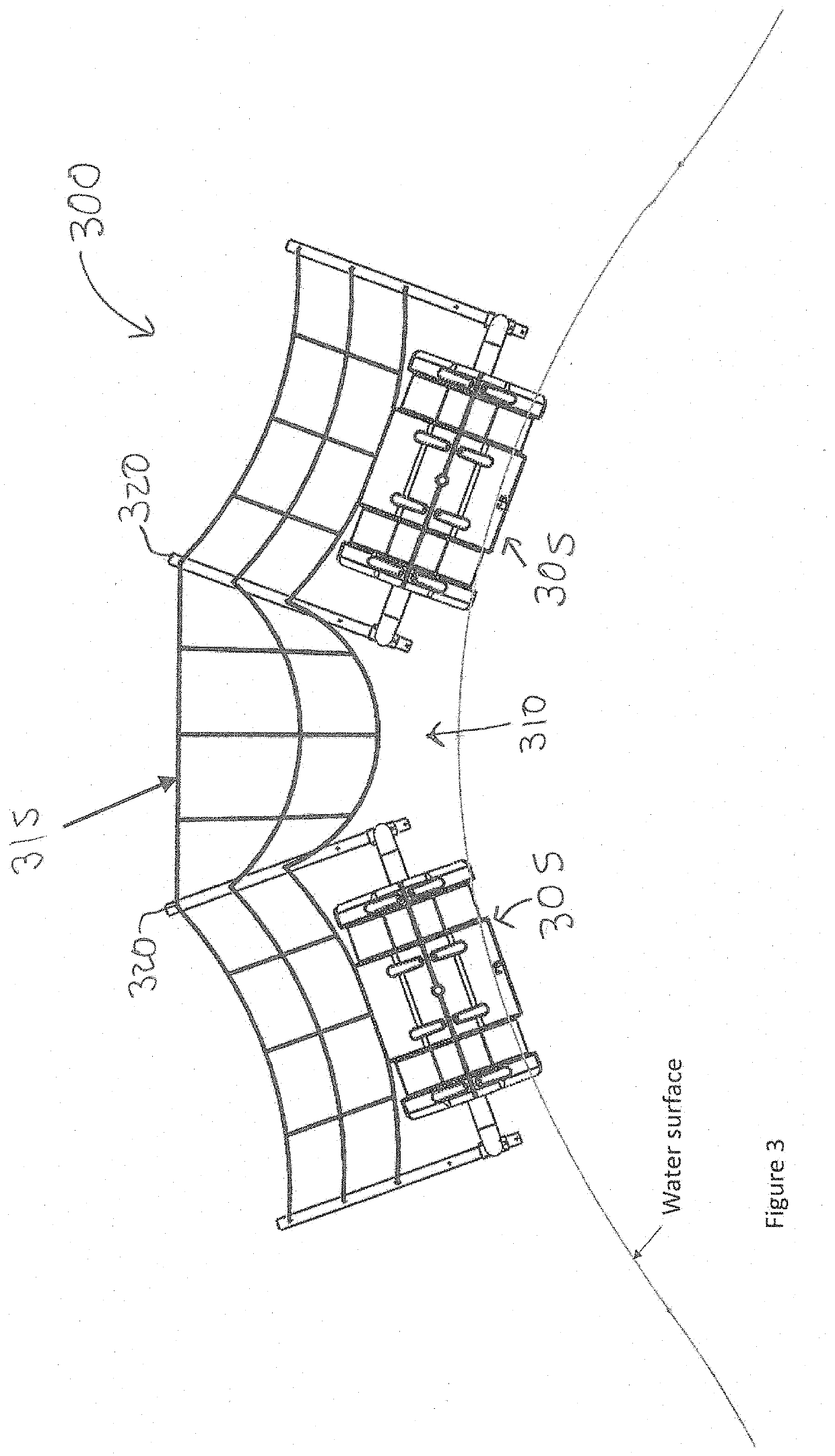

Compliant net support system for marine barriers

ActiveUS20210114700A1Increase service lifeDecrease maintenanceDefensive equipmentDefence devicesEngineeringStructural engineering

A compliant net support system for supporting a net of a marine barrier is provided. Embodiments include a floating marine barrier module comprising a flotation device; a supporting framework attached to the flotation device; a plurality of impact net support posts; and an impact net attached to each of the support posts and extending between the plurality of support posts along a longitudinal axis of the barrier module. At least one of the impact net support posts is a compliant net support post having a unidirectionally elastic spring element attached between a bottom of the support post and the supporting framework; and the spring element is movable in a direction substantially parallel to the longitudinal axis of the barrier module, and substantially inflexible in a direction substantially perpendicular to the longitudinal axis of the barrier module.

Owner:HALO MARITIME DEFENSE SYST INC

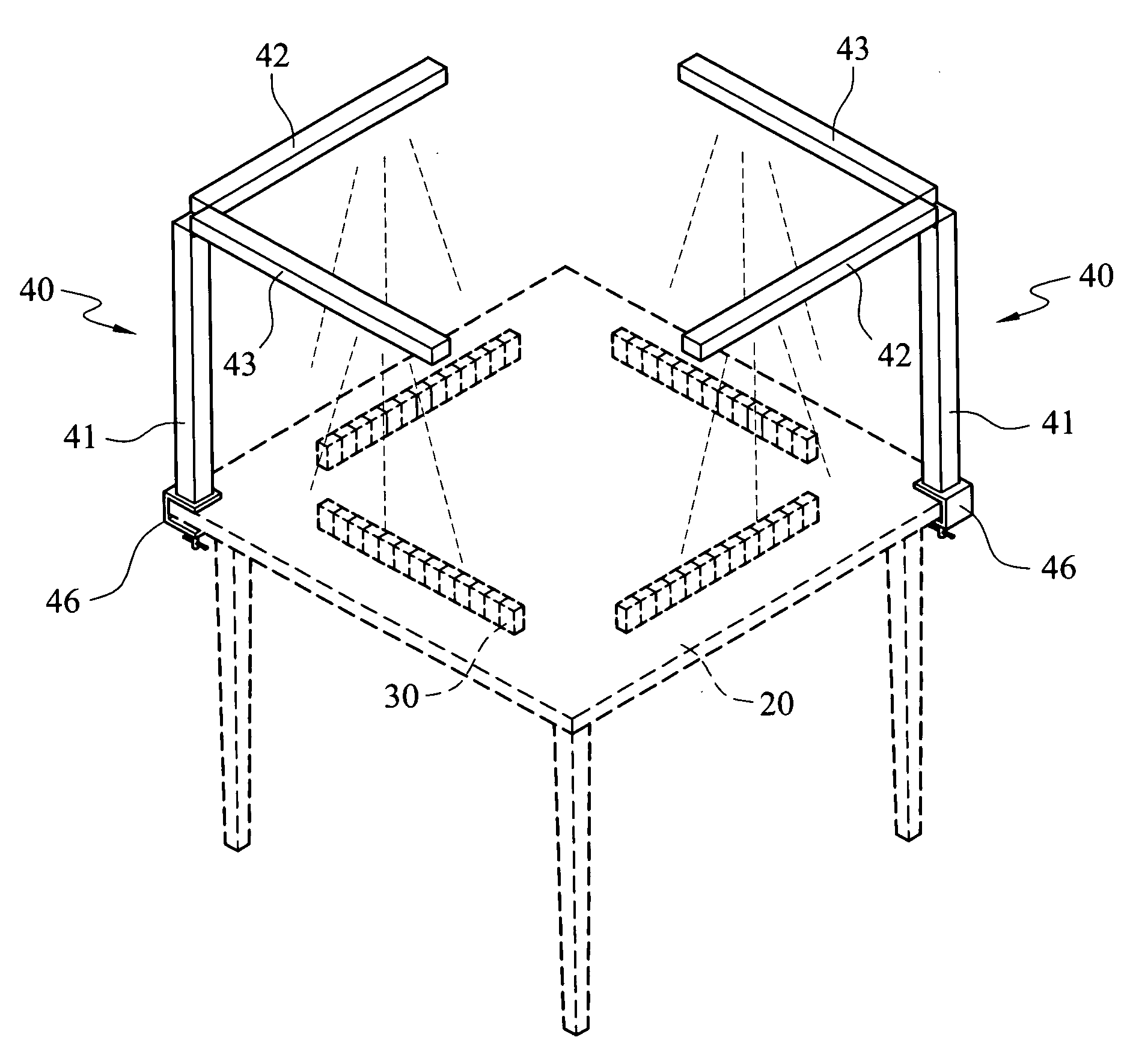

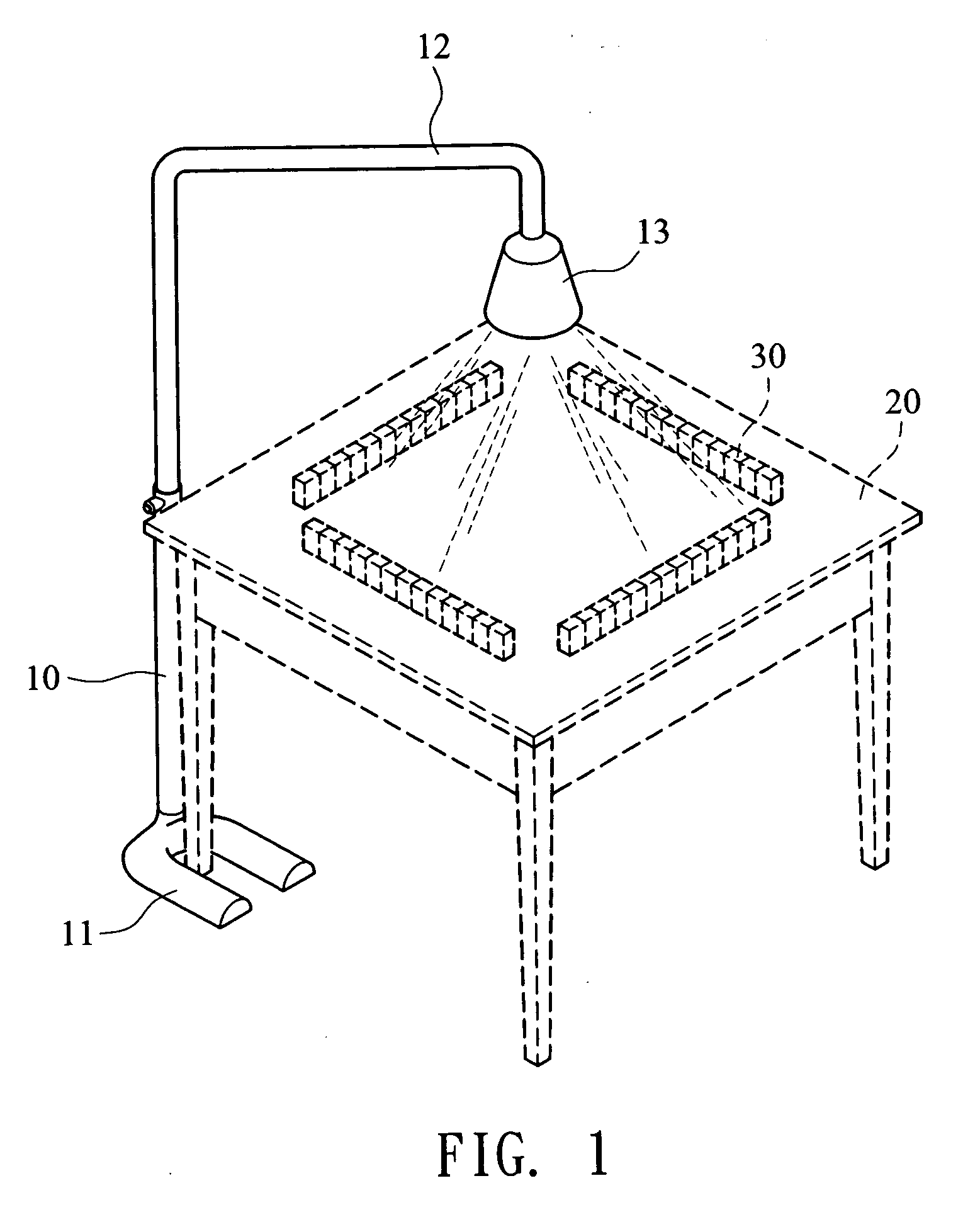

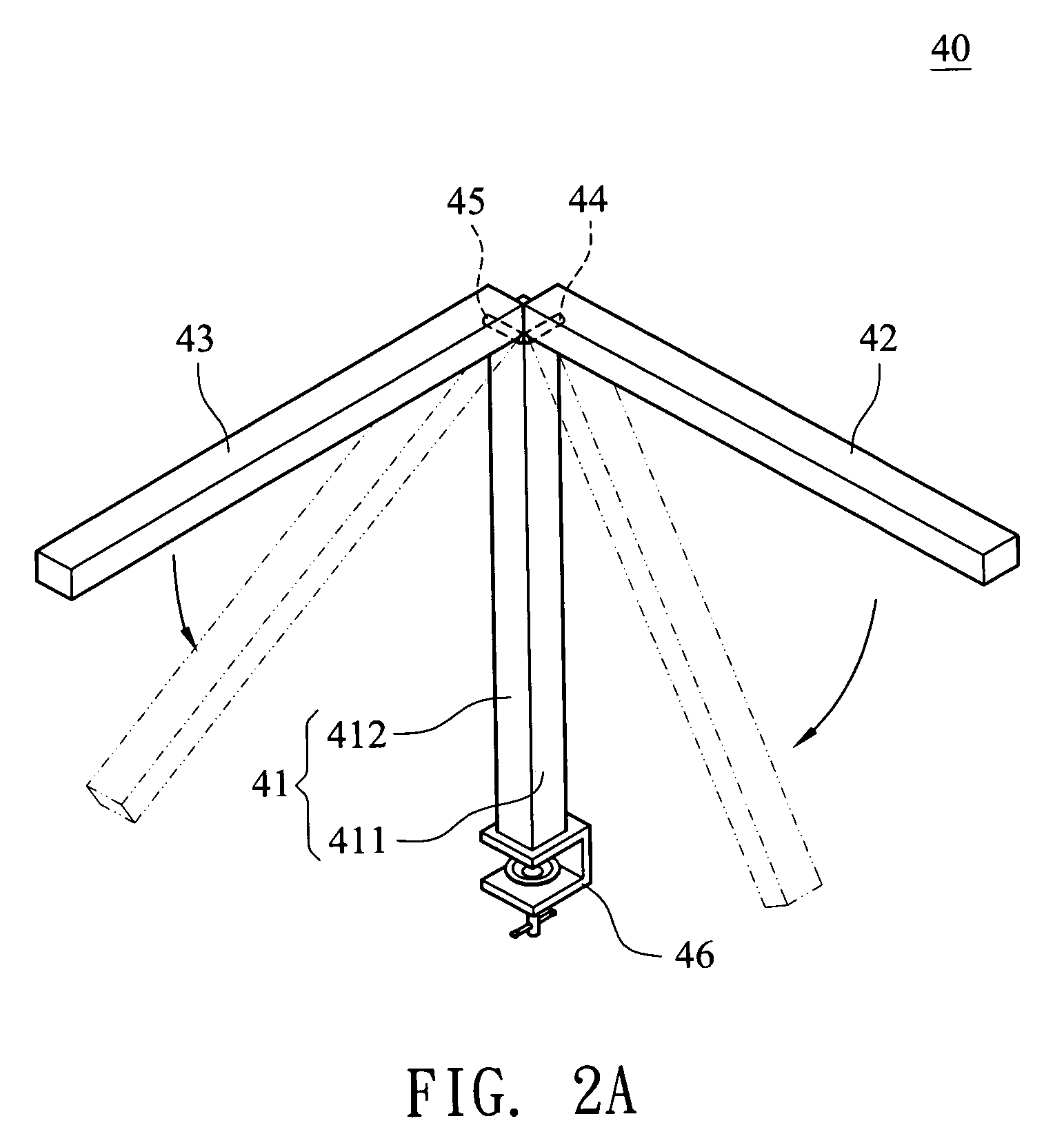

Biaxial folding lamp structure

InactiveUS20090161374A1Increase illuminated areaIncrease service lifeLighting support devicesElongate light sourcesEngineeringElectrical and Electronics engineering

Owner:PRODISC TECH INC

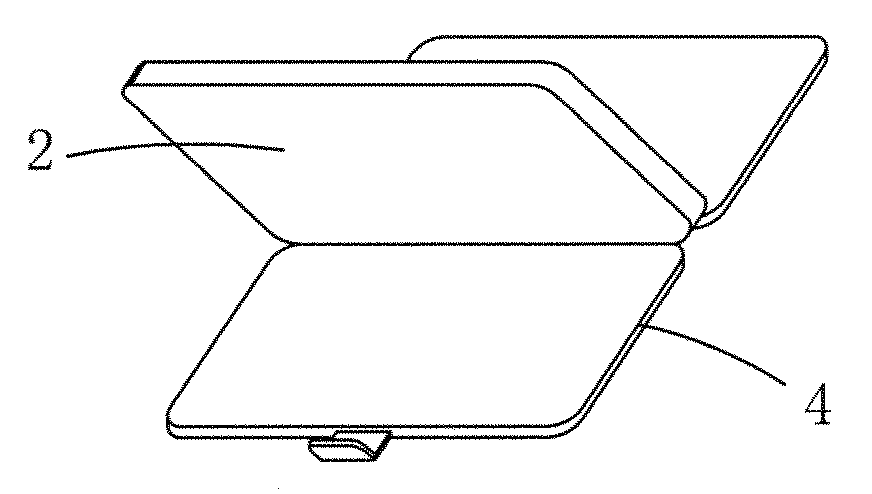

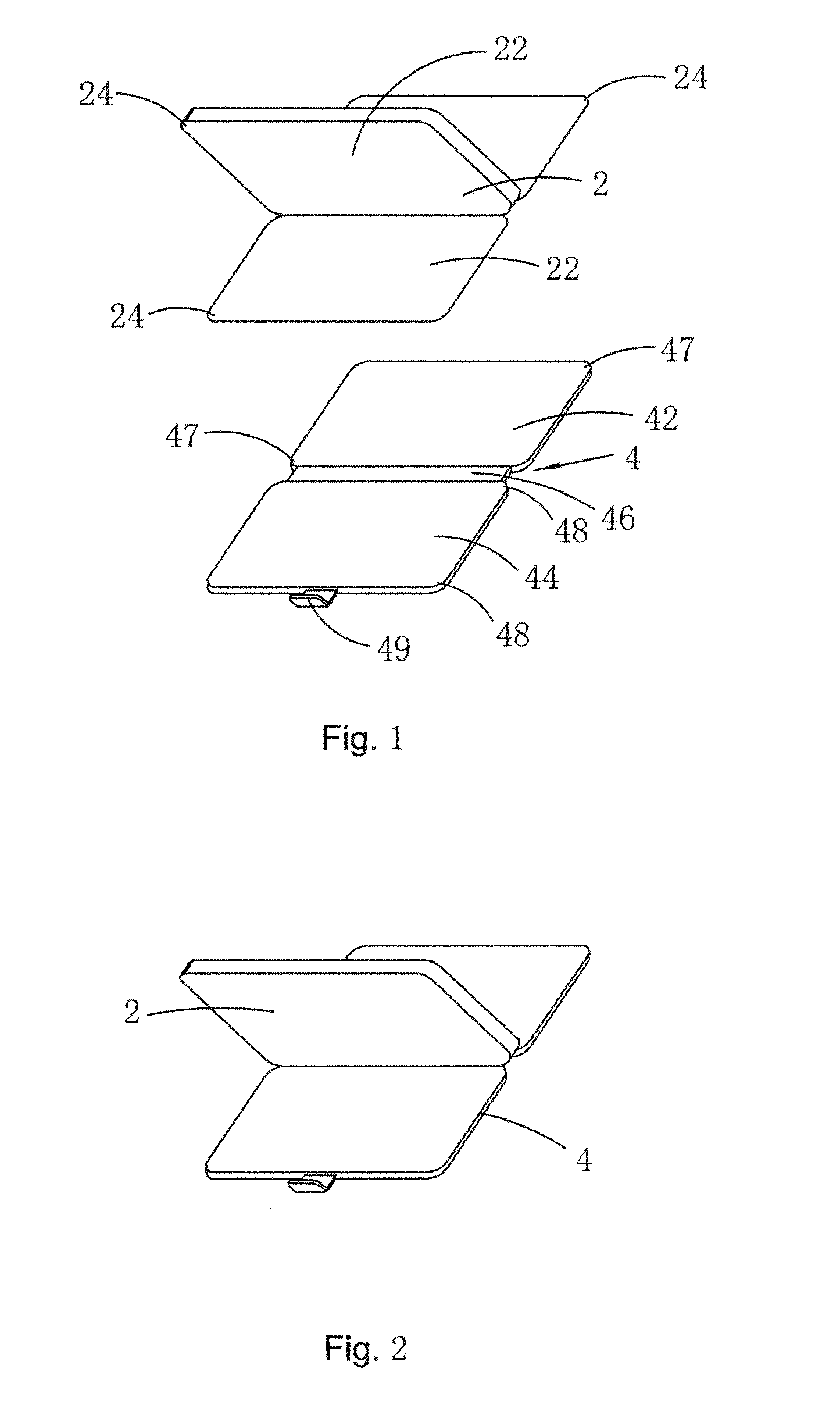

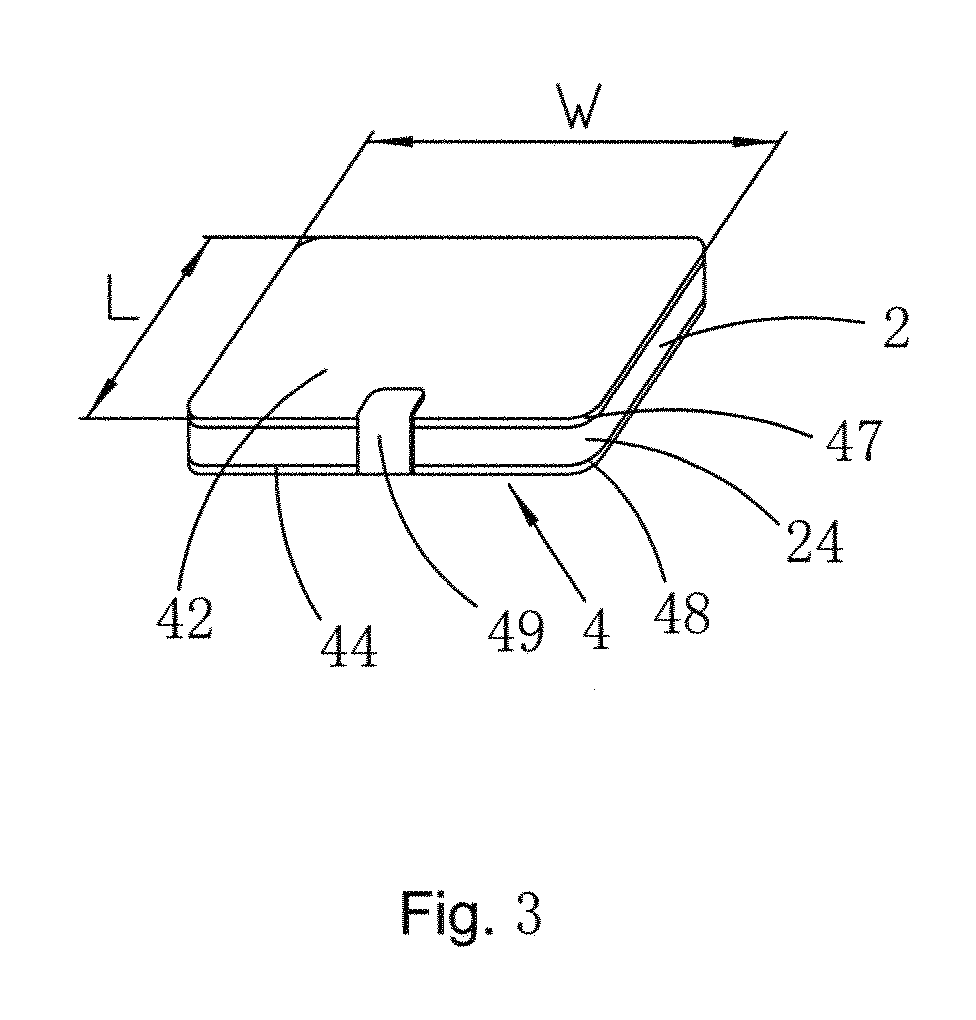

Notebook

InactiveUS20100320741A1Increase service lifeExtended service lifeBook coversEngineeringClean appearance

A notebook of the present invention comprises a main body, and a cover. The main body includes a plurality of pages with four corners thereof being round. The cover covers the main body with round corners corresponding to the four round corners of the main body. The width of the notebook from left to right is larger than the length of the notebook from up to down. The notebook of the present invention can protect the corners thereof from curling, deforming, or damaging during contact with other objects. Not only the notebook is kept a clean appearance, but also the service life of the notebook can be increased at a certain extent The notebook is convenient to use through flipping upwards and making the proportion between the width and the length greater than 1.

Owner:TAO JIAN

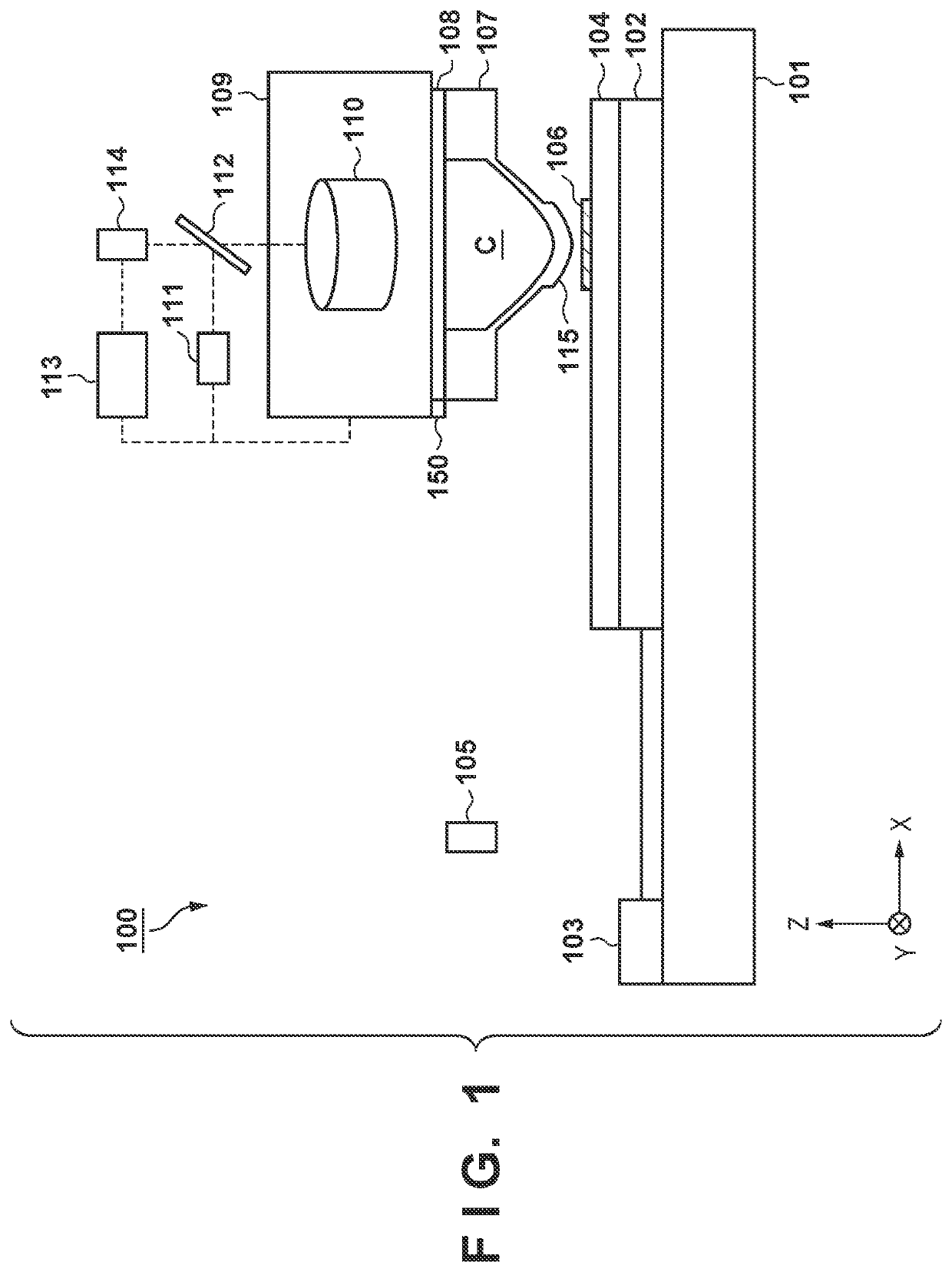

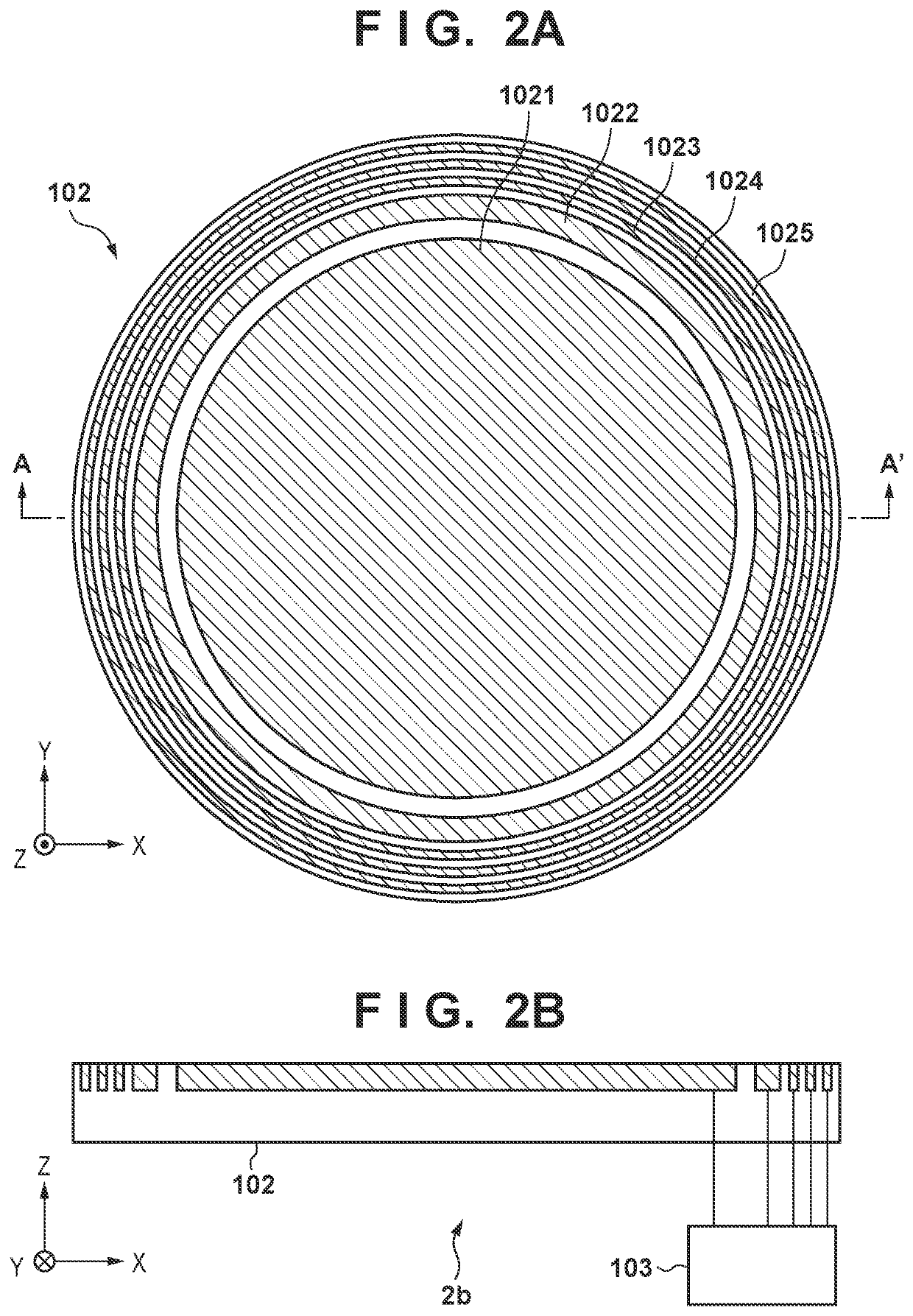

Forming apparatus and method of manufacturing article

ActiveUS20200387067A1Reduce defectIncrease service lifePhotomechanical apparatusSemiconductor/solid-state device manufacturingManufacturing engineeringMechanical engineering

Owner:CANON KK

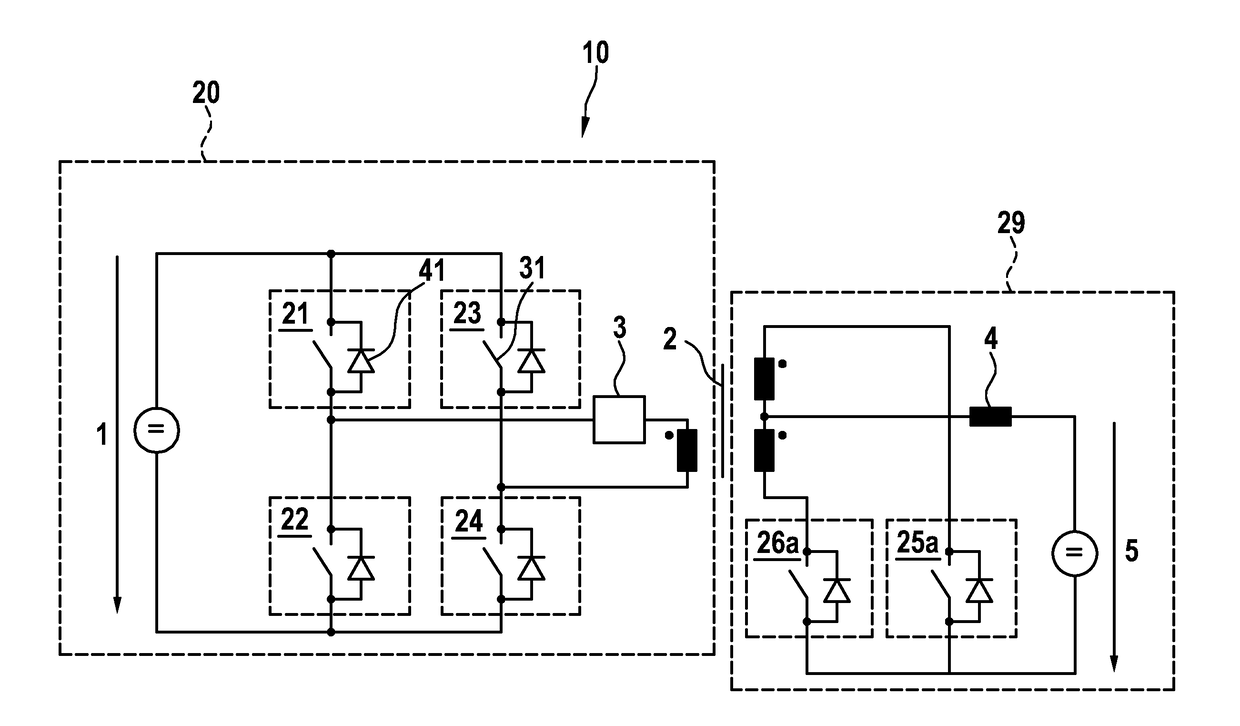

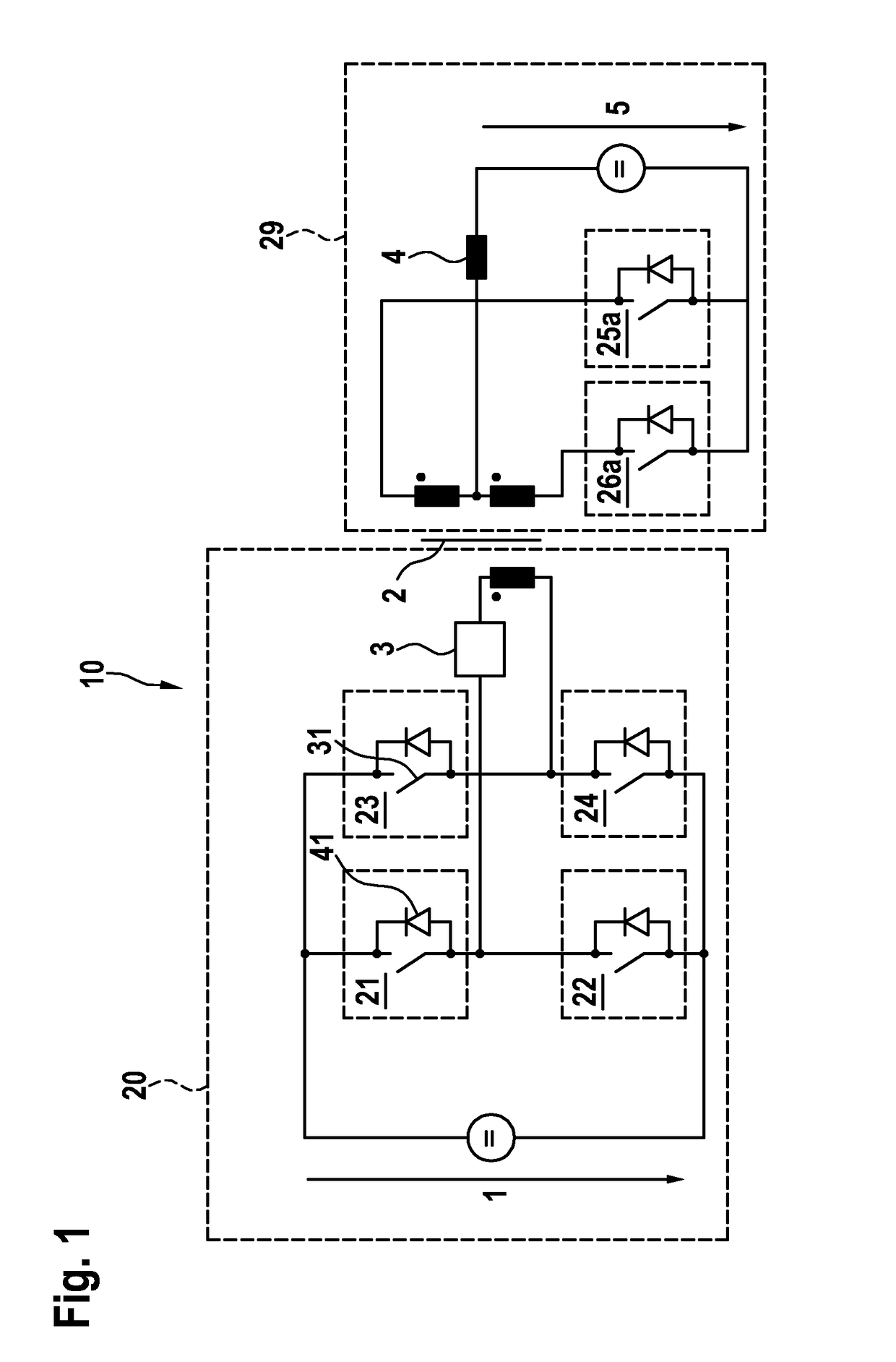

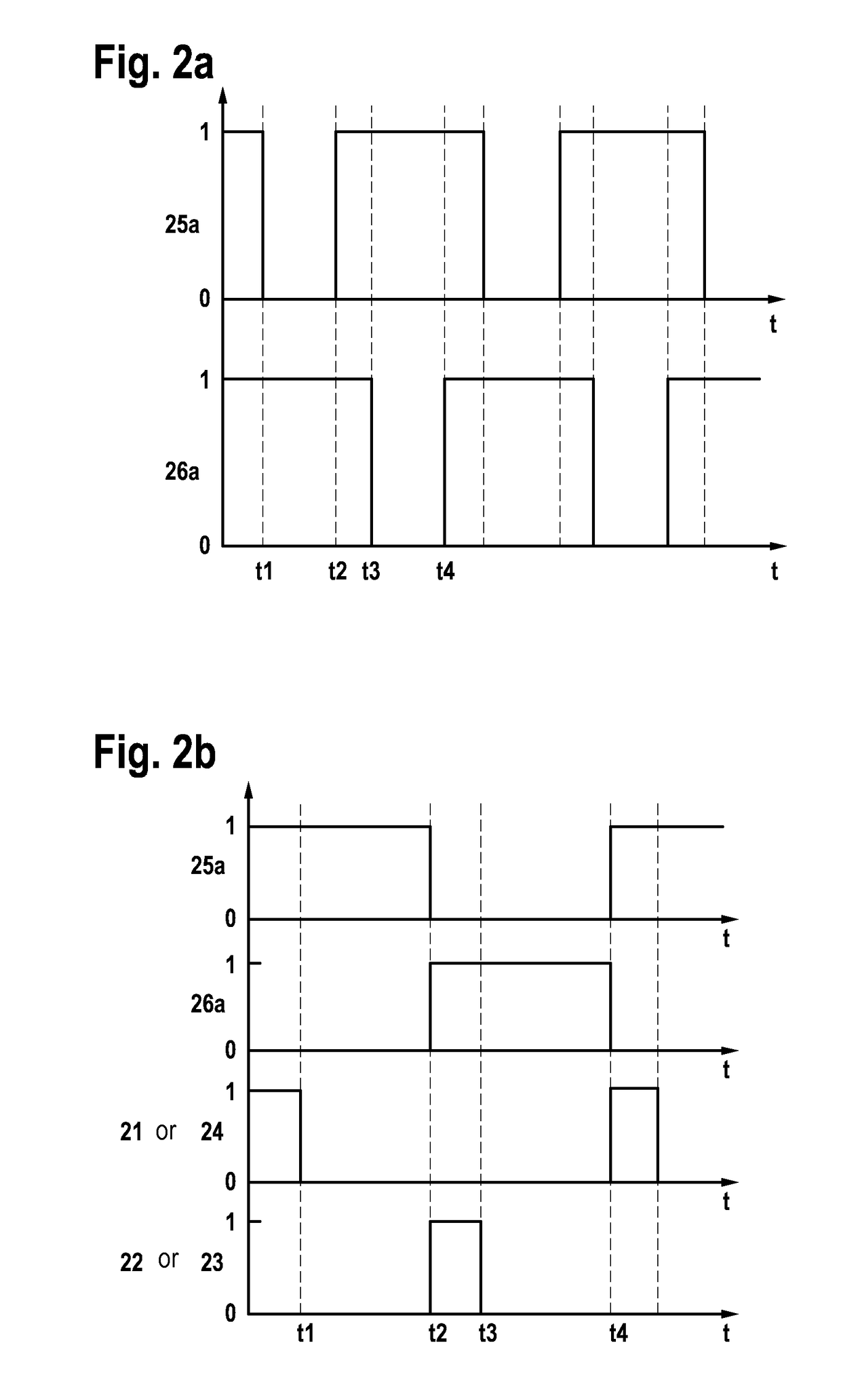

Modulation method for the boost converter operating mode of a push-pull converter

ActiveUS20170093288A1Increase service lifeEasy to implementDc-dc conversionElectric variable regulationPush–pull converterBoost converter

The invention relates to a method for modulating the boost converter operating mode of a push-pull converter having a low-voltage-side circuit, having a first low-voltage-side switching device and a second low-voltage-side switching device; having a transformer having a high-voltage-side winding; and having a high-voltage-side circuit, which is configured as a full-bridge rectifier, having a first and a second rectification element which form a first half-bridge and a third and a fourth rectification element which form a second half-bridge; wherein the method comprises the steps of closing the first low-voltage-side switching device whilst simultaneously short-circuiting the high-voltage-side winding via the first or the fourth rectification element during a first time segment; opening the rectification element used for short-circuiting the high-voltage-side winding during a second time segment; opening the first low-voltage-side switching device and closing the second low-voltage-side switching device whilst simultaneously short-circuiting the high-voltage-side winding via the third or the fourth rectification element in the second half-bridge during a third time segment; and opening the rectification element used for short-circuiting the high-voltage-side winding during a fourth time segment.

Owner:ROBERT BOSCH GMBH

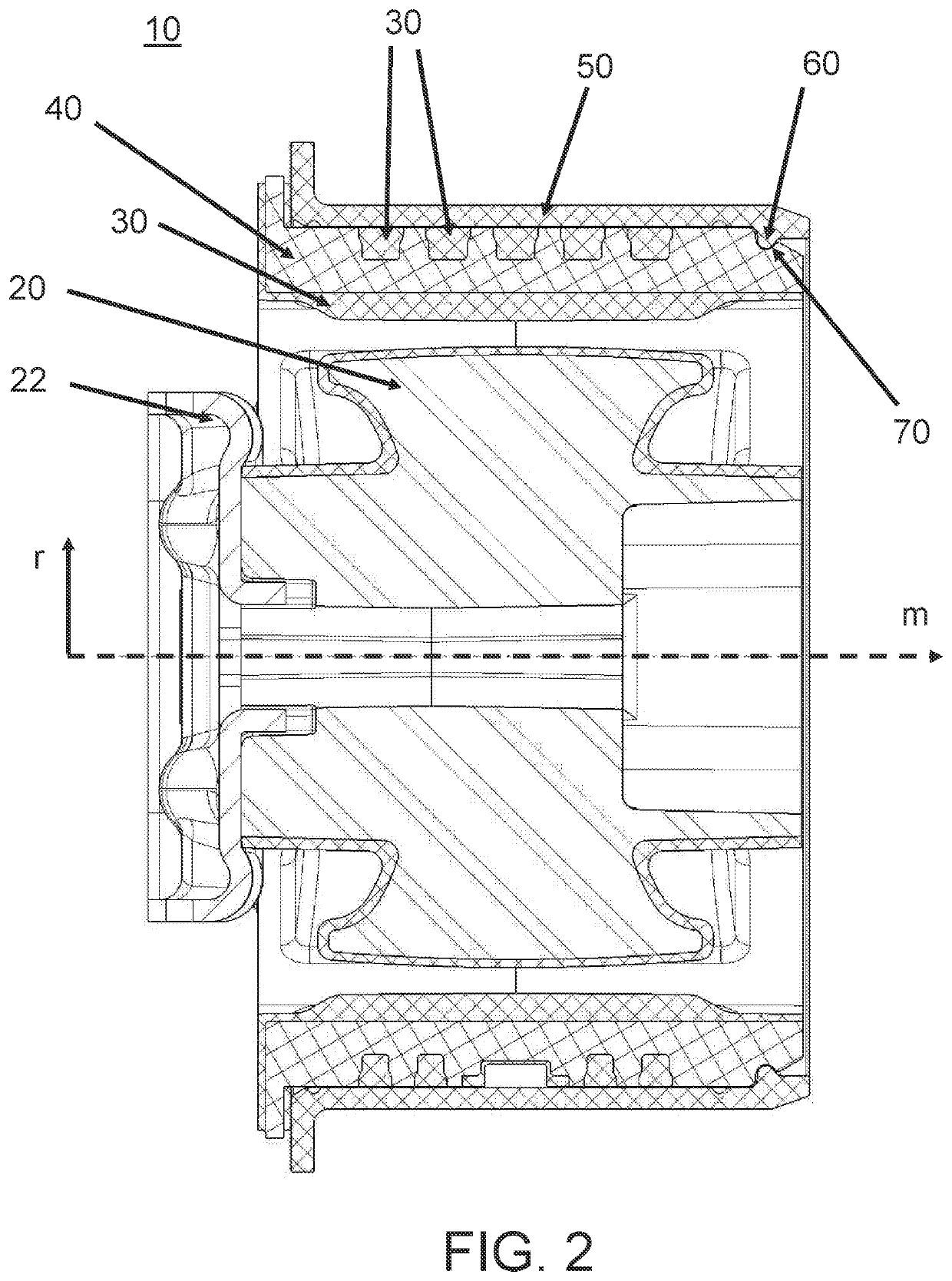

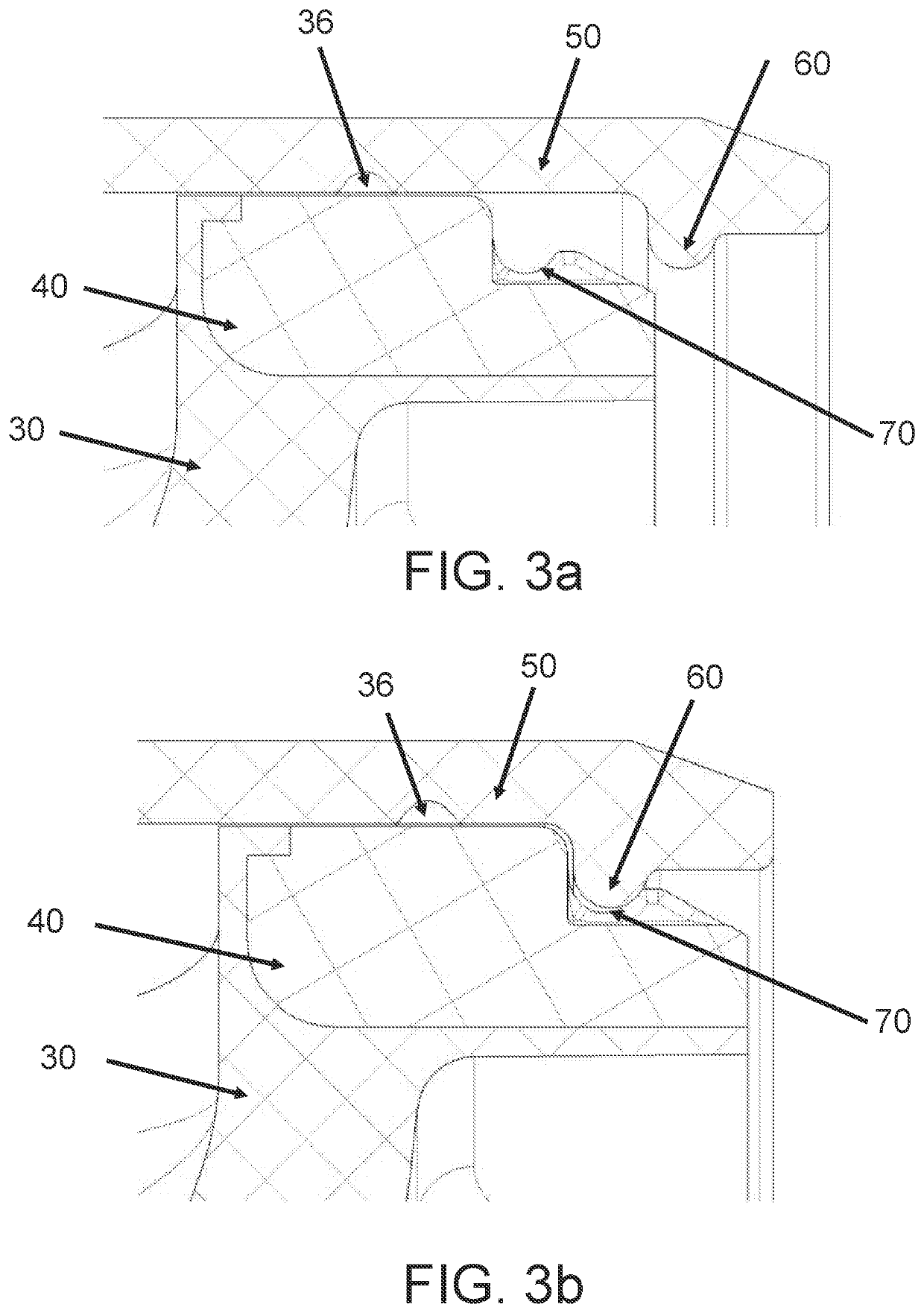

Bearing with at least one sealing element and at least one adjusting shim for axially displacing said sealing element

ActiveUS20210140482A1Increase service lifeEasy to implementRolling contact bearingsShaftsStructural engineeringClassical mechanics

A bearing providing a first ring assembly and a second ring assembly, the first ring assembly including at least a first ring and an outer cap reversibly fixed to first ring. The bearing further providing at least one sealing element mounted radially into a cylindrical surface of the first ring assembly and provided with a sealing lip in sliding frictional contact with the second ring assembly. The bearing including at least one adjusting shim mounted radially between the first and second ring assemblies, the adjusting shim being axially located between the outer cap of the first ring assembly and the sealing element; or between the first ring of the first ring assembly and the sealing element.

Owner:AB SKF

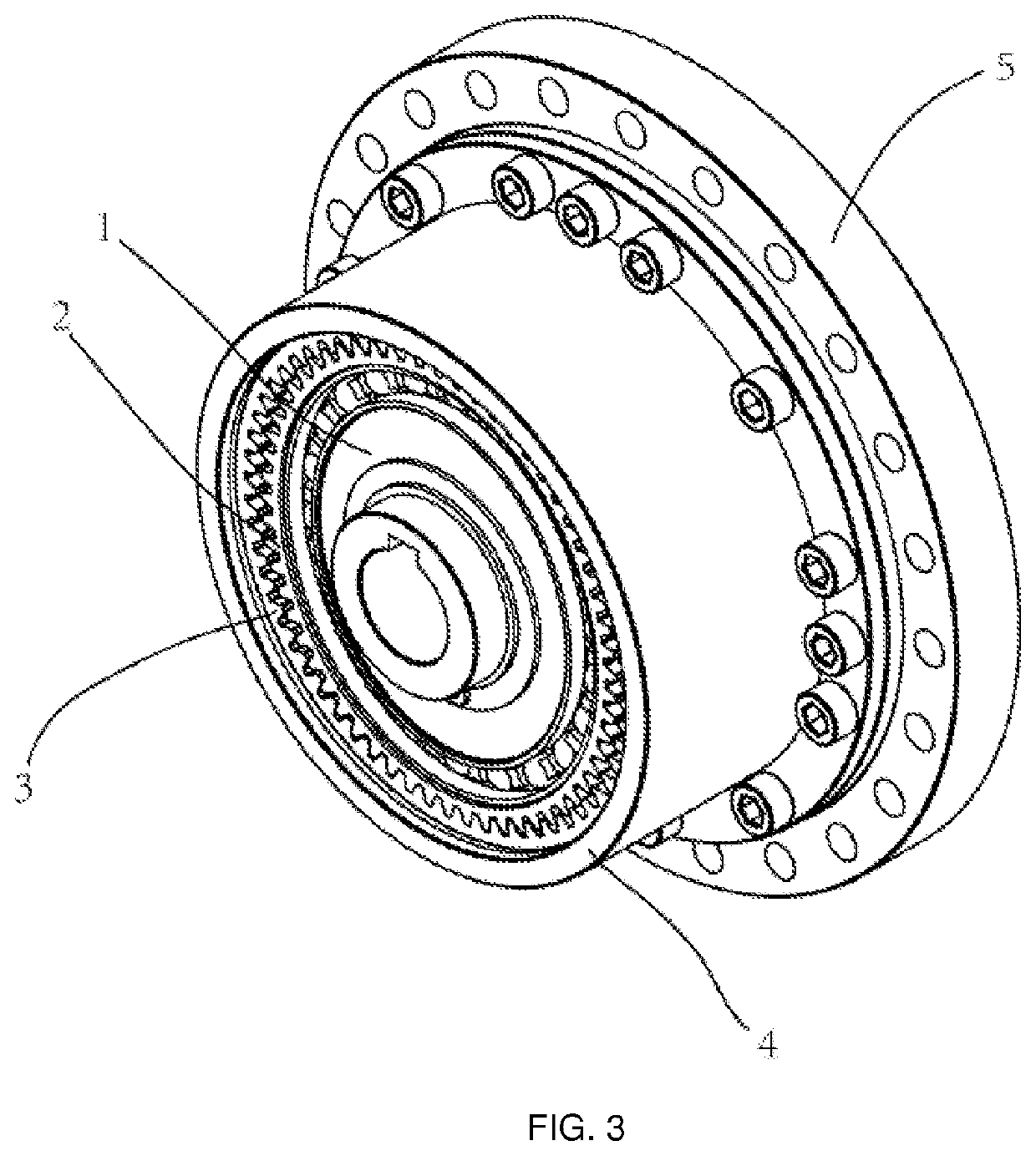

Double-flexspline harmonic reducer with limitable deformation

ActiveUS20210348679A1Increase service lifeCost reductionGearingPortable liftingPhysicsMechanical engineering

The present application discloses a double-flexspline harmonic reducer, comprising a strong flexspline (3), a weak flexspline (2), a wave generator (1), and a deformation stopper (4) of the strong flexspline; the strong flexspline and the weak flexspline are coaxially fixed axially and radially, the strong flexspline and the weak flexspline are respectively provided with teeth that can engage with each other; the number of teeth of the strong flexspline and the weak flexspline are different; the wave generator is used to make the weak flexspline to undergo non-circular elastic deformation and partially engage with the strong flexspline; the contact part of the strong flexspline and the weak flexspline is subjected to the radial pressure of the weak flexspline to generate a non-circular elastic deformation, a flexible tubular wall of the strong flexspline has a toothless surface, and a limiting contact surface is processed on the toothless surface.

Owner:AICI TECH (NINGBO) CO LTD

Cable machine

ActiveUS20190300341A1Increase service lifeGreat rotational speedRolling contact bearingsRope making machinesEngineeringPulley

A machine for manufacturing cables includes a winch that includes a tube, which includes at least a pulley, a reducer and an input shaft to the reducer in its interior. A system for attaching the reducer includes two concentric bearings. An outer bearing is attached to the reducer and the tube, and an inner bearing is attached to the pulley and outer bearing, such that the pulley is supported by the inner bearing and by bearings of the input shaft of the reducer.

Owner:CONSTR MECANICAS CABALLE

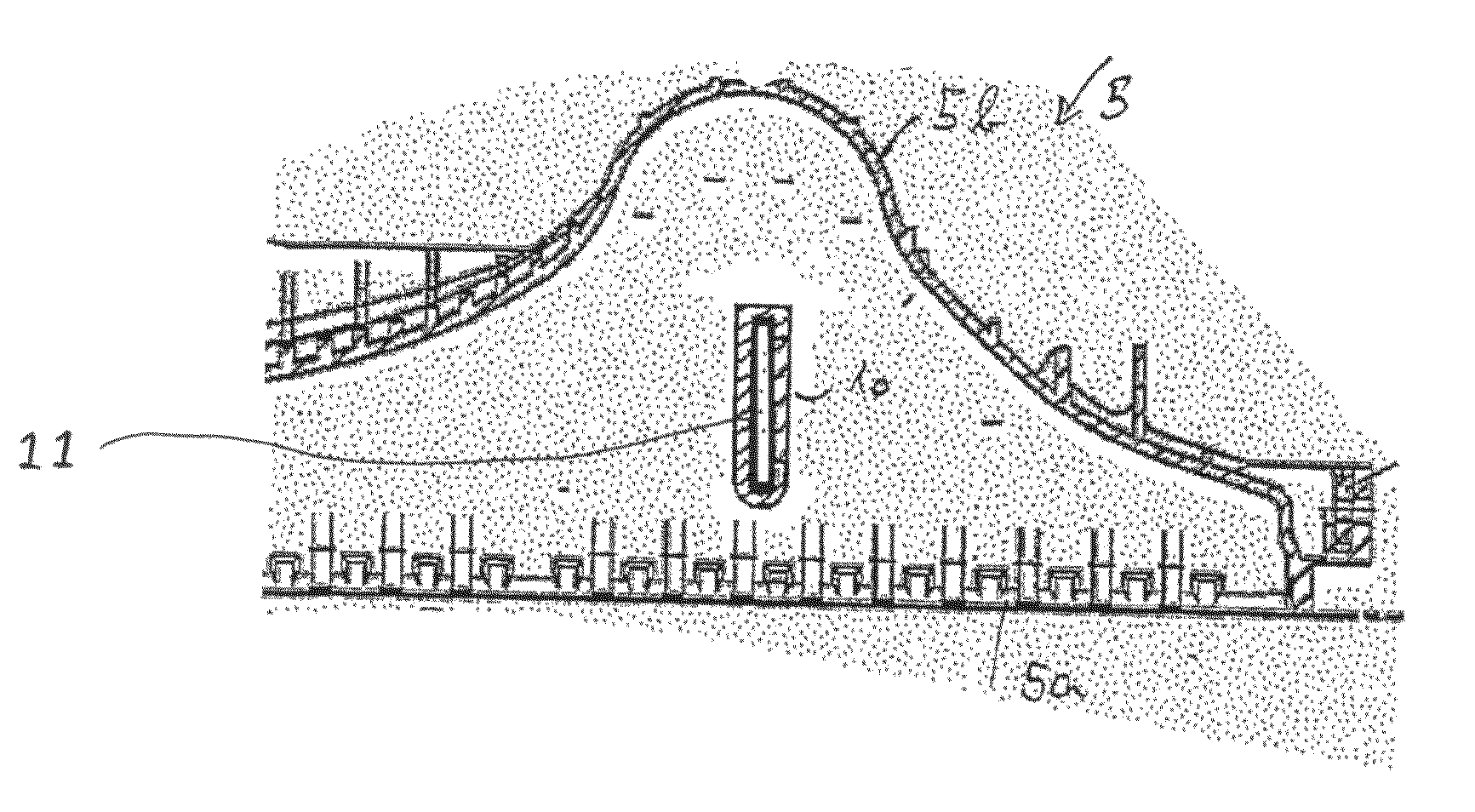

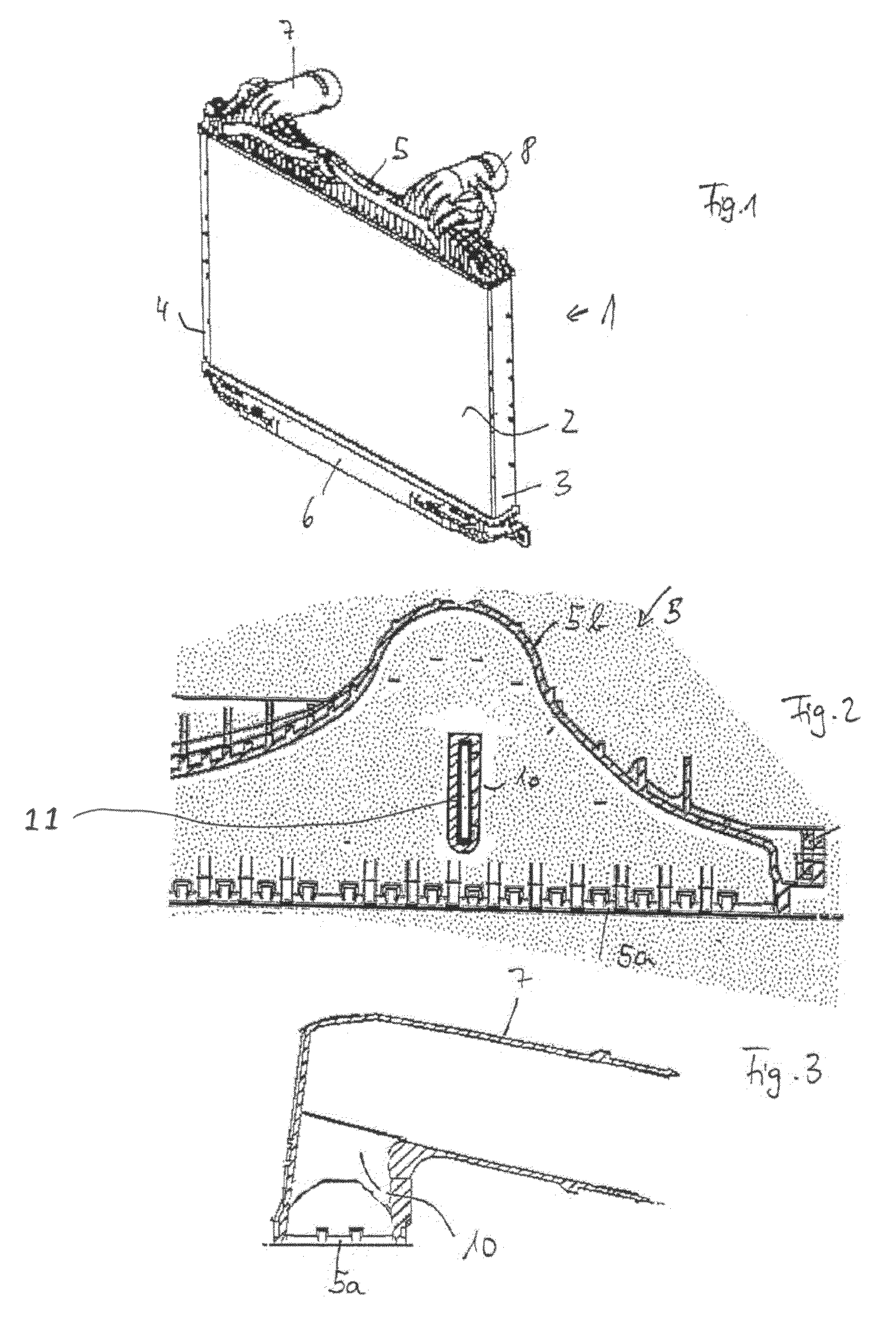

Collecting tank and heat exchanger

ActiveUS7971635B2Oxidative aging be slowIncrease service lifeReinforcing meansStationary conduit assembliesEngineeringHeat exchanger

The invention relates to a plastic charge air tank or coolant tank (5) comprising at least one tie rod (10) that is integrated thereinto and is connected thereto as a single piece or in a fixed manner. The tie rod (10) is provided with at least one continuous hollow space which extends along the longitudinal axis thereof.

Owner:BEHR GMBH & CO KG

Bearing bush and production method for a bearing bush

ActiveUS20210293300A1Increase service lifeHigh press-out forceSpringsNon-rotating vibration suppressionManufacturing engineeringMechanical engineering

A bearing bush and a method for producing a bearing bush are provided. The bearing bush includes a core element, an elastomer element, a cage element and a sleeve element. The cage element is at least partially embedded in the elastomer element. The elastomer element elastically connects the cage element and the core element to each other. The core element, the cage element and the elastomer element form a pre-assembly element. One of the sleeve element and the cage element includes a protrusion. The other of the sleeve element and the cage element includes a groove, which is engageable with the protrusion, in an assembled state of the bearing bush. The pre-assembly element is fixed in the sleeve element. The protrusion and the groove form a two-point contact in a cross-section.

Owner:TOKAI RUBBER IND LTD

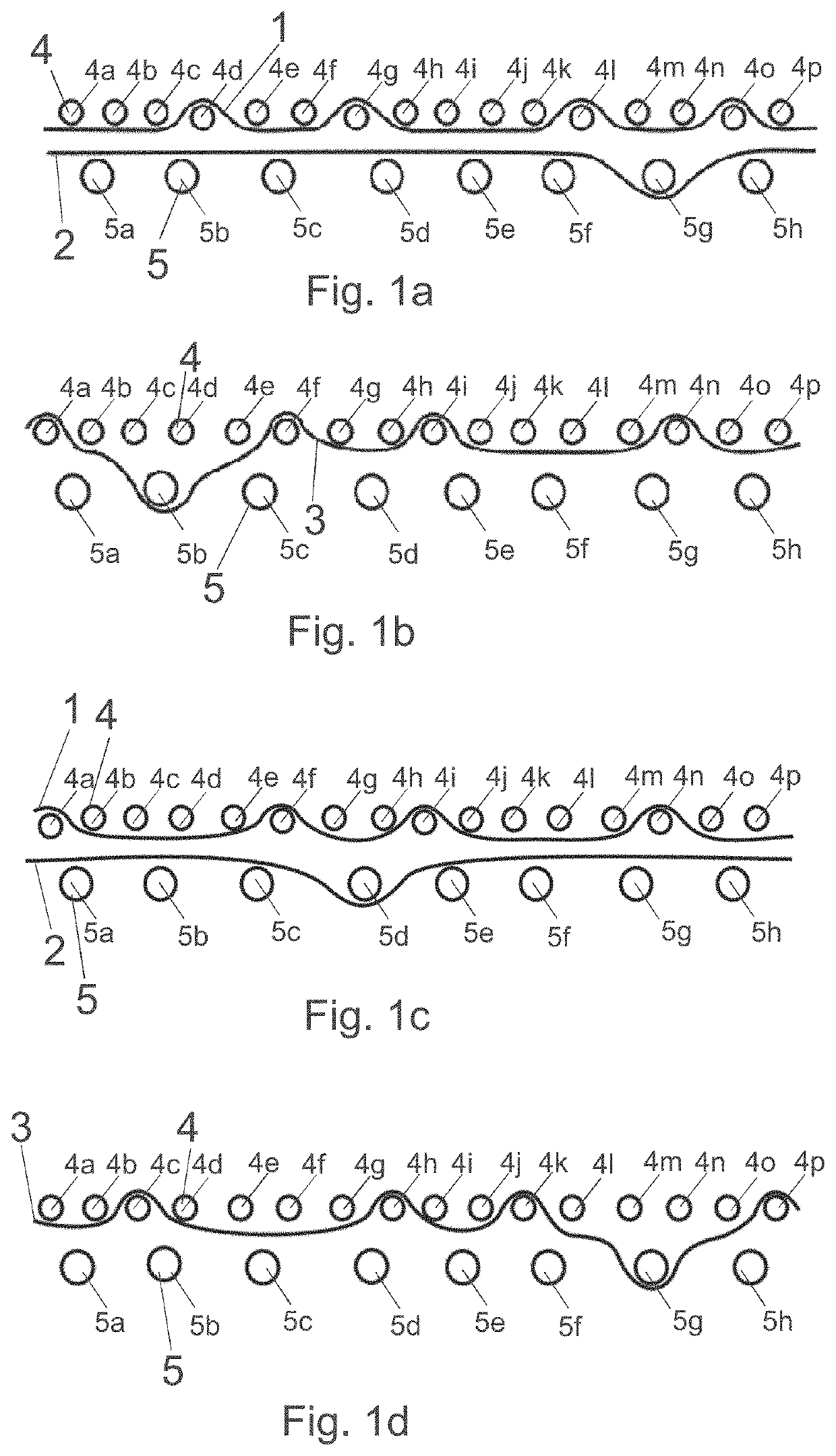

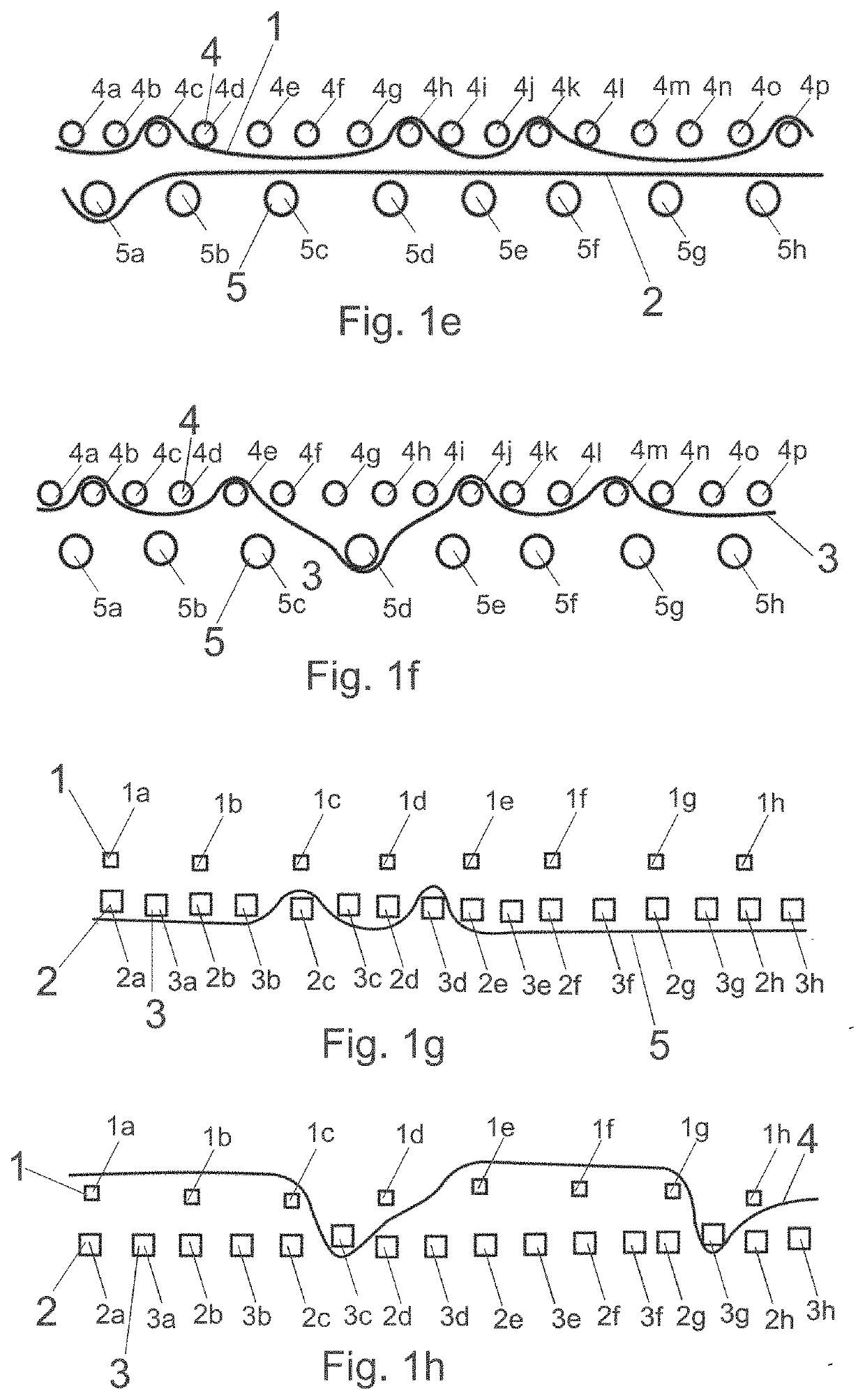

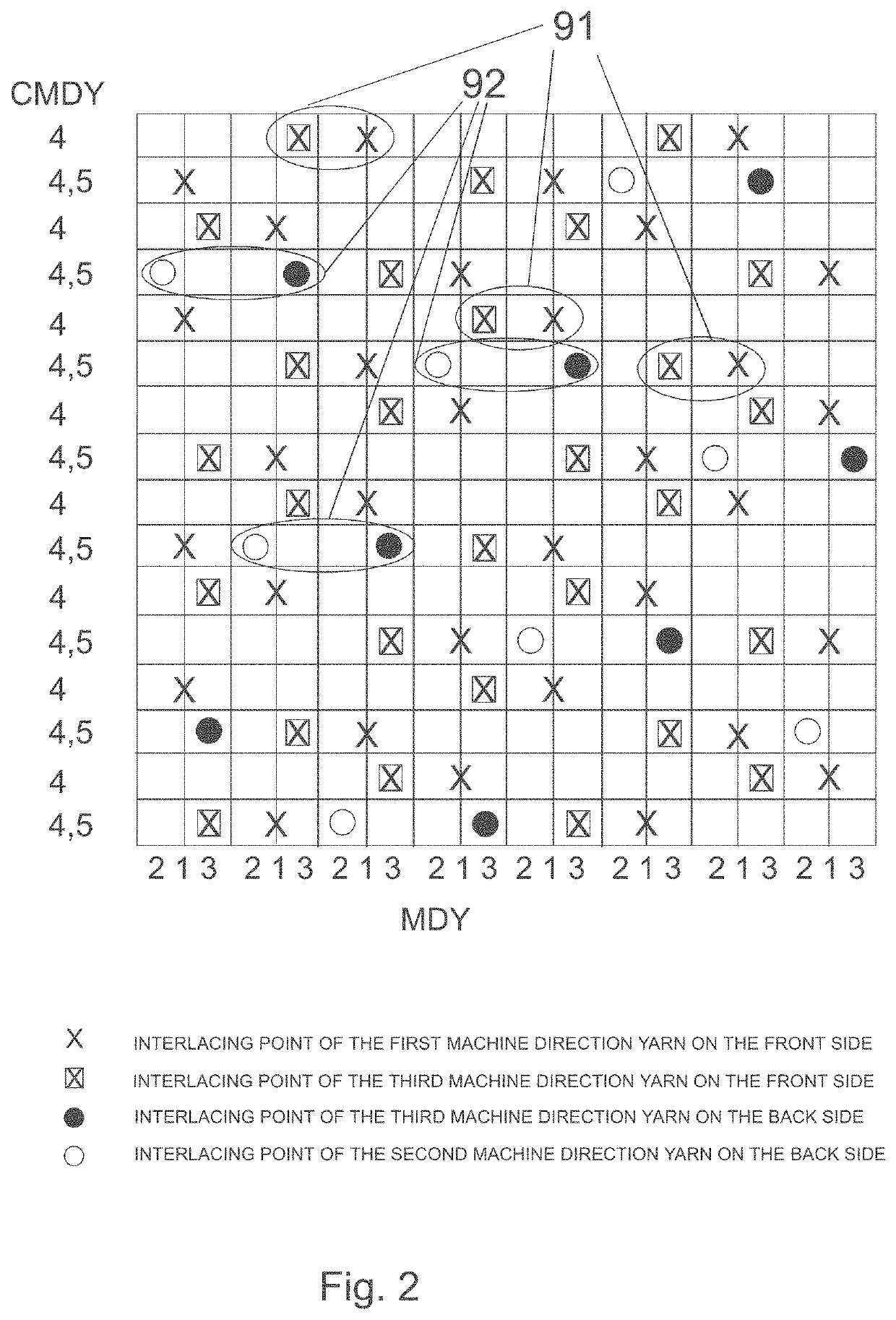

Industrial Textile for Manufacturing a Fibrous Web

ActiveUS20210381165A1Uneven water permeabilityIncrease service lifeMachine wet endMulti-ply fabricsWoven fabricYarn

An industrial textile (6) for manufacturing a fibrous web has first machine direction yarns (1) on the front side (7) which bind to first cross-machine direction yarns (4) in a first pattern, while second machine direction yarns (2) on the back side bind to second cross-machine direction yarns (5) in a second pattern. Third machine direction yarns (3) bind to the first cross-machine direction yarns (4) and the second cross-machine direction yarns (5) in a third pattern. The third pattern has at least one interlacing point (71) on the front side where one of the third machine direction yarns (3) passes over one of the first cross-machine direction yarns (4) and at least one interlacing point (72) on the back side (8) where the same third machine direction yarn (3) passes under one of the second cross-machine direction yarns (5).

Owner:VALMET TECH OY

Clamping roller freewheel

InactiveUS20100040318A1Idle run wear be prevent and at least reducedIncrease service lifeBearing componentsFreewheel clutchesFlywheelEngineering

Owner:SCHAEFFLER TECH AG & CO KG

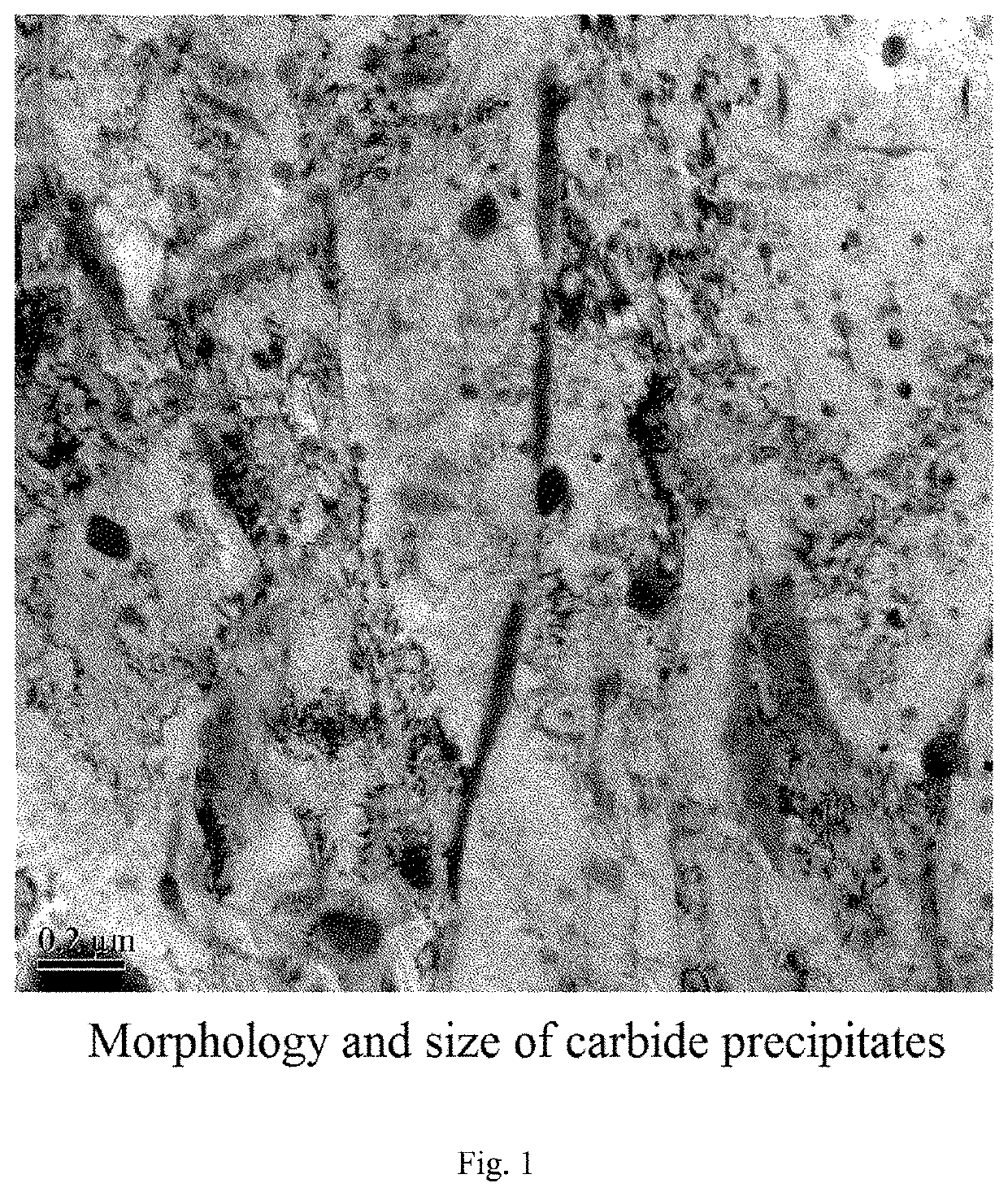

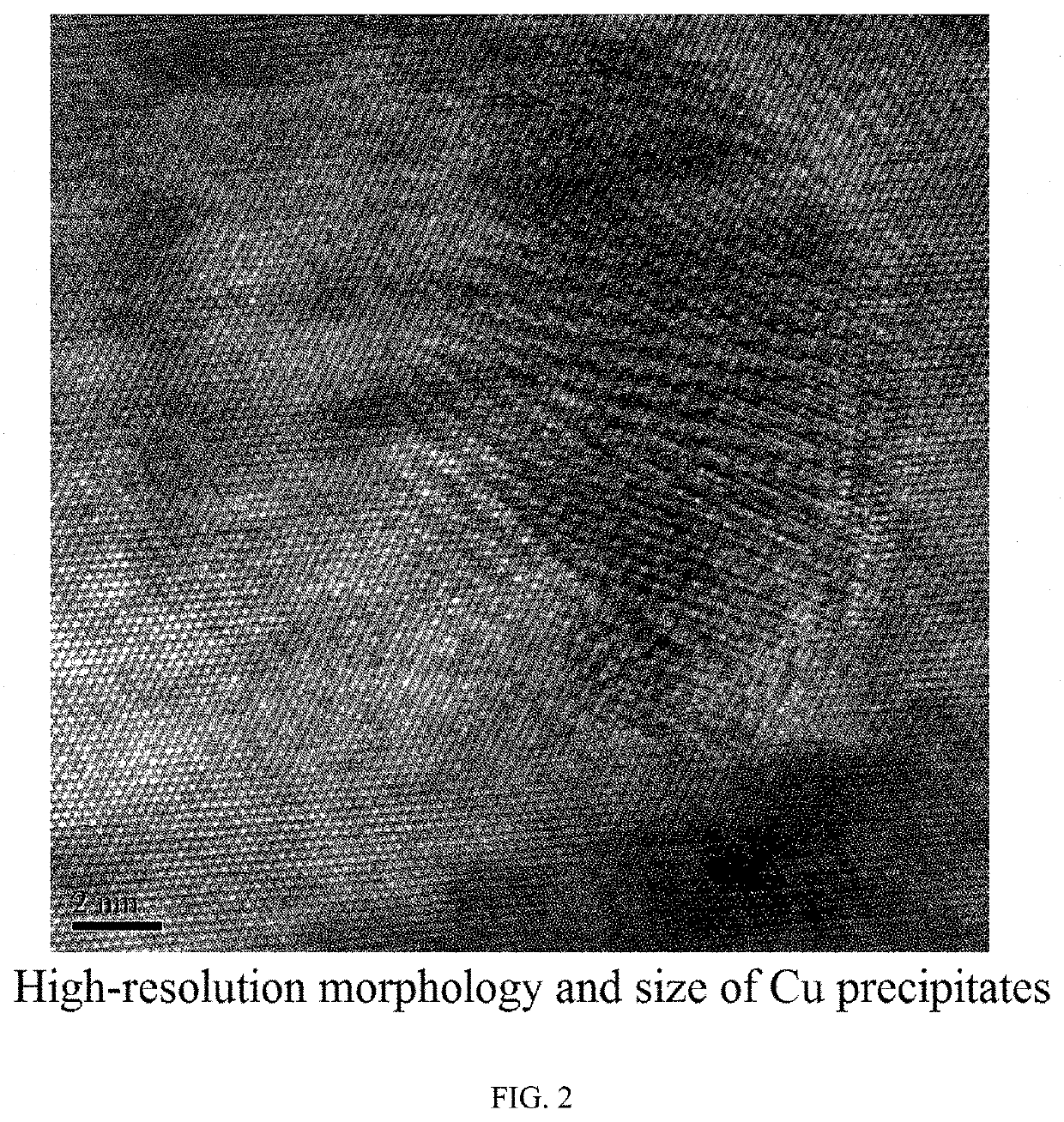

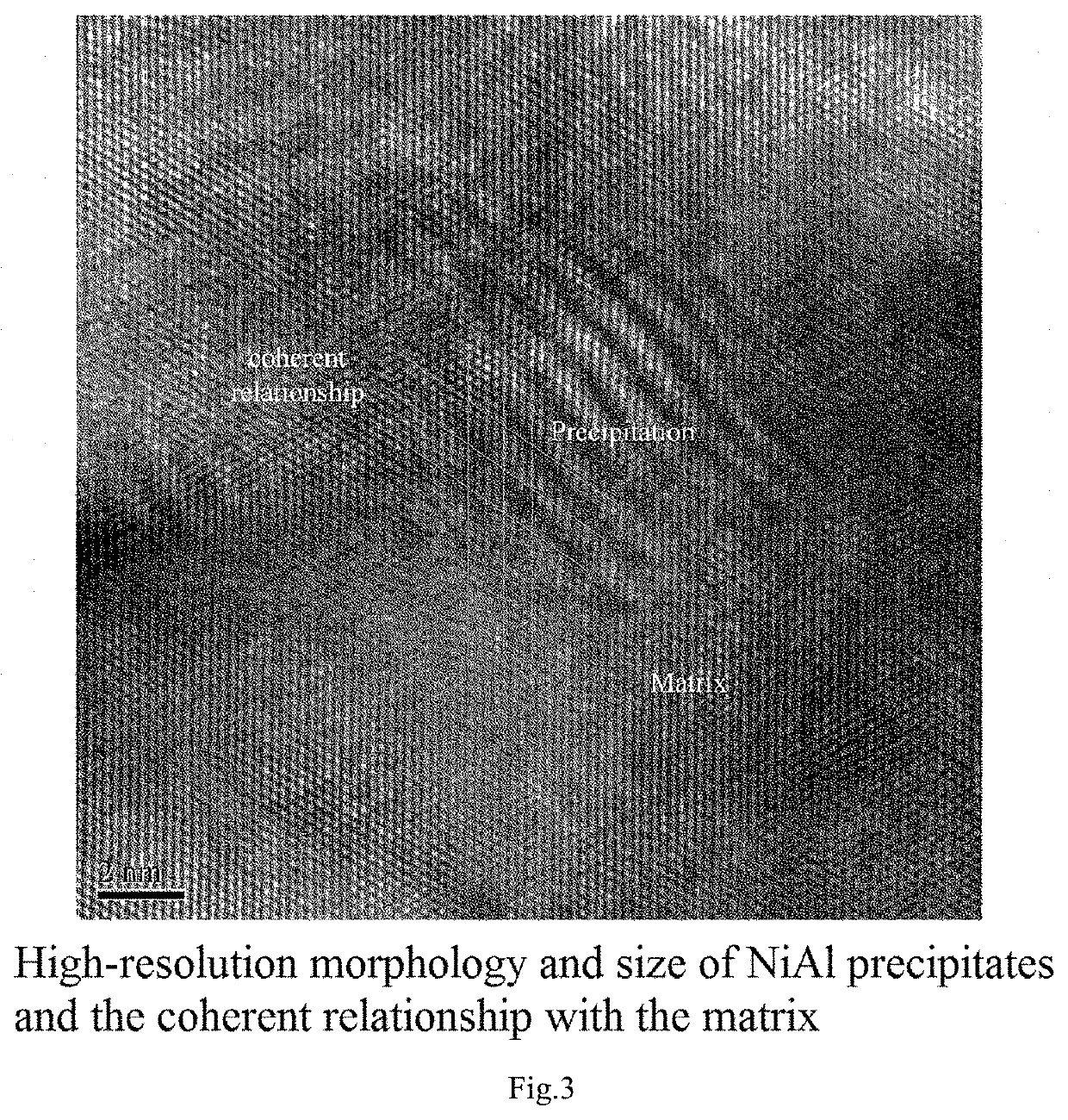

Hot-working die steel, heat treatment method thereof and hot-working die

PendingUS20220162731A1High thermal conductivityIncrease service lifeShaping toolsFurnace typesAlloy elementAlloy composition

Owner:IRONOVATION MATERIALS TECH CO LTD

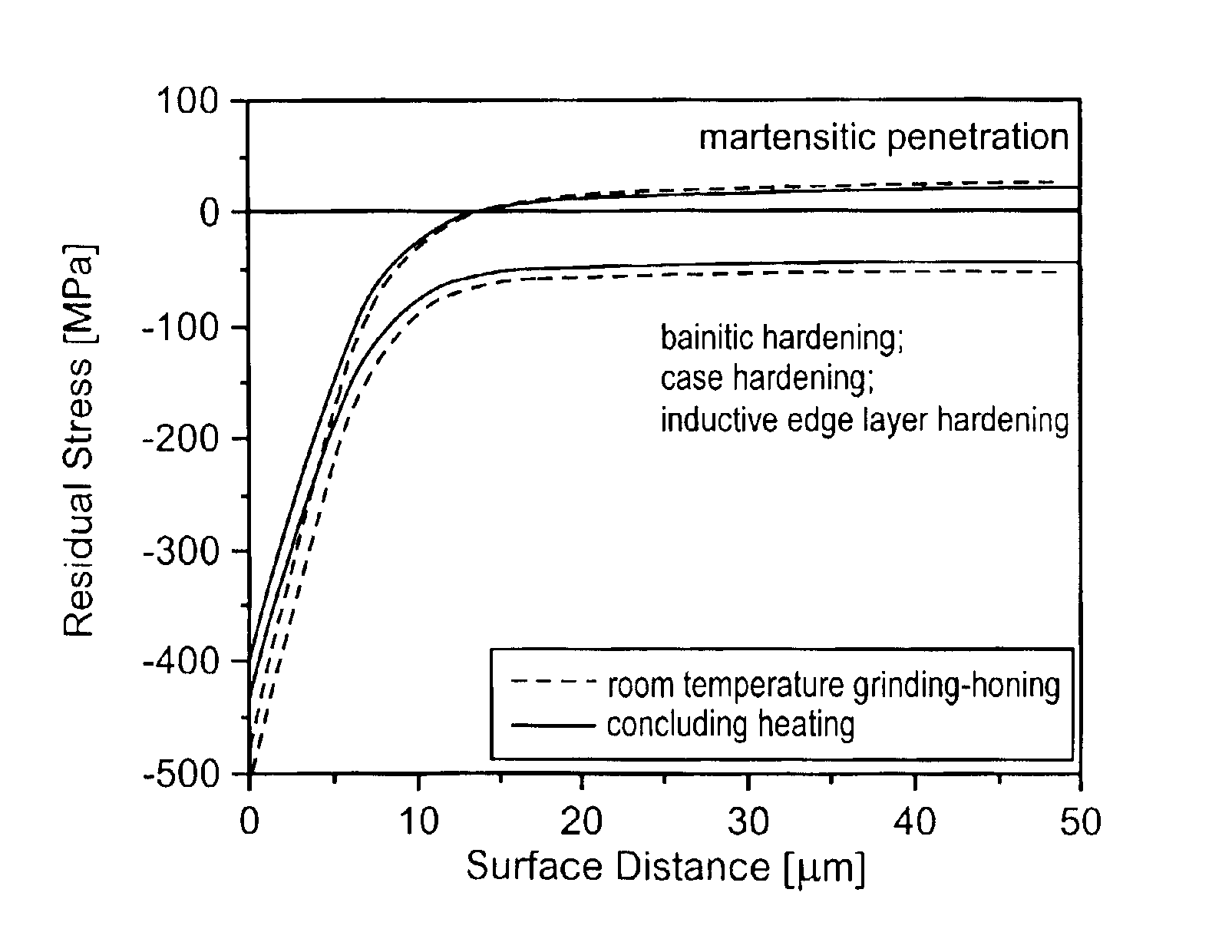

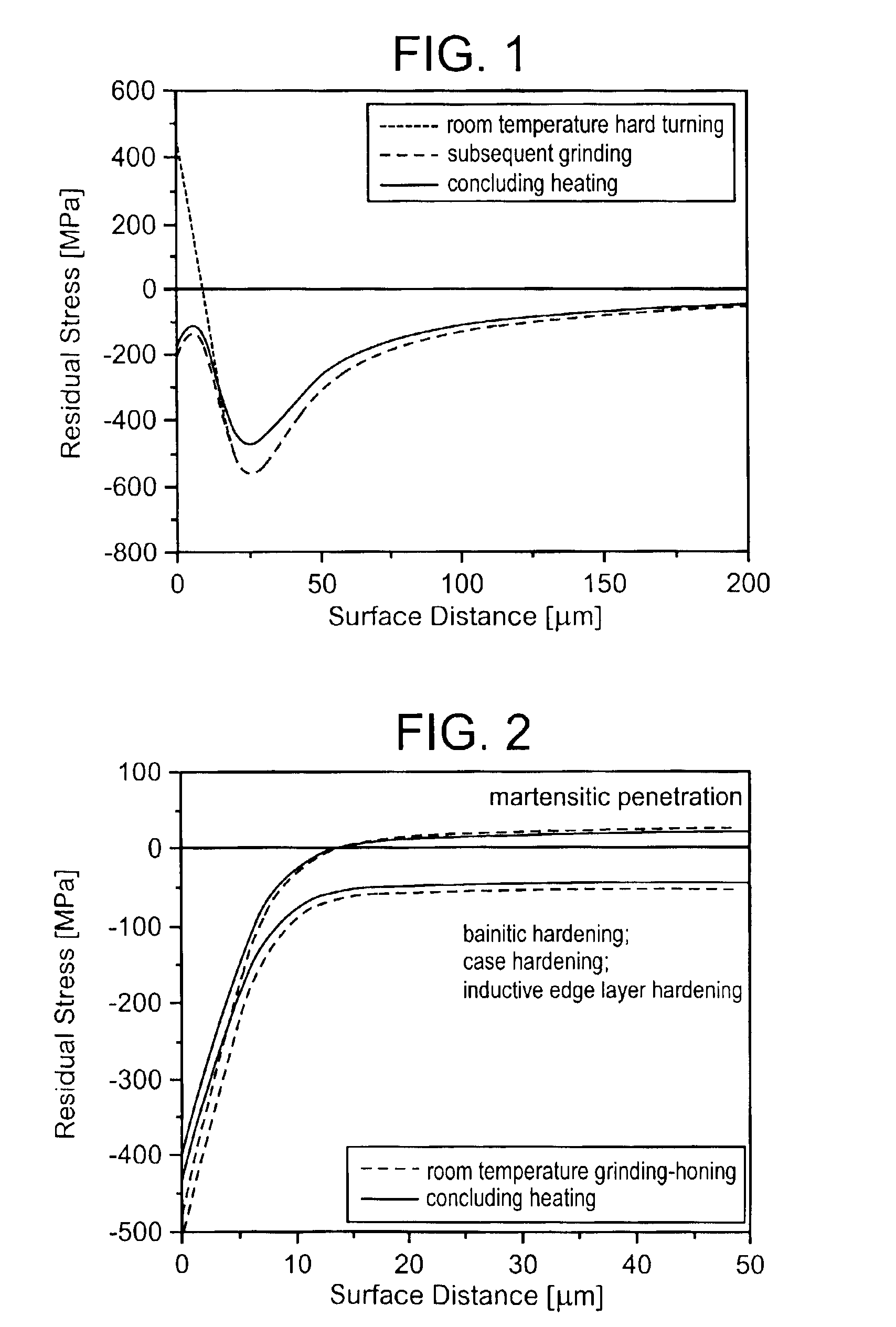

Process for producing a component from metal

ActiveUS7037383B2Increase service lifeIncrease fatigue resistanceShaftsBearing componentsMicrostructureMetal fabrication

A process for producing a component of metal includes a) carrying out a heat treatment to harden the component, which ends with a heating process, especially with a tempering or microstructural transformation process, at a given temperature (TE); b) carrying out at least machining of the component at room temperature (TU) in order to provide its desired geometrical shape; and c) subsequent heating of the component to a temperature (T) which is greater than room temperature (TU).

Owner:AB SKF

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com