Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

221 results about "Metal fabrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal fabrication is the creation of metal structures by cutting, bending and assembling processes. It is a value-added process involving the creation of machines, parts, and structures from various raw materials.

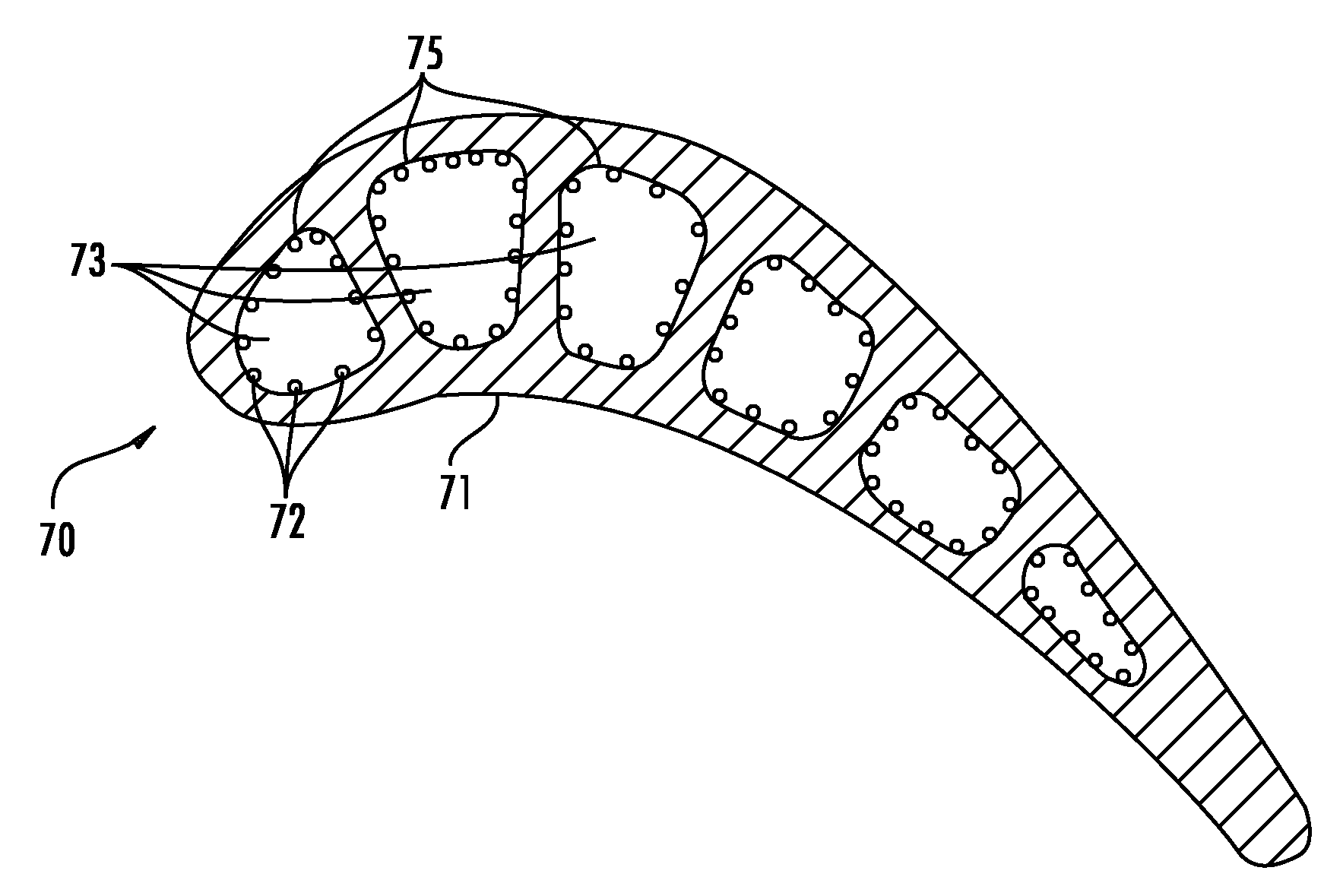

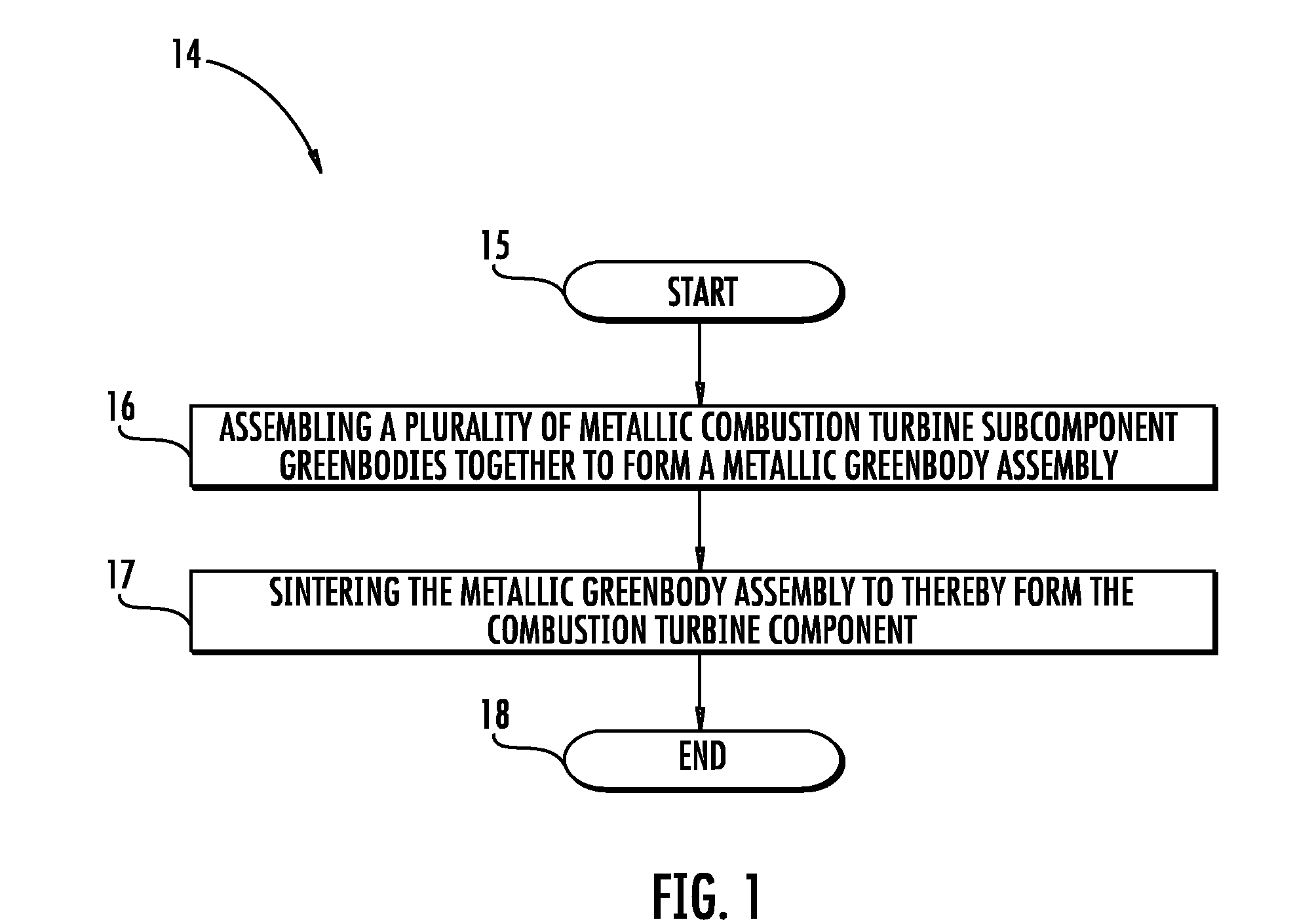

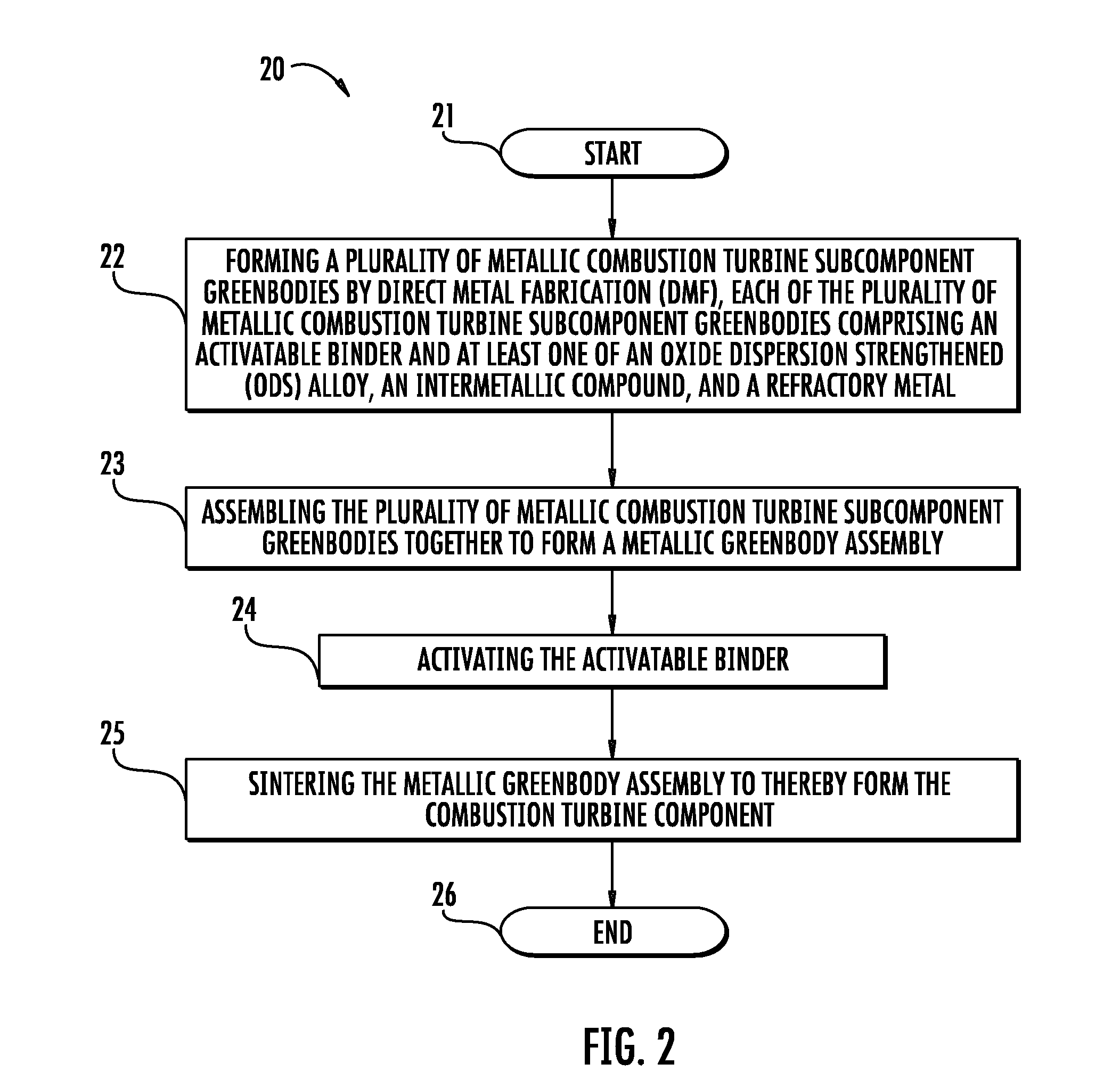

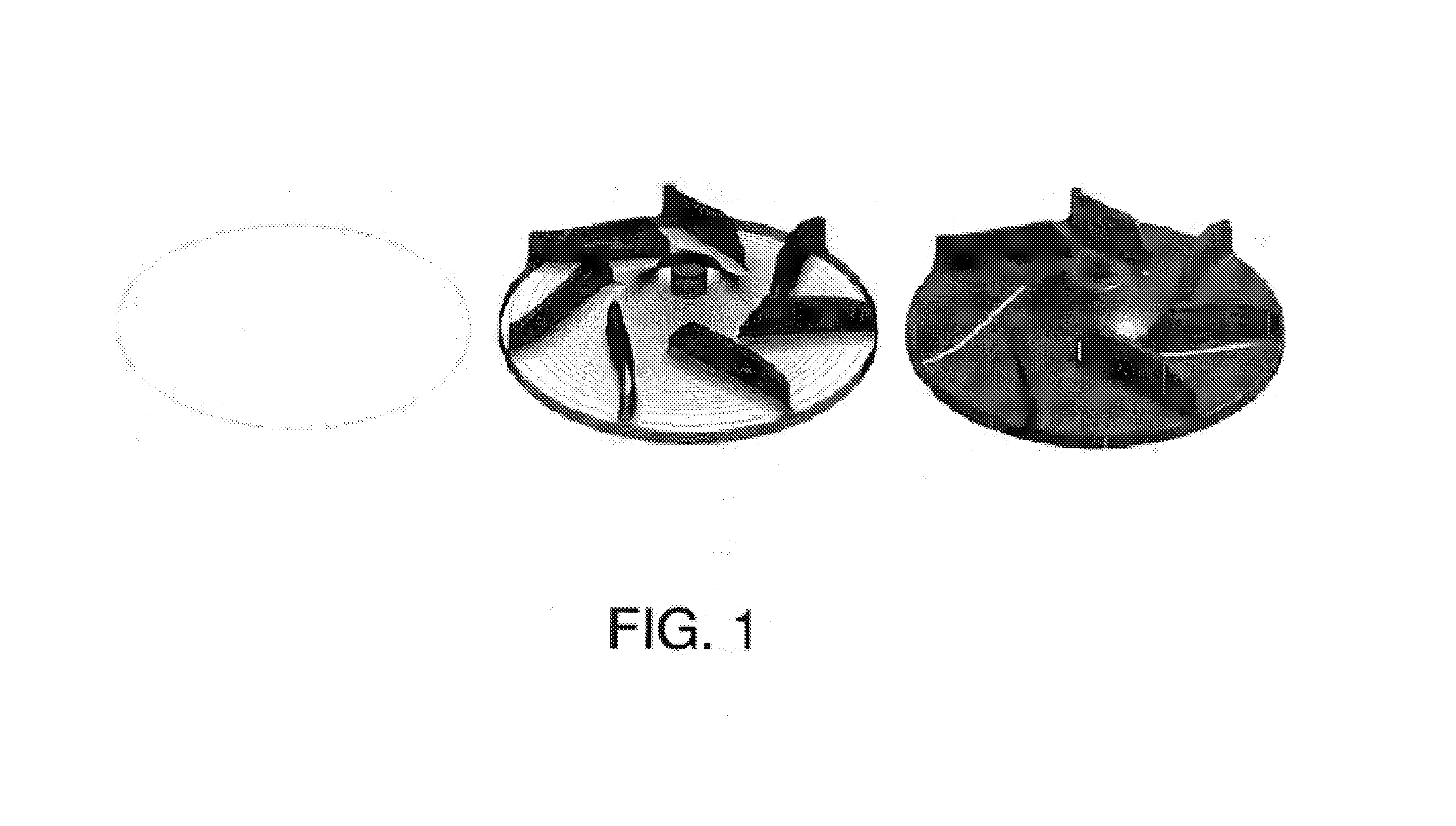

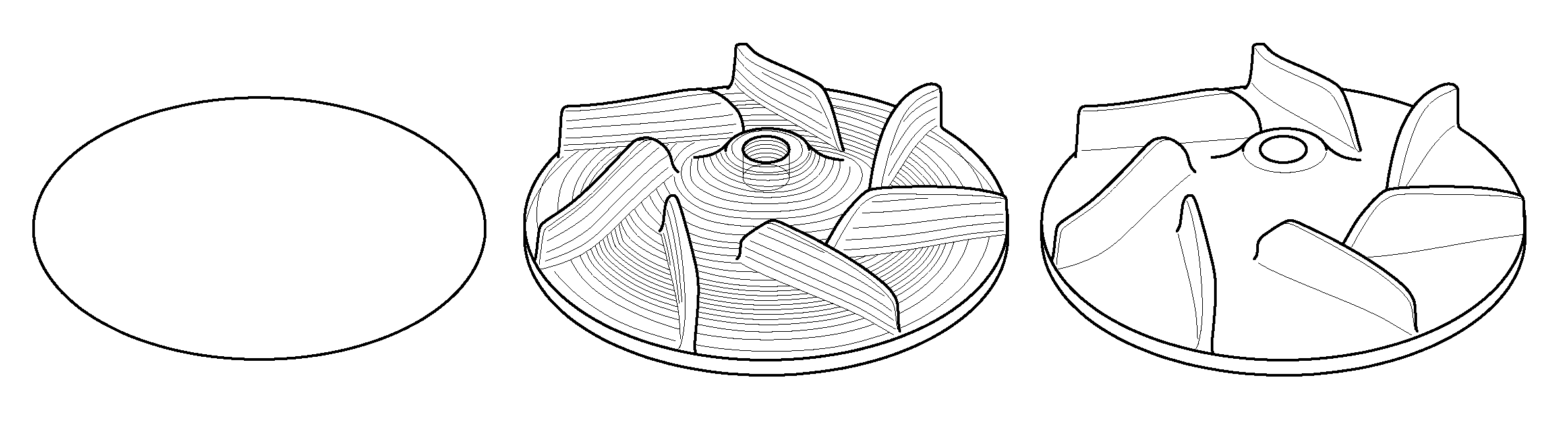

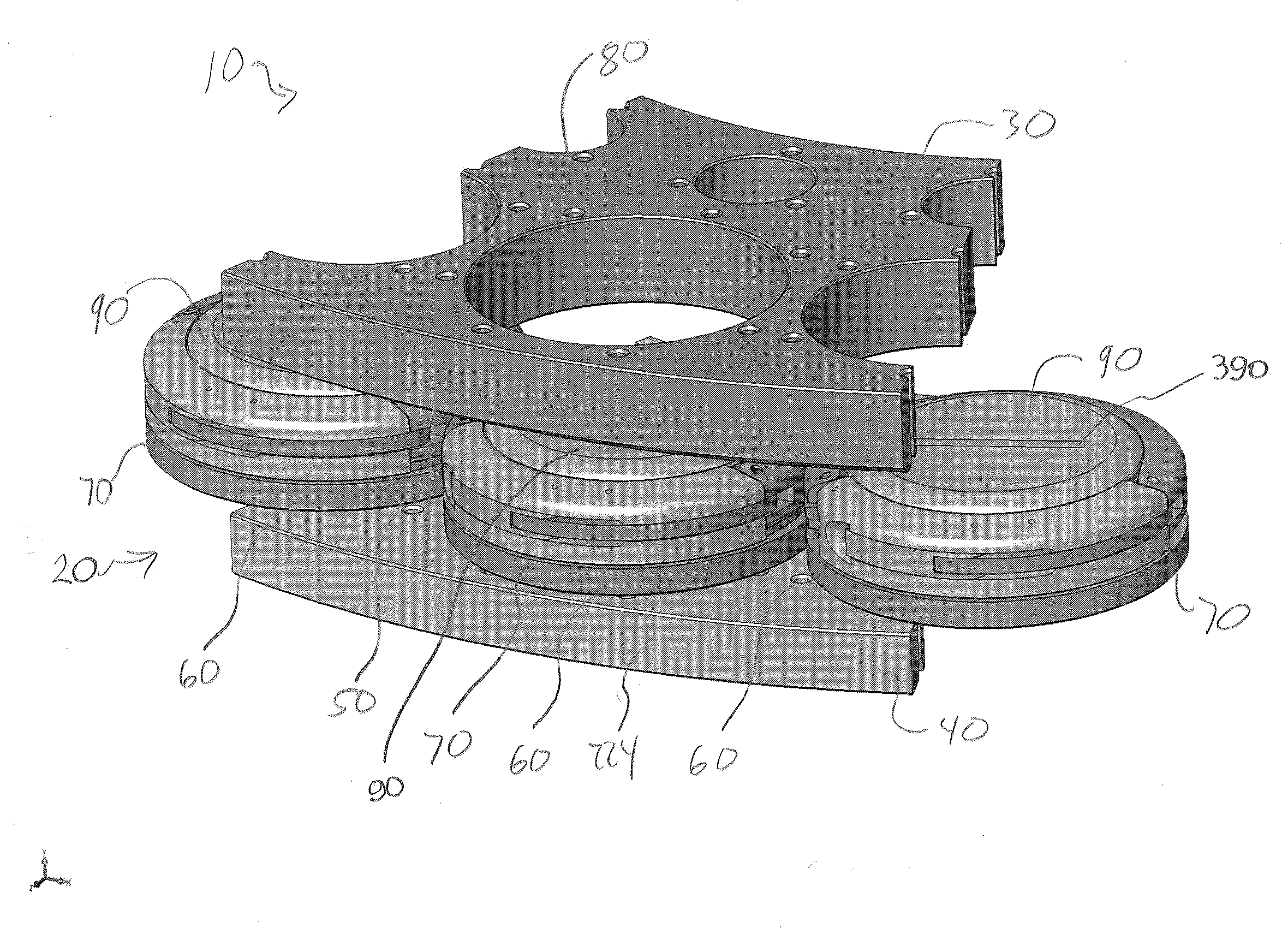

Method of Making a Combustion Turbine Component from Metallic Combustion Turbine Subcomponent Greenbodies

InactiveUS20090183850A1Improve cooling effectHigh temperature resistanceTurbinesAdditive manufacturingCombustionMetal fabrication

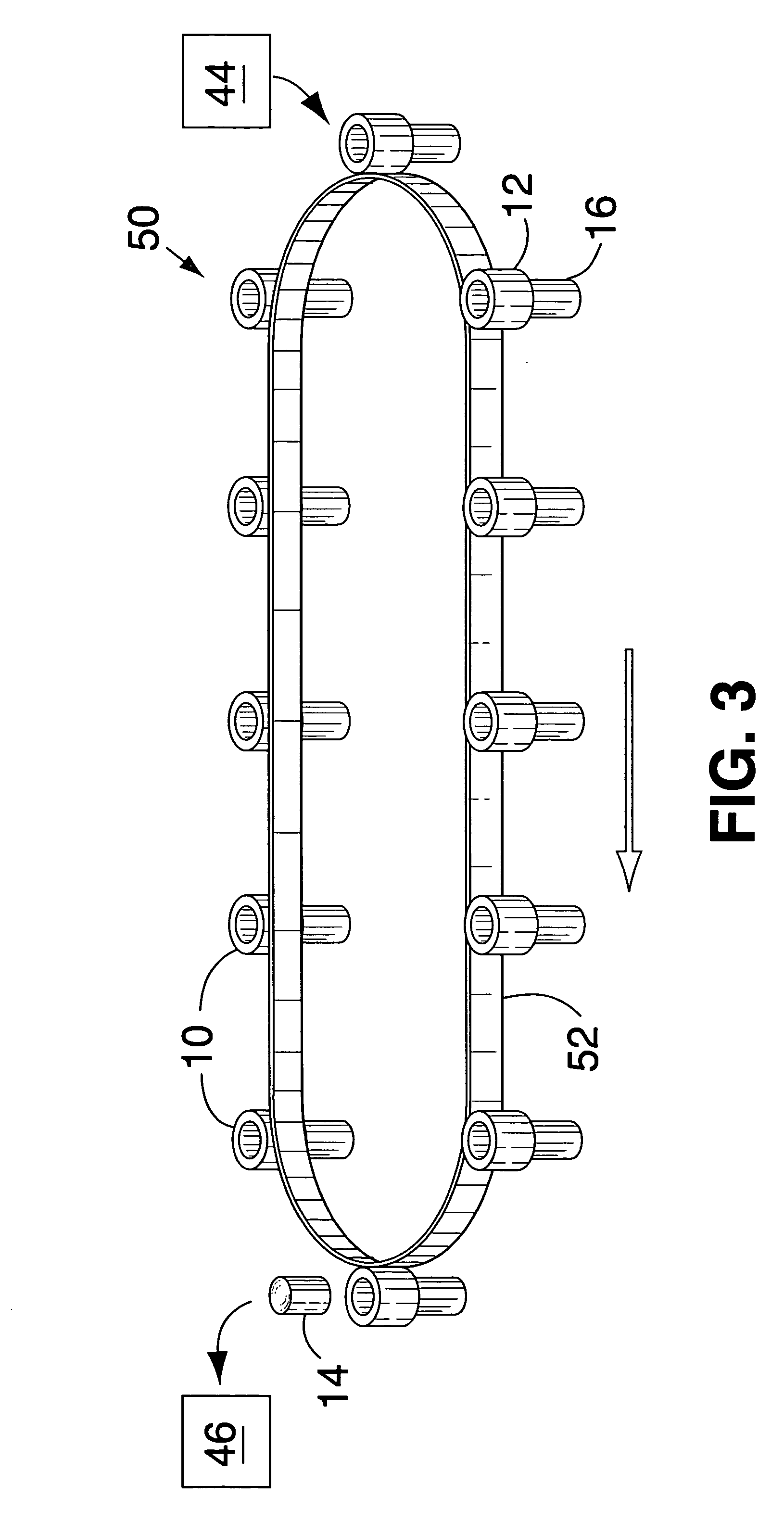

A method of making a combustion turbine component includes assembling a plurality of metallic combustion turbine subcomponent greenbodies together to form a metallic greenbody assembly and sintering the metallic greenbody assembly to thereby form the combustion turbine component. Each of the plurality of metallic combustion turbine subcomponent greenbodies may be formed by direct metal fabrication (DMF). In addition, each of plurality of metallic combustion turbine subcomponent greenbodies may include an activatable binder and the activatable binder may be activated prior to sintering.

Owner:MIKRO SYSYTEMS INC +1

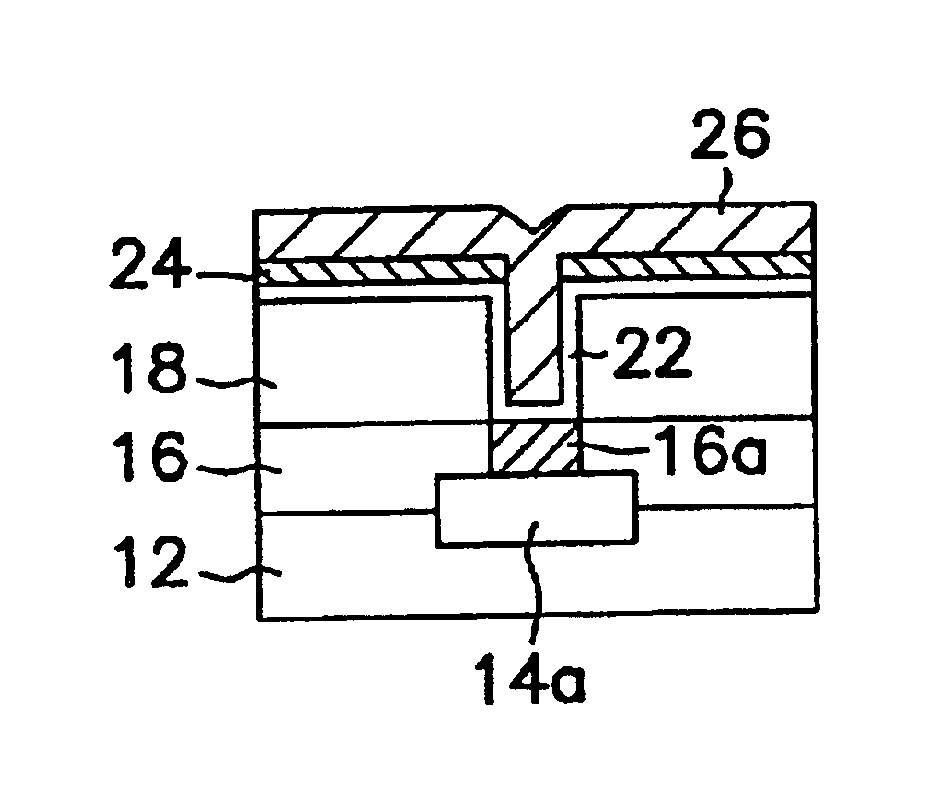

Methods for making copper and other metal interconnections in integrated circuits

InactiveUS6984891B2Increase the cross-sectional areaReduce resistanceSemiconductor/solid-state device detailsSolid-state devicesMetal interconnectAcute angle

A typical integrated-circuit fabrication requires interconnecting millions of microscopic transistors and resistors with aluminum wires. Yet, aluminum wires have greater electrical resistance and are less reliable than copper wires. Unfortunately, current techniques for making copper wires are time-consuming and inefficient. Accordingly, the invention provides a method of making wires or interconnects from copper or other metals. One embodiment entails forming a first diffusion barrier inside a trench using ionized-magnetron sputtering for better conformal coating of the trench, and a second diffusion barrier outside the trench using jet-vapor deposition. The jet-vapor deposition has an acute angle of incidence which prevents deposition within the trench and thus eliminates conventional etching steps that would otherwise be required to leave the trench free of this material. After formation of the two diffusion barriers, the trench is filled with metal and annealed.

Owner:MICRON TECH INC

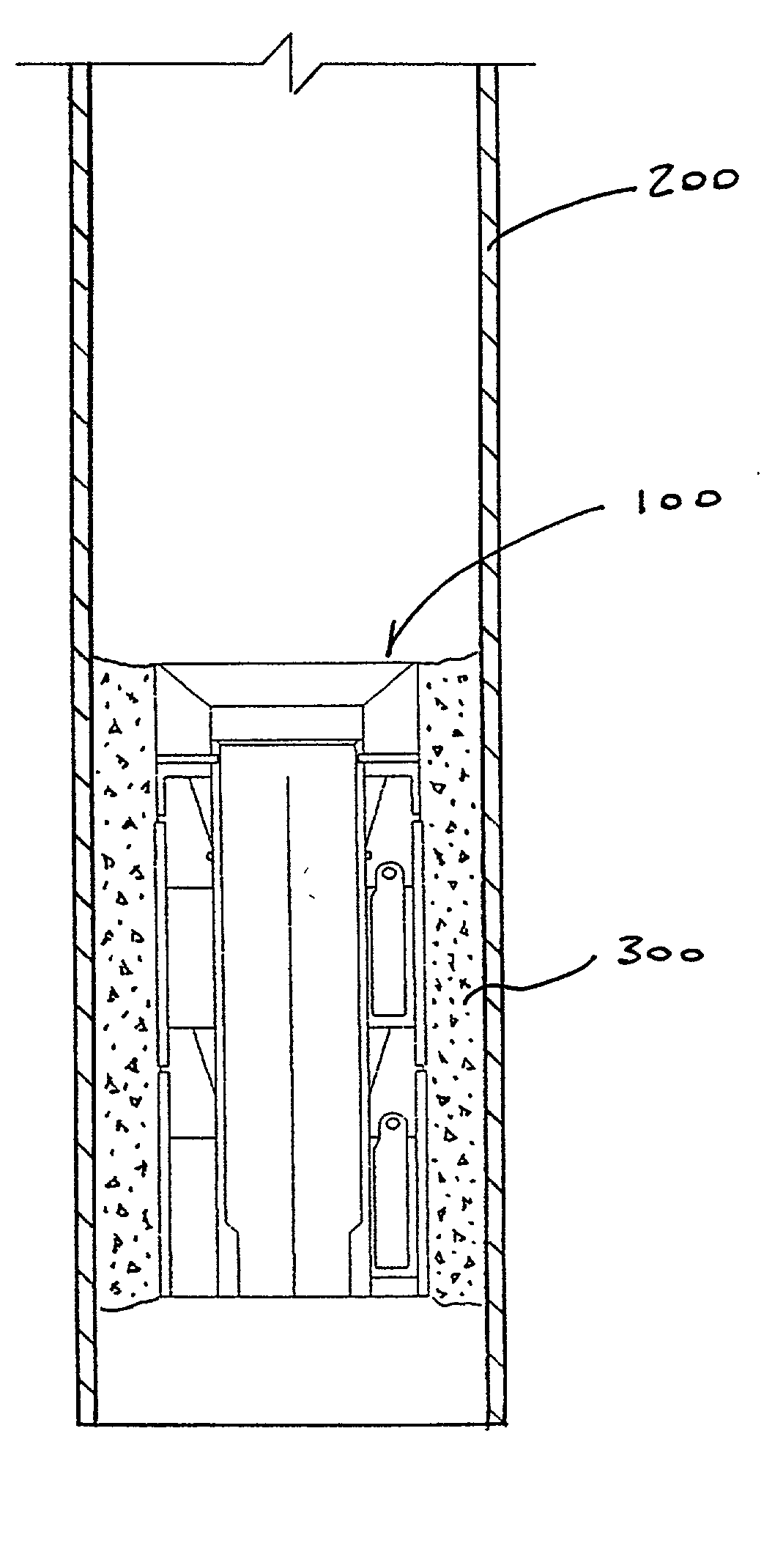

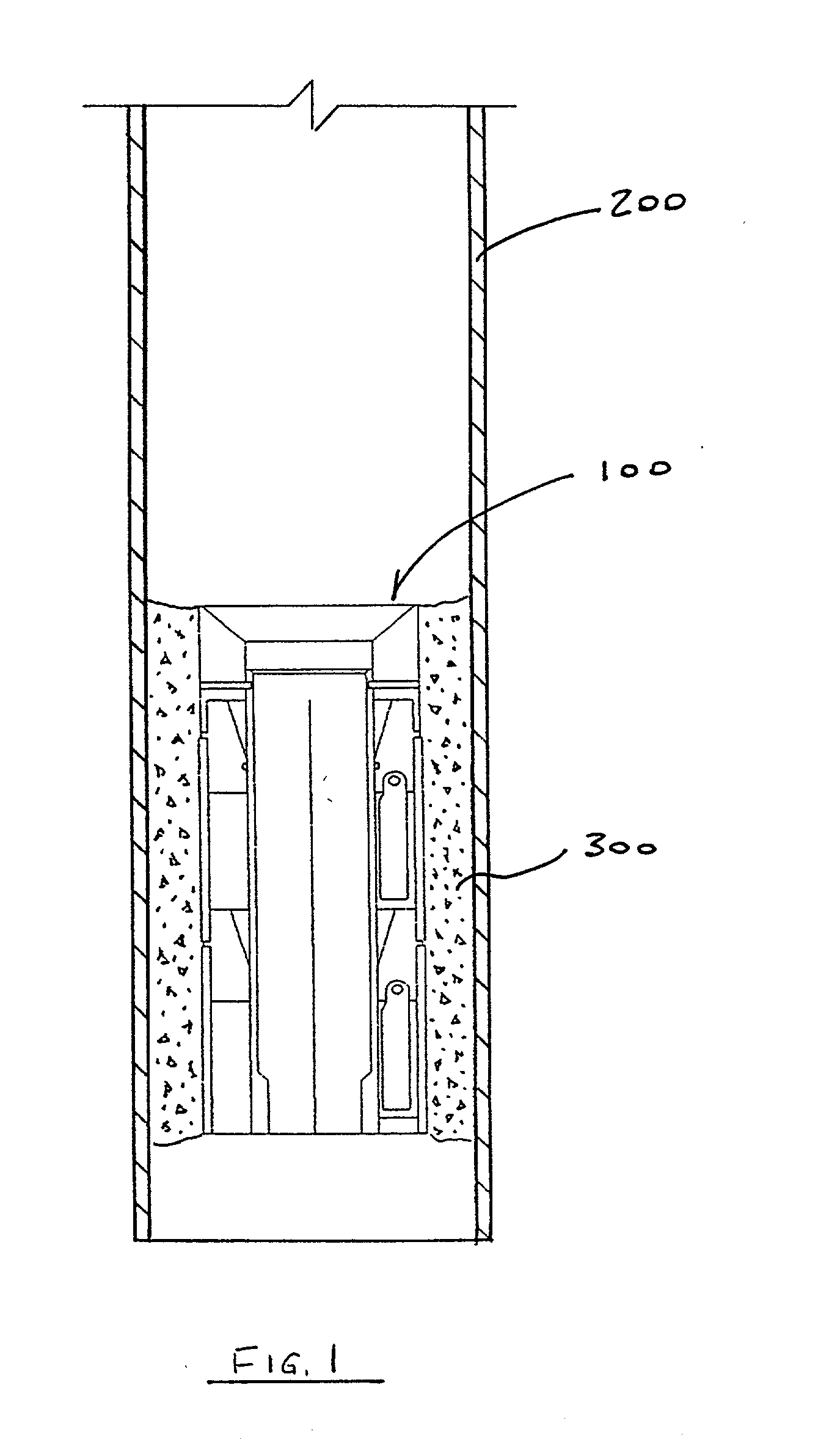

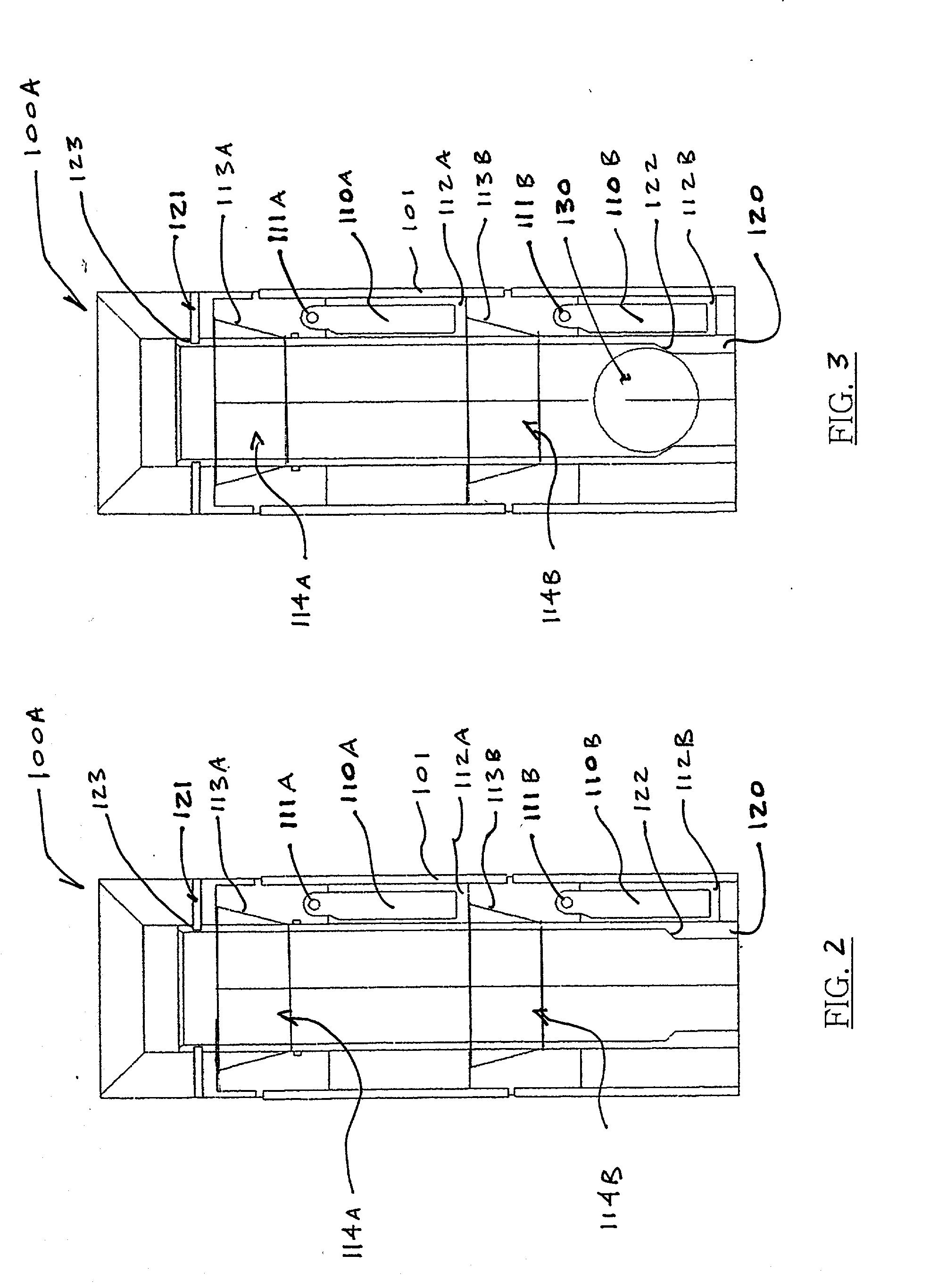

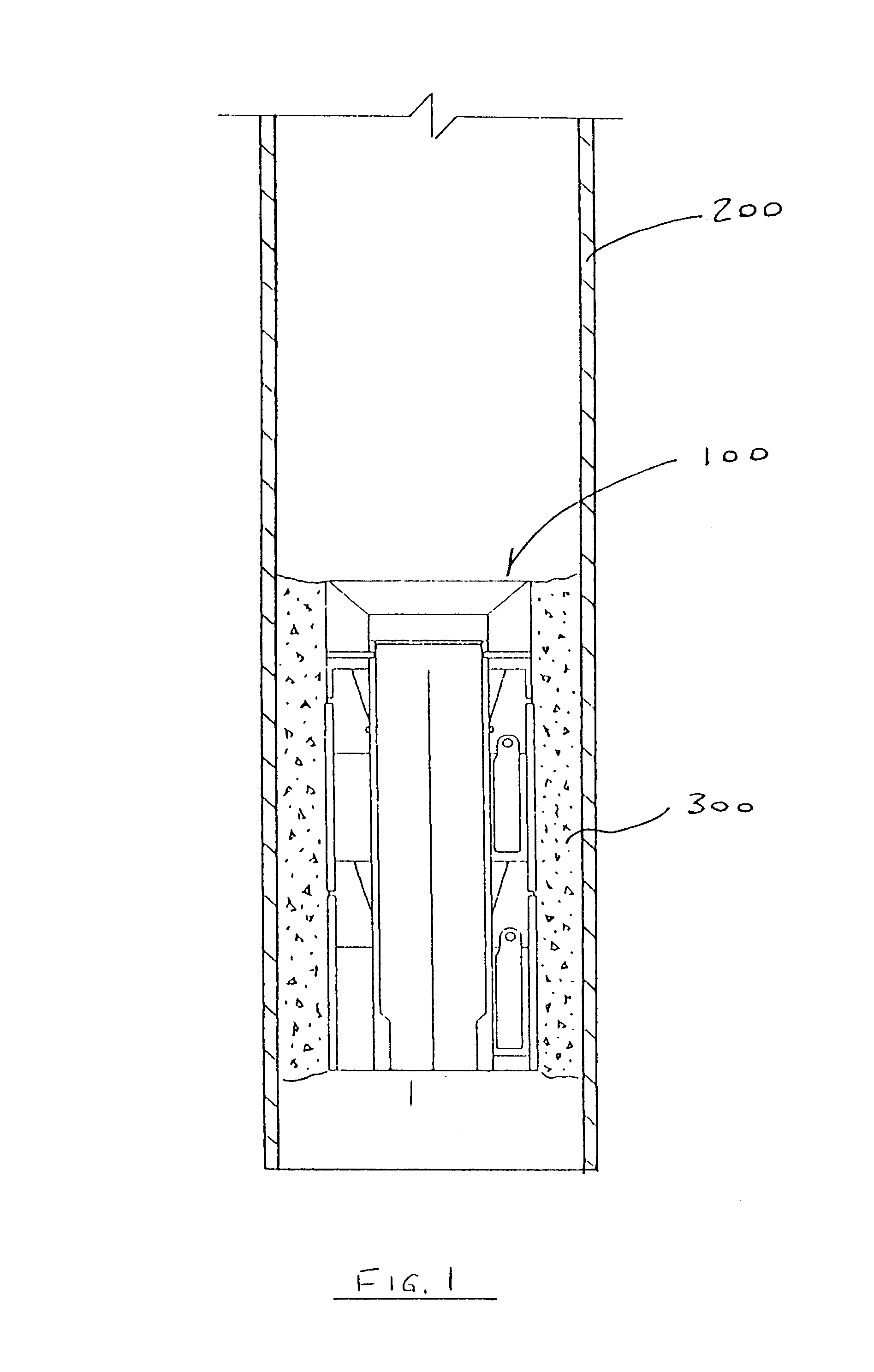

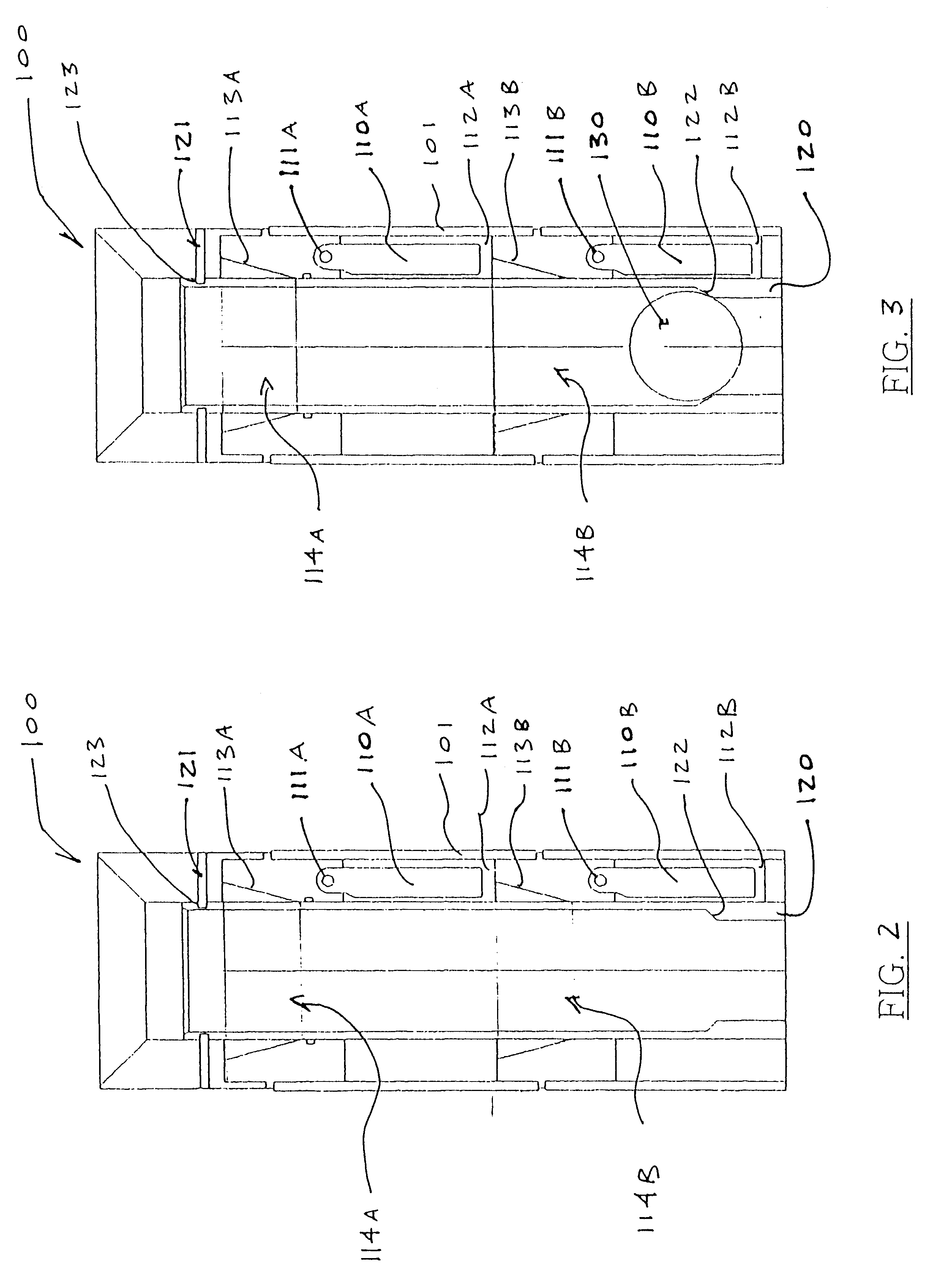

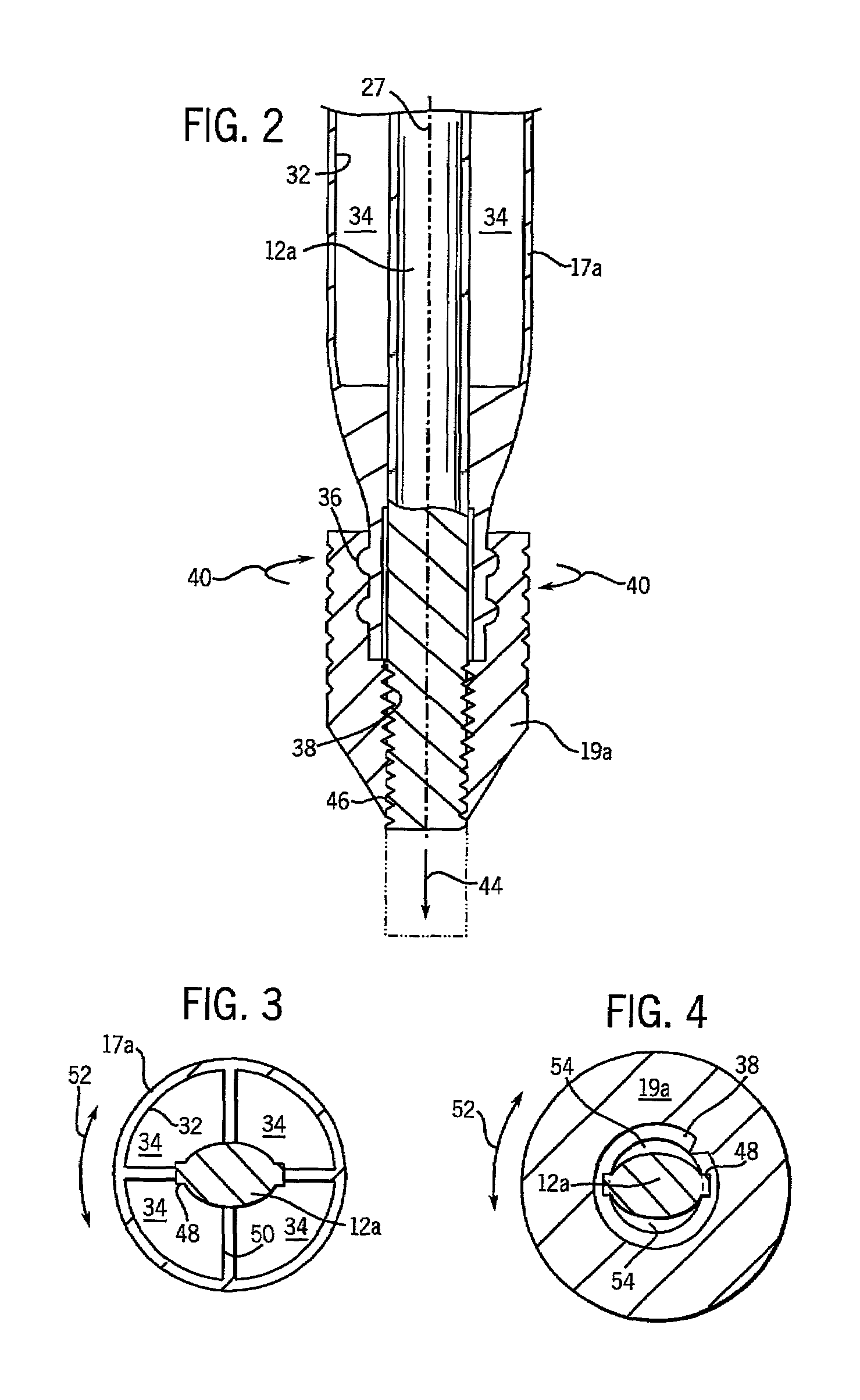

Float collar

The present invention relates to a float collar apparatus for regulating the passage of fluid through a drilling / production liner or sub-sea casing. Apparatus of the present invention is fabricated using plastic flapper valves and valve-actuating sleeve components in contrast to prior art float collar components which are fabricated almost entirely of hard metals. Particularly, the plastic may be nylon, phenolic, or a phenolic-nylon laminate. The use of plastic components in the float collar apparatus of the present invention provides a substantial reduction in time and resources expended during drilling out of the float collar once cementing operations are completed. Additionally, the float collar apparatus of the present invention is fabricated from a pre-determined combination of plastic components and metal components thereby ensuring that the improved float collar can still endure substantial hydrostatic stresses encountered during casing liner running in and cementing operations.

Owner:ALLAMON JERRY P +2

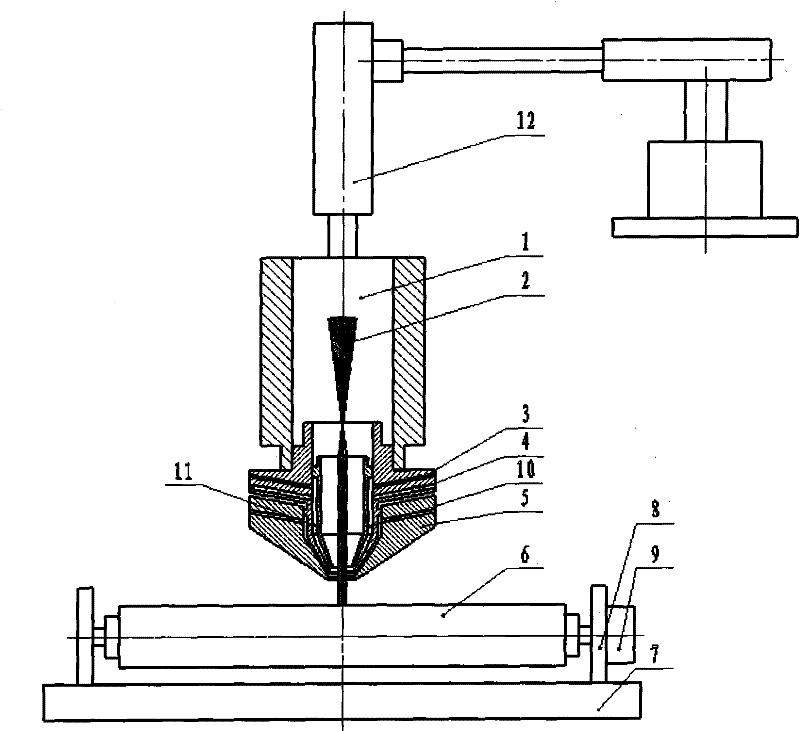

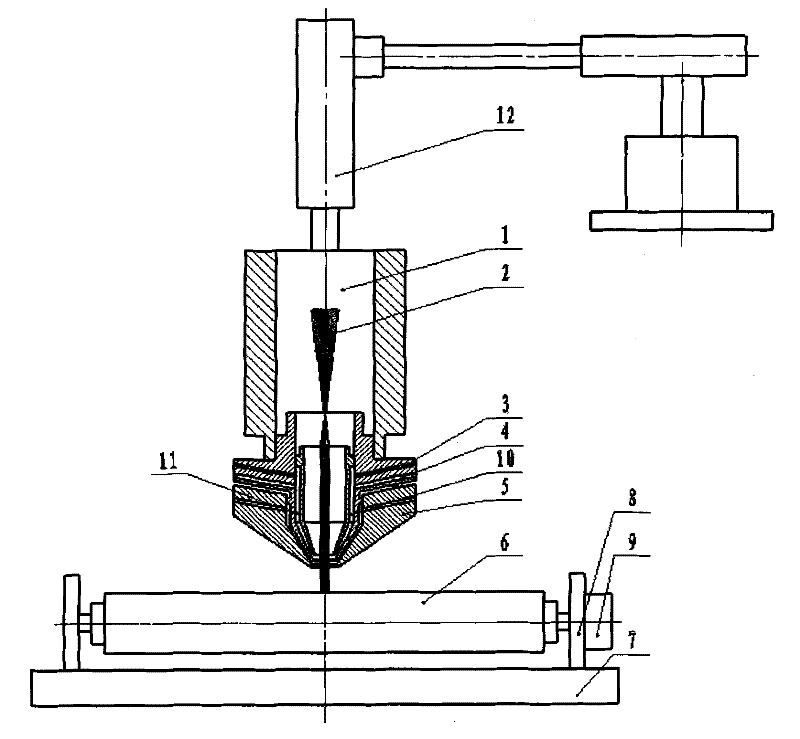

A high-performance composite roll laser injection forming manufacturing and repair method and equipment

InactiveCN102259187AEvenly distributedIncrease the area of actionIncreasing energy efficiencyRollsLaser lightRisk stroke

The invention provides a method and equipment for manufacturing and repairing a high-performance composite roll by laser spray forming, which uses laser spray forming to manufacture the transition layer and the working layer of the roll. It is characterized in that the specific method steps are as follows: A) removing the surface of the core of the roll B) Put the powder of the working layer material and the powder of the roller core into the powder feeding system respectively, and start the laser jet synchronous powder feeding through the surface of the roller whose stroke is controlled by the mechanical arm Direct metal Manufacture the intermediate transition layer of the roll; C) After one layer is deposited, the interlaced deposition is realized by changing the direction of the square spot and the movement direction of the mechanical arm; D) After the transition layer is formed, the spray forming on the surface of the transition layer is completely formed by the added The functional material constitutes the working layer. The invention uses a high-power short-wavelength laser as a processing light source and shapes the light spot of the laser into a rectangle, thereby effectively improving the quality of spray forming and increasing the processing speed.

Owner:周明

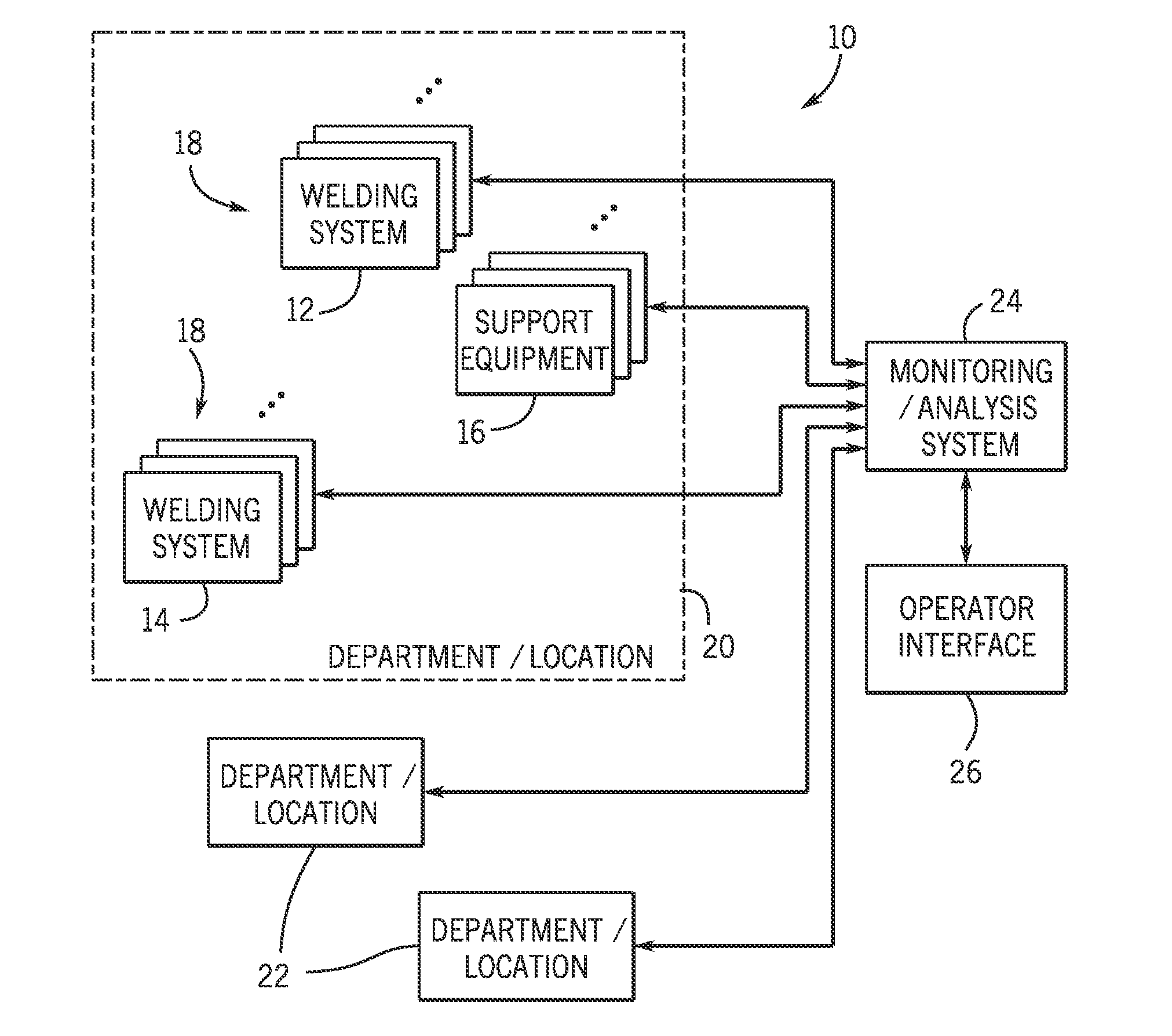

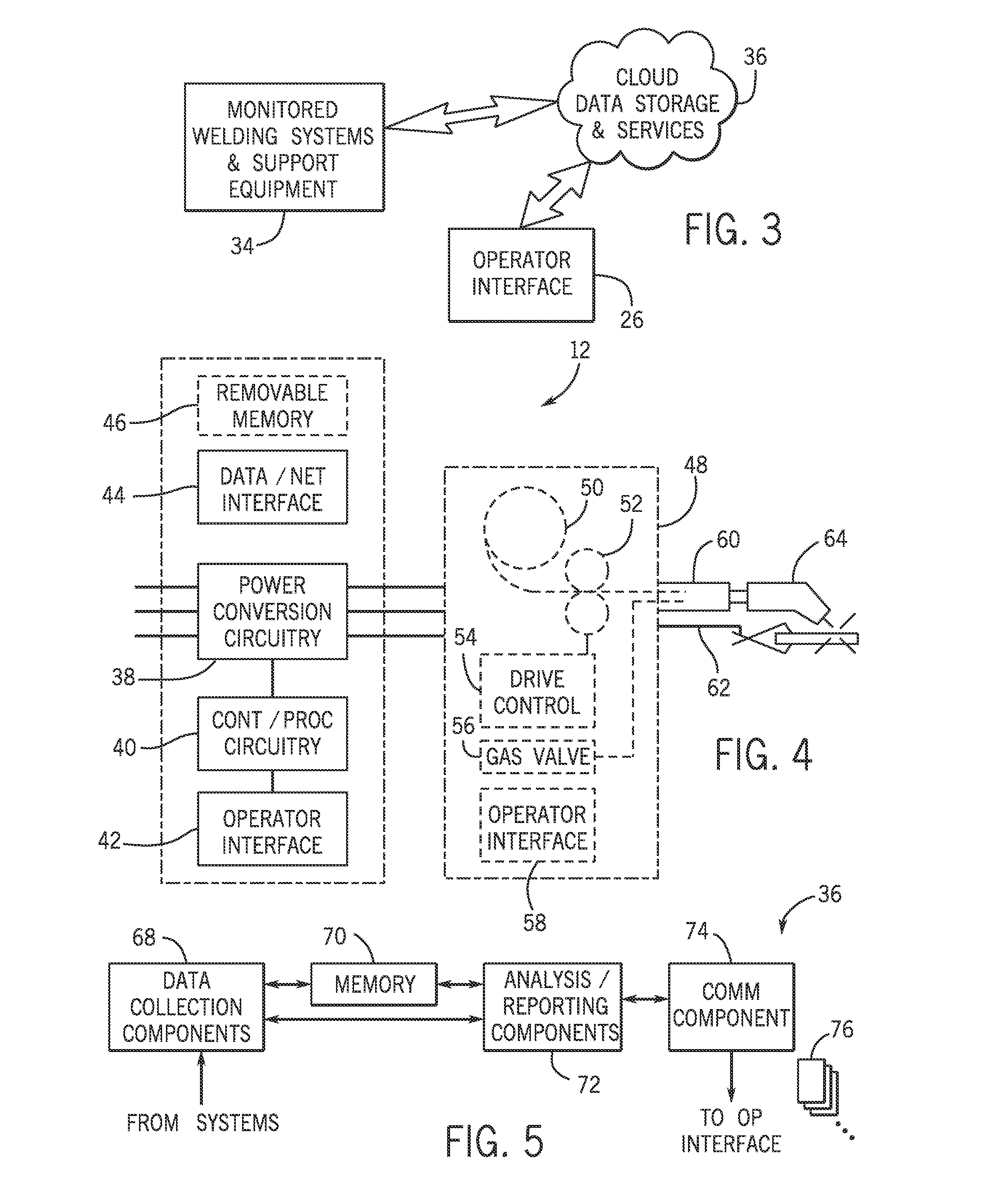

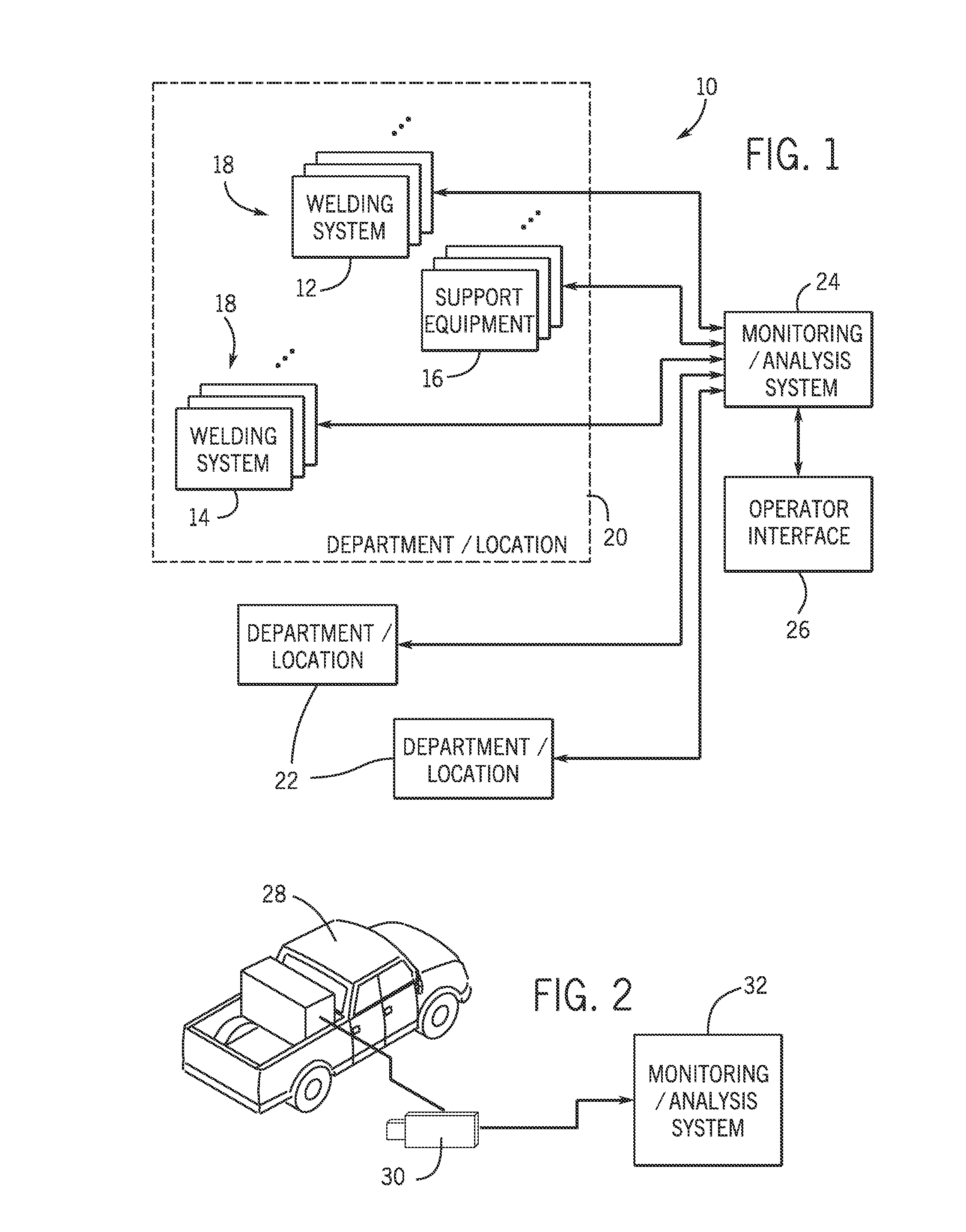

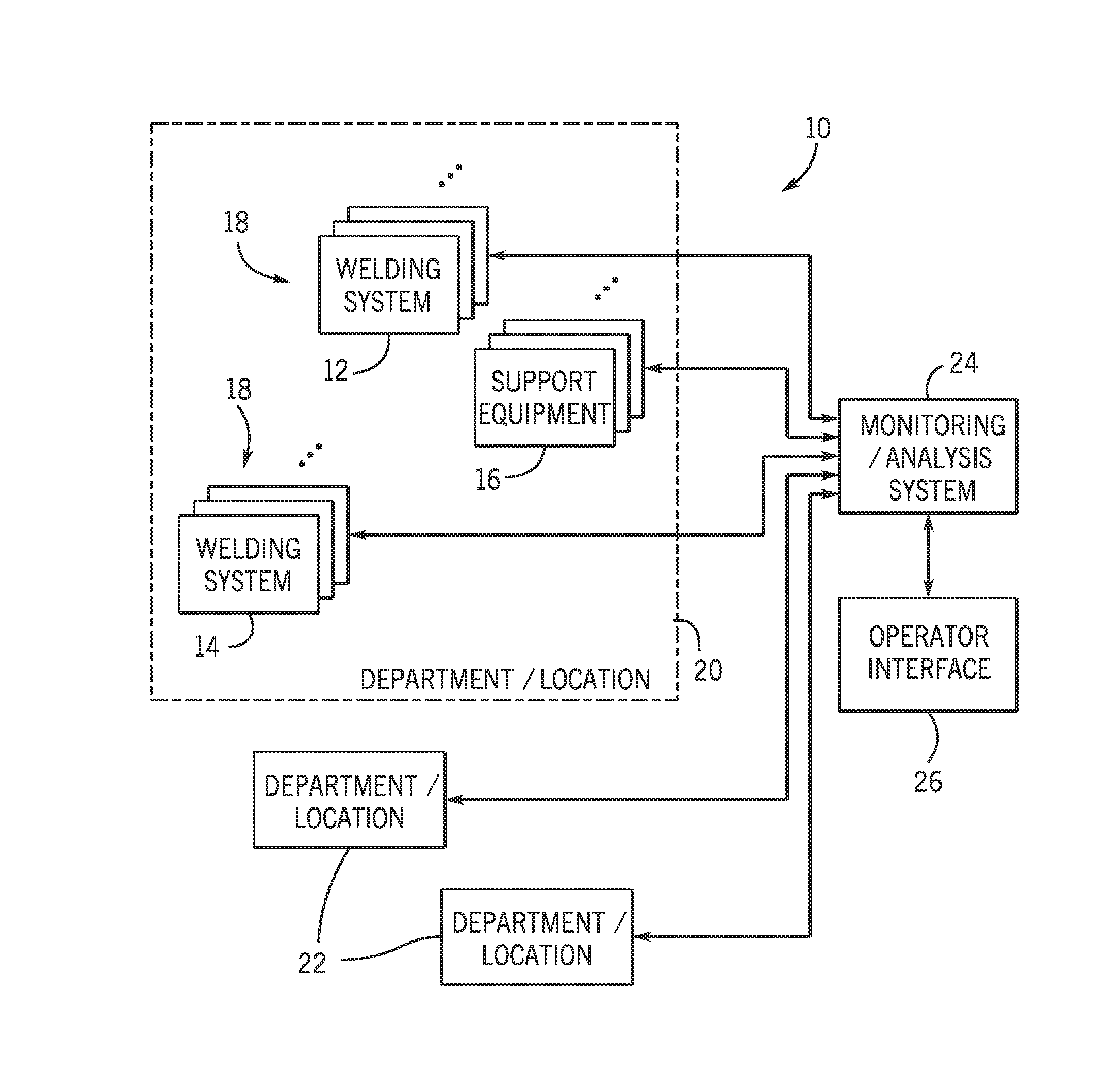

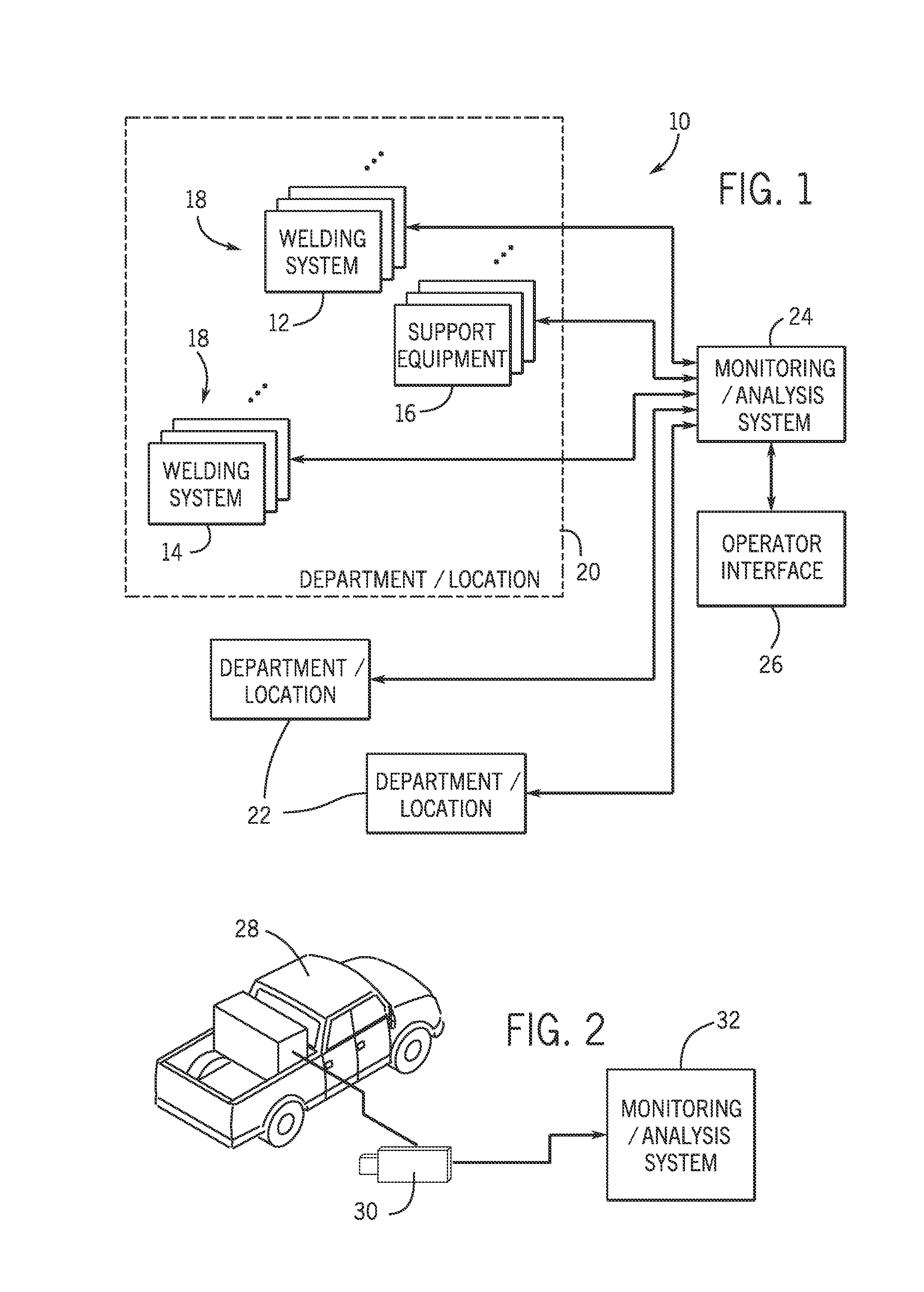

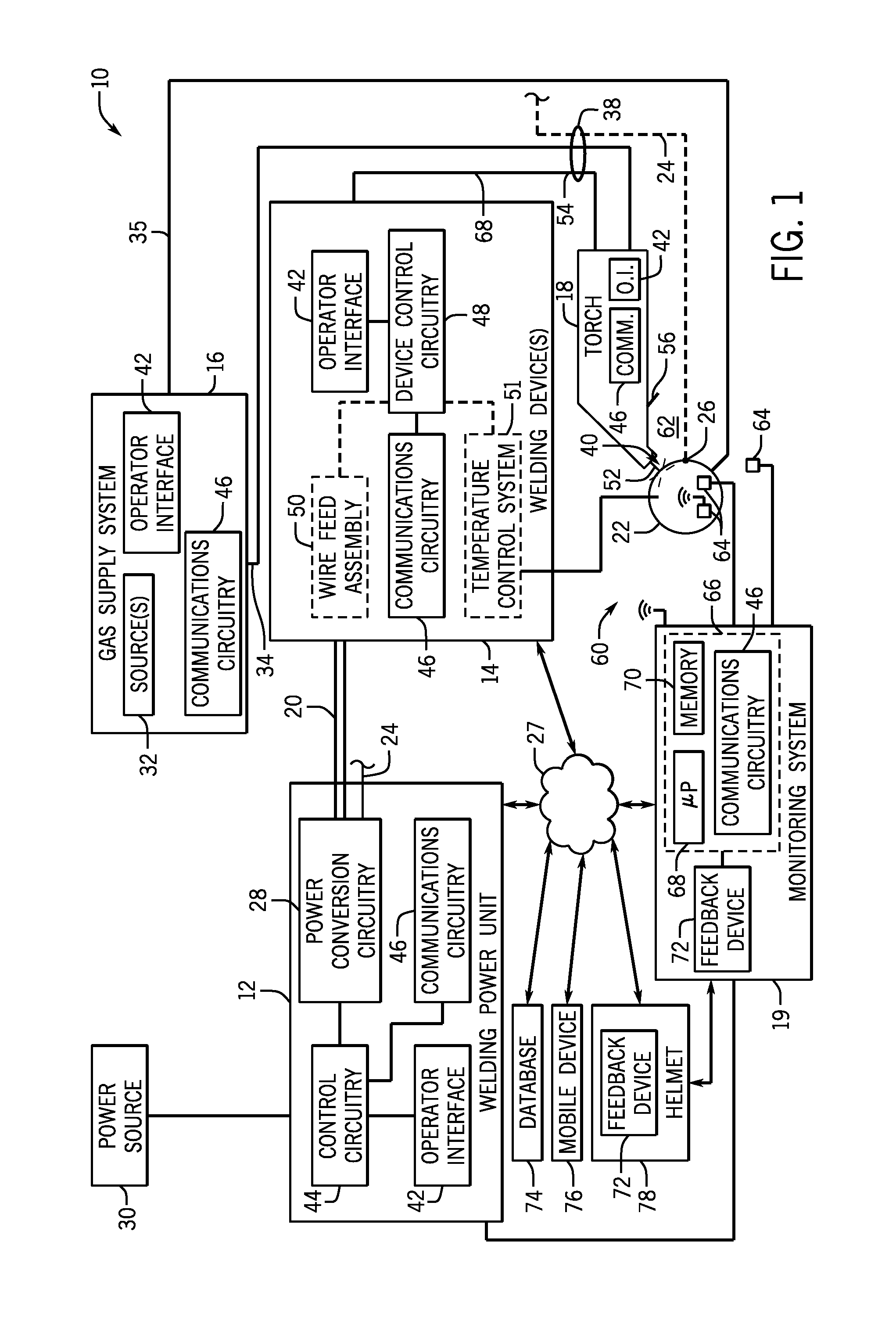

Welding resource tracking and analysis system and method

ActiveUS20140278243A1Testing/monitoring control systemsWelding/cutting auxillary devicesGraphicsEngineering

Metal fabrication systems, such as welding systems and related equipment may be monitored and parameters sensed or calculated during metal fabrication operations. The parameter values are stored and transmitted to a web based analysis system. Sampled values of the parameters are used to generate graphical presentations that are used to populate user viewable pages. The pages may be configured by users, and systems and parameters of interest selected.

Owner:ILLINOIS TOOL WORKS INC

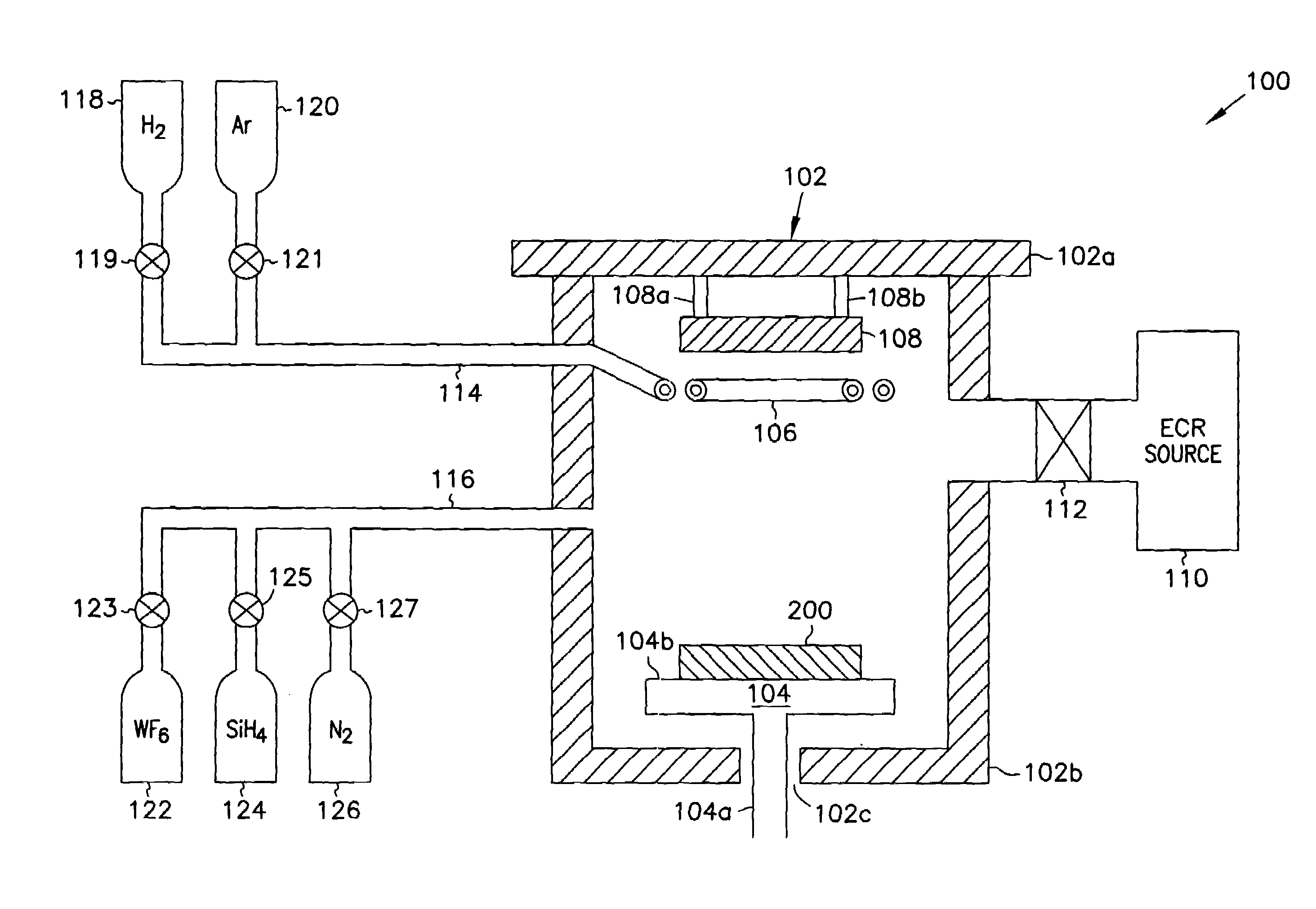

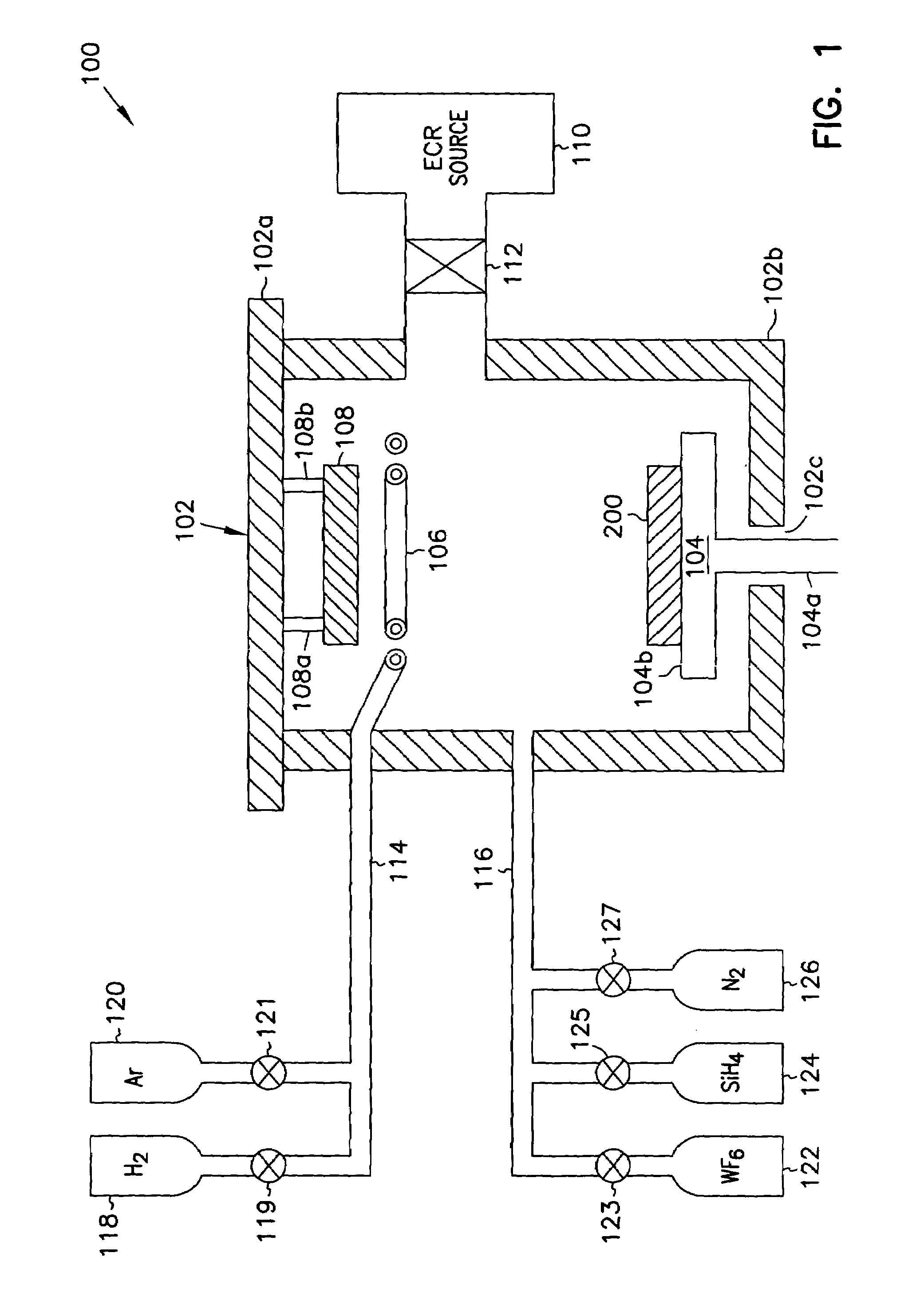

Methods and apparatus for making integrated-circuit wiring from copper, silver, gold, and other metals

InactiveUS7285196B2Promote formationImprove production efficiencyTransistorCellsCopper platingGas phase

In recent years, copper wiring has emerged as a promising substitute for the aluminum wiring in integrated circuits, because copper offers lower electrical resistance and better reliability at smaller dimensions than aluminum. However, use of copper typically requires forming a diffusion barrier to prevent contamination of other parts of an integrated circuit and forming a seed layer to facilitate copper plating steps. Unfortunately, conventional methods of forming the diffusion barriers and seed layers require use of separate wafer-processing chambers, giving rise to transport delays and the introduction of defect-causing particles. Accordingly, the inventors devised unique wafer-processing chambers and methods of forming barrier and seed layers. One embodiment of the wafer-processing chamber includes equipment for physical vapor deposition and equipment for chemical vapor deposition to facilitate formation of diffusion barriers and seed layers within one chamber, thereby promoting fabrication efficiency and reducing defects.

Owner:ROUND ROCK RES LLC

Welding resource performance goal system and method

Metal fabrication systems and related equipment may be monitored by collecting and transmitting parameter data relating to welding operations to a memory and processing system. Goals for selected parameters may be pre-defined, and certain of these may be standard for corresponding welding systems, locations, operations, operators, and so forth. Upon request a web based report is generated and delivered to a user that indicates the system or systems, comparisons of the actual system performance versus the goals, time periods for the comparisons, and so forth.

Owner:ILLINOIS TOOL WORKS INC

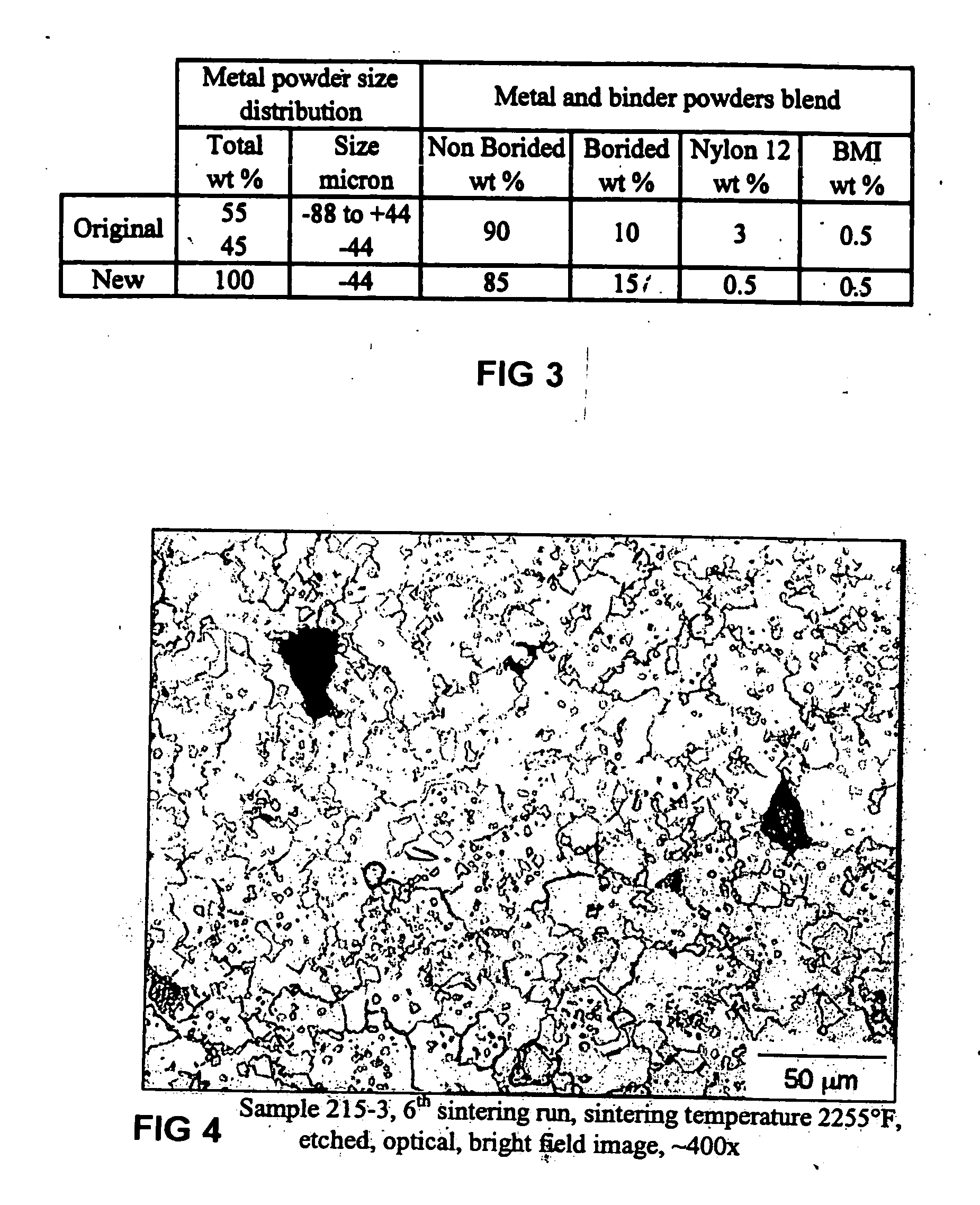

Method and composition for metal free form fabrication

InactiveUS20050191200A1Additive manufacturing apparatusTransportation and packagingSelective laser sinteringPowder mixture

A method of direct metal fabrication to form a metal part which has a relative density of at least 96%. There is provided a powder blend which comprises a parent metal alloy, a powdered lower-melting-temperature alloy that comprises greater than 10% of total weight of the powder blend, and an organic polymer component (a thermoplastic polymer and a thermosetting polymer) that comprises less than 3% by weight of a total weight of the powdered blend. There is a laser-build powder processing operation (a selective laser sintering (SLS) operation) to fabricate a green body. The green body is then placed in a furnace and the temperature raised to sufficiently high temperature to perform a supersolidus liquid phase sintering operation to form the metal part.

Owner:THE BOEING CO +1

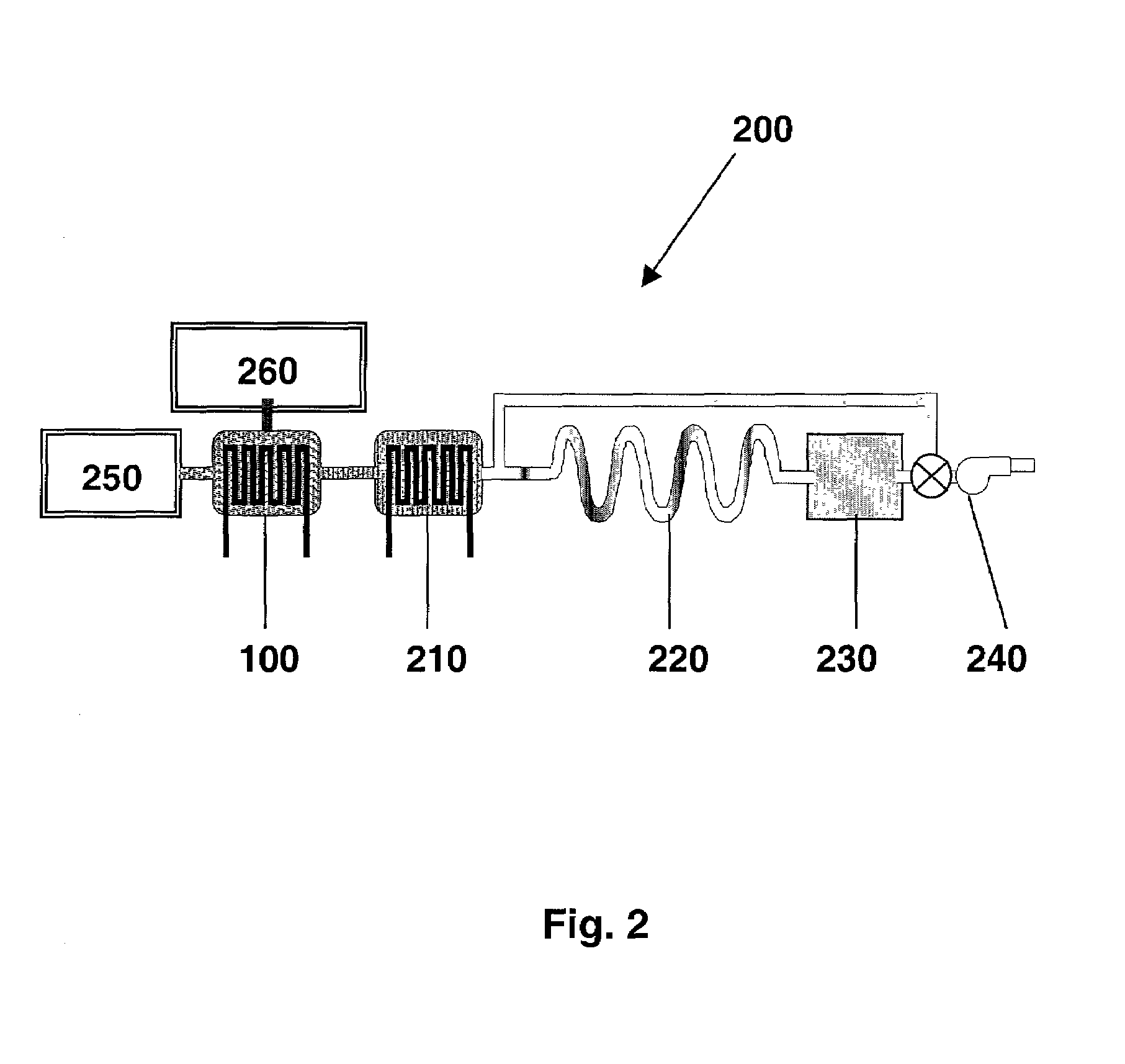

Micropyrolyzer for chemical analysis of liquid and solid samples

InactiveUS7078237B1Chemical analysis using combustionParticle separator tubesSemiconductor materialsField analysis

A micropyrolyzer has applications to pyrolysis, heated chemistry, and thermal desorption from liquid or solid samples. The micropyrolyzer can be fabricated from semiconductor materials and metals using standard integrated circuit technologies. The micropyrolyzer enables very small volume samples of less than 3 microliters and high sample heating rates of greater than 20° C. per millisecond. A portable analyzer for the field analysis of liquid and solid samples can be realized when the micropyrolyzer is combined with a chemical preconcentrator, chemical separator, and chemical detector. Such a portable analyzer can be used in a variety of government and industrial applications, such as non-proliferation monitoring, chemical and biological warfare detection, industrial process control, water and air quality monitoring, and industrial hygiene.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

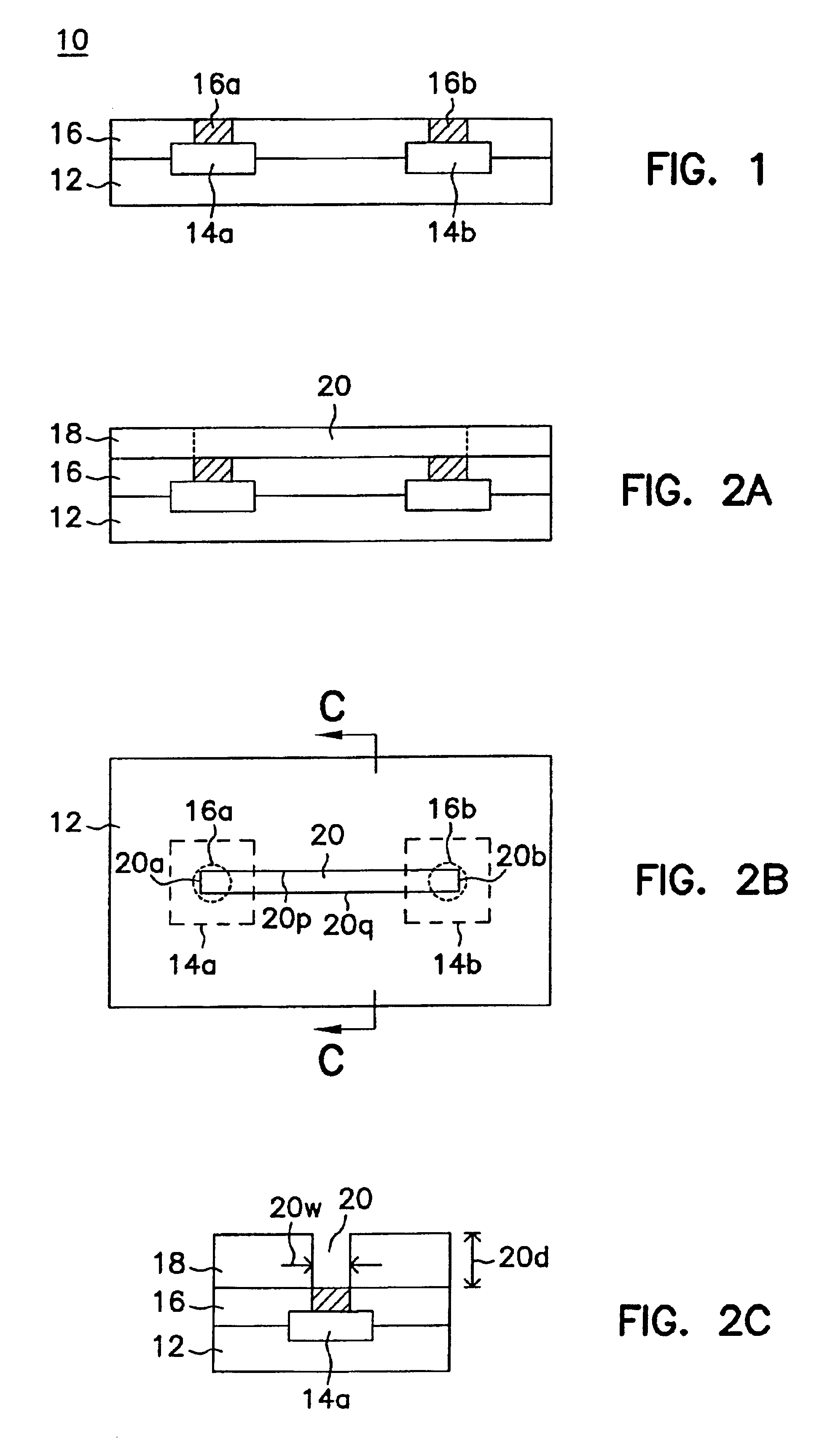

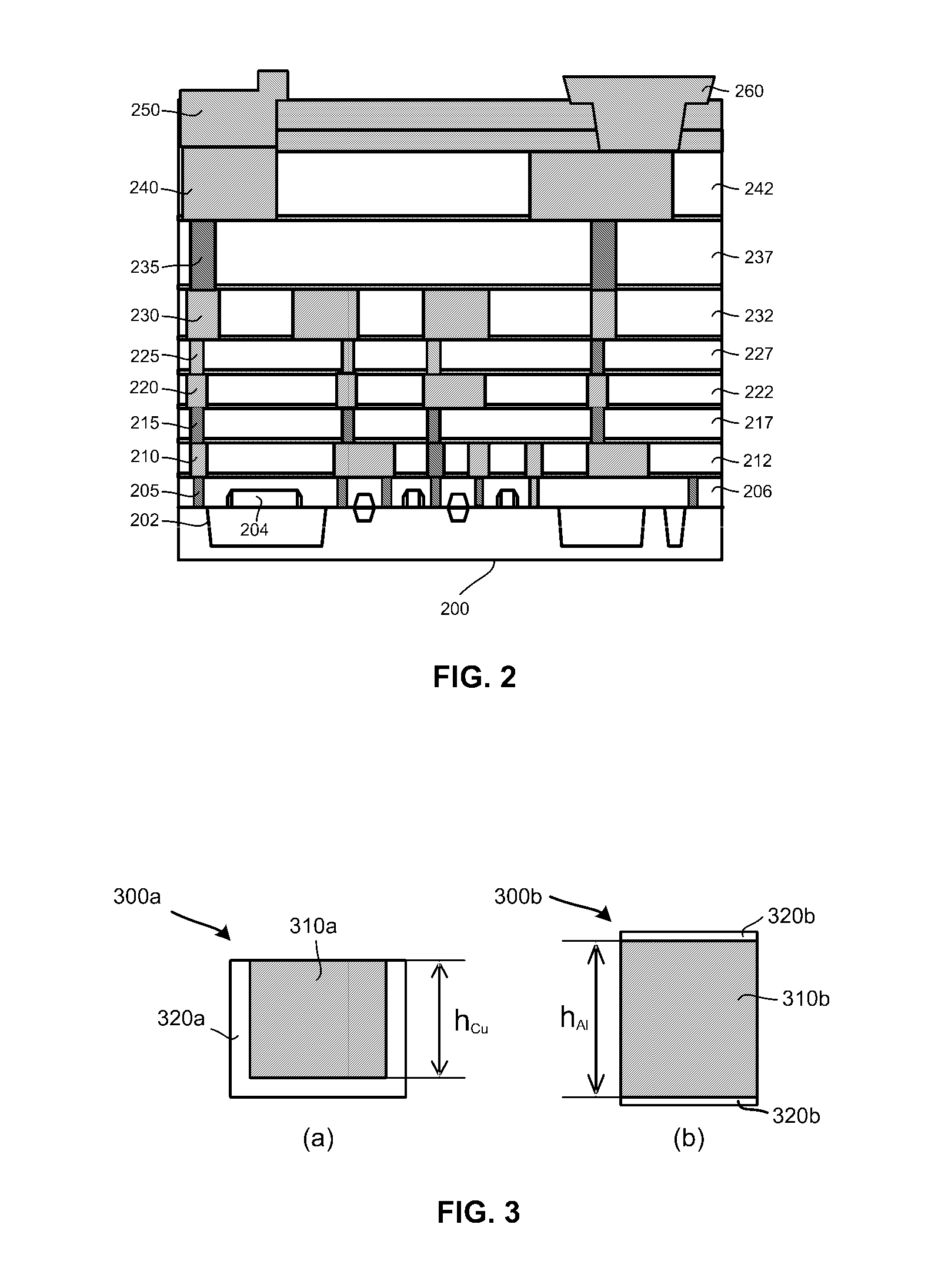

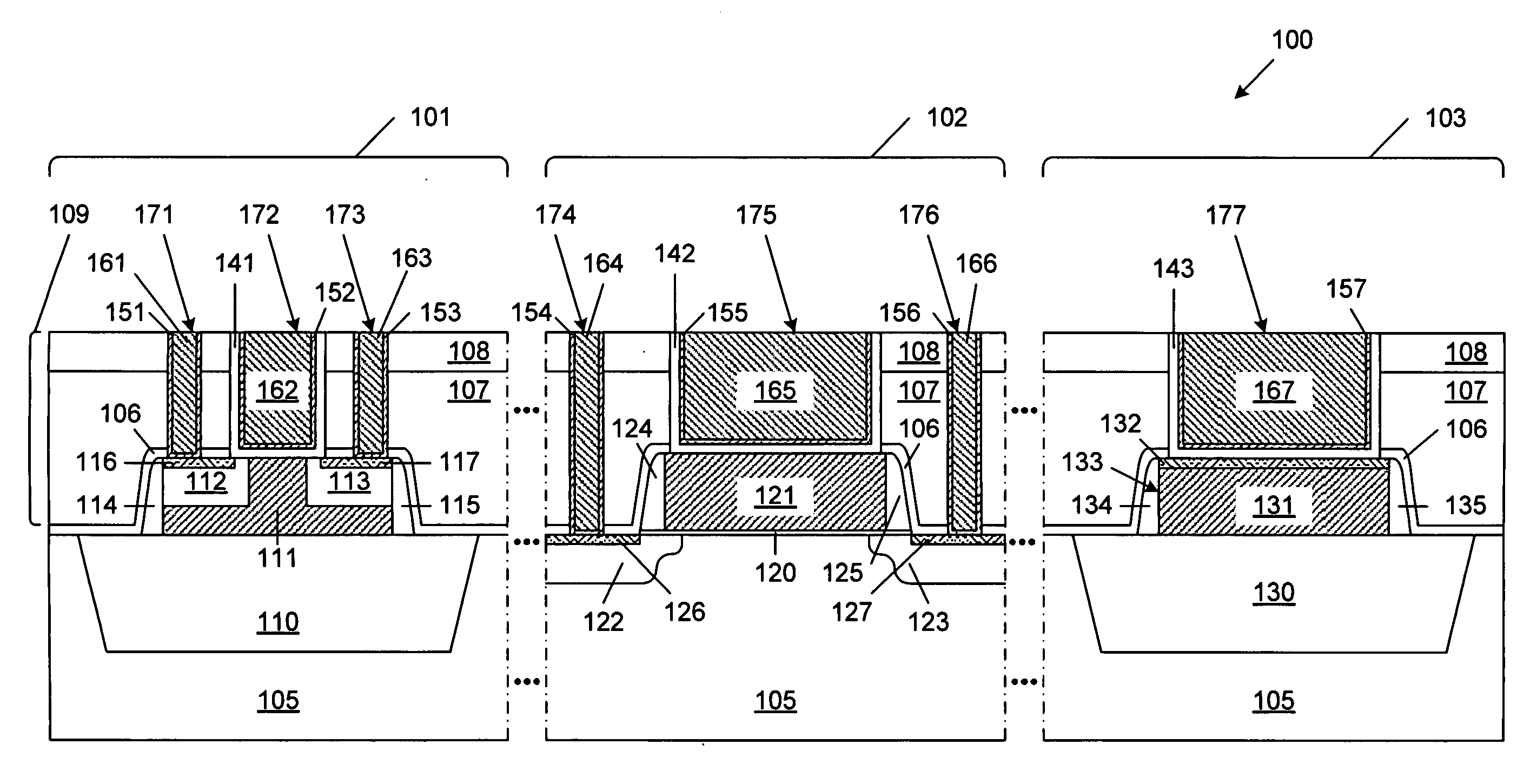

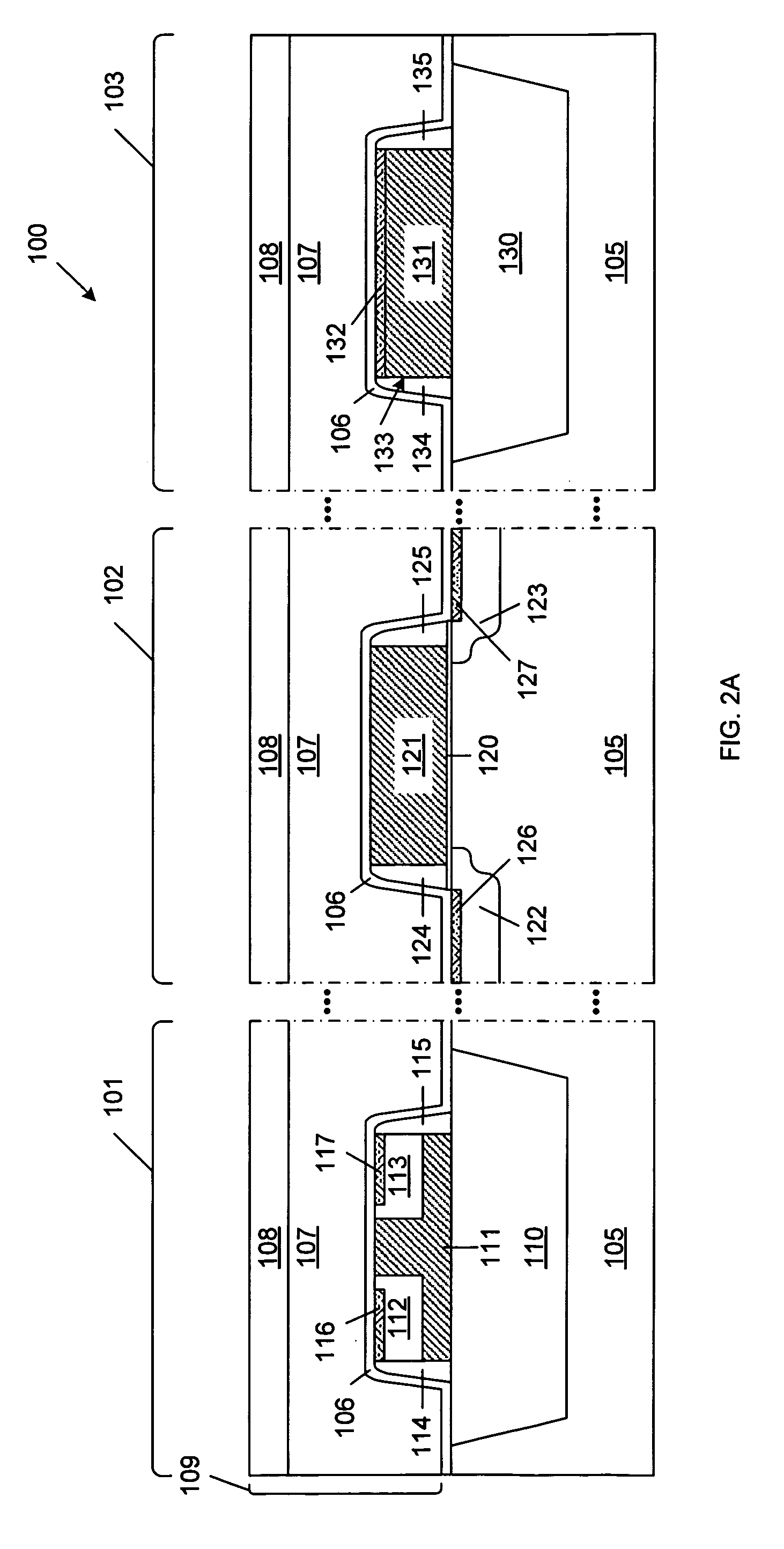

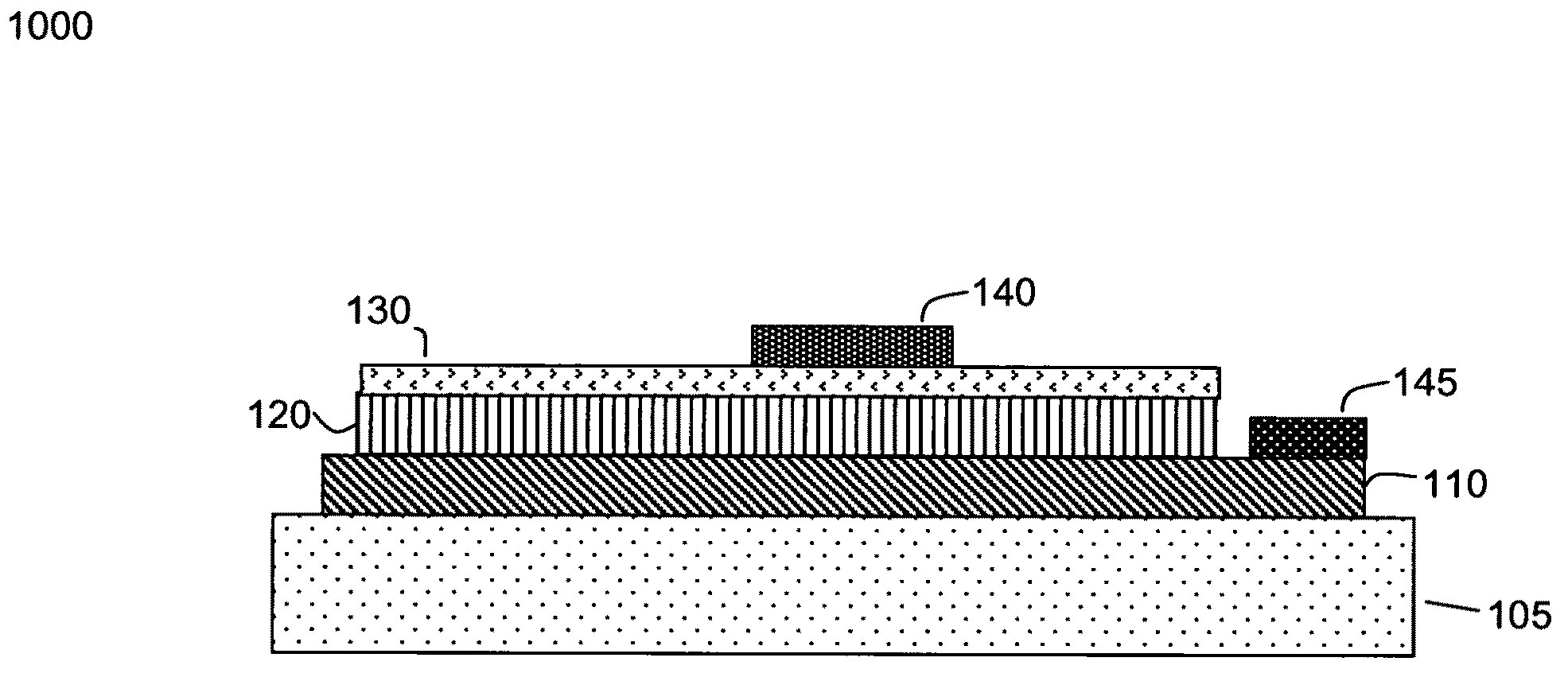

A method for processing IC designs for different metal beol processes

InactiveUS20070037384A1Easy to understandSemiconductor/solid-state device detailsSolid-state devicesCapacitanceMetal fabrication

A method for processing IC designs for different metal BEOL processes is provided for enabling fabricating using a metal fabrication process an IC originally having a backend design for a different metal fabrication process. The method first determines layer constructions of an original design of an IC for a first metal backend process, and, based on the layer constructions of the original design of the IC, constructs primitive layer constructions of a target design of the IC for a second metal backend process. The method then tunes an effective dielectric constant of a dielectric layer of the target design to match an associated capacitance of the target backend design with a corresponding capacitance of the original backend design. The method can be used to convert a backend design of an IC from an old metal process (such as Al process) to a new metal process (such as Cu process), without redesigning the IC for the new metal BEOL fabrication process.

Owner:CHARTERED SEMICONDUCTOR MANUFACTURING

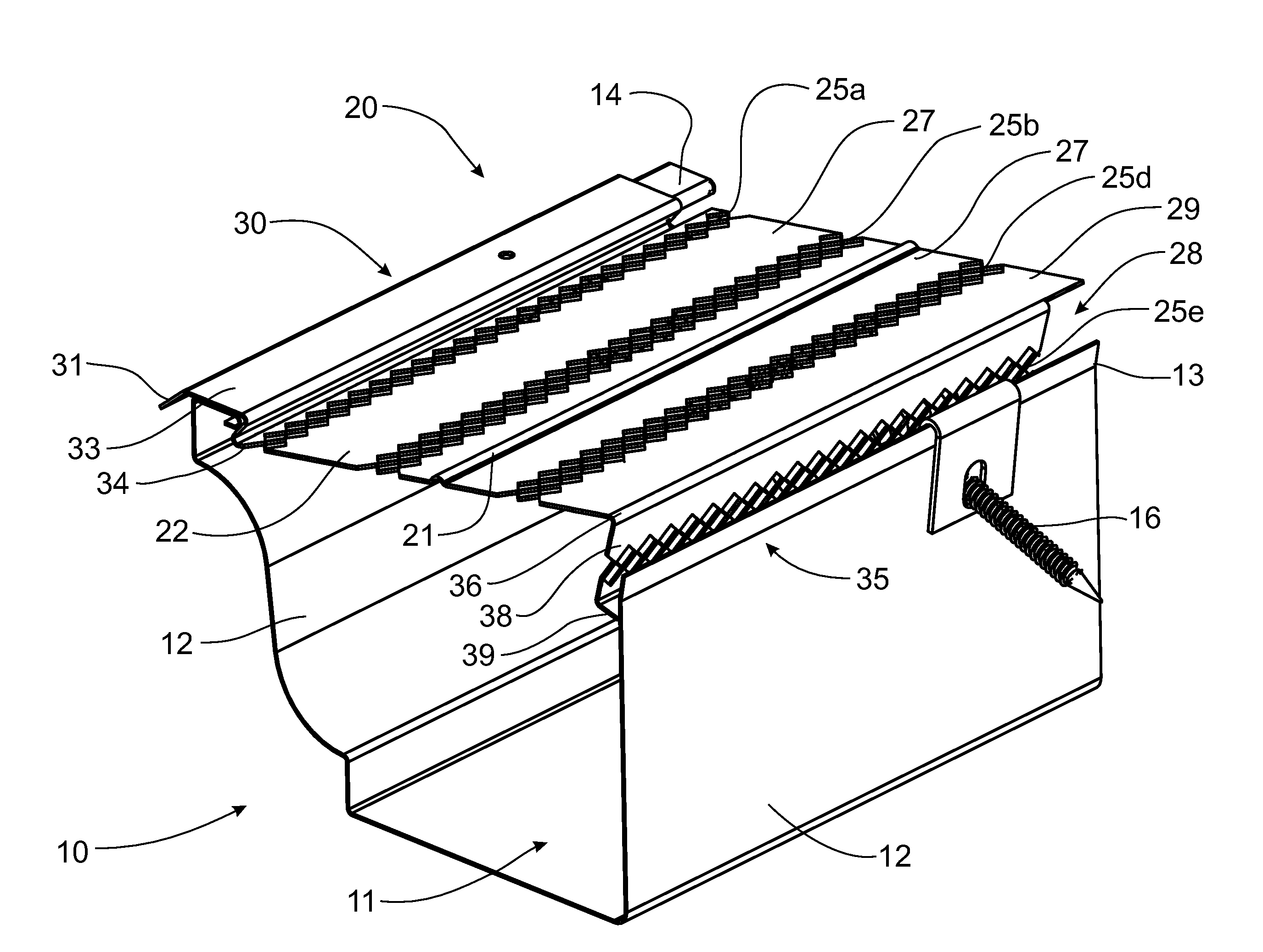

Expanded Metal Gutter Cover and Method of Installation

InactiveUS20110041414A1Overcome disadvantagesPromote sheddingRoof coveringBuilding repairsMetal fabricationExpanded metal

A gutter cover is formed through expanded metal manufacturing techniques to create alternating areas of solid metal and diamond-shaped openings to facilitate the shedding of leaves while passing water into the gutter. The gutter cover is mounted without fasteners by securing a hook portion underneath the front lip of the gutter and arcing the body portion of the gutter cover to press the rearward drip foot against the gutter and the drip hip adjacent to the fascia board into a pressure fit. The length of the gutter cover from the rearward edge to the front end being slightly longer than the corresponding length of the gutter structure. The gutter cover includes an integral drip leg projecting downwardly from the drip hip and being formed with an area of expanded metal diamond-shaped apertures to direct water into the gutter trough. A front drip lip directs water away from the gutter face.

Owner:OMNIMAX INT INC

Welding resource performance comparison system and method

ActiveUS20140278242A1Testing/monitoring control systemsWelding/cutting auxillary devicesMetal fabricationDatabase

Metal fabrication systems, such as welding systems and related equipment may be analyzed and performance compared by collecting parameter data from the systems during welding operations via a web based system. The data is stored and analyzed upon request by a user. A user viewable page may be provided that allows for selection of systems and groups of systems of interest. Parameters to be used as the basis for comparison may also be selected. Pages illustrating the comparisons may be generated and transmitted to the user based upon the selections.

Owner:ILLINOIS TOOL WORKS INC

Method for processing IC designs for different metal BEOL processes

InactiveUS7442637B2Semiconductor/solid-state device detailsSolid-state devicesCapacitanceMetal fabrication

Owner:CHARTERED SEMICONDUCTOR MANUFACTURING

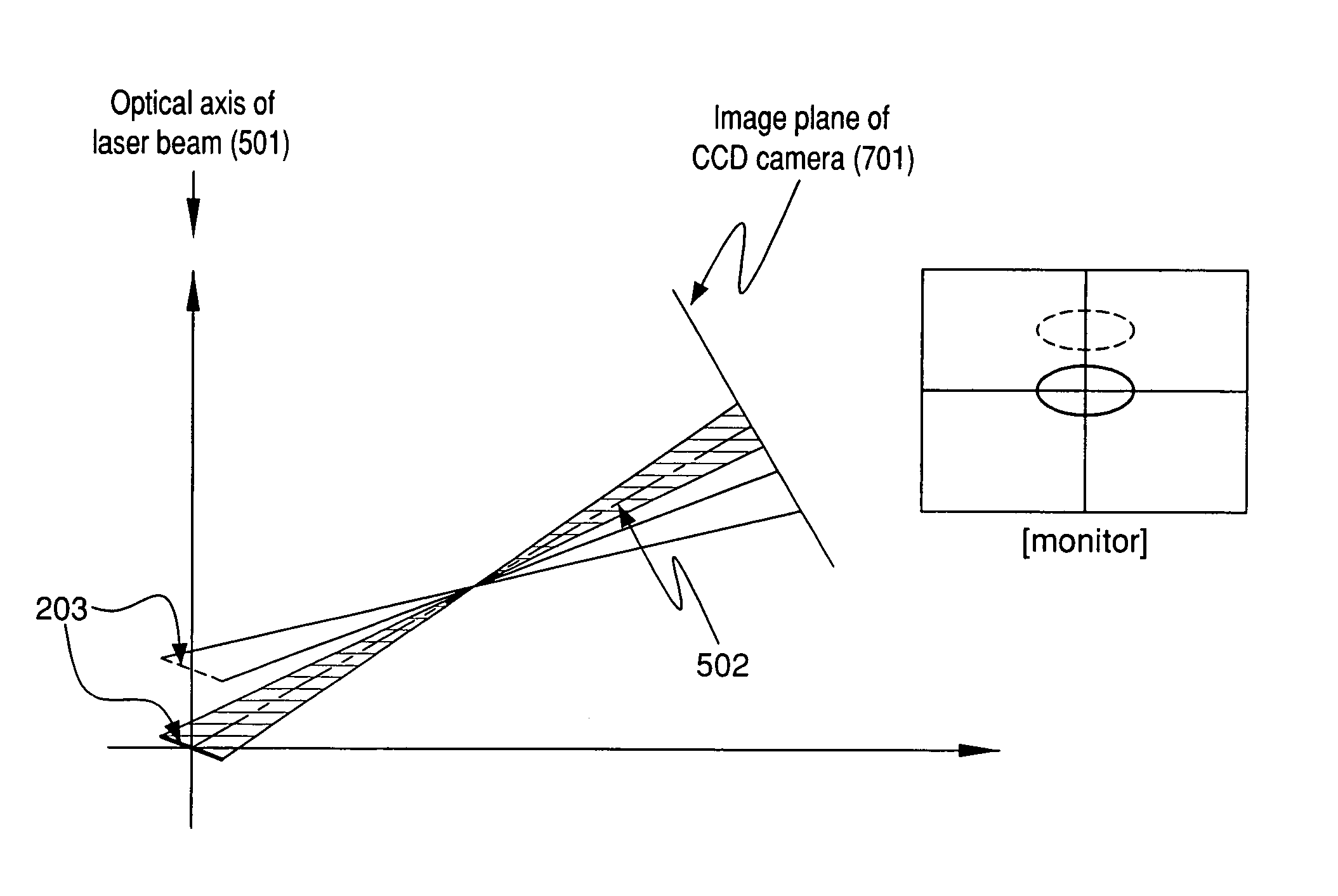

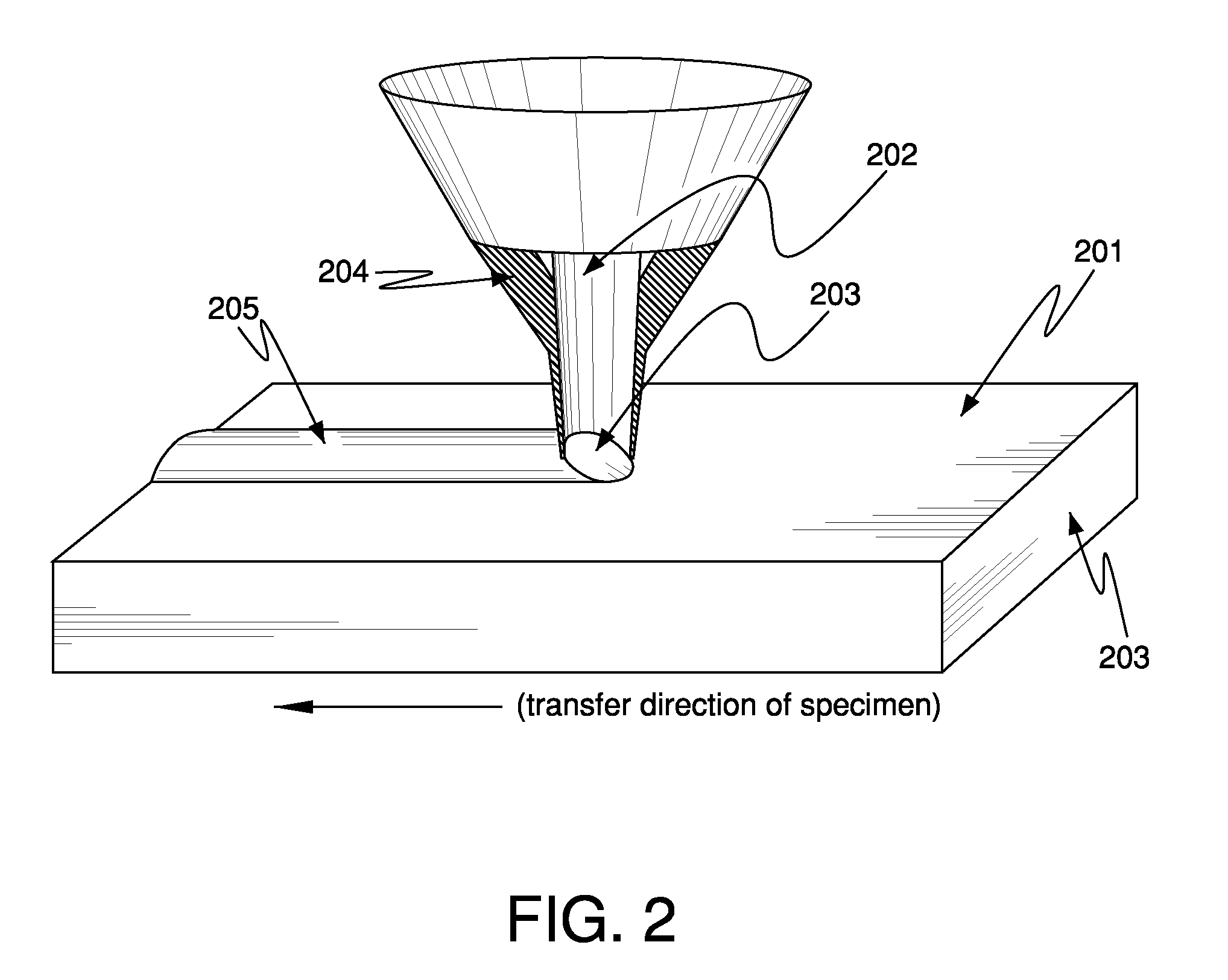

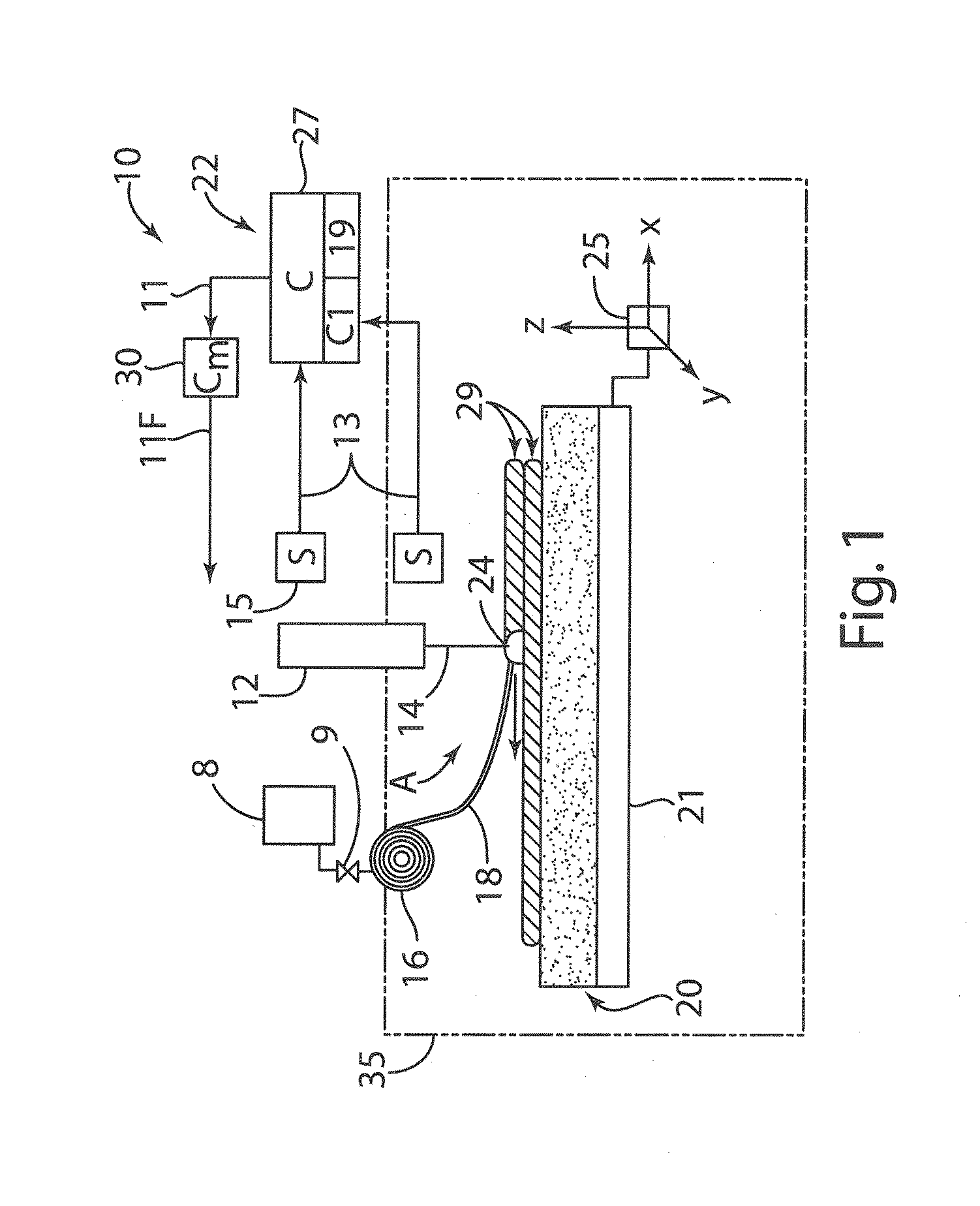

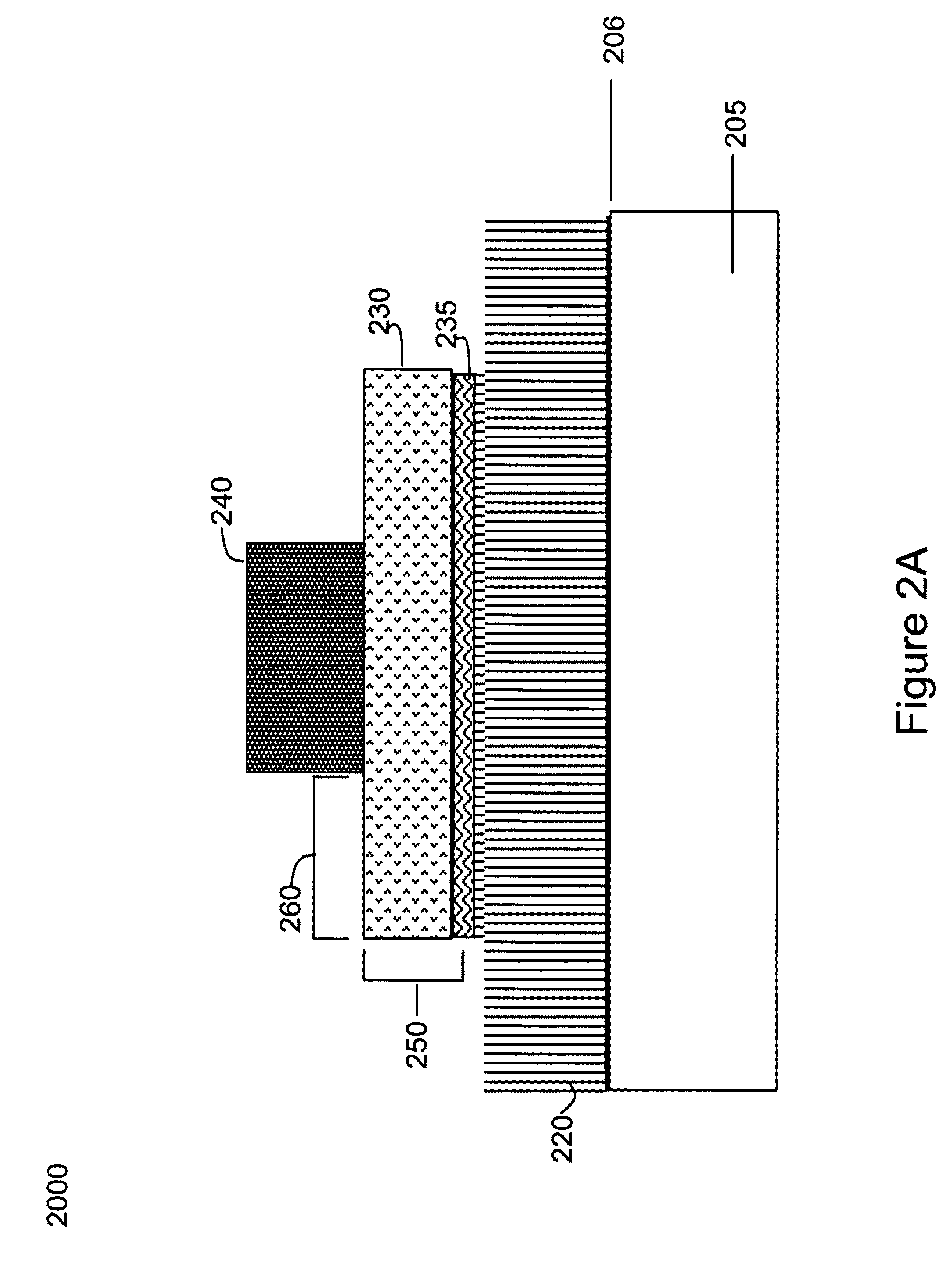

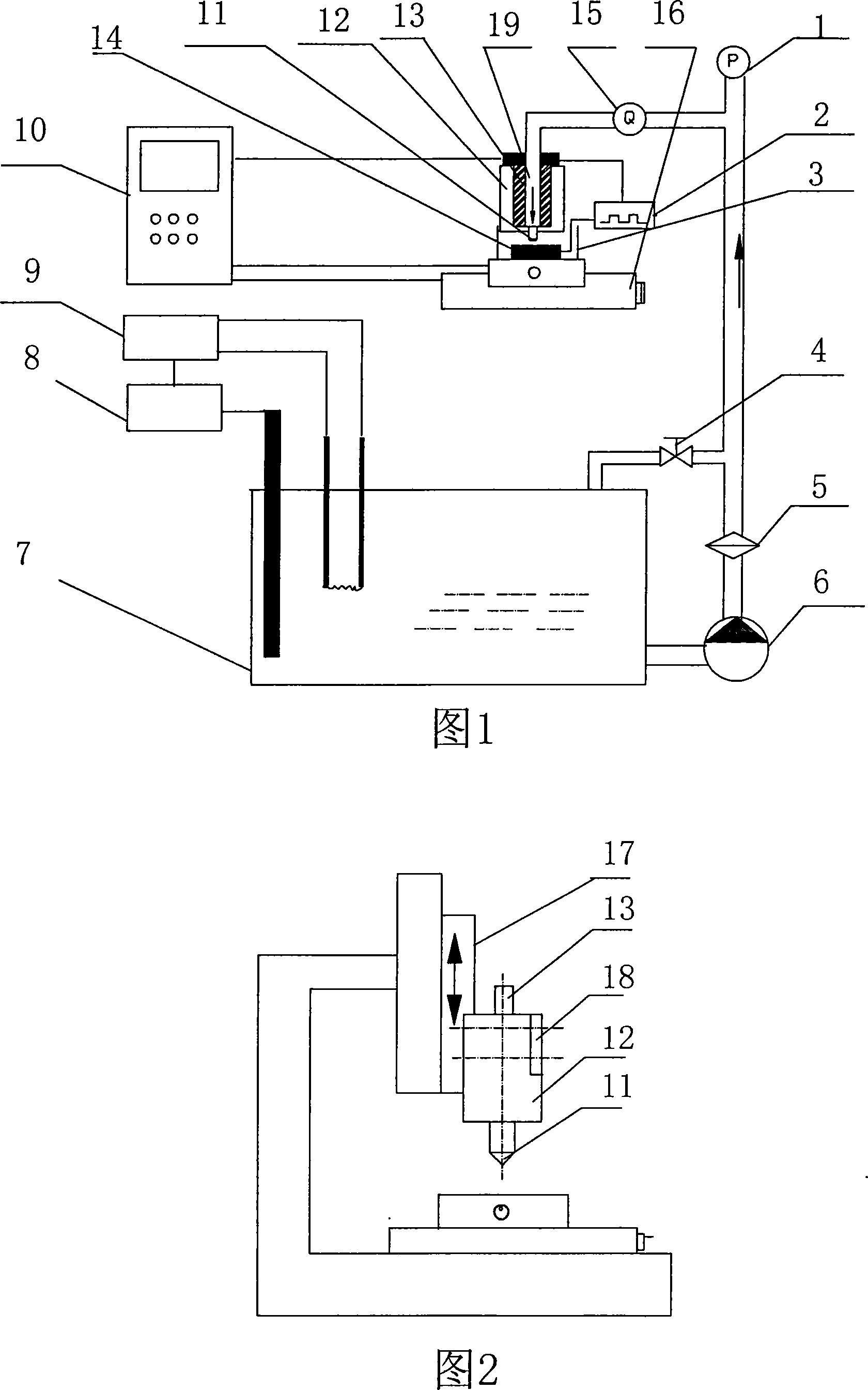

Method and system for real-time monitoring and controlling height of deposit by using image photographing and image processing technology in laser cladding and laser-aided direct metal manufacturing process

InactiveUS7423236B2Programme controlAdditive manufacturing apparatusMelting tankManufacturing technology

The object of this invention is to provide a method and system for real-time monitoring and controlling the height of a deposit by using image photographing and image processing technology in a laser cladding and laser-aided direct metal manufacturing process. This invention also provides a method of controlling the intensity of laser power, which is one of the most important process variables, regardless of the operational condition of a laser power unit (401). The method and system of this invention controls the height of a deposit (205) by real-time monitoring the position and the height of a melt pool (203) and controlling the process variables using the image photographing and image processing technology in such a laser cladding and laser-aided direct metal manufacturing process based on a laser surface modification technology, such as laser surface alloying and laser cladding, or a laser-aided direct metal manufacturing technology.

Owner:INSSTEK

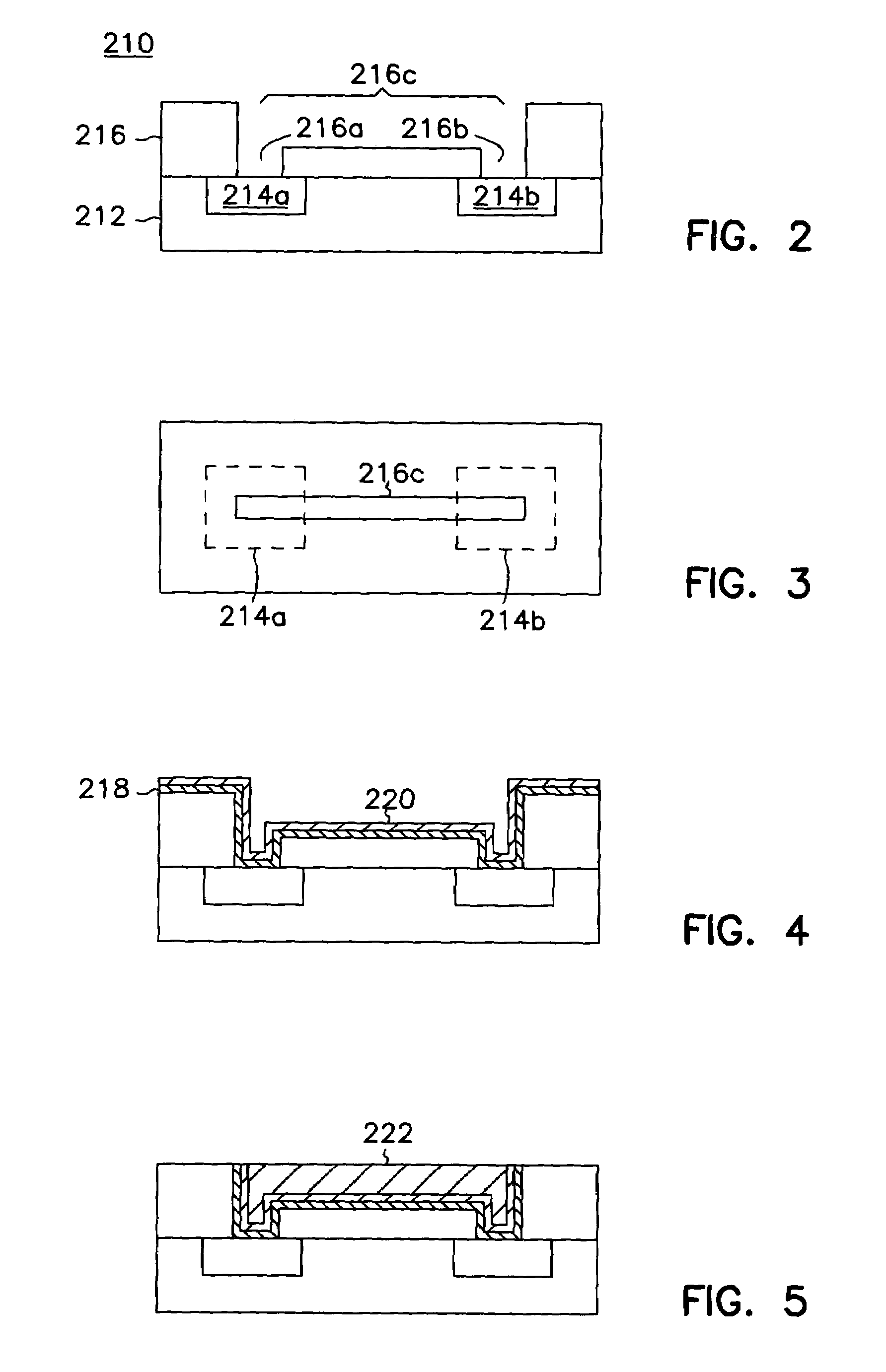

Method For Fabricating Capacitor Structures Using The First Contact Metal

ActiveUS20090239351A1Reduce layout areaIncrease capacitanceSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMetal electrodes

A capacitor structure is fabricated with only slight modifications to a conventional single-poly CMOS process. After front-end processing is completed, grooves are etched through the pre-metal dielectric layer to expose polysilicon structures, which may be salicided or non-salicided. A dielectric layer is formed over the exposed polysilicon structures. A conventional contact process module is then used to form contact openings through the pre-metal dielectric layer. The mask used to form the contact openings is then removed, and conventional contact metal deposition steps are performed, thereby simultaneously filling the contact openings and the grooves with the contact (electrode) metal stack. A planarization step removes the upper portion of the metal stack, thereby leaving metal contacts in the contact openings, and metal electrodes in the grooves. The metal electrodes may form, for example, transistor gates, EEPROM control gates or capacitor plates.

Owner:TOWER SEMICONDUCTOR

Method and system for real-time monitoring and controlling height of deposit by using image photographing and image processing technology in laser cladding and laser-aided direct metal manufacturing process

InactiveUS20090024243A1Programme controlAdditive manufacturing apparatusMelting tankManufacturing technology

Owner:INSSTEK

Laser sintered titanium alloy and direct metal fabrication method of making the same

ActiveUS7540996B2Additive manufacturing apparatusIncreasing energy efficiencyPowder mixtureSintered titanium

Methods and powder blends are provided for fabricating a metal part. One method includes the first steps of spreading a layer of a powder blend on a platform, the powder blend including a titanium base metal or alloy, and an alloying metal having a lower melting temperature than that of the base metal or alloy. Next, an energy beam is directed onto selected areas of the powder blend layer to thereby melt the alloying metal. Then, the alloying metal is re-solidified by withdrawing the energy beam from the powder blend layer. Then, a preform part is built up by iteratively performing the spreading, melting, and re-solidifying steps on additional adjacently formed layers. A metal liquid phase sintering process is performed at a temperature sufficient to melt the alloying metal but not the base metal or alloy.

Owner:THE BOEING CO

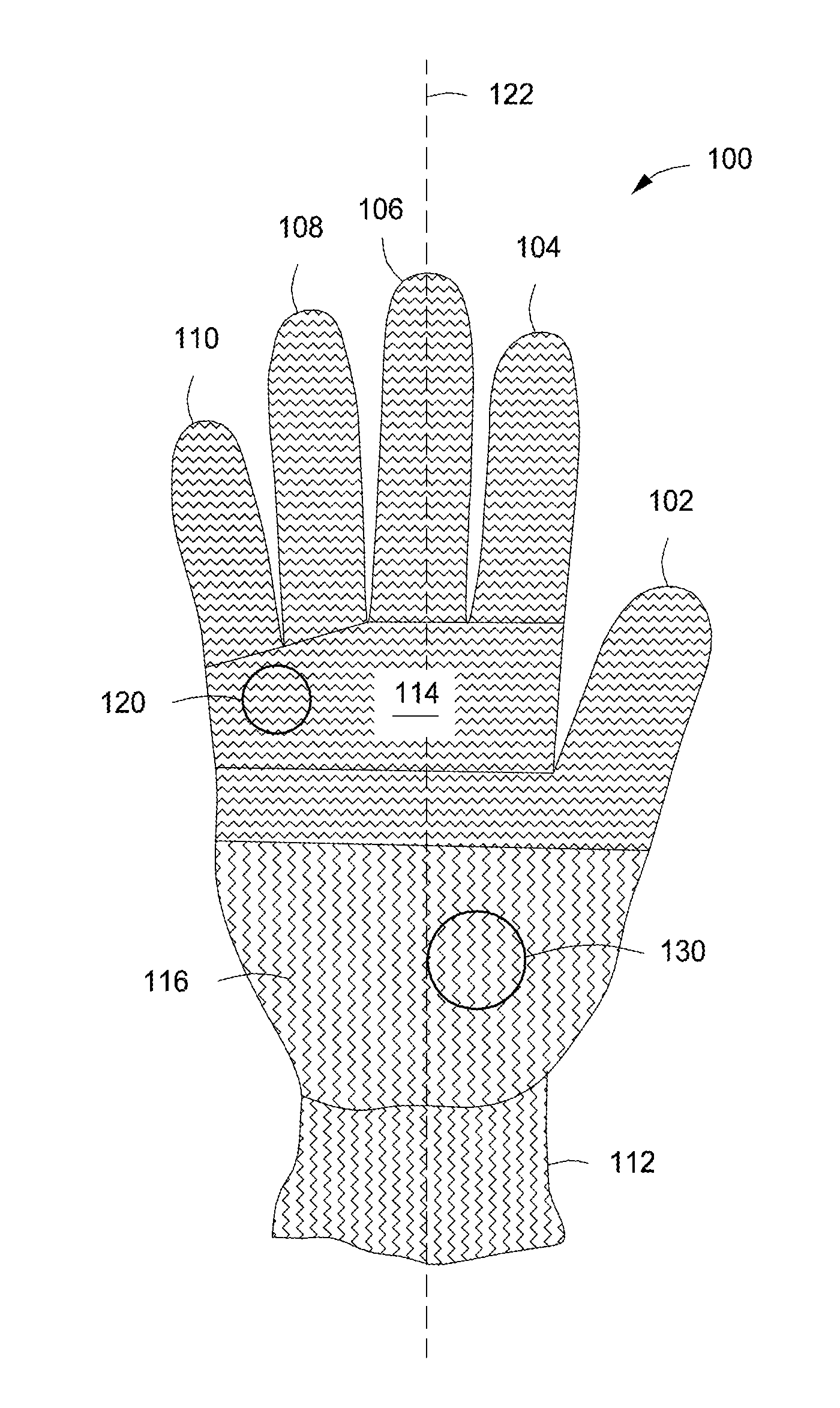

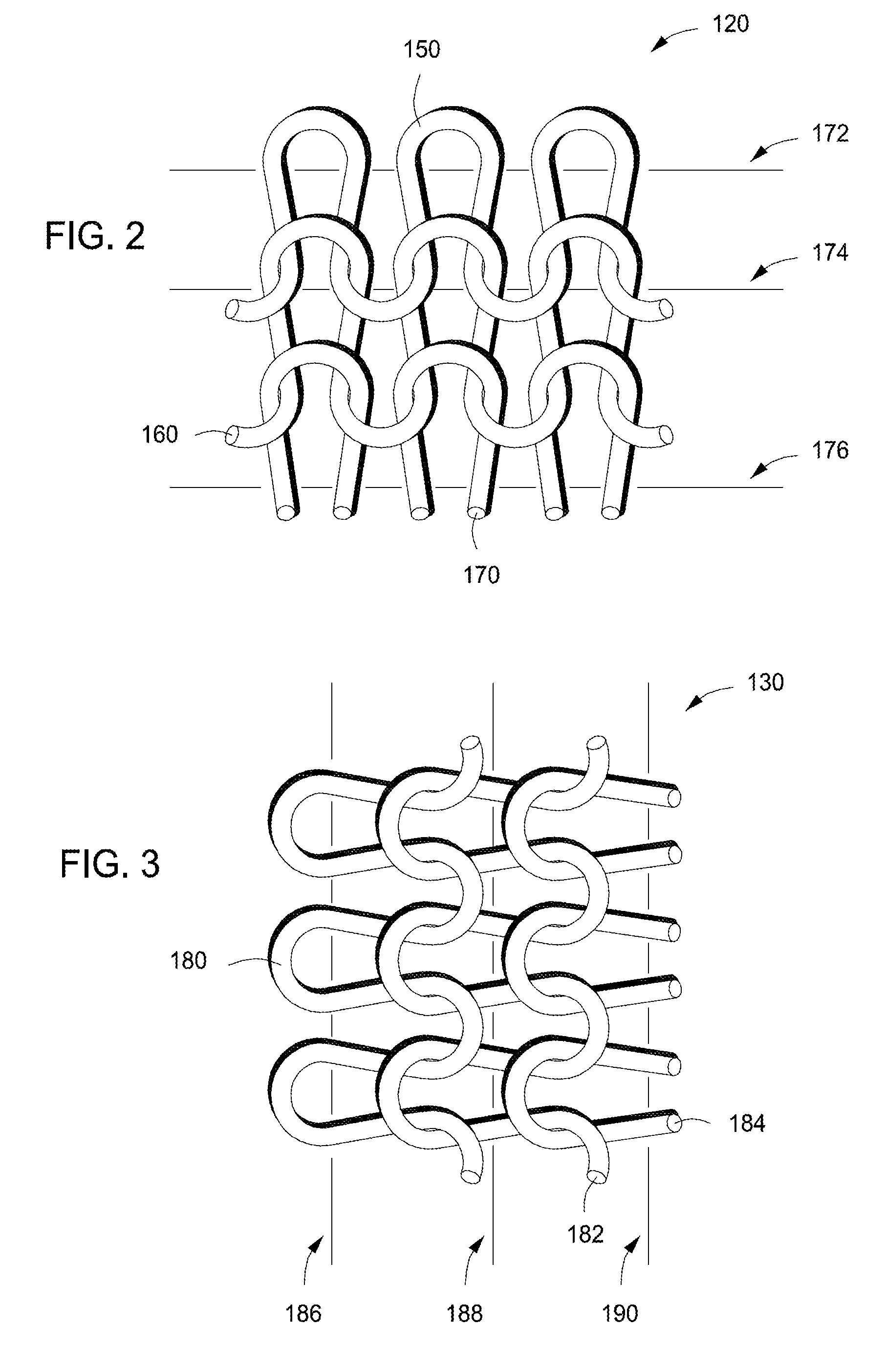

Method of manufacturing solid solution perforator patches

InactiveUS20120193840A1Problem is complicatedEasy to fillButtonsMicroneedlesSolid solutionMetal fabrication

Provided are methods for fabricating and manufacturing solid solution perforators (SSPs) using sharp metal and subsequent molding and use. The methods entail making microneedles by precision machining techniques and micromold structures from plastic materials. Various designs of patch are described.

Owner:THERAJECT INC.

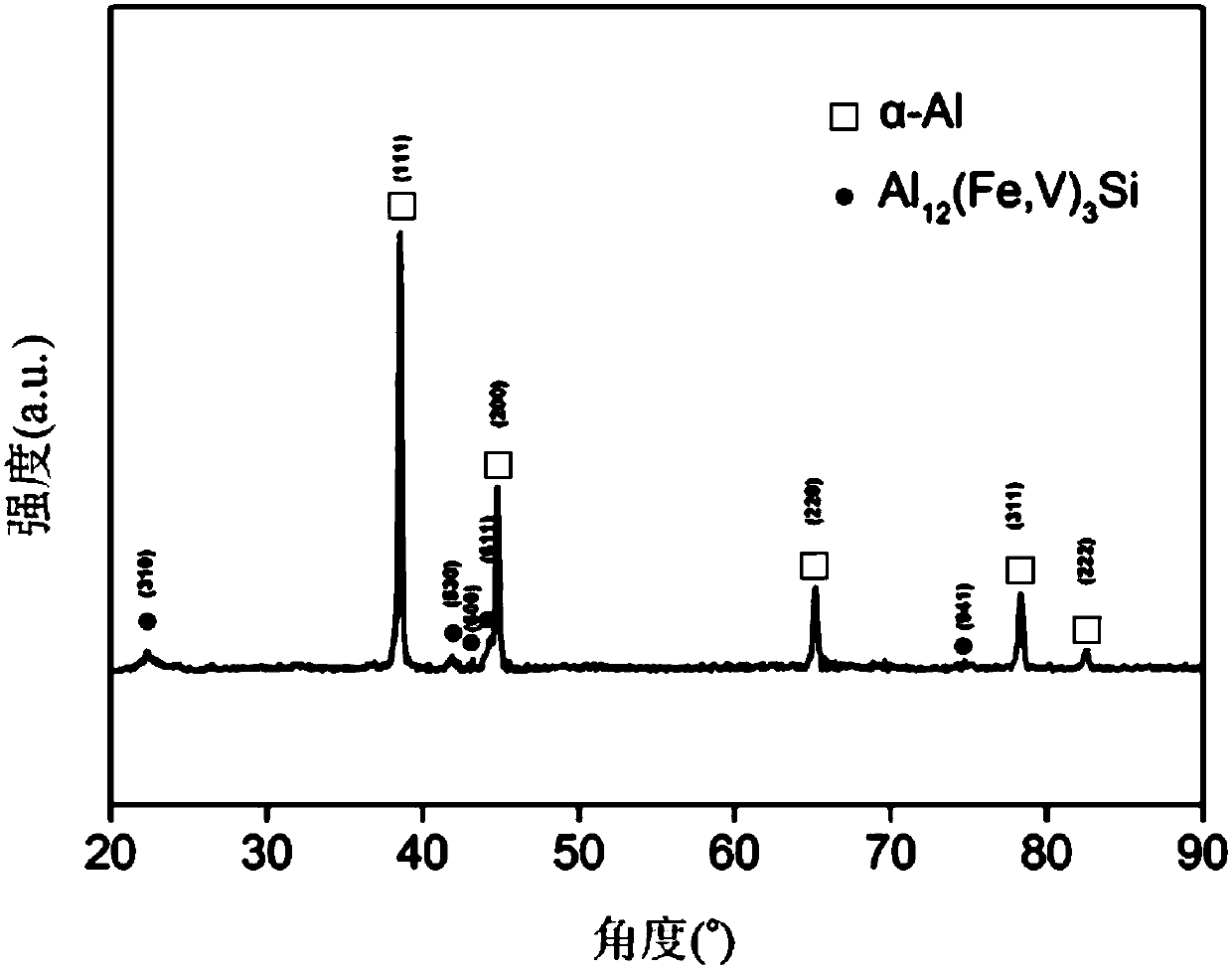

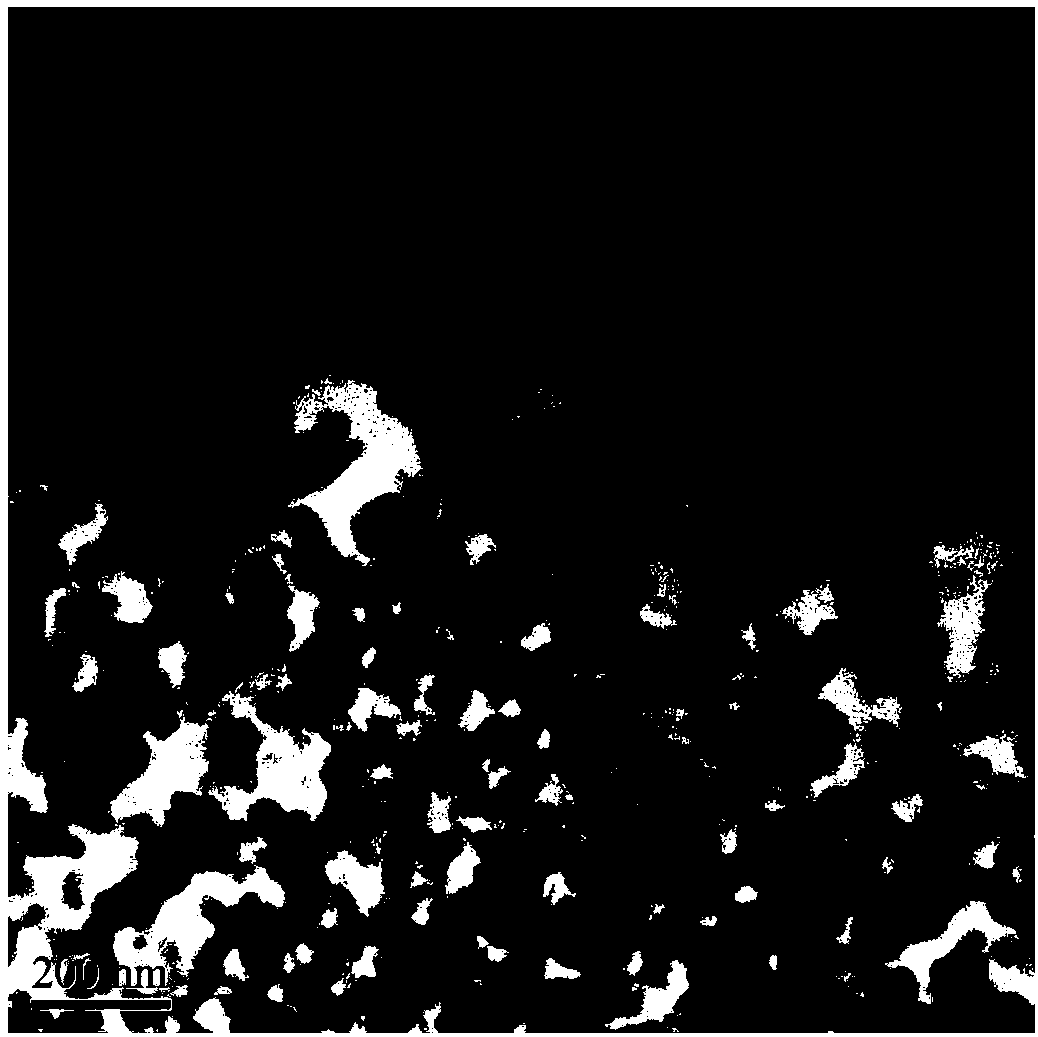

Method for preparing heat-resisting aluminum alloy

InactiveCN107649681ASave R&D cycleSave manufacturing cycleAdditive manufacturing apparatusIncreasing energy efficiencySlice thicknessControl table

The invention discloses a method for preparing a heat-resisting aluminum alloy, and belongs to the field of metal manufacturing. The method comprises the steps that according to the shape of an Al-Fe-V-Si alloy part to be processed, a three-dimensional model is established; layered slice cutting processing is conducted on the three-dimensional model, so that the preset slice thickness in the height direction is formed; a scanning path of each slice is determined according to the cross section profile information of each slice of the three-dimensional model; a layer of pre-alloy powder is laidin accordance with the slice thickness to form a powder layer; the current powder layer is scanned by using a laser beam according to the scanning path, thus a deposition layer corresponding to a slice of the three-dimensional model is made; a control table is controlled to be dropped to the distance of the thickness of a slice, and a layer of pre-alloy powder is laid on the deposition layer againof a formed substrate plate through a powder paving mechanism according to the slice thickness to form a powder layer; and repeating is conducted until processing is finished. The alloy part preparedby the method is high in surface forming precision and good in quality, the research and manufacture cycle can be effectively shortened, the production efficiency is improved, and the production costis reduced.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Gas Phase Alloying for Wire Fed Joining and Deposition Processes

Gas is introduced into molten metal during an additive metal fabrication process and / or during a metal fusion process. The gas may comprise a process gas that flows through a tubular feed wire. The amount of process gas introduced can be controlled to vary the composition and / or material properties of metal deposits formed from a molten metal. Material properties such as yield strength, hardness, and fracture toughness can be increased or decreased in specific regions to provide material property gradients that closely correspond to expected requirements of components fabricated utilizing additive and / or fusion processes.

Owner:NASA

Float collar

The present invention relates to a float collar apparatus for regulating the passage of fluid through a casing liner or sub-sea casing. Apparatus of the present invention is fabricated using plastic flapper valves and sleeve components in contrast to prior art float collar components which are fabricated almost entirely of hard metals. The use of plastic components in the float collar apparatus of the present invention provides a substantial reduction in time and resources expended during drilling out of the float collar once cementing operations are completed. Additionally, the float collar apparatus of the present invention is fabricated from a pre-determined combination of plastic components and metal components thereby ensuring that the improved float collar can still endure substantial hydrostatic stresses encountered during casing liner running in and cementing operations.

Owner:ALLAMON JERRY P +2

Dual temperature indicator stick holder

InactiveUS7316506B2Easy to replaceThermometer detailsThermometers using physical/chemical changesMetal fabricationHeat treating

An apparatus to combine temperature indicator sticks used in the welding, metal fabrication, and heat treatment industries and capable of identifying at least two given temperatures is disclosed. The apparatus includes a first temperature indicator stick aligned along a first axis and comprised of a compound which melts at a first temperature, and a second temperature indicator stick aligned along a second axis and formed of another compound which melts at a second temperature. The apparatus also includes a connector physically connecting and aligning the first and second indicator sticks.

Owner:LA CO IND INC

Hydraulic cylinder of carbon fiber composite material

InactiveCN103727092AGood mechanical propertiesHigh strengthFluid-pressure actuatorsFiberHydraulic cylinder

The invention discloses a hydraulic cylinder of a carbon fiber composite material. A cylinder body (2) is made of a high-strength carbon fiber precursor of which the strength is greater than or equal to 3500MPa as a reinforcing material and thermosetting resin as a substrate by adopting a technology of winding and molding carbon fiber into a carbon fiber composite material layer; a cylinder bottom (1), a piston (6) and a cylinder cover (10) are made of a high-strength aluminum alloy of which the strength is greater than or equal to 500MPa; a piston rod (9) is made of hard chromium-plated steel. Compared with a common hydraulic cylinder made of metal, the hydraulic cylinder has the significant advantage of weight reduction, and the weight-carrying capacity is obviously superior to that of an existing common hydraulic cylinder made of metal. Therefore, the hydraulic cylinder has a good application prospect in hydraulic drive and hydraulic control equipment in which water is used as a fluid medium.

Owner:WUHAN UNIV OF TECH

System and method for monitoring welding threshold conditions

InactiveUS20160101481A1Cooking-vessel materialsWelding/cutting media/materialsElectrical and Electronics engineeringMetal fabrication

A metal fabrication system includes one or more sensors configured to transmit a first signal relating to a first condition of an environment of the metal fabrication system, processing circuitry coupled to the one or more sensors, and a feedback device coupled to the processing circuitry. The processing circuitry is configured to determine the first condition of the environment based at least in part on the first signal and to compare the first condition to a first threshold. The feedback device is configured to provide a first notification when the first condition satisfies the first threshold.

Owner:ILLINOIS TOOL WORKS INC

Method of forming a carbon nanotube-based contact to semiconductor

InactiveUS7563711B1Reduce contact resistanceHigh light transmittanceSemiconductor/solid-state device manufacturingNanoopticsSemiconductor materialsElectrical conductor

Manufacturers encounter limitations in forming low resistance ohmic electrical contact to semiconductor material P-type Gallium Nitride (p-GaN), commonly used in photonic applications, such that the contact is highly transparent to the light emission of the device. Carbon nanotubes (CNTs) can address this problem due to their combined metallic and semiconducting characteristics in conjunction with the fact that a fabric of CNTs has high optical transparency. The physical structure of the contact scheme is broken down into three components, a) the GaN, b) an interface material and c) the metallic conductor. The role of the interface material is to make suitable contact to both the GaN and the metal so that the GaN, in turn, will make good electrical contact to the metallic conductor that interfaces the device to external circuitry. A method of fabricating contact to GaN using CNTs and metal while maintaining protection of the GaN surface is provided.

Owner:NANTERO

Method and apparatus for semi-solid material processing

InactiveUS20050279479A1Small granularityReduce processingMetal foundingSemi solidMaterials processing

A method of forming a material includes the steps of: vibrating a molten material at an ultrasonic frequency while cooling the material to a semi-solid state to form non-dendritic grains therein; forming the semi-solid material into a desired shape; and cooling the material to a solid state. The method makes semi-solid castings directly from molten materials (usually a metal), produces grain size usually in the range of smaller than 50 μm, and can be easily retrofitted into existing conventional forming machine.

Owner:UT BATTELLE LLC +1

Metal Casting System, Engineered Molds, Process and Articles Made Thereby

Disclosed is a metal casting system, an engineered mold for use therewith, a process for utilizing the system and mold, and articles having a clean, oxide-free sand casting of molten metals that have been produced under an inert environment. This is especially advantageous for making automotive and airplane parts from the manufacture of lightweight metals, and more especially for the production of magnesium parts in order to reduce weight while maintaining properties found in other lightweight metals. Currently, sand cast articles are being used for automotive, aerospace and semiconductor parts and other industrial applications. The advantages of the present invention include a greatly reduced cycle time as conventional gating systems no longer apply; an ability to pour highly reactive metals by the use of a protective environment; even greater reduced cycle times because speed of metal delivery is greatly increased; carbon outgassing by binder resin is minimized since no oxygen is allowed into the process; sand and resin usage and disposal is minimized due to the new engineered mold; and cooling of the poured sand casting is much faster through these unique features.

Owner:HETKE ADOLF

Jet electroform method and equipment for manufacturing foamed metal

InactiveCN101092719AChange the mass transfer processUniform thicknessElectroforming processesSpray nozzleMetallic materials

This invention discloses method and apparatus for producing electroplated foam metal by spraying. The method comprises: placing surface-treated cathode plate into an electroforming tank, controlling the temperature of the electroforming solution at 20-65 deg.C, spraying via the spray nozzle connected with the central chamber of the anode bar to the cathode plate at a rate of 1.5-7.5 m / s to obtain a branch-like or sponge-like metal deposition layer, controlling the current density at 200-750 A / dm2, controlling the movement of the spray nozzle along the vertical direction, the horizontal lateral direction and horizontal longitudinal direction to form a porous foam metal deposition layer with required thickness and shape, and drying the foam metal deposition layer. The method has such advantages as no need for auxiliary medium, simple process and convenient production.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Die Holder Technology for Metal-Fabricating Press

ActiveUS20080216551A1Easy to insertEasy to removeShaping toolsWithdrawing sample devicesMetal machiningEngineering

The invention involves a die holder for a press, such as a metal-fabricating press. The die holder can be configured to receive a die, and can include a clamp portion and a wall portion. Preferably, the clamp and wall portions can be positioned in an open configuration or a closed configuration, and the die holder can be adjusted from an unclamped configuration to a clamped configuration. The die holder may have a die-release mechanism useful for overcoming stiction and facilitating removal of the die from the die holder.

Owner:WILSON TOOL INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com