Method for preparing heat-resisting aluminum alloy

An aluminum alloy, heat-resistant technology, applied in the field of metal manufacturing, can solve the problems of limiting the wide application of Al-Fe-V-Si alloy components, growing the grains of the alloy matrix, reducing the mechanical properties of the alloy, etc. Processing and post-processing links, high surface forming accuracy, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] 1. Select Al-11.5Fe-1.4V-2.3Si pre-alloyed powder prepared by argon atomization method, the powder is spherical or nearly spherical, and the diameter is between 20-55 μm, and it is loaded into the powder coating of the laser selective melting system in the institution.

[0057] 2. According to the shape of the alloy parts to be processed, use the computer to establish a three-dimensional CAD model, and use the slicing software to perform layered slice discretization in the height direction of the model. The thickness of the slices is uniform (thickness is 0.06mm), and includes Cross-sectional profile information and scanning processing path, save multi-layer slice information as STL file, and transfer to SLM computer numerical control device, preset forming parameters.

[0058] 3. Grind the surface of the pure Al forming substrate with a size of 200mm×200mm×10mm with #800 sandpaper and clean it with acetone, and then fix it on a liftable workbench. You can choose pure A...

Embodiment 2

[0065] The slice thickness was set at 0.03 mm.

[0066] The forming parameters are set as follows: the power is 350W, the scanning speed is 800mm / s, the scanning distance is 0.08mm, and the times of melting are 2-4 times.

[0067] Other steps in this embodiment are the same as in Embodiment 1.

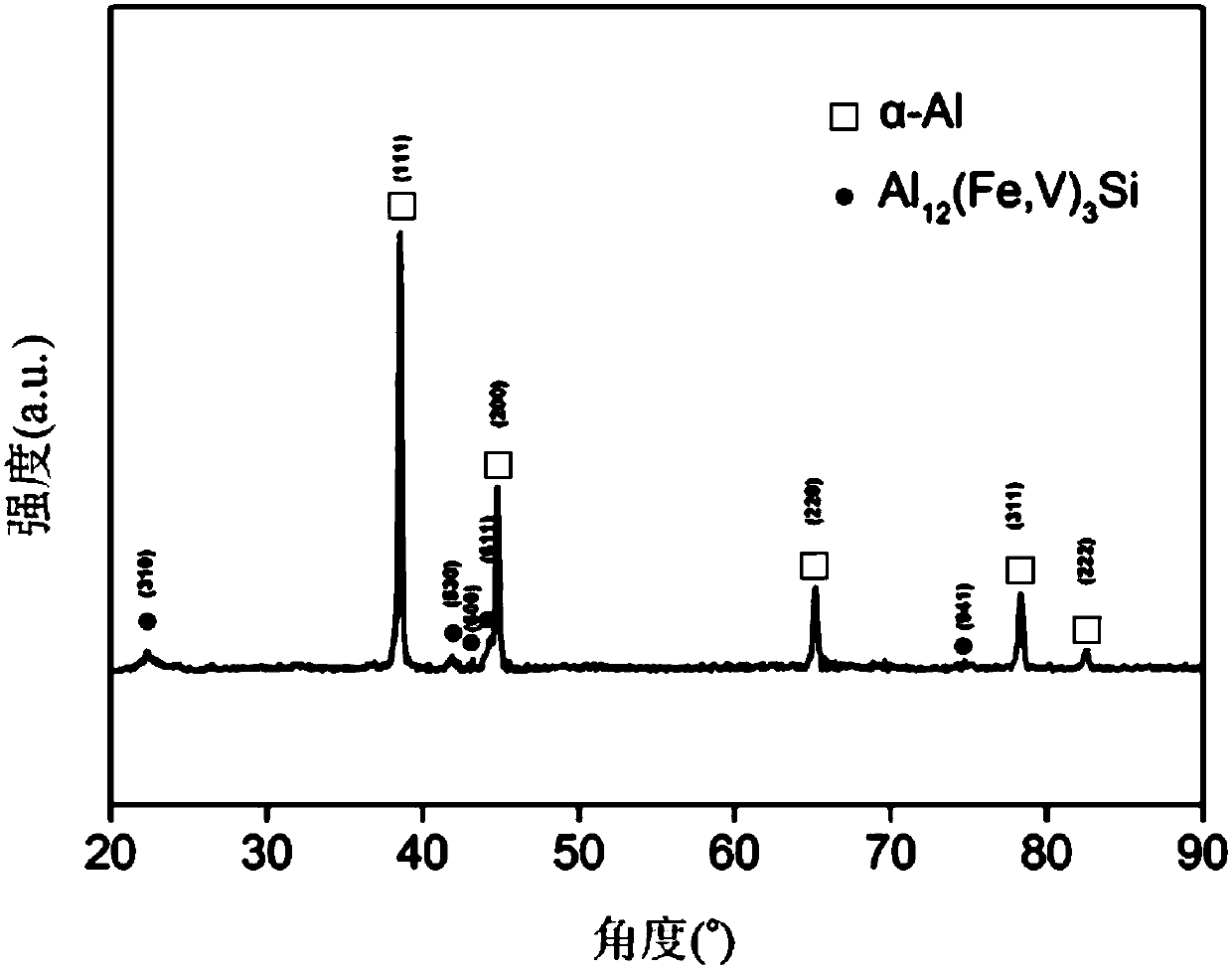

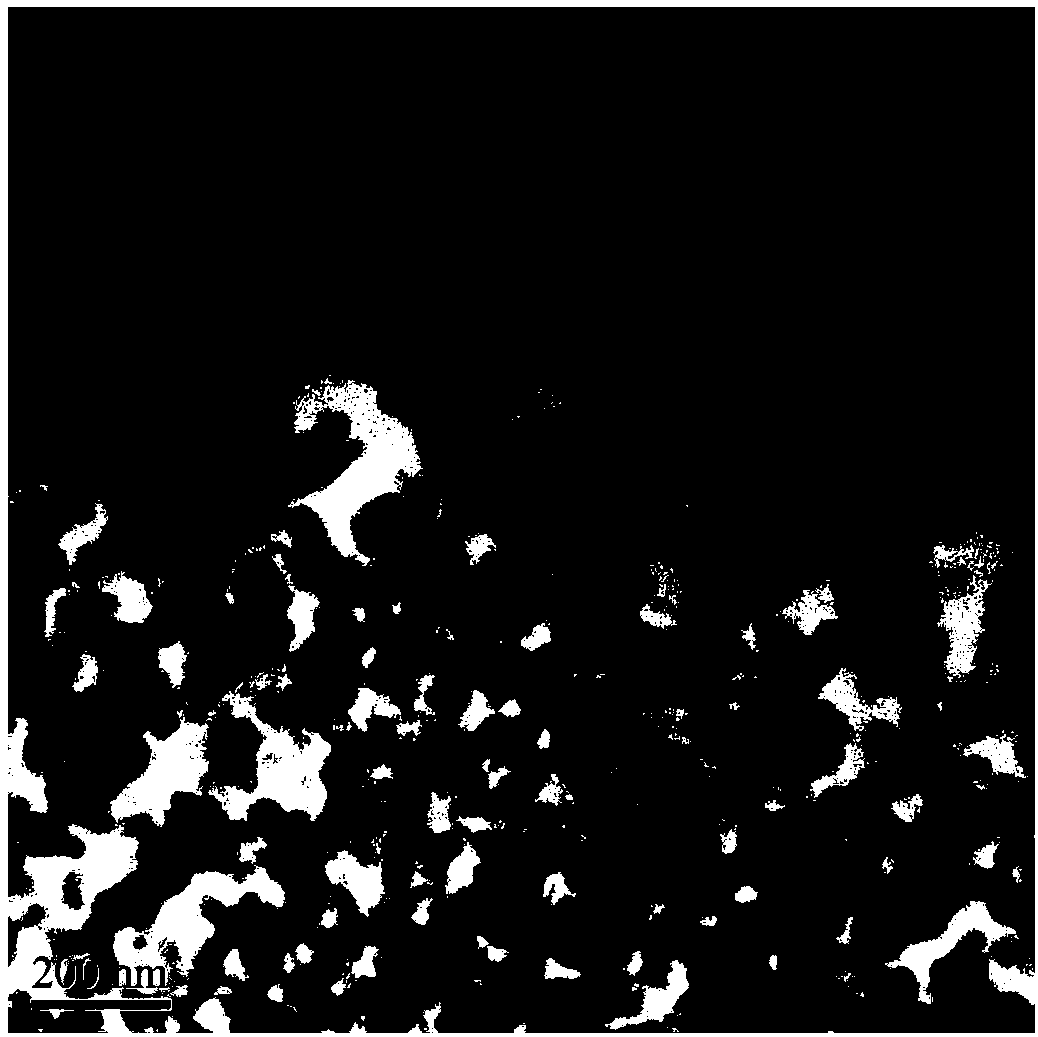

[0068] The prepared Al-11.5Fe-1.4V-2.3Si alloy has a high density of 99.2%, no pores and microcracks. Mainly composed of Al solid solution and Al 12 (Fe,V) 3 Si strengthening phase composition. Al 12 (Fe,V) 3 Si is uniformly dispersed and distributed, and the phase size is extremely small, and the phase size is 20-80nm. The alloy has excellent mechanical properties, and its ultimate tensile strength, yield strength and elongation are 552MPa, 529MPa and 7%, respectively.

Embodiment 3

[0070] The slice thickness was set at 0.15 mm.

[0071] The forming parameters are set as follows: the power is 400W, the scanning speed is 1200mm / s, the scanning distance is 0.15mm, and the number of melting times is 4 times.

[0072] Other steps in this embodiment are the same as in Embodiment 1.

[0073] The prepared Al-11.5Fe-1.4V-2.3Si alloy has a high density of 99.2%, no pores and microcracks. Mainly composed of Al solid solution and Al 12 (Fe,V) 3 Si strengthening phase composition. Al 12 (Fe,V) 3 Si is uniformly dispersed and distributed, and the phase size is extremely small, and the phase size is 20-80nm. The alloy has excellent mechanical properties, and its ultimate tensile strength, yield strength and elongation are 554MPa, 527MPa and 7%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com